Contents

The PTC of lithium battery systems is a crucial safety component. It serves as a safeguard by increasing resistance when temperatures rise, effectively controlling current flow during critical conditions. For instance, the PTC of lithium battery materials triggers a resistance increase around 100°C, reducing overheating risks and cutting the likelihood of explosions by 53%. This innovative feature ensures your lithium-ion batteries deliver reliable performance while maintaining safety.

Key Takeaways

PTC technology makes lithium batteries safer by blocking heat buildup. This lowers the chance of overheating or explosions.

Adding PTC parts to lithium batteries helps them last longer. It controls heat and electricity flow for steady performance.

To stay safe, use PTC with Battery Management Systems (BMS). Pair it with other safety tools for better protection.

Part 1: Understanding the PTC of Lithium Battery

1.1 What is the PTC of Lithium Battery?

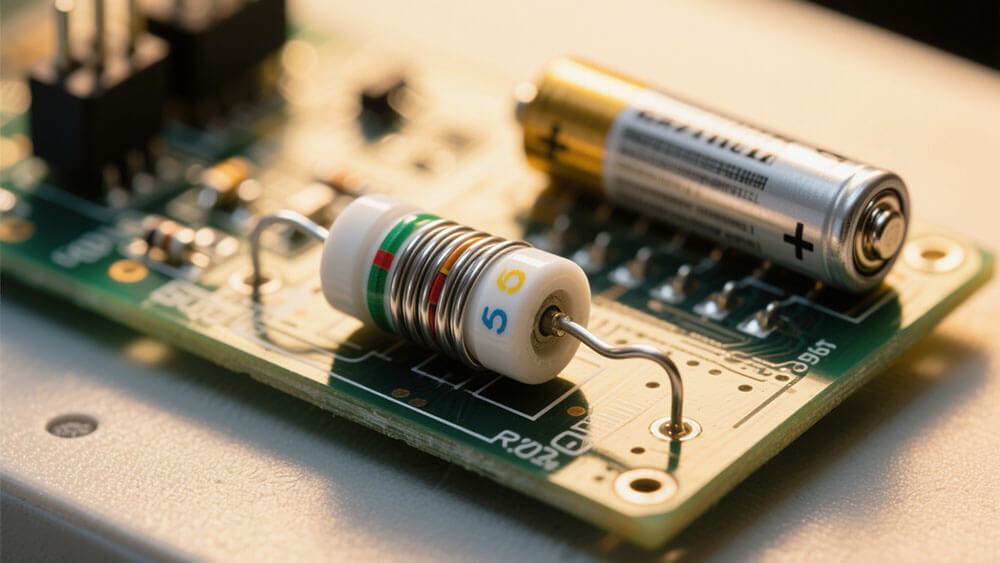

The Positive Temperature Coefficient (PTC) is a critical component in lithium battery systems, designed to enhance safety and reliability. It is a type of thermistor whose resistance increases as the temperature rises. This unique property makes it an essential safeguard against overheating and overcurrent conditions in lithium-ion batteries. By responding to temperature changes, the PTC ensures that the battery operates within safe limits, preventing potential hazards such as thermal runaway.

