Operating lithium batteries in high-altitude environments introduces unique safety concerns. Reduced pressure and extreme temperature fluctuations can compromise lithium battery safety, increasing risks like thermal runaway and fire hazards. You must address these challenges to prevent incidents and ensure reliable performance of high-altitude lithium battery packs, especially in aviation and logistics sectors.

Key Takeaways

High-altitude areas can make lithium batteries overheat and fail. Use strong designs and smart systems to keep them safe.

Big temperature changes can harm battery life and workability. Use insulation and cooling systems to keep temperatures steady.

Store and handle batteries carefully to avoid dangers. Check them often and use metal cabinets for better safety.

Part 1: Effects of High-Altitude Conditions on Lithium Batteries

1.1 Reduced Atmospheric Pressure and Lithium Battery Safety

Operating lithium batteries at high altitudes exposes them to reduced atmospheric pressure. This condition can significantly affect lithium battery safety. Lower pressure decreases the cooling efficiency of the surrounding air, which can lead to overheating. Overheated cells may trigger thermal runaway, a dangerous chain reaction that can result in fires or explosions.

Pressure changes also impact the structural integrity of lithium battery packs. Sealed enclosures may experience stress due to internal gas expansion, increasing the likelihood of leaks or ruptures. These structural failures can compromise lithium battery safety and lead to operational hazards.

To mitigate these risks, you should consider using pressure-resistant designs and advanced battery management systems (BMS). These systems monitor internal conditions and prevent lithium battery hazards caused by pressure fluctuations.

1.2 Temperature Variations and Their Impact on Battery Performance

High-altitude environments often experience extreme temperature variations. Lithium batteries are sensitive to temperature changes, which can affect their performance and safety. Cold temperatures reduce the electrochemical activity within the cells, leading to lower energy output and slower charging rates. Conversely, high temperatures accelerate chemical reactions, increasing the risk of thermal runaway and fire risk.

Temperature fluctuations also degrade the materials inside lithium batteries, shortening their lifespan. For example, NMC Lithium batteries, with energy densities ranging from 160 to 270 Wh/kg, may experience reduced cycle life under extreme conditions.

To ensure lithium battery safety, you should implement thermal management solutions, such as insulation and active cooling systems. These measures stabilize the battery’s operating temperature and minimize fire risks.

1.3 Electrochemical Instability in High-Altitude Lithium Batteries

Electrochemical instability is another challenge for lithium batteries in high-altitude environments. Reduced pressure and temperature variations disrupt the balance of chemical reactions within the cells. This imbalance can lead to uneven charge distribution, reduced capacity, and increased internal resistance.

Electrochemical instability also heightens the risk of lithium plating, a phenomenon where lithium deposits form on the battery’s anode. Lithium plating can cause short circuits, leading to fires or explosions.

To address these issues, you should prioritize lithium battery designs with stable chemistries, such as LiFePO4 Lithium batteries. These batteries offer platform voltages of 3.2V and cycle lives of up to 5,000 cycles, making them more resilient to electrochemical instability.

For industries like aviation and robotics, consulting experts for custom battery solutions can help optimize lithium battery safety in high-altitude applications. Explore custom solutions at Large Power.

Part 2: Lithium Battery Hazards in High-Altitude Environments

2.1 Thermal Runaway Risks in Low-Pressure Conditions

Thermal runaway poses one of the most significant hazards for lithium batteries in high-altitude environments. Reduced atmospheric pressure exacerbates this risk by impairing heat dissipation. When heat builds up within the battery cells, it can trigger a self-sustaining reaction, leading to rapid temperature increases, gas release, and potential fires.

You must address this hazard by implementing robust thermal management systems. These systems monitor temperature fluctuations and prevent runaway events. For example, integrating advanced battery management systems (BMS) can help detect early signs of overheating and mitigate risks effectively.

2.2 Fire and Explosion Hazards in Lithium Battery Packs

Lithium battery fires and explosions are critical safety concerns in high-altitude environments. These incidents often result from internal short circuits, thermal runaway, or structural failures. Reduced pressure and temperature extremes amplify these hazards, making fire protection a top priority.

To minimize fire risks, you should adopt fire-resistant materials in battery pack designs. Incorporating flame-retardant separators and protective enclosures can significantly reduce the likelihood of lithium battery fires. Additionally, regular inspections and maintenance protocols ensure early detection of potential hazards.

Note: Lithium battery safety incidents can have devastating consequences for industries like aviation and robotics. Custom solutions tailored to your operational needs can enhance fire protection and overall safety. Explore custom solutions at Large Power.

