Contents

Electromagnetic Susceptibility (EMS) of lithium batteries pertains to their capacity to endure disturbances caused by electromagnetic interference (EMI). Understanding the Electromagnetic Susceptibility (EMS) of lithium batteries is crucial, as it significantly affects their performance and dependability. Inadequate EMS of lithium batteries can result in severe failures within battery management systems, posing safety hazards and reducing operational efficiency.

The Electromagnetic Susceptibility (EMS) of lithium batteries is essential in avoiding malfunctions, particularly in critical sectors such as medical, robotics, and security systems.

Key Takeaways

Electromagnetic Susceptibility (EMS) is important for lithium batteries. It allows them to work well around electromagnetic interference (EMI).

Weak EMS can cause problems like overheating and system failures. This can make batteries unsafe and shorten their life.

Using designs like shielding and filtering can improve EMS. These steps help batteries work safely in areas with strong electromagnetic signals.

Part 1: Understanding Electromagnetic Susceptibility (EMS) of Lithium Batteries

1.1 What is Electromagnetic Susceptibility (EMS)?

Electromagnetic susceptibility (EMS) refers to the ability of a device, such as a lithium battery, to function correctly in the presence of electromagnetic interference (EMI). For energy storage lithium batteries, EMS plays a critical role in maintaining performance and reliability. When a battery is exposed to EMI, it may experience disruptions in its normal operation, leading to potential malfunctions or reduced efficiency.

In the context of lithium-ion batteries, EMS ensures that these systems can withstand external electromagnetic disturbances without compromising their functionality. This is particularly important in applications like medical devices, robotics, and security systems, where uninterrupted performance is essential. Learn more about medical battery solutions here.

1.2 How EMS Affects Lithium Batteries

EMS directly impacts the performance and safety of lithium batteries. When a battery lacks sufficient electromagnetic compatibility, it becomes more susceptible to interference. This can lead to issues such as:

Disrupted Battery Management Systems (BMS): EMI can interfere with the BMS, which is responsible for monitoring and controlling the battery’s operation. This may result in inaccurate readings or improper charging cycles. Explore how BMS operates here.

Thermal Runaway Risks: In severe cases, EMI can trigger overheating, increasing the likelihood of thermal runaway—a dangerous condition where the battery overheats uncontrollably.

Reduced Lifespan: Prolonged exposure to EMI can degrade the battery’s components, shortening its operational life.

For energy storage lithium batteries used in industrial and infrastructure applications, these effects can lead to costly downtime and safety hazards. Learn more about industrial battery solutions here.

1.3 Common Sources of Electromagnetic Interference (EMI) in Battery Systems

Electromagnetic interference can originate from various sources, both internal and external to the battery system. Understanding these sources is crucial for designing batteries with robust EMS. Common sources include:

Internal Components: Components like inverters, converters, and high-frequency circuits within the battery system can generate EMI. EMC testing ensures these components do not emit harmful levels of interference or malfunction due to external EMI. Testing standards such as FCC 47CFR Part 15 and the EU EMC Directive 2014/30/EU are commonly followed.

External Devices: Nearby electronic devices, such as communication equipment or consumer electronics, can emit EMI that affects the battery. Explore consumer electronics battery solutions here.

Environmental Factors: Lightning strikes, power surges, and electromagnetic fields from industrial machinery can also introduce EMI into the system.

By identifying these sources, manufacturers can implement design strategies to enhance the electromagnetic compatibility of lithium batteries, ensuring they operate reliably in diverse environments.