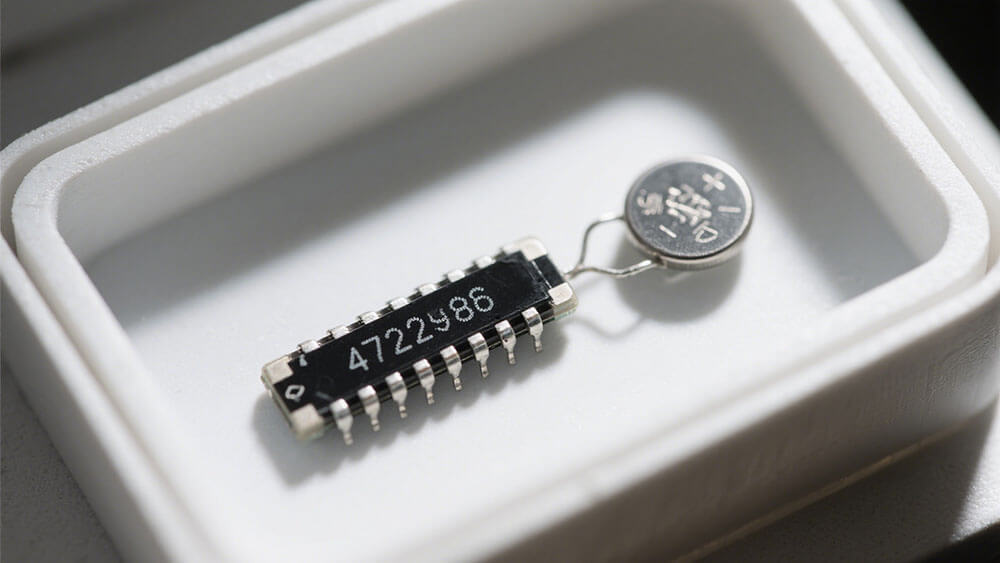

In lithium battery applications, the PTC is often integrated into individual cells or battery packs. For instance, in 18650 batteries, PTC resistors are mandatory in the United States to prevent overheating, while other components like Protection Circuit Boards (PCBs) focus on limiting current discharge. The table below highlights the differences between PTC resistors and PCBs in battery systems:

Feature | PTC Resistors | PCB (Protection Circuit Board) |

|---|---|---|

Function | Prevents overheating | Limits amp discharge |

Usage in Batteries | Required in 18650 batteries in the US | Commonly absent in vaporizer cells |

Type of Protection | Thermal fuses (hard blow or resettable) | Current limiting |

The PTC’s role extends beyond basic protection. It contributes to the overall efficiency and longevity of lithium-ion batteries by minimizing risks associated with excessive heat and current. This makes it indispensable in applications ranging from consumer electronics to industrial systems.

Note: For more insights into the sustainability of lithium battery technologies, visit Sustainability at Large Power.

1.2 How Does PTC Work in Lithium-Ion Batteries?

The PTC operates through a straightforward yet effective mechanism. Under normal conditions, it maintains a low resistance, allowing the battery to function efficiently. However, when the temperature or current exceeds safe thresholds, the PTC’s resistance increases significantly. This rise in resistance limits the current flow, preventing overheating and potential damage to the battery.

Here’s a step-by-step breakdown of how the PTC functions:

Overcurrent and Short Circuit Protection: The PTC detects abnormal current levels and responds by increasing resistance, effectively reducing the current flow.

Temperature Sensitivity: As the battery heats up, the PTC’s resistance rises, providing a thermal safeguard.

Regular Operation: During normal use, the PTC remains in a low-resistance state, ensuring optimal performance.

Response to Excessive Current: In overcurrent scenarios, the PTC acts swiftly to limit current and prevent overheating.

Automatic Reset: Once the fault condition is resolved, the PTC resets itself, restoring normal operation without requiring manual intervention.

Complementary Protection: The PTC works in tandem with other safety components, such as Battery Management Systems (BMS), to enhance overall battery safety.

The operational efficiency of the PTC is influenced by various factors, including the battery’s specific heat capacity, heat generation methods, and heat exchange mechanisms. The table below summarizes these factors:

Evidence Type | Description |

|---|---|

Specific Heat Capacity | Crucial for calculating heat production in lithium-ion batteries. |

Heat Generation Method | Utilizes thermocouples to measure temperature changes during discharge. |

Heat Exchange Mechanisms | Includes conduction, convection, and radiation, affecting performance. |

Factors Affecting Heat Production | Cathode materials, charge-discharge rates, and environmental conditions. |

Heat Production Equation | Q = Q_rea + Q_act + Q_ohm + Q_sid, accounting for different heat sources. |

By integrating PTC technology, lithium-ion batteries achieve a balance between safety and performance. This makes them suitable for diverse applications, including robotics, medical devices, and consumer electronics. For customized battery solutions tailored to your needs, explore Large Power’s Custom Battery Solutions.

Part 2: PTC’s Role in Lithium-Ion Battery Safety

2.1 Preventing Thermal Runaway in Lithium-Ion Batteries

Thermal runaway is one of the most critical challenges in lithium battery systems. It occurs when excessive heat triggers a chain reaction, leading to rapid temperature escalation and potential battery failure. The PTC (Positive Temperature Coefficient) component plays a pivotal role in mitigating this risk by acting as a thermal management solution.

