The purpose of this blog is try to answer what is ultra thin lithium polymer battery, i.e. how it works, why it works and where it works. Please contact us for more details if you have any questions on ultra thin lithium polymer battery!

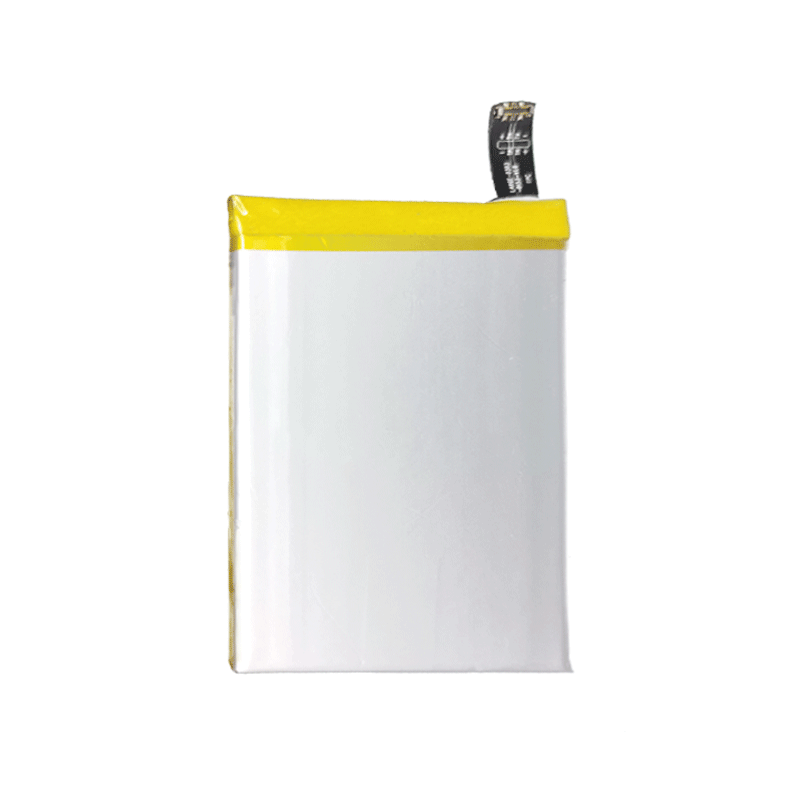

Ultra-thin lithium polymer (LiPo) batteries represent a specialized category of energy storage devices designed for applications where minimal thickness and flexible form factors are critical. Compared to lithium-ion (Li-ion) batteries, which are known for their improved power-to-size ratios and safety features, LiPo batteries typically have a thickness below 2.5 mm and leverage advancements in polymer electrolyte technology and electrode design to achieve compact dimensions while maintaining competitive energy densities. The production of LiPo batteries is lower in cost than that of traditional lithium-ion batteries due to their pouch design. This report examines the technical foundations, manufacturing processes, applications, and challenges associated with ultra-thin lithium polymer cells, LiPo batteries, drawing insights from industry specifications, academic literature, and commercial product data.

What is an ultra-thin lithium polymer battery?

