Contents

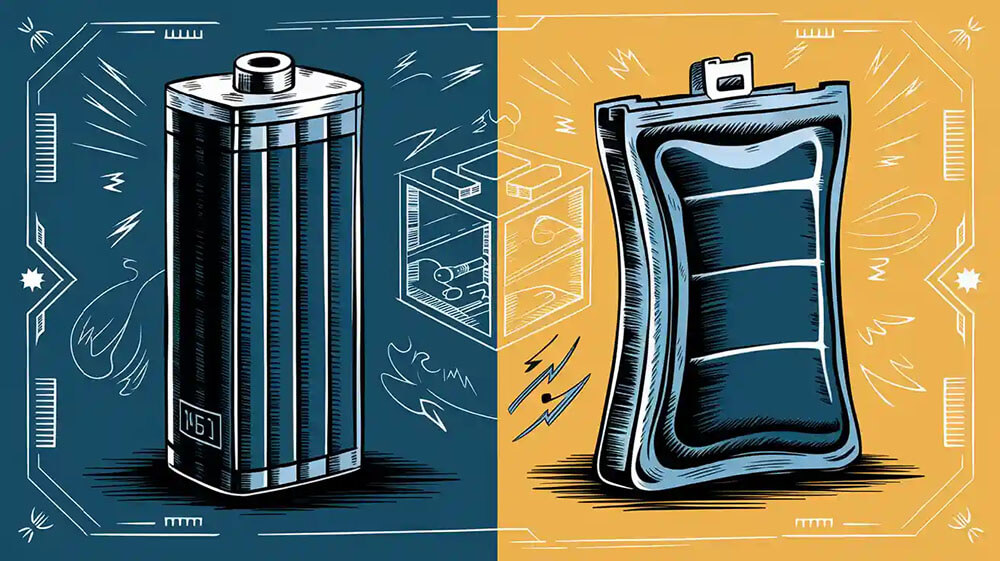

Lithium batteries come in different forms, with prismatic and pouch designs being two prominent types. A Prismatic Lithium Battery features a rigid rectangular casing, offering durability and efficient cooling. In contrast, pouch cells use a flexible, lightweight design, maximizing energy density in compact spaces.

Understanding the key differences between these batteries is crucial for battery pack design and industrial applications. The market reflects this importance, with the lithium battery sector projected to grow from $17.14 billion in 2024 to $124.84 billion by 2034, driven by a 21.96% CAGR. Selecting the right battery type ensures optimal performance, cost-efficiency, and reliability across industries like medical equipments and robotics.

Key Takeaways

Prismatic lithium batteries are strong and store lots of energy. They work well in medical equipments and energy storage systems.

Pouch lithium batteries are light and bendable. They are great for gadgets and medical tools.

When picking a battery, think about space, energy needs, and safety.

Part 1: Overview of Prismatic and Pouch Lithium Batteries

1.1 What Is a Prismatic Lithium Battery?

A prismatic lithium battery is a type of lithium-ion battery that features a rigid, rectangular casing. This design allows for efficient use of space, making it ideal for applications requiring compact and durable energy storage solutions. The cells are either laminated or wound inside the hard shell, ensuring structural integrity and better thermal management. Prismatic batteries are commonly used in electric vehicles (EVs), industrial equipment, and energy storage systems due to their high reliability and energy efficiency.

Aspect | Details |

|---|---|

Production Data (2016) | Cylindrical: 13.92GWh, Polymer: 21.64GWh, Prismatic: 28.14GWh (44.17% market share) |

Advantages | High reliability, energy efficiency, light weight, high energy density, simple structure |

Disadvantages | Customization leads to many models, low production automation, shorter system life |

Standard Reference | GB/T 34013-2017 for product specifications and dimensions of power batteries for EVs |

1.2 What Is a Pouch Battery Cell?

A pouch battery cell, also known as a lithium-polymer (LiPo) battery, uses a flexible polymer shell instead of a rigid casing. This design maximizes energy density and reduces weight, making it 40% lighter than traditional lithium batteries. Pouch cells are highly adaptable, allowing manufacturers to customize their size and shape to fit specific applications. These batteries are widely used in consumer electronics, robotics, and medical devices due to their lightweight and compact design.

Parameter | Value/Description |

|---|---|

Packaging Efficiency | 90 to 95 percent, highest among battery packs |

Weight Comparison | 40% lighter than equivalent capacity shell lithium battery |

20% lighter than aluminum shell lithium battery | |

Design Flexibility | Size can be arbitrary, shape can be thinner |

Energy Density | Greater than other shaped cells |

Part 2: Understanding the Key Differences Betweem Prismatic and Pouch Battery Cells

2.1 Structural Design and Manufacturing

Prismatic Batteries:

Encased in rigid aluminum or steel shells, forming a rectangular structure. This design facilitates stacking in modules and offers mechanical stability, making them suitable for large-scale equipments such as medical equipments and robots.

Production involves laser welding and standardized processes, balancing automation efficiency with moderate customization.

Pouch Batteries:

Use flexible aluminum-plastic laminated film, enabling lightweight and slim designs. Their soft packaging allows for shape flexibility, optimizing space in thin devices like smartphones or handheld surveying devices.

Manufacturing requires precise sealing to prevent electrolyte leakage, which increases complexity and cost compared to prismatic cells.

