Contents

A Battery Monitor Shunt helps you achieve precise current measurements and real-time battery insights. Its design ensures accurate tracking of charge and discharge cycles. By understanding shunt specifications and performing proper shunt selection, you can optimize battery health and longevity. This tool is indispensable for managing lithium battery systems efficiently.

Key Takeaways

Battery monitor shunts measure current accurately, helping track battery use.

A shunt stops overcharging and deep discharging to protect batteries.

Shunts work with many battery types, making them useful for solar power, electric cars, and factories.

Part 1: Understanding the Battery Monitor Shunt

1.1 What Is a Battery Monitor Shunt?

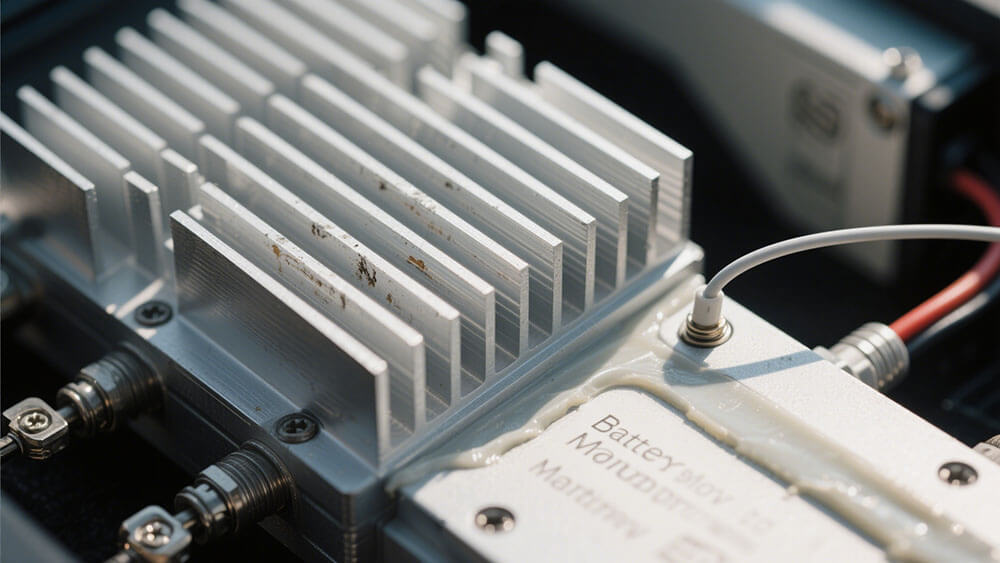

A battery monitor shunt is a precision component designed to measure the current flowing in and out of a battery system. It consists of a low-resistance electrical conductor, typically made of a durable alloy, that is installed in series with the battery’s main circuit. When current passes through the shunt, it generates a small voltage drop proportional to the current. This voltage is then measured by a battery monitor to calculate the real-time current.

The shunt’s ability to provide accurate current readings makes it a cornerstone of modern battery management systems (BMS). It is particularly valuable for lithium-ion battery systems, where precise monitoring is essential to maintain safety and performance. By integrating a shunt into your system, you gain access to critical data that helps optimize battery usage and extend its lifespan.

Tip: When selecting a shunt, ensure it matches the maximum current rating of your battery system to avoid inaccuracies or potential damage.