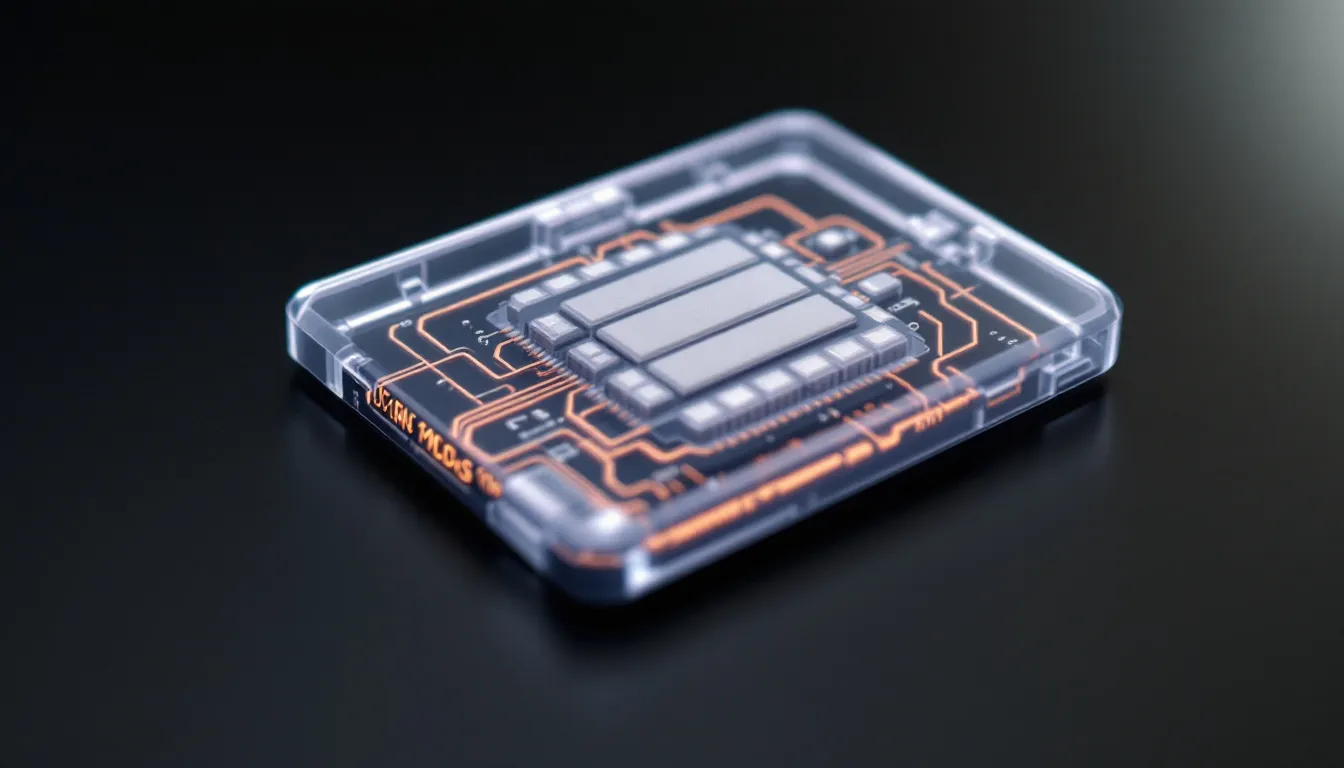

Lithium polymer batteries, categorized as lithium batteries, are a subset of lithium-ion technology that replaces traditional liquid electrolytes with solid or gel-like polymer electrolytes. This innovation enables flexible packaging and reduced thickness, making them ideal for modern compact electronics. Ultra-thin variants push these boundaries further, with thicknesses ranging from 0.4 mm to 2.5 mm, as exemplified by commercial offerings. These batteries are usually packaged in a flexible aluminum foil pouch, which allows for various custom configurations.

Ultra-thin lithium polymer batteries are particularly suitable for the thinnest application, such as mini card phones and smart cards, which demand minimal thickness while providing sufficient power and longevity.

The defining characteristic of ultra-thin LiPo batteries is their ability to conform to stringent spatial constraints without compromising performance. For instance, Motoma’s 3.7V LIP094648 model measures just 0.9 mm in thickness, thinner than a standard credit card. Such batteries, utilizing solid polymer electrolytes, are engineered for devices where traditional cylindrical or prismatic cells are impractical, such as wearable sensors, smart cards, and medical implants. PowerStream is developing ultra-thin lithium polymer batteries of 2.0 mm to 0.5 mm thick, further expanding the range of applications.

Key features of ultra-thin lithium polymer battery

Ultra-Slim Profile

Entire cell thicknesses below 1 mm (often 200–800 μm) are crucial to achieving the rated capacity enable integration into thin devices such as smart cards and flexible displays.

High Energy Density

Specific energies comparable to standard LiPo (150–250 Wh/kg) provide sufficient runtime despite minimal thickness. This is crucial for products requiring minimal power consumption while ensuring a longer working time. For more detailed information on different types of batteries, you may refer to the comparison energy density of LCO batteries.

