Contents

Electrostatic discharge (ESD) poses a significant risk to lithium battery systems, potentially damaging sensitive components and compromising overall reliability. Implementing strong ESD protection is essential to maintain operational safety and prolong the lifespan of lithium batteries. Without proper safeguards, lithium battery performance can deteriorate, leading to safety concerns and reduced efficiency. Prioritizing ESD protection ensures your lithium battery systems remain secure and perform optimally.

Key Takeaways

Use grounding methods to keep lithium batteries safe from ESD. This stops dangerous shocks that might harm delicate parts.

Use ESD-safe items, like special packaging, to protect batteries when moving or storing them. This keeps them safer and lasts longer.

Check battery systems often for any ESD damage. This helps them work well and stay reliable for a long time.

Part 1: What is ESD?

1.1 Definition of ESD

Electrostatic discharge (ESD) refers to the sudden flow of electricity between two objects with different electrical potentials. This phenomenon often occurs when a charged object comes into contact with a conductive surface, releasing stored energy. In technical terms, ESD is defined by industry standards as follows:

Type of Document | Definition |

|---|---|

Standard | A precise statement of a set of requirements to be satisfied by a material, product, system, or process that also specifies the procedures for determining whether each of the requirements is satisfied. |

Standard Test Method | A definitive procedure for the identification, measurement, and evaluation of one or more qualities, characteristics, or properties of a material, product, system, or process that yields a reproducible test result. |

Standard Practice | A procedure for performing one or more operations or functions that may or may not yield a test result. Note: If a test result is obtained, it may not be reproducible between labs. |

Understanding ESD is crucial for protecting sensitive electronic components, especially in battery systems. Without proper ESD protection, these systems are vulnerable to damage, which can compromise their performance and safety.

1.2 How ESD Occurs in Lithium Battery Systems

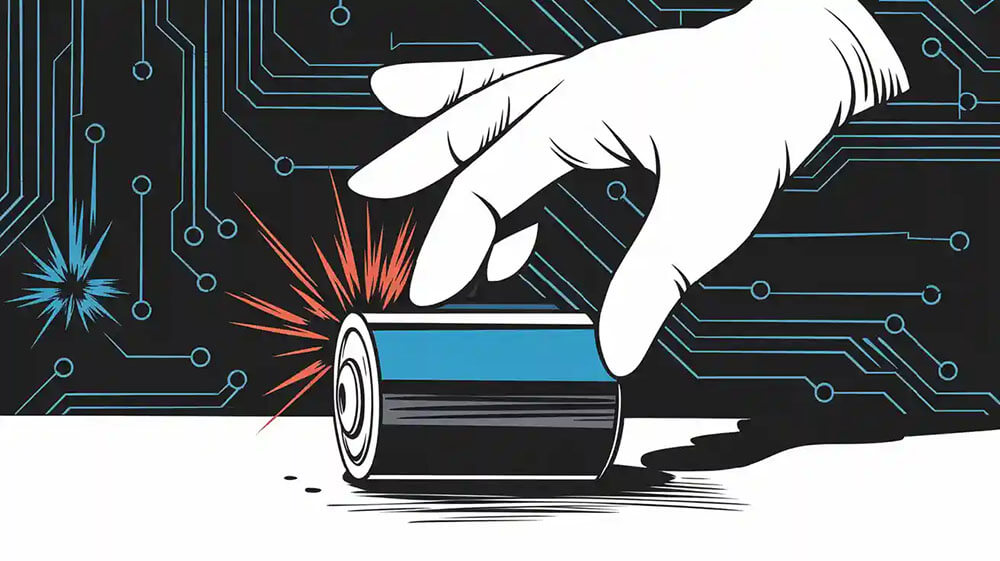

ESD and lithium battery systems are closely linked due to the sensitive nature of battery components. ESD occurs when static electricity builds up on a surface and discharges into the battery system. This can happen during manufacturing, handling, or even regular operation. For example, when you touch a battery without grounding yourself, the static charge from your body can transfer to the battery, causing ESD damage.

The effects of ESD on lithium batteries can be severe. It can lead to short-circuits, which increase the risk of fires or explosions. Additionally, ESD damage can degrade the battery’s internal components, reducing its lifespan and reliability. Implementing effective ESD protection measures, such as grounding techniques and protective materials, is essential to ensure the safety and performance of battery systems.

Tip: Always handle lithium batteries in an ESD-safe environment to minimize risks and maintain their longevity.

