CE Certification plays a vital role in the lithium battery industry. It ensures that products meet strict health, safety, and environmental standards. In the European Economic Area (EEA), over 70% of all products require this mark to access the market. By obtaining CE Certification, you demonstrate compliance and prioritize user safety, building trust with consumers.

Key Takeaways

- CE Certification is needed for lithium batteries sold in Europe. It shows they meet health, safety, and environmental rules.

- Getting CE Certification helps gain trust from buyers and partners. It shows a promise to quality and safety, making sales easier.

- Important tests, like safety and environmental checks, are required for CE Certification. These tests prove the batteries are safe and reliable.

Part 1: What is CE Certification and Why is it Essential for Lithium Batteries?

1.1 Definition and Purpose of CE Certification

CE Certification is a mandatory conformity mark for products sold within the European Economic Area (EEA). It signifies that a product complies with EU directives related to health, safety, and environmental protection. For lithium batteries, this certification ensures adherence to strict standards, safeguarding users and the environment.

The CE Certificate of Conformity serves as a critical document in this process. It confirms that the product meets applicable EU regulations and includes essential details such as the issuing company, product specifications, and relevant directives. While this certificate demonstrates compliance, manufacturers must also issue a Declaration of Conformity before affixing the CE mark to their products.

1.2 Importance of CE Certification for Lithium Batteries

Lithium batteries power a wide range of applications, from consumer electronics to industrial equipment. Their safety and reliability are paramount, given the potential risks associated with improper handling or manufacturing defects. For instance, in 2022, a German energy storage company failed the short-circuit test under EN 62133-2, resulting in thermal runaway during transportation and a recall costing over €5 million. In contrast, industry leaders like Tesla, whose battery packs exceed standard requirements (≥1,500 cycles in life cycle testing), demonstrate how compliant design ensures long-term safety. CE Certification plays a vital role in mitigating these risks by ensuring compliance with stringent safety and environmental standards.

By obtaining CE Certification, manufacturers demonstrate their commitment to quality and safety. This not only facilitates market entry but also strengthens relationships with partners and clients who prioritize compliance. For lithium battery commodities, this certification is more than a regulatory requirement—it is a testament to their dedication to delivering safe and reliable energy solutions.

Part 2: Key CE Certification Standards for Lithium Batteries

2.1 EN 62133-2:2017 (Safety Standard for Lithium Batteries)

EN 62133-2:2017 is one of the most critical safety standards for lithium batteries. It outlines specific requirements for the safe operation of rechargeable cells and battery packs. This standard focuses on identifying and mitigating risks such as overheating, fire, or explosion during normal use or foreseeable misuse.According to Dr. Martin Schneider, an expert from the International Electrotechnical Commission (IEC), “EN 62133-2:2017 is not only a gateway to the EU market but also a global benchmark for lithium battery safety design. Companies must integrate dynamic test data with design optimization to fully meet its stringent requirements.” By adhering to EN 62133-2:2017, you demonstrate a commitment to safety and reliability, which is essential for gaining CE Certification and accessing the European market.

2.2 Low Voltage Directive (LVD) and Related Standards

The Low Voltage Directive (LVD) ensures that electrical equipment operates safely within specified voltage ranges. For lithium batteries, this directive applies to battery packs with voltages between 50V and 1,000V for alternating current or 75V and 1,500V for direct current. Compliance with LVD involves rigorous testing to verify insulation, protection against electric shock, and thermal stability.

Meeting LVD requirements not only ensures safety but also facilitates CE Certification. It allows your products to meet the expectations of industrial clients who prioritize compliance with electrical safety standards.

2.3 Electromagnetic Compatibility (EMC) Directive 2014/30/EU

The EMC Directive addresses the electromagnetic emissions and immunity of electronic devices, including lithium battery packs. The European Battery Association (EUROBAT) states in its 2023 Compliance Whitepaper: “The mandatory carbon footprint labeling under the new regulation will drive companies to adopt blockchain technology for supply chain transparency.” Additionally, Dr. Elena Kovac, a renowned compliance consultant, emphasizes: “Businesses must establish recycling systems in advance to meet the Battery Passport requirements effective from 2027.” It ensures that your batteries do not interfere with other electronic equipment and can withstand external electromagnetic disturbances.