Mechanical Flexibility

The pouch-style aluminum-plastic laminate and gel polymer electrolyte allow gentle bending without mechanical failure.

Enhanced Safety

Solid or gel polymer electrolytes reduce leakage and thermal runaway risks; pouch design bulges rather than explodes under abuse. Additionally, lithium polymer separators can act as shutdown separators that can stop current flow if the battery overheats, adding another layer of safety. However, it is important to note that lithium ion polymer battery structures can expand at high levels of state of charge (SOC) or overcharge, which can lead to delamination and reduced reliability, posing safety risks in various applications like vehicles and electronic devices.

Designed for hundreds to thousands of cycles with minimal capacity fade, often exceeding 500 cycles at 80 % depth of discharge

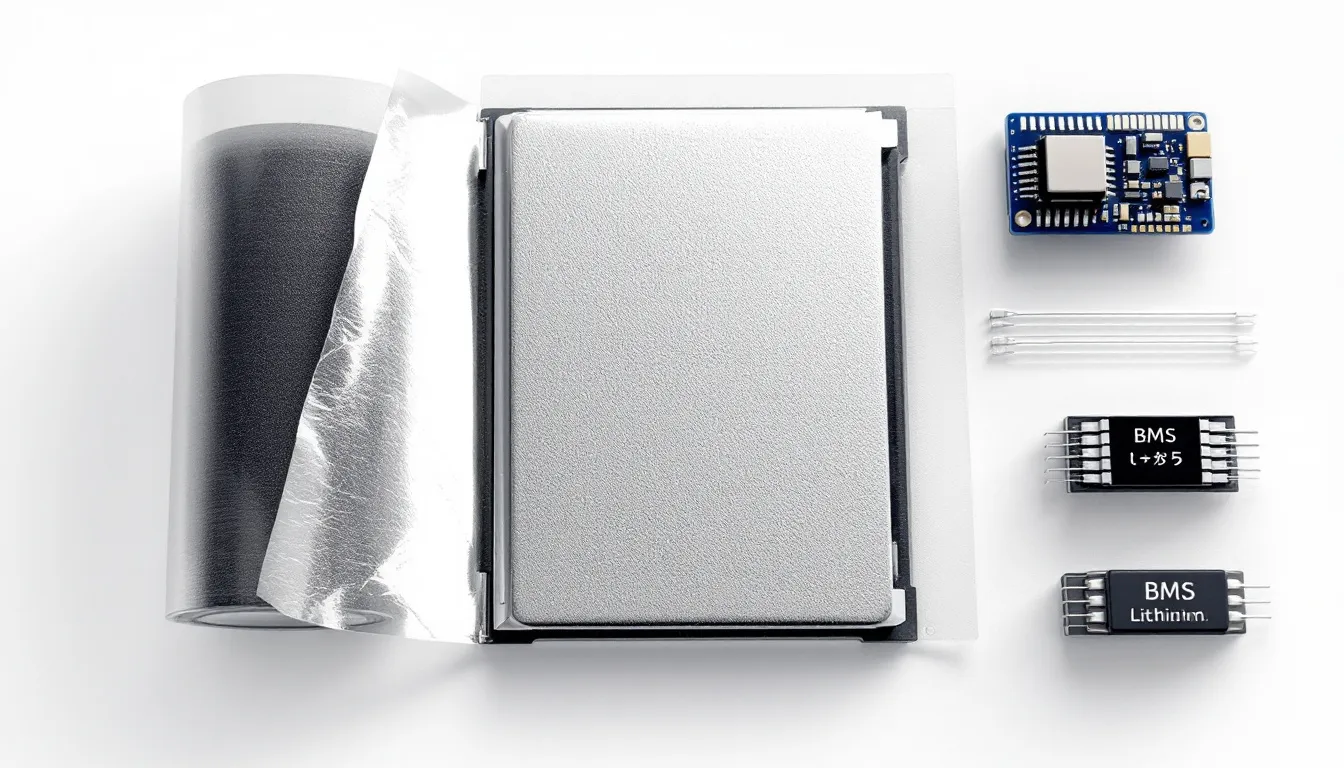

Ultra-thin lithium polymer battery components

Cathode (Positive Electrode): Lithium-transition-metal oxides (e.g., LiCoO₂, LiMn₂O₄) coated on aluminum foil.