1.2 How Does a Battery Monitor Shunt Work?

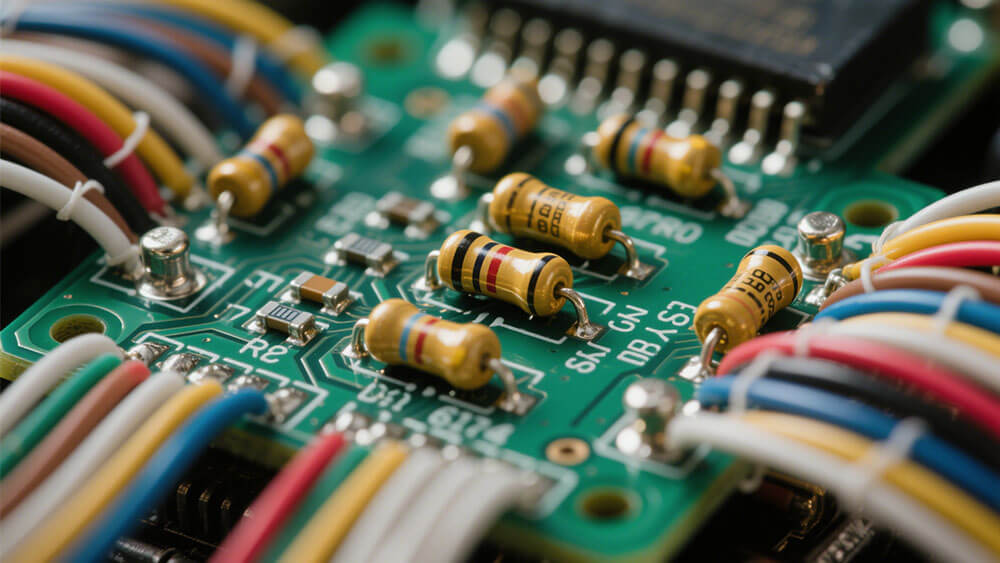

The operation of a battery monitor shunt is based on Ohm’s Law, which states that voltage equals current multiplied by resistance (V = I × R). The shunt’s resistance is extremely low, often in the milliohm range, to minimize energy loss. As current flows through the shunt, it creates a small voltage drop. This voltage is measured by the battery monitor, which uses it to calculate the current.

Here’s a simplified breakdown of how it works:

Current Measurement: The shunt detects the flow of current in both directions—charging and discharging.

Voltage Conversion: The small voltage drop across the shunt is converted into a readable current value by the monitor.

Data Integration: The monitor processes this data to provide insights into the battery’s state of charge (SOC), state of health (SOH), and overall performance.

This real-time monitoring ensures that your battery system operates within safe parameters, preventing issues like overcharging or deep discharging. It also supports advanced features like energy optimization and fault detection.

1.3 Why Is It Ideal for Lithium Battery Systems?

Battery monitor shunts are particularly well-suited for lithium battery systems due to their high accuracy and compatibility with the unique characteristics of lithium chemistries. Lithium-ion batteries, including LiFePO4 and NMC variants, require precise monitoring to ensure safety and efficiency. Shunts provide the level of detail needed to manage these batteries effectively.

Al Thomason, a seasoned expert in lithium battery systems, highlights the importance of accurate data for balancing and monitoring. His extensive work with leading BMS manufacturers underscores the critical role of shunts in achieving optimal battery performance.

Shunts enable advanced SOC and SOH calculations, which are vital for lithium-ion batteries. These calculations help you track capacity degradation and plan maintenance schedules.

Unlike voltage-only monitors, shunts offer bidirectional current measurement, making them indispensable for applications like renewable energy storage, electric vehicles, and industrial systems.

By using a shunt-based battery monitor, you can maximize the performance and longevity of your lithium battery system. This approach not only enhances operational efficiency but also contributes to sustainability by reducing battery waste. For more insights into sustainable battery solutions, visit Sustainability at Large Power.

Part 2: Key Benefits of Using a Battery Monitor Shunt

2.1 High Accuracy and Real-Time Monitoring

A battery monitor shunt provides unparalleled accuracy in measuring current flow, making it an essential tool for precise battery management. By leveraging Ohm’s Law, the shunt detects even the smallest voltage drops caused by current passing through its low-resistance conductor. This data is then processed by the battery monitoring system to deliver real-time monitoring of charge and discharge cycles.

Real-time monitoring ensures you can track your battery’s performance under various conditions. For instance, in lithium-ion battery systems, this level of precision is critical for maintaining safety and efficiency. Whether you’re managing a renewable energy setup or an industrial power system, the shunt-based battery monitor offers the insights needed to optimize operations and prevent potential failures.

Pro Tip: Use a shunt-based battery monitor to detect anomalies early, such as unexpected current spikes, which could indicate system faults or inefficiencies.

2.2 Enhanced Battery Health and Longevity

Maintaining battery health is crucial for extending the lifespan of your energy storage system. A battery monitor shunt plays a pivotal role in achieving this by providing accurate data on the state of charge (SOC) and state of health (SOH). These metrics allow you to make informed decisions about charging and discharging cycles, preventing overcharging or deep discharging, which can degrade battery performance over time.

For lithium-ion batteries, such as LiFePO4 or NMC variants, this is particularly important. These batteries are sensitive to improper charging practices, and a shunt-based monitoring system ensures they operate within safe parameters. By using this technology, you can reduce the risk of capacity loss and improve the overall efficiency of your battery system.

Note: Regularly monitoring SOC and SOH with a battery monitoring system can help you plan maintenance schedules and avoid unexpected downtime.

2.3 Compatibility with Lithium and Other Battery Types

One of the standout features of a battery monitor shunt is its compatibility with a wide range of battery chemistries. Whether you’re working with lithium-ion, LiFePO4, lead-acid, or nickel-metal hydride batteries, the shunt-based system adapts seamlessly to your setup. This versatility makes it a valuable tool for diverse applications, from renewable energy systems to electric vehicles.