When the temperature within a lithium battery rises beyond a safe threshold, the PTC increases its resistance sharply. This resistance spike limits current flow, effectively reducing heat generation. Key factors such as the thermal time constant, activation temperature, and resistance determine the PTC’s effectiveness in preventing runaway events. By integrating PTC devices, you can ensure that your batteries remain stable even under demanding conditions.

PTC devices limit current flow during internal short circuits by increasing resistance.

Their design enhances safety and performance across various lithium battery applications.

The thermal management capabilities of PTCs reduce the likelihood of thermal runaway by addressing excessive heat promptly.

This proactive approach to thermal management not only safeguards the battery but also protects the surrounding environment and connected devices. Whether in consumer electronics or industrial applications, PTC technology ensures that your lithium batteries operate safely and efficiently.

2.2 Protection Against Short Circuits and Overcurrent

Short circuits and overcurrent conditions pose significant risks to lithium battery safety. A short circuit occurs when unintended contact between conductive components allows excessive current to flow, potentially causing overheating or damage. Overcurrent conditions, on the other hand, arise when the current exceeds the battery’s designed capacity. Both scenarios can lead to severe consequences without proper protection mechanisms.

PTC components serve as a reliable short circuit protection measure. When a short circuit or overcurrent condition occurs, the PTC detects the abnormal current levels and responds by increasing resistance. This action reduces the current flow, preventing further escalation of the issue. Unlike traditional fuses, PTCs are reversible. Once the temperature normalizes, the PTC resets itself, restoring the battery to its original state without requiring replacement.

PTCs increase resistance when temperature rises, effectively reducing current flow during overcurrent conditions.

Protection circuits, including PTCs, are mandatory for lithium-ion battery packs to prevent hazards associated with short circuits.

The reversible nature of PTCs ensures long-term reliability and cost-effectiveness.

By incorporating PTC technology into your lithium battery systems, you can achieve robust protection against short circuits and overcurrent. This enhances the overall safety of the battery while maintaining its performance and longevity.

2.3 Enhancing Battery Longevity and Reliability

The integration of PTC components in lithium batteries not only improves safety but also contributes to battery life and reliability. By regulating temperature and current flow, PTCs minimize the stress on battery cells, reducing the risk of permanent damage. This ensures that your batteries deliver consistent performance over an extended period.

Studies on battery longevity highlight the importance of maintaining optimal operating conditions. For instance, lithium batteries perform best within a temperature range of 15°C to 35°C. Operating outside this range can lead to efficiency drops and permanent deterioration. PTCs help maintain this optimal range by preventing overheating and excessive current, thereby extending the battery’s lifespan.

Temperature Range (°C) | Battery Performance Impact | Longevity Effect |

|---|---|---|

Below 15 | Efficiency drops, life shortens | Permanent deterioration |

15 – 35 | Optimal performance maintained | Prolonged battery life |

In addition to enhancing battery life, PTCs improve reliability by providing consistent protection against thermal and electrical risks. This makes them indispensable in applications where safety and durability are paramount, such as medical devices, robotics, and infrastructure systems. By choosing lithium batteries equipped with PTC technology, you can ensure long-lasting and dependable performance.

For customized battery solutions tailored to your specific needs, explore Large Power’s Custom Battery Solutions.

Part 3: Applications and Limitations of PTC in Lithium-Ion Batteries

3.1 Applications in Consumer Electronics and Portable Devices

PTC technology plays a vital role in ensuring the safety and reliability of lithium battery systems used in consumer electronics. Devices such as smartphones, laptops, and wearable gadgets rely on lithium-ion batteries to deliver consistent performance. PTC components act as a safeguard by preventing overheating and overcurrent, which are common risks in compact, high-energy devices.

For example, in smartphones, PTCs protect against accidental short circuits caused by physical damage or manufacturing defects. Their self-resetting capability ensures that the battery remains operational after resolving the fault, reducing downtime and maintenance costs. This makes PTCs an indispensable feature in portable devices where safety and durability are critical.

Tip: Explore more about consumer electronics applications here.