Part 2: Why ESD Protection Matters for Battery Systems

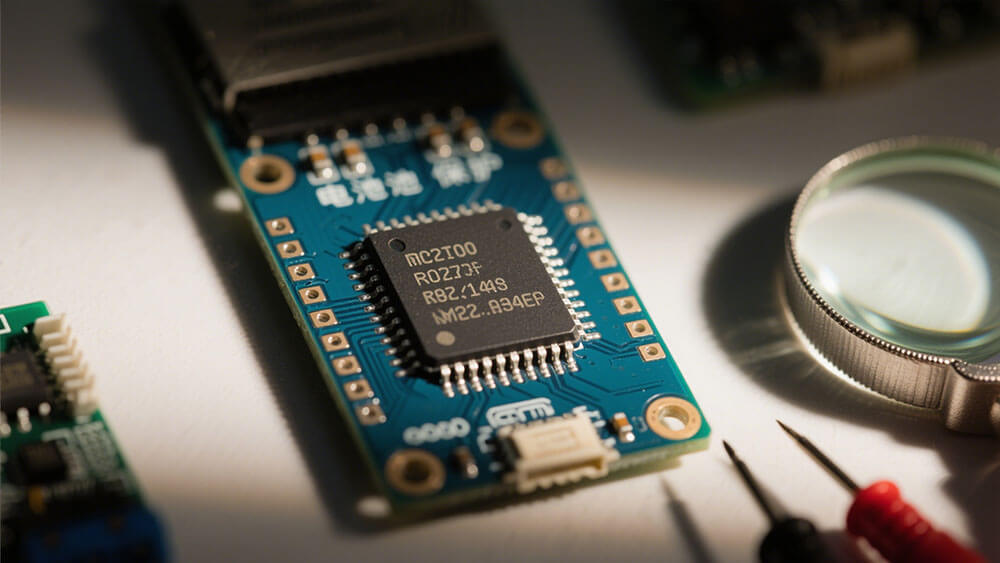

2.1 Preventing Failures in Battery Management Systems

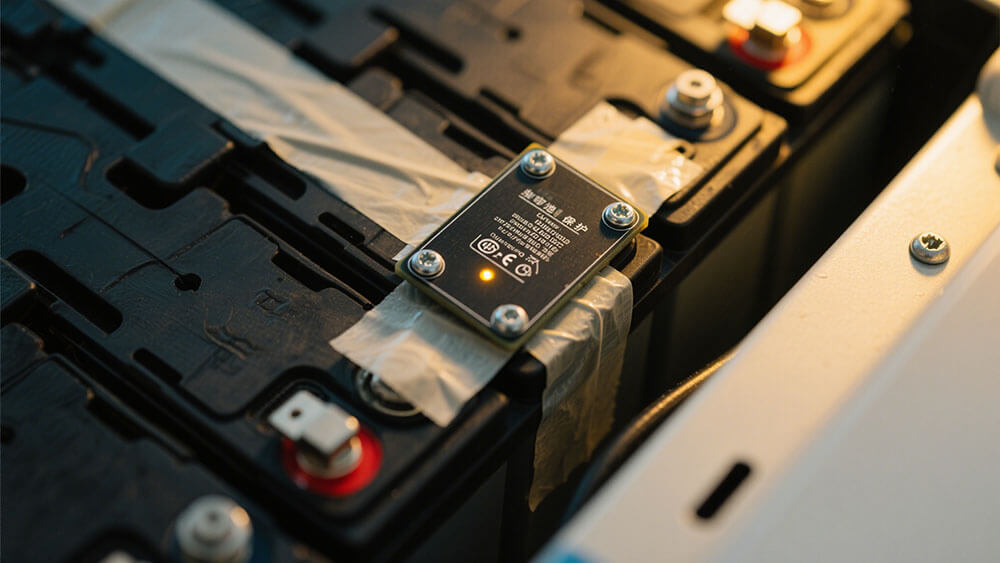

Battery management systems (BMS) are the backbone of modern lithium battery technology. They monitor and regulate critical functions like charging, discharging, and temperature control. However, ESD can disrupt these systems, leading to failures that compromise battery performance. For instance, sudden current spikes caused by ESD can damage protection circuitry, resulting in overcharge or over-discharge conditions. These issues not only shorten battery lifespan but also increase the risk of safety hazards.

In consumer electronics, ESD protection is vital due to the compact design of devices like smartphones. Schottky diodes are often used to safeguard BMS components, ensuring reliable operation. Similarly, automotive electronics rely on TVS diodes to protect engine control units from ESD-induced failures. By implementing robust ESD measures, you can prevent costly disruptions and maintain the integrity of your battery systems.