Here’s a quick comparison of compatibility across battery types:

The BMV-712 Smart Battery Monitor from Victron, for example, supports a wide voltage range and handles up to 500 amps of current. This makes it suitable for various battery types and nearly any solar component, ensuring you can integrate it into your existing infrastructure without complications.

2.4 Cost-Effectiveness and Long-Term Value

Investing in a battery monitor shunt delivers significant cost savings over time. By providing accurate data on battery performance, the shunt helps you optimize energy usage and reduce waste. This leads to lower operational costs and a longer lifespan for your battery system, minimizing the need for frequent replacements.

For industrial applications, where energy demands are high, the long-term value of a shunt-based battery monitor becomes even more apparent. It not only enhances efficiency but also supports sustainability goals by reducing battery waste. By integrating this technology into your system, you can achieve both economic and environmental benefits.

Call to Action: Explore custom battery solutions tailored to your specific needs by visiting Large Power’s Custom Battery Solutions.

Part 3: Comparing Shunt-Based Monitors with Other Methods

3.1 Shunt-Based Monitors vs. Voltage-Only Monitors

Shunt-based monitors outperform voltage-only monitors in several critical areas, especially when managing lithium-ion battery systems. Voltage-only monitors rely solely on battery voltage to estimate the state of charge (SOC). However, this approach often leads to inaccuracies due to factors like temperature fluctuations and battery aging. In contrast, shunt-based monitors provide precise current measurements, enabling more reliable SOC calculations.

Here’s how shunt-based monitors excel:

They measure amp-hours by tracking the current flowing in and out of the battery, offering real-time insights.

They allow you to input battery capacity and efficiency, ensuring SOC readings remain accurate over time.

Voltage-only monitors fail to account for variations in battery capacity, making them less dependable for lithium-ion batteries.

Note: For lithium-ion systems, accurate SOC readings are essential to prevent overcharging or deep discharging, which can degrade battery performance.

3.2 Advantages Over Amp-Hour Counters

Shunt-based monitors also surpass traditional amp-hour counters in functionality and compatibility. Amp-hour counters focus solely on tracking the cumulative current flow, which limits their ability to provide a comprehensive view of battery health. Shunt-based monitors, on the other hand, integrate multiple parameters like voltage, current, and temperature to deliver a holistic analysis.

Key advantages include:

Real-time monitoring of current and SOC, preferred by users managing lithium-ion systems.

Enhanced compatibility with lithium chemistries, such as LiFePO4 and NMC batteries, making them more versatile.

This advanced functionality ensures that shunt-based monitors meet the demands of modern applications, from renewable energy systems to industrial setups.

3.3 Why Shunt-Based Monitors Are Superior for Lithium Batteries

Real-world tests highlight the superiority of shunt-based monitors in enhancing lithium battery performance. Under load conditions, voltage-only monitors often provide inconsistent readings due to voltage drops. Shunt-based monitors, however, deliver precise data by measuring the current directly through a shunt resistor. This method ensures accurate SOC calculations and better performance tracking.

Additionally, shunt-based monitors measure critical parameters like battery voltage and temperature, offering a comprehensive view of battery health. This capability is particularly valuable for lithium-ion batteries, where maintaining optimal performance and safety is crucial. By using a shunt-based monitor, you can maximize the efficiency and lifespan of your lithium battery system.

Call to Action: Discover how custom battery solutions can optimize your lithium battery systems by visiting Large Power’s Custom Battery Solutions.

Part 4: Practical Applications of Shunt-Based Battery Monitors

4.1 Use in Renewable Energy Systems

Shunt-based battery monitors play a critical role in renewable energy systems by ensuring efficient energy storage and distribution. Solar and wind energy systems rely on batteries to store excess energy for later use. Accurate monitoring of charge and discharge cycles is essential to maximize energy capture and prevent overcharging or deep discharging.

For example, global solar energy capacity reached 1.6 terawatts in 2023, with inverters increasingly using high-precision shunt resistors to enhance efficiency. The table below highlights key statistics:

Application Area | Key Statistics |

|---|---|

Electric Vehicles | Global EV sales surpassed 14 million units in 2023, driving demand for automotive-grade shunt resistors. |

Solar Energy Systems | Global solar energy capacity reached 1.6 terawatts in 2023, with inverters using high-precision shunt resistors for efficiency. |

By integrating shunt-based monitors, you can optimize energy usage and extend the lifespan of lithium-ion batteries in renewable energy setups. Learn more about sustainable battery solutions at Large Power.