Part 2: The Impact of EMS on Lithium Battery Performance and Safety

2.1 Effects of EMS on Battery Management Systems (BMS)

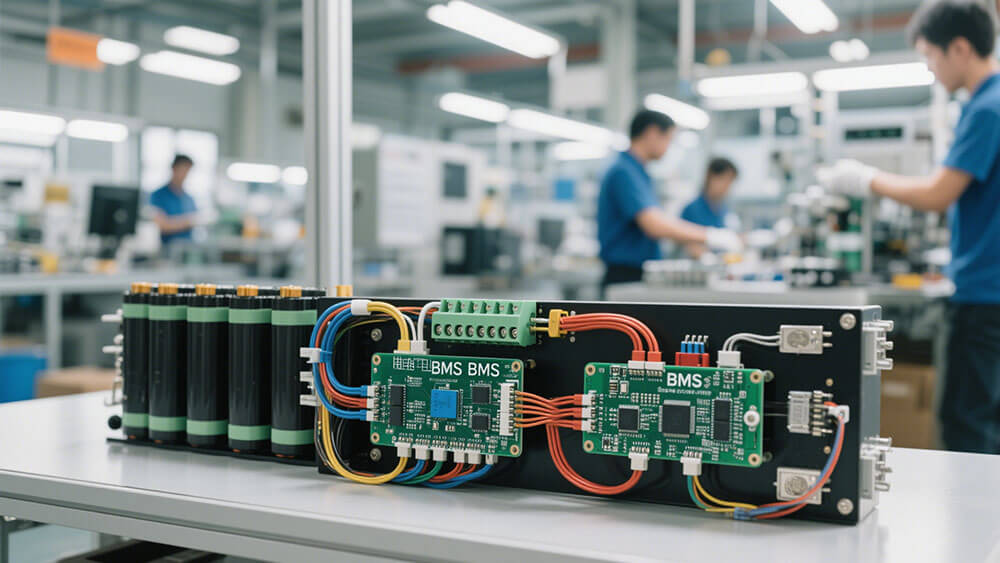

Electromagnetic susceptibility (EMS) directly influences the functionality of Battery Management Systems (BMS), which serve as the brain of lithium battery systems. A BMS monitors critical parameters such as voltage, temperature, and state of charge (SOC). When exposed to electromagnetic interference (EMI), the BMS may experience disruptions that compromise its ability to perform these essential tasks.

For instance, EMI can cause inaccurate voltage readings, leading to improper charging or discharging cycles. This not only reduces the battery’s efficiency but also accelerates wear and tear on its components. In severe cases, EMI may trigger false alarms or even disable the BMS entirely, leaving the battery unprotected against overcharging or overheating. Such scenarios pose significant risks, especially in applications like robotics, where precise energy management is crucial. Learn more about robotics battery solutions here.

To mitigate these effects, manufacturers often incorporate shielding and filtering techniques into the BMS design. These measures help reduce the impact of EMI, ensuring the system operates reliably even in environments with high electromagnetic activity.

2.2 Safety Risks Associated with EMS in Lithium Batteries

Poor EMS management in lithium batteries can lead to serious safety hazards. One of the most critical risks is thermal runaway, a condition where the battery’s temperature rises uncontrollably due to internal or external factors. EMI can exacerbate this risk by interfering with the BMS, which is responsible for monitoring and regulating the battery’s temperature.

Another safety concern is the potential for short circuits. EMI can induce voltage spikes within the battery system, damaging its internal components and increasing the likelihood of a short circuit. This is particularly dangerous in high-capacity batteries used in industrial applications, where a single failure can result in significant downtime and financial losses. Explore industrial battery solutions here.

Additionally, EMI can compromise the structural integrity of lithium-ion batteries over time. Prolonged exposure to electromagnetic disturbances can weaken the battery’s separators, increasing the risk of internal short circuits. This highlights the importance of robust EMS testing during the design phase to identify and address potential vulnerabilities.

2.3 Real-World Implications of Poor EMS Management

The consequences of inadequate EMS management extend beyond individual battery failures. In real-world scenarios, poor EMS can disrupt entire systems, leading to operational inefficiencies and safety incidents. For example, in medical devices, a malfunctioning battery due to EMI can jeopardize patient safety. Learn more about medical battery solutions here.

In the transportation sector, where lithium-ion batteries power electric vehicles and infrastructure systems, EMI-related issues can cause unexpected breakdowns or delays. This not only affects user experience but also undermines the reliability of the technology. Explore infrastructure battery solutions here.