2.2 Enhancing Safety and Reliability

ESD protection plays a crucial role in ensuring the safety and reliability of lithium battery systems. Without it, sensitive components are vulnerable to damage, which can lead to dangerous outcomes like fires or explosions. For example, ESD bags have been shown to reduce failures in critical medical equipment, enhancing patient safety. In aerospace applications, these protective measures improve avionics reliability, preventing costly delays and safety risks.

By prioritizing ESD protection, you can enhance the overall reliability of your systems. This is especially important in industries where safety considerations are paramount. Whether you’re working with lithium-polymer batteries or other advanced technologies, effective ESD strategies ensure consistent performance and peace of mind.

2.3 Ensuring Long-Term Battery Protection

Long-term protection is essential for maintaining the performance and lifespan of lithium batteries. ESD can cause gradual degradation of internal components, leading to reduced efficiency over time. Implementing grounding techniques and proper circuit placement minimizes this risk. For instance, ESD bags have been proven to lower return rates for consumer electronics, demonstrating their effectiveness in preserving battery health.

In industrial automation, ESD protection reduces system failures, increasing uptime and productivity. By addressing ESD risks proactively, you can extend battery lifespan and avoid unnecessary replacements. This not only saves costs but also supports sustainable practices by reducing electronic waste.

Tip: Regularly inspect your battery systems for signs of ESD damage to ensure long-term reliability and safety.

Part 3: Effective ESD Protection Strategies for Lithium Batteries

3.1 Grounding Techniques for Battery Systems

Grounding is one of the most effective ways to protect lithium battery systems from ESD. By creating a direct path for static electricity to dissipate safely, grounding prevents harmful discharges that could damage sensitive components. You can implement grounding techniques during both the manufacturing and operational phases of battery systems.

For instance, using conductive flooring in production facilities ensures that static charges are neutralized before they reach the battery. Similarly, grounding straps and wristbands allow workers to handle batteries without transferring static electricity. These measures are especially critical for environments where battery management systems (BMS) are involved, as ESD can disrupt their protection circuitry and lead to system failures.

Tip: Regularly inspect grounding equipment to ensure it remains effective. Even minor wear and tear can compromise its ability to protect your battery systems.