2.3 Structural Failures and Safety Incidents

Structural failures in lithium battery packs often occur due to pressure changes and mechanical stress in high-altitude environments. These failures can lead to gas leaks, ruptures, or compromised insulation, increasing the risk of lithium battery safety incidents.

You should prioritize designs that withstand extreme conditions. Pressure-resistant enclosures and reinforced materials can prevent battery failure caused by structural stress. Testing protocols, such as altitude simulation tests, ensure the reliability of lithium battery packs under varying conditions.

Failure Type | Cause | Preventive Measure |

|---|---|---|

Gas Leaks | Internal pressure changes | Pressure-resistant enclosures |

Ruptures | Mechanical stress | Reinforced materials |

Insulation Compromise | Temperature fluctuations | Flame-retardant separators |

Alert: Lithium battery safety incidents can disrupt operations and endanger lives. Investing in high-quality designs and rigorous testing standards is essential for industries like aerospace and infrastructure.

For industries requiring reliable lithium battery solutions, consulting experts for custom designs can help address structural challenges effectively. Learn more about sustainability in lithium battery design of Large Power.

Part 3: Preventive Measures for Lithium Battery Safety

3.1 Storage and Handling Protocols for High-Altitude Lithium Batteries

Safe handling of lithium batteries in high-altitude environments requires strict adherence to established protocols. Mishandling or improper storage can lead to serious safety risks, including fires or structural failures. To mitigate these risks, you should follow industry best practices and comply with lithium battery safety regulations.

Regulatory standards provide a comprehensive framework for safe handling, storage, and transportation. These guidelines address critical areas such as packaging, labeling, and documentation. Adhering to these regulations minimizes risks and ensures compliance with safety standards.

Here are some essential storage and handling protocols for lithium batteries:

Purchase batteries only from reputable manufacturers to guarantee quality and reliability.

Store batteries away from combustible materials like paper, fabric, or flammable liquids.

Remove batteries from devices if they will remain unused for extended periods to prevent leakage or damage.

Maintain recommended storage temperatures to preserve performance and prevent degradation.

Separate fresh and depleted cells to avoid accidental use of depleted batteries.

Use metal storage cabinets for additional containment and fire resistance.

Regularly inspect batteries for signs of damage, leakage, or swelling.

Keep batteries partially charged, ideally at 50% capacity, during storage to maintain their longevity.

Tip: Implementing these protocols not only enhances lithium battery safety but also extends the lifespan of your battery packs. For custom storage solutions tailored to your operational needs, consult experts in lithium battery design.

3.2 Testing and Certification Standards for Safety

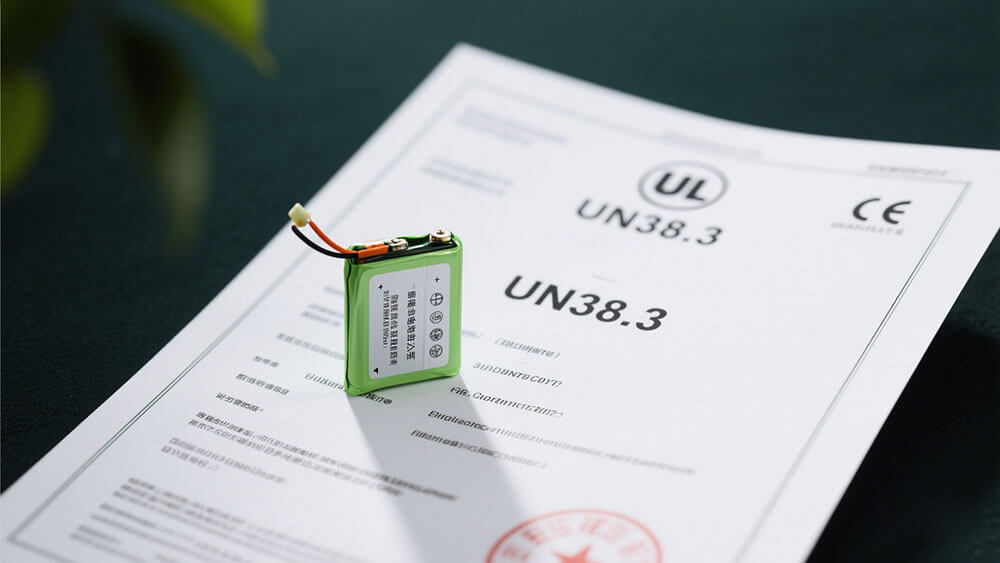

Testing and certification play a pivotal role in ensuring lithium battery safety, particularly in high-altitude applications. Rigorous testing validates the performance and resilience of batteries under extreme conditions, including reduced pressure and temperature fluctuations. Certification standards provide a benchmark for compliance, ensuring that batteries meet global safety requirements.