Anode (Negative Electrode): Graphitic carbon or lithium metal films coated on copper foil.

Electrolyte: Solid or gel polymer (e.g., polyethylene oxide, PEO) infused with lithium salt to facilitate ion transport.

Separator/Packaging: Microporous polymer separator may be integrated into the solid electrolyte; pouch housing of aluminum-plastic laminate provides barrier and mechanical support.

Current Collectors: Ultra-thin metal foils (aluminum for cathode, copper for anode) or advanced options like silver nanowires/carbon nanotube films for flexible designs. Delamination can affect the internal layers, leading to poor contact and reduced reliability and cycle life of the battery.

Lithium Polymer Cells: These advanced battery technologies offer design flexibility and improved performance characteristics compared to traditional lithium-ion cells. Their unique packaging and form factors, such as the flexible, pouch-like structure, make them ideal for compact electronic devices.

Electrolyte and Electrode Configuration

Ultra-thin LiPo batteries utilize gel polymer electrolytes, which provide ionic conductivity comparable to liquid electrolytes while enabling mechanical flexibility. The electrolyte is typically composed of polymers like poly(vinylidene fluoride) (PVdF) or polyethylene oxide (PEO), infused with lithium salts such as lithium hexafluorophosphate (LiPF₆). This formulation, essentially a polymer matrix swollen with lithium salts, enhances ionic conductivity and plays a crucial role in facilitating ion transfer while maintaining the material’s flexibility, safety, and overall stability. This eliminates the need for rigid casing, allowing the battery to be encapsulated in lightweight aluminum-laminated pouches. LiPo batteries are made with a high conductivity gel polymer electrolyte, which enhances their performance and reliability.

A polymer medium in solid-state systems can significantly enhance battery performance by improving safety and energy density.

Electrode materials are optimized for thin-film deposition. The cathode often consists of lithium cobalt oxide (LiCoO₂) or lithium iron phosphate (LiFePO₄), while the anode employs graphite or silicon-based composites. These materials are coated onto current collectors using precision techniques like physical vapor deposition (PVD) or slot-die coating, achieving layers as thin as 10–20 μm.

Thickness and Capacity Trade-offs

Reducing battery thickness necessitates trade-offs in capacity and current handling. For example, Motoma’s 0.9 mm battery delivers 85 mAh, whereas thicker variants (e.g., 1.9 mm) can exceed 200 mAh. The energy density of ultra-thin cells ranges from 250–670 Wh/L, influenced by the active material loading and electrolyte volume. Manufacturers mitigate capacity limitations through advanced electrode architectures, such as 3D nanostructuring, which increases surface area for lithium-ion intercalation.

For applications requiring little power while maintaining long working times, such as smart cards, mini mobile phones, and other thinner applications, ultra-thin LiPo batteries are ideal due to their efficiency and space-saving design.

How ultra-thin lithium polymer battery work

Ultra-thin LiPo cells operate via lithium-ion intercalation: during discharging, Li⁺ ions migrate from the anode through the polymer electrolyte to the cathode, generating an external current; charging reverses this process. The discharging process impacts battery performance and includes safety considerations such as temperature ranges and the potential hazards of over-discharging that could lead to failures.

The polymer electrolyte also acts as a separator, eliminating the need for separate porous membranes used in liquid electrolyte cells.

Voltage per cell ranges from 3.0 V (discharged) to 4.2 V (fully charged), with a nominal operating voltage around 3.7 V and a high operating voltage of 3.6V.