3.2 Applications in Energy Storage Systems

Energy storage systems, including those used in renewable energy grids and backup power solutions, benefit significantly from PTC integration. These systems often involve large-scale lithium battery packs that operate under varying environmental conditions. PTC components enhance the safety of these systems by mitigating risks associated with thermal runaway and overcurrent.

In renewable energy applications, PTCs ensure stable operation by regulating temperature and current flow. This is particularly important in solar and wind energy storage, where fluctuations in power generation can stress the battery. By incorporating PTC technology, energy storage systems achieve higher reliability and longer service life, making them more sustainable and efficient.

3.3 Limitations of PTC in Lithium-Ion Batteries

While PTC technology offers numerous benefits, it has certain limitations. The response time of PTC components may not be sufficient to address extremely rapid current spikes. Additionally, their effectiveness can vary depending on the battery’s design and operating conditions. These factors necessitate the use of complementary safety measures to ensure comprehensive protection.

3.4 Complementary Technologies: BMS and Other Safety Measures

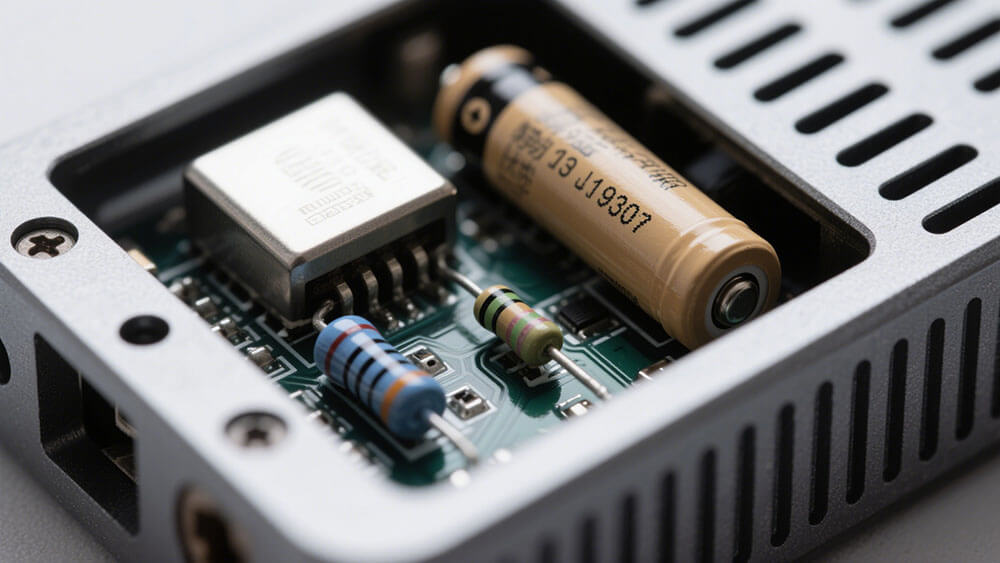

To overcome the limitations of PTCs, lithium battery systems often integrate complementary technologies like Battery Management Systems (BMS). A BMS actively monitors parameters such as voltage, temperature, and current, providing real-time protection. It works alongside PTC components to enhance overall safety and performance.

Other safety measures, such as thermal fuses and advanced circuit designs, further strengthen the protection framework. By combining these technologies, you can create a robust safety system that addresses the diverse challenges of lithium battery applications.

Learn More: Discover how BMS enhances battery safety at Large Power.

PTC technology plays a vital role in modern lithium-ion batteries by enhancing safety, performance, and reliability. It prevents overheating and overcurrent, ensuring stable operation across diverse applications. To address its limitations, you should integrate complementary technologies like Battery Management Systems (BMS). For tailored battery solutions, explore Large Power’s Custom Battery Solutions.

FAQ

1. What is the role of a battery management system in lithium-ion batteries?

A battery management system monitors voltage, temperature, and current. It ensures safe operation and prevents risks like overcharging or overheating.

2. How does PTC technology complement a BMS?

PTC technology provides passive protection by limiting current during overheating. A BMS actively monitors and controls battery parameters for enhanced safety.

3. Can PTC components be reused after activation?

Yes, PTC components reset automatically after resolving faults. This feature ensures long-term reliability without requiring manual replacement.

For customized solutions tailored to your specific needs, consult Large Power’s Custom Battery Solutions.