Contents

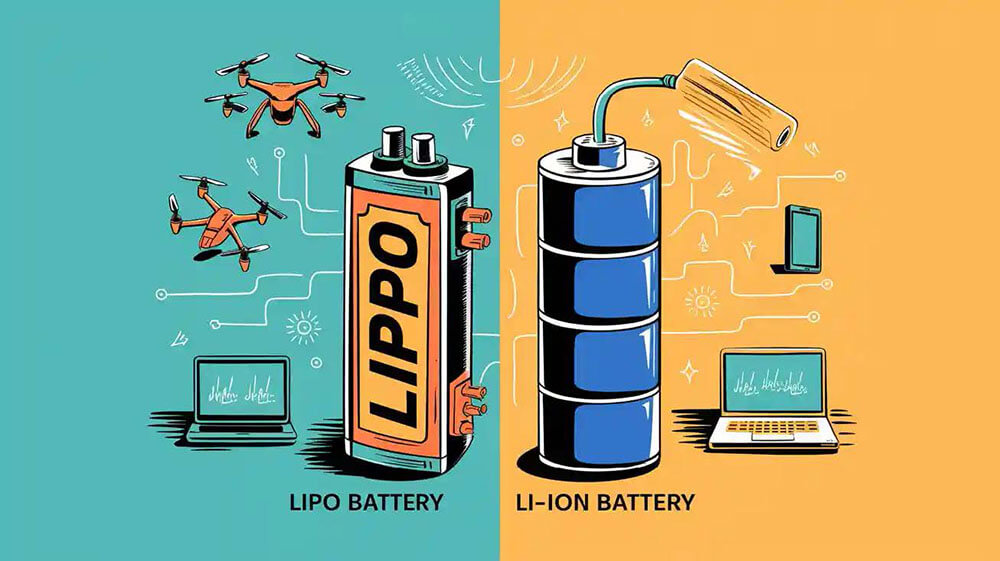

Choosing between LiPo and Li-ion batteries requires a clear understanding of their differences. Li-ion batteries offer higher energy density, making them ideal for applications in electric vehicles and electronics. On the other hand, LiPo batteries, known for their flexible packaging, are well-suited for high-discharge applications such as drones. When it comes to safety, Li-ion batteries typically incorporate protection circuits, while LiPo batteries are resistant to leakage but may experience swelling. For tailored solutions that meet your industrial needs, explore Large Power custom battery solutions.

Key Takeaways

LiPo batteries are great for light and bendable designs. They work