Applications of Ultra-Thin Batteries

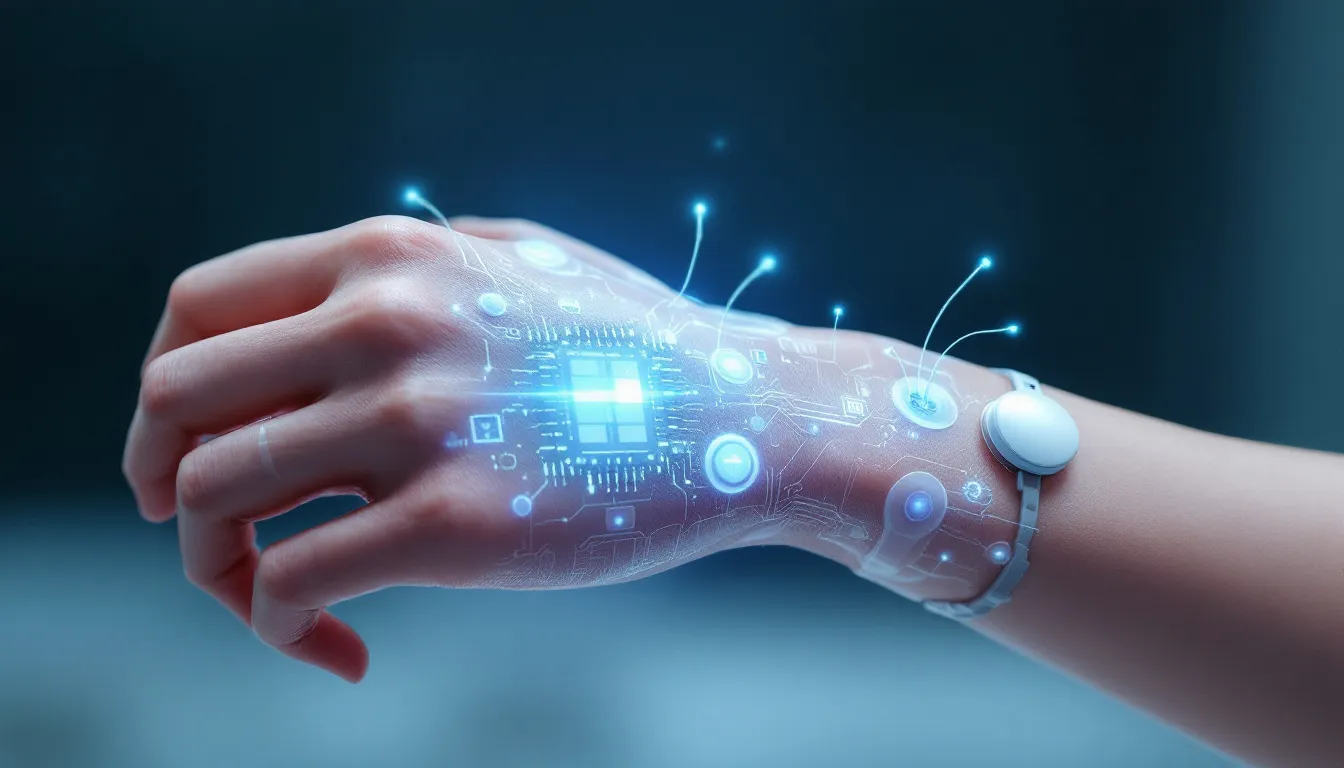

Wearable Electronics

Ultra-thin LiPo batteries are integral to wearable devices like fitness trackers and smartwatches, as well as mobile devices such as smartphones and tablets, where space constraints preclude bulkier alternatives. Their flexibility allows integration into curved surfaces, such as wristbands or eyewear frames. For instance, Benzo Energy’s super-thin batteries are used in hearables and AR/VR headsets, providing 3–5 days of runtime on a single charge.

Medical Implants and Biosensors

In medical applications, these batteries power implantable devices such as glucose monitors and neurostimulators. The 0.4–1.5 mm thickness range enables subcutaneous implantation without discomfort, while biocompatible coatings ensure safety. Recent advancements include biodegradable LiPo batteries for temporary medical devices, though these remain experimental.

Smart Cards and RFID Tags

Ultra-thin batteries are revolutionizing contactless technologies. Credit-card-sized batteries with 1.2 mm thickness are embedded in active RFID tags, enabling real-time tracking in logistics and retail. These batteries support low-power communication protocols like NFC, with lifespans exceeding 3 years under intermittent use. Additionally, these ultra-thin batteries are ideal for compact applications such as mini phones and smart cards, where minimal thickness and long-lasting performance are crucial.