4.2 Applications in Electric Vehicles and Marine Systems

Electric vehicles (EVs) and marine systems demand precise battery management to ensure safety and performance. Shunt-based monitors provide real-time data on current flow, enabling accurate state-of-charge (SOC) and state-of-health (SOH) calculations.

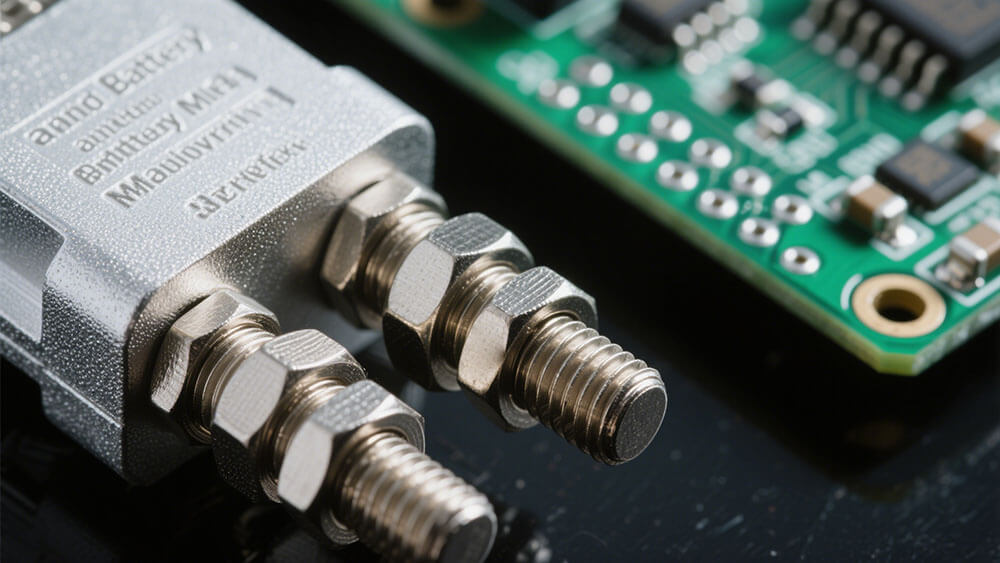

Resistance (Rshunt): Typically in milliohms, ensuring minimal energy loss. Example: A 500A/50mV shunt has a resistance of 0.1 mΩ.

Voltage Drop (Vshunt): Common values include 50mV or 75mV, balancing energy efficiency and measurement accuracy.

Power Dissipation (Pshunt): Calculated as P = I²R, with minimal loss critical for high-current applications.

These features enhance reliability and operational efficiency, making shunt-based monitors indispensable for EVs and marine systems. They also regulate power distribution, ensuring optimal battery performance.

4.3 Industrial and Commercial Use Cases for Lithium Battery Systems

In industrial and commercial sectors, shunt-based monitors support the efficient operation of lithium battery systems. They are vital for applications like robotics, infrastructure, and consumer electronics. The table below illustrates their importance:

Sector | Importance of Battery Monitors |

|---|---|

Electric Vehicles | Critical for performance and longevity of EV batteries |

Consumer Electronics | Enhances user experience and prevents overheating |

Renewable Energy | Essential for maximizing energy capture and storage |

Healthcare | Ensures functionality of portable medical devices |

By adopting shunt-based monitors, you can improve battery health, reduce downtime, and achieve long-term cost savings. Explore custom battery solutions tailored to your needs at Large Power.

Battery monitor shunts deliver precise current measurements, ensuring unmatched accuracy for lithium-ion battery systems. Their adaptability across diverse applications enhances compatibility, making them essential for maintaining electrical network integrity. By investing in this technology, you optimize performance, extend battery lifespan, and achieve cost-effective solutions.

FAQ

1. How do you choose the right battery monitor shunt for your system?

Select a shunt based on your battery’s maximum current rating. Ensure compatibility with your monitoring device for accurate readings.

Tip: Always check the shunt’s resistance value to minimize energy loss.

2. Can a battery monitor shunt work with all battery types?

Yes, shunts are compatible with lithium-ion, lead-acid, and nickel-metal hydride batteries. They adapt to various chemistries for versatile applications.

Battery Type | Compatibility |

|---|---|

Lithium-Ion | ✅ |

Lead-Acid | ✅ |

Nickel-Metal Hydride | ✅ |

3. What maintenance does a battery monitor shunt require?

Keep the shunt clean and ensure secure connections. Periodically check for wear or damage to maintain accurate performance.

Note: Regular inspections prevent errors in current measurements. Explore custom battery solutions tailored to your needs at Large Power.