Consumer electronics are another area where poor EMS management can have significant implications. Devices like smartphones and laptops rely on lithium batteries for consistent performance. EMI can lead to reduced battery life or sudden shutdowns, impacting user satisfaction and brand reputation. Learn more about consumer electronics battery solutions here.

To address these challenges, businesses must prioritize EMS testing and adopt design strategies that enhance electromagnetic compatibility. Partnering with experienced manufacturers like Large Power can provide customized solutions tailored to your specific needs. Request a consultation here.

Part 3: Mitigating Electromagnetic Susceptibility in Lithium Batteries

3.1 Testing Methods for EMS in Lithium Batteries

Testing for electromagnetic susceptibility ensures lithium batteries maintain their performance and immunity to electromagnetic interference. Manufacturers use standardized EMC testing procedures to evaluate how batteries respond to EMI. These tests simulate real-world conditions, exposing batteries to various electromagnetic environments.

Key testing methods include:

Radiated Immunity Testing: This evaluates how well a battery resists electromagnetic fields emitted by nearby devices.

Conducted Immunity Testing: This measures the battery’s ability to withstand EMI transmitted through power lines or cables.

Emission Testing: This ensures the battery system does not emit harmful levels of EMI that could affect other devices.

By conducting these tests, you can identify vulnerabilities early and implement corrective measures to enhance the battery’s immunity.

3.2 Design Strategies to Reduce EMS Vulnerability

Designing lithium batteries with robust EMS involves integrating features that minimize susceptibility to electromagnetic interference. Effective strategies include:

Shielding: Adding conductive materials around sensitive components to block external EMI.

Filtering: Using filters to suppress unwanted frequencies in power and signal lines.

Grounding: Ensuring proper grounding to prevent EMI from affecting the battery’s internal circuits.

You can also optimize the layout of internal components to reduce electromagnetic coupling. These design improvements enhance the battery’s immunity, ensuring reliable operation in environments with high electromagnetic activity.

3.3 Regulatory Standards for EMS in Lithium Battery Systems

Compliance with regulatory standards ensures lithium batteries meet global benchmarks for electromagnetic compatibility. These standards define acceptable levels of EMI and immunity, promoting safety and reliability.

Standard | Description |

|---|---|

FCC Regulations | Specifies the Class A (industrial) and Class B (residential) limits on intentional and unintentional electromagnetic interference (EMI) radiation. |

IEC 61000-4 Series | The IEC 61000-4 series is the core standard for EMS testing, covering various immunity tests. |

IEC 61000-6 Series | IEC 61000-6-1: Immunity for residential, commercial, and light-industrial environments. IEC 61000-6-2: Immunity for industrial environments, covering harsher EMI conditions like heavy machinery interference. |

ISO Standards | ISO 11452: Radiated Immunity Testing for Vehicle Components ISO 7637: Conducted Transient Immunity |

Adhering to these standards not only ensures compliance but also enhances the marketability of your battery systems. Partnering with experienced manufacturers like Large Power can help you navigate these requirements effectively. Request a consultation here.

Electromagnetic susceptibility (EMS) of lithium batteries plays a vital role in ensuring their performance and safety. Testing and mitigation strategies help you identify vulnerabilities and enhance battery reliability. By adopting robust EMS management practices, you can prevent malfunctions and improve operational efficiency. Prioritizing EMS in battery design ensures long-term success in demanding applications.

FAQ

1. What is the difference between EMI and EMS?

Electromagnetic interference (EMI) refers to external disturbances affecting devices. Electromagnetic susceptibility (EMS) measures a device’s ability to resist these disturbances and maintain proper functionality.

2. Why is EMS testing important for lithium batteries?

EMS testing ensures lithium batteries can operate reliably in environments with electromagnetic interference. It helps identify vulnerabilities, enhances safety, and improves performance in critical applications like medical devices and robotics.

3. How can you reduce EMS in lithium batteries?

You can reduce EMS by using shielding, filtering, and proper grounding. Optimizing internal component layouts also minimizes electromagnetic coupling, improving the battery’s resistance to interference.

Partnering with experienced manufacturers like Large Power can help you navigate these requirements effectively.