3.2 Protective Materials for ESD Mitigation

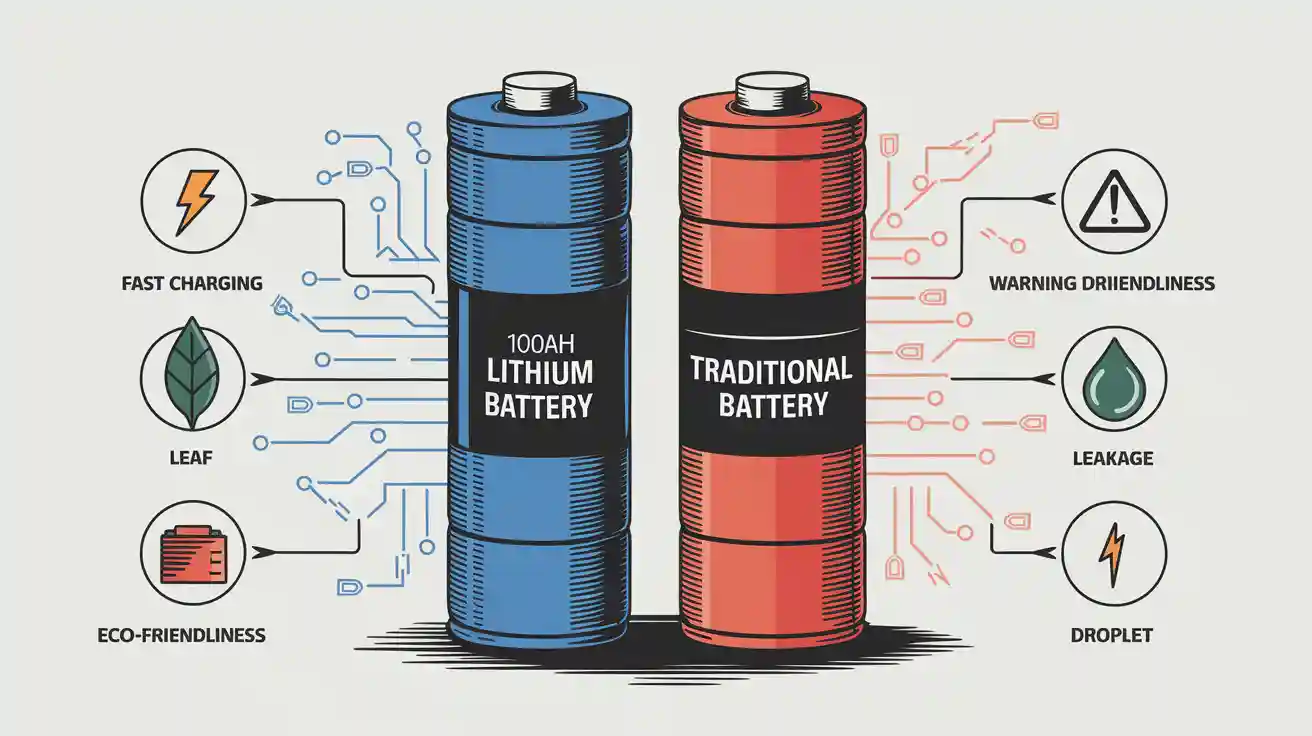

The choice of materials plays a significant role in ESD protection. Specialized materials, such as conductive and dissipative polymers, are designed to shield batteries from static electricity. These materials are lightweight, durable, and highly effective in preventing ESD-related damage.

Here’s a quick comparison of industry benchmarks for protective materials:

ESD Protection Strategy | Key Features | Applications |

|---|---|---|

Conductive Fiber Packaging | Lightweight, durable materials | EV battery transportation |

Conductive & Dissipative Polymers | High durability, effective static shielding | Automotive consumer electronics |

Metal-based Packaging | Compliance with global safety standards | High-tech manufacturing applications |

You can use these materials in various stages of battery handling, from packaging to storage. For example, conductive fiber packaging is ideal for transporting electric vehicle batteries, while dissipative polymers are commonly used in consumer electronics. By integrating these materials into your processes, you can significantly reduce the risk of ESD damage and enhance battery protection.

3.3 Design Considerations for Battery Protection

Effective design is the cornerstone of long-term battery protection. By incorporating ESD-resistant features into your battery systems, you can minimize the risk of damage and ensure reliable performance. Engineering research highlights several best practices for ESD-resistant designs.

Practice | Description | Benefit |

|---|---|---|

Battery Safety Design | Guidelines for designing battery-operated equipment for space vehicles to ensure safety for personnel and equipment. | Addresses hazards associated with battery use in manned space flight vehicles, ensuring safe handling and operation. |

ESD Analysis | Conduct analyses to ensure nonconductive surfaces store less than 3 mJ and prevent ESD near sensitive circuits. | Identifies potential ESD sources early, allowing for design changes to mitigate risks. |

For example, conducting an ESD analysis during the design phase helps you identify potential risks and make necessary adjustments. This proactive approach ensures that nonconductive surfaces store minimal energy, reducing the likelihood of ESD near sensitive circuits. Similarly, adhering to safety design guidelines ensures that your battery systems meet industry standards, providing robust protection against ESD-induced failures.

Note: Collaborate with experienced engineers to implement these design considerations effectively. Their expertise can help you address complex challenges and optimize your battery systems for safety and reliability.

ESD poses serious risks to lithium battery systems, including component damage and safety hazards.

As demand for lithium-ion batteries grows nearly seven-fold by 2030, implementing safety measures becomes increasingly urgent. The NTSB has investigated fires linked to battery failures, highlighting risks like thermal runaway and reignition.

Investing in ESD protection ensures reliability, reduces costs, and safeguards your systems against these challenges.

Sector | Key Insights |

|---|---|

Electronics Manufacturing | Accounts for over 40% of global antistatic sheet consumption; critical for protecting sensitive components. |

Automotive (EVs) | Accelerating demand for ESD controls in battery assembly; EV market expected to exceed $130 billion by 2030. |

FAQ

1. What is the most effective way to prevent ESD damage during battery handling?

Use grounding tools like wrist straps and conductive mats. These tools safely dissipate static electricity, protecting sensitive battery components from ESD damage.

2. Can ESD affect lithium battery performance over time?

Yes, ESD can degrade internal components, reducing efficiency and lifespan. Regular inspections and protective measures help maintain long-term battery performance.

Tip: For professional guidance on safety performance tests for lithium batteries, visit Large Power.

3. Are ESD-safe materials necessary for battery packaging?

Absolutely! Materials like conductive fiber packaging shield batteries from static electricity, ensuring safe transportation and storage, especially for high-value applications like EV batteries. 🚗

Tip: Always store lithium batteries in ESD-safe environments to minimize risks and extend their lifespan.