2.2 Energy Density and Performance

Energy Density:

Pouch cells generally achieve higher volumetric energy density due to minimal casing weight and efficient space utilization. For example, Nissan Leaf’s pouch batteries improved energy density from 157 Wh/kg (LMO) to 174 Wh/kg (NCM).

Prismatic cells, while lagging slightly in energy density, are catching up through innovations like GM’s “inverted U-shaped” design, which enhances cooling and allows for compact packing, potentially increasing energy density.

Thermal Management:

Prismatic cells benefit from rigid structures that simplify cooling system integration. Modifying prismatic design reduces cooling system volume by 50%, improving thermal performance.

Pouch cells generate lower internal pressure during thermal abuse but require advanced thermal management to mitigate swelling and localized overheating.

2.3 Safety and Failure Modes

Failure Mechanisms:

Prismatic: Under thermal abuse, Prismatic battery cells exhibit high internal pressure (e.g., 5577 N expansion force) and temperatures (121°C), leading to violent venting or explosion risks. However, rigid casings delay thermal runaway propagation.

Pouch: Swelling (“pregnancy”) is common due to gas buildup, but the soft packaging releases pressure gently, reducing explosion risks. However, pouch cells may still combust under extreme conditions.

Early Warning Signals:

With analysis of multidimensional signals evolution in prismatic and pouch LiFePO4 batteries under thermal abuse, for both types, abnormal expansion force (≥5 N/s) serves as the earliest thermal runaway indicator, providing ~80 seconds of warning pre-venting.

Part 3: Challenges and Considerations for Battery Pack Design

3.1 Challenges of Prismatic Lithium Batteries

Prismatic lithium batteries face several challenges during battery pack design. Their rigid structure, while beneficial for durability, can limit flexibility in compact applications. Thermal runaway remains a significant concern, especially in high-energy systems like electric vehicles or energy storage. This phenomenon can lead to overheating, fire, or even explosions. Manufacturing defects, such as contamination, may cause internal short circuits, further increasing the risk of thermal runaway. Despite these issues, the actual failure rate of lithium-ion batteries remains low compared to the vast number produced globally.

Another challenge lies in the customization of prismatic cells. Each model often requires unique specifications, which complicates mass production and increases costs. Additionally, the lower automation level in manufacturing prismatic batteries can lead to inconsistencies in quality, impacting their reliability in critical applications like infrastructure or industrial systems.

3.2 Challenges of Pouch Lithium Batteries

Pouch cells, while offering advantages like lightweight and flexible design, also present unique challenges. Their soft casing makes them more susceptible to physical damage, such as punctures or swelling under stress. This vulnerability can compromise safety, especially in high-demand applications like robotics or medical devices. Swelling, in particular, can lead to performance degradation or device failure over time.

Thermal management is another critical issue. Pouch cells lack the structural rigidity of prismatic batteries, making heat dissipation less efficient. This can result in uneven temperature distribution, reducing the lifespan of the battery pack. Additionally, pouch cells require meticulous quality checks during production to ensure safety and reliability, which can increase manufacturing costs.

3.3 Factors to Consider When Choosing Between Prismatic and Pouch Cells

When selecting between prismatic and pouch cells, you must evaluate several factors. Consider the application’s space constraints and energy requirements. Prismatic cells are ideal for large-scale systems like energy storage or transportation, where durability and long cycle life are priorities. In contrast, pouch cells excel in applications requiring lightweight and compact designs, such as consumer electronics or medical devices.

Safety is another critical factor. Prismatic cells offer better thermal stability, making them suitable for high-energy environments. However, pouch cells provide design flexibility, which can be advantageous in custom solutions. Cost considerations also play a role. Prismatic batteries may involve higher initial costs due to customization, while pouch cells require additional investment in quality assurance.

Ultimately, aligning your choice with the specific demands of your application ensures optimal performance and cost-efficiency. For custom battery solutions from Large Power tailored to your needs, consider consulting experts like Large Power for guidance.

Prismatic and pouch lithium batteries each offer unique advantages. Prismatic cells stand out for their durability and suitability in high-power applications, while pouch cells excel in lightweight, flexible designs for portable devices. Both types share similar voltage and capacity, but prismatic cells are better for energy storage systems, and pouch cells are ideal for compact electronics.

When choosing a battery type, consider your application’s requirements. For solar energy storage systems or electric vehicles, prismatic cells provide long-term reliability and safety. For consumer electronics or medical devices, pouch cells deliver design flexibility and cost efficiency. Aligning your choice with performance, cost, and design needs ensures optimal results.

FAQ

1. How do differences between LiFePO4 pouch cells and LiFePO4 prismatic cells in terms of lifespan?

Prismatic batteries typically last longer, with up to 5,000 charge cycles. Pouch cells may degrade faster due to their flexible casing and thermal management challenges.

2. Which battery type is safer for high-energy applications?

Prismatic batteries offer better thermal stability, making them safer for high-energy environments like large-scale equipments or energy storage systems.

3. Can LiFePO4 pouch cell handle extreme temperatures?

LiFePO4 pouch cells struggle with extreme temperatures due to their soft casing. Proper thermal management is essential to maintain performance and safety.

Tip: Always consult a battery expert from Large Power to match the right battery type with your application’s requirements.