Testing under this directive includes radiated emissions and immunity tests. Compliance with EMC standards is vital for CE Certification, as it guarantees that your battery packs perform reliably in diverse environments without causing or being affected by electromagnetic interference.

2.4 New Battery Regulation (EU) 2023/1542

The New Battery Regulation (EU) 2023/1542 introduces stricter requirements for lithium batteries, focusing on the green transition through full lifecycle management (production, use, recycling). The Regulation was published in the EU Official Journal on 28 July 2023 and entered into force on 17 August 2023, replacing the former Battery Directive 2006/66/EC. As an EU Regulation, it is directly applicable across all EU member states without requiring national transposition. Its stringent rules on hazardous substances, carbon footprint labeling, and digital tracking will reshape the global battery industry. Companies must align product design, compliance processes, and market strategies with the phased timelines to ensure continued EU market access.

Key Requirements

Restrictions on Hazardous Substances

- Mercury: All batteries must contain ≤0.0005% mercury (by weight).

- Cadmium: Portable batteries must contain ≤0.002% cadmium.

- Lead: From 18 August 2024, portable batteries must contain ≤0.01% lead (exemption for zinc-air button cells until 2028).

Labeling and Information Requirements

- General Information (from 18 August 2026):

Must include manufacturer details, production date, chemistry, critical raw materials (>0.1%), and hazardous substances. - Separate Collection Symbol (from 18 August 2025):

All batteries must display the “crossed-out wheeled bin” symbol. Additional Cd or Pb labels required if exceeding cadmium/lead limits. - QR Code (from 18 February 2027):

Mandatory for EV, LMT, and large industrial batteries to link to a “battery passport” or general information.

Carbon Footprint Requirements

- Applicability: EV batteries, rechargeable industrial batteries (>2 kWh), and LMT batteries.

- Phased Implementation:Phase 1: Declare carbon footprint in technical documentation.Phase 2: Affix carbon footprint performance label.Phase 3: Demonstrate compliance with carbon footprint thresholds.

Part 3: Key Testing Items about CE Certification for Lithium Batteries

3.1 Safety Tests

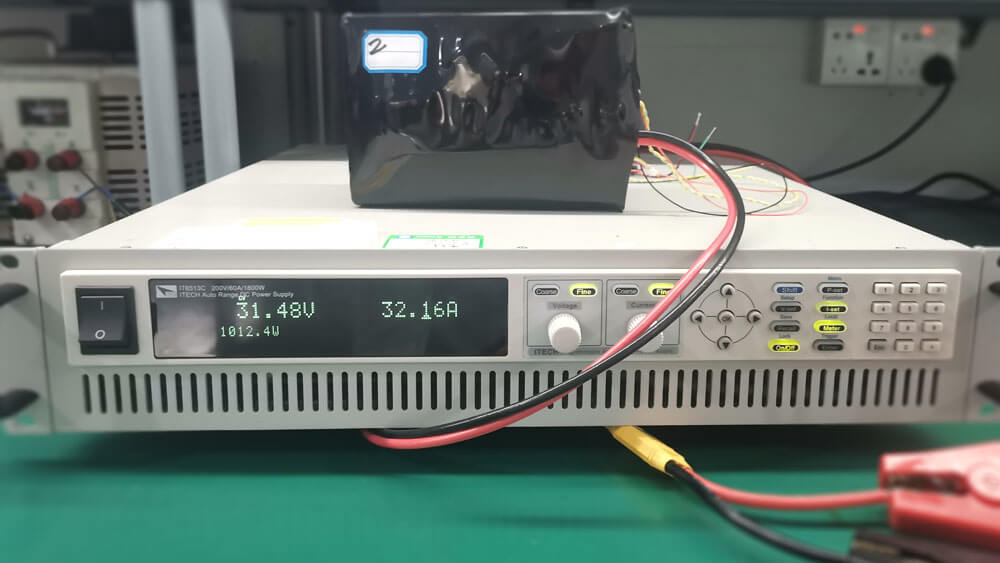

Overcharge/Overdischarge Protection

- Test Method:

Overcharge: Charge the battery at its rated current to 1.5× its nominal voltage (e.g., 5.55V for a 3.7V battery) for 24 hours. Monitor for protection circuit activation, leakage, or fire.