Benefits of High Energy Density

Ultra thin battery at Large Power

At Large Power, we specialize in ultra thin lithium polymer batteries tailored to customer-specific dimensions from 0.3 mm to 1 mm thickness. Our in-house manufacturing achieves industry-leading cycle life (> 500 cycles at 80 % DOD) and strict AQL testing for safety and reliability. We understand that many customers are looking for customized solutions to meet their specific needs and preferences, such as ultra-thin batteries for unique devices like smart cards and mini phones. As a top lithium polymer battery manufacturer, we offer:

- Custom form factors and capacities up to 100 mAh

- Gel polymer electrolytes for enhanced safety

- Tailored voltage cutoff and integrated protection circuits

- ISO 9001 and UL certifications

For detailed datasheets and design consultation, contact Large Power today.

Future trend in ultra thin battery

Emerging Innovations

Research is focused on solid-state ultra-thin batteries, which replace gel electrolytes with inorganic solid conductors (e.g., LLZO garnets). These promise higher energy densities (>300 Wh/kg) and enhanced safety, though manufacturing complexities persist. Another frontier involves stretchable LiPo batteries for foldable smartphones, achieved through elastomeric substrates and serpentine electrode designs. Companies like PowerStream are working with engineering teams to develop innovative lithium polymer batteries through a streamlined production process , specifically focusing on creating thinner designs suitable for advanced applications such as smart cards and RFID tags.

The environmental impact of ultra-thin batteries is a growing concern. Current recycling methods struggle with laminated pouches, which require delamination before material recovery. Startups are developing solvent-based processes to separate aluminum, copper, and lithium compounds efficiently.

Conclusion

Ultra-thin lithium polymer batteries are pivotal enablers of the miniaturization trend in electronics, offering unparalleled flexibility and adaptability in various systems. While challenges in energy density and thermal management persist, ongoing advancements in materials science and manufacturing techniques are addressing these limitations. Beyond personal electronics, these batteries find other applications in military equipment, sensors, RFID tags, and devices requiring thin battery solutions. As industries demand ever-smaller energy solutions, ultra-thin LiPo batteries will remain at the forefront of portable and implantable technology, driven by innovations in solid-state electrolytes and sustainable production practices.

Frequently Asked Questions

1. What qualifies a lithium polymer battery as “ultra-thin”?

An ultra-thin LiPo battery typically has a total cell thickness below 1.5 mm, with many designs achieving 0.3–1.0 mm through pouch-cell and laminate packaging techniques.

2. Are ultra-thin LiPo batteries as energy-dense as standard LiPo cells?

Yes, ultra-thin cells maintain comparable specific energy (150–250 Wh/kg) by using high-capacity cathode materials and optimized electrode loading despite their reduced thickness.

3. How flexible are ultra-thin LiPo batteries?

Thanks to their polymer electrolyte and aluminum-plastic laminate casing, many ultra-thin batteries can tolerate gentle bending to radii of a few millimeters without damage.

4. What is the typical cycle life of an ultra-thin LiPo battery?

They often deliver 500+ charge/discharge cycles at 80 % depth of discharge, comparable to thicker pouch cells, due to stable electrode–electrolyte interfaces in gel or solid polymer electrolytes.

5. Are ultra-thin LiPo batteries safe?

Polymer electrolytes significantly reduce leakage and thermal runaway risk. Under mechanical or thermal abuse, pouch cells bulge rather than rupture explosively, enhancing safety.

6. How should I charge an ultra-thin LiPo battery?

Charge at C-rates ≤ 1 C using a dedicated LiPo charger with voltage cutoff at 4.2 V and balance charging features for multi-cell stacks; typical charging currents are 0.5–1 A for small capacities. For further information on battery safety, including essential safety tips for charging LiFePO4 batteries, be sure to keep updated with the latest guidelines.

7. What applications best leverage ultra-thin LiPo batteries?

They excel in wearables (smartwatches, e-textiles), medical sensors, smart cards, and flexible electronics where minimal thickness and weight are critical.

Still have questions?

Contact Large Power for detailed technical consultation on ultra-thin lithium polymer battery integration and custom solutions.