The UN 38.3 standard is a critical certification for lithium batteries used in high-altitude environments. It includes altitude simulation tests to evaluate battery performance under low-pressure conditions. This standard ensures that batteries can withstand the unique challenges of high-altitude operations. In contrast, the IEC 62133 standard focuses on safety requirements for portable electronic devices but lacks specific altitude testing.

Key certification standards include:

UN 38.3: Covers transport safety, including altitude simulation tests.

IEC 62133: Addresses general safety requirements but does not focus on altitude conditions.

Performance Metric | Description |

|---|---|

Resilience under extreme conditions | Evaluates how batteries perform under various stressors, including altitude, to ensure safety. |

Environmental condition assessment | Tests battery performance across different conditions such as temperature, humidity, and altitude. |

Note: Certification standards like UN 38.3 and IEC 62133 are essential for ensuring lithium battery safety in high-altitude applications. Partnering with certified testing labs can help you meet these standards and enhance the reliability of your battery packs.

For industries like aviation and robotics, investing in certified lithium battery solutions ensures compliance with safety regulations and minimizes operational risks. Explore custom solutions designed to meet your specific requirements.

Part 4: Regulatory Standards for High-Altitude Lithium Battery Safety

4.1 Overview of Lithium Battery Safety Regulations

Regulatory standards play a critical role in ensuring lithium battery safety, especially in high-altitude environments. These regulations address key concerns such as fire risks, structural failure, and hazard mitigation during transportation and operation. International agencies have established guidelines to standardize safety practices and minimize risks across industries.

Key updates from the Lithium Battery Guide for Shippers highlight essential safety measures. These include marking requirements for batteries, revised test summaries, and quantity limits for cells and batteries. Compliance with these guidelines ensures that lithium battery packs meet global safety standards, reducing the likelihood of fires or other incidents.

For high-altitude applications, regulations like UN38.3 and UNECE standards are indispensable. UN38.3 mandates altitude simulation tests to evaluate battery performance under low-pressure conditions. UNECE enforces these standards globally, promoting harmonized safety practices. Adhering to these regulations not only enhances safety but also ensures seamless operations in industries like aviation and logistics.

Tip: Partnering with certified testing labs can help you meet these stringent requirements and improve lithium battery reliability.

4.2 Compliance Requirements for High-Altitude Applications

Meeting compliance requirements for high-altitude lithium battery applications involves rigorous testing and documentation. Regulatory bodies demand adherence to specific standards to address concerns like thermal runaway, fire hazards, and structural failure.

Regulation | Description | Impact on Compliance |

|---|---|---|

UN38.3 | Addresses transportation safety for lithium batteries, including altitude simulation tests. | Required by airlines and shipping carriers for product distribution. |

UNECE | Enforces UN38.3 globally, ensuring manufacturers meet safety standards. | Influences compliance across different regions, promoting harmonization. |

To achieve compliance, you must implement robust risk mitigation strategies. These include using pressure-resistant enclosures, flame-retardant materials, and advanced battery management systems (BMS). Regular inspections and documentation further ensure that lithium battery packs meet safety benchmarks.

Note: Investing in certified lithium battery solutions tailored to your operational needs can significantly reduce risks. Explore custom solutions designed for high-altitude applications here.

Lithium batteries face unique challenges in high-altitude environments, including thermal runaway, fire risks, and structural failures. Addressing these issues requires robust preventive measures and strict adherence to regulatory standards. The growing demand for ternary low-temperature lithium batteries in aerospace and military sectors underscores the need for ongoing innovation. These advancements ensure reliable performance and enhanced safety in extreme conditions. Prioritizing these efforts will help you minimize risks and maintain operational efficiency.

FAQ

1. What are the common signs of battery failure in lithium ion batteries?

Swelling, leakage, overheating, or unusual odors indicate potential battery failure. Address these signs promptly to prevent accidents or hazards.

2. Can lithium ion batteries cause accidents during transport by passenger plane?

Yes, improper handling or undetected damage can lead to thermal runaway, fire, or explosions. Follow strict safety protocols to minimize risks.

3. What are some essential battery safety tips for high-altitude environments?

Store batteries in pressure-resistant enclosures, monitor for signs of battery failure, and use certified lithium ion batteries to reduce hazards and risks.

Tip: For professional guidance on battery safety tips for high-altitude environments, visit Large Power.