Overdischarge: Discharge the battery below its cutoff voltage (e.g., 2.0V for a 3.0V nominal battery) and observe for protection circuit activation or damage.

- Standard: EN 62133-2 (no fire, explosion, or leakage).

Short-Circuit Test

- Test Method: Apply an external short circuit (resistance ≤5mΩ) between the terminals until the battery temperature stabilizes or for ≥1 hour.

- Pass Criteria: No fire/explosion; case temperature ≤150°C.

Thermal Abuse Test

- Conditions: Expose the battery to 130°C for 30 minutes (some standards require 150°C).

- Pass Criteria: No fire/explosion; case integrity maintained (minor deformation allowed).

Crush Test

- Test Method:

Cylindrical Cells: Apply 13kN lateral force until 50% deformation.

Pouch Cells: Apply 10kN force via a 75mm-radius curved surface for 10 minutes.

- Pass Criteria: No fire/explosion (smoke or temperature rise permitted).

3.2 EMC Tests

Radiated Emissions

- Standard: EN 55032 (measures emissions in 30MHz–1GHz range).

- Limits: Class B (residential) or Class A (industrial).

Immunity

- Test Items:

Electrostatic Discharge (ESD): ±8kV contact discharge, ±15kV air discharge (EN 61000-4-2).

RF Immunity: 10V/m field strength at 80MHz–2.7GHz (EN 61000-4-3).

- Pass Criteria: No functional abnormalities (e.g., false protection circuit triggering).

3.3 Chemical Tests

Heavy Metal Analysis

- Method: ICP-MS (Inductively Coupled Plasma Mass Spectrometry).

- Limits: Cd ≤20ppm, Pb ≤100ppm, Hg ≤5ppm (EU 2023/1542).

Cycle Life Test

- Conditions:

Charge/discharge at 0.5C/1C until capacity drops to 80% of initial value.

Temperature: 25°C±2°C.

- Requirement: ≥500 cycles for portable batteries (EN 62133-2).

3.4 Mechanical Tests

Vibration Test

- Parameters:

Frequency: 7Hz–200Hz, 12 hours per axis (XYZ, total 36 hours).

Acceleration: 1.5g (sine sweep).

- Pass Criteria: No leakage; mass loss ≤0.1%.

Shock Test

- Parameters: 150g half-sine pulse, 6ms duration, 3 shocks per axis (XYZ).

- Standard: UN38.3 (transport safety).

Free-Fall Test

- Height: 1-meter drop onto concrete surface, 6 orientations (one drop per face).

- Pass Criteria: No fire/explosion; case intact.

3.5. Environmental Tests

Temperature Cycling

- Conditions:

Range: -40°C → +85°C, 1 hour per extreme, 10 cycles.

Ramp rate: ≤5°C/min.

- Pass Criteria: ≤20% capacity loss; no structural damage.

Low-Pressure Test

- Conditions: Simulate 15,000m altitude (11.6kPa) for 6 hours.

- Standard: UN38.3 (no leakage, rupture, or fire).

Note: These tests align with industry guidelines, including visual inspections, performance evaluations, and regulatory compliance checks. They ensure that lithium batteries meet the stringent requirements of CE Certification, enhancing safety and reliability.

FAQ

What documents are required for CE Certification of lithium batteries?

You need a Declaration of Conformity, technical documentation, and test reports. These documents demonstrate compliance with EU directives and ensure your product meets safety standards.

How long does the CE Certification process take?

The process typically takes 4-8 weeks. The timeline depends on the complexity of the product and the testing requirements outlined by applicable standards. Large Power has thousands of successful cases in obtaining CE Certification.

Can CE Certification be reused for different battery models?

No, CE Certification applies to specific products. Each model requires separate testing and documentation to ensure compliance with relevant safety and environmental standards.

Tip: Always consult Large Power’s certification experts to streamline the process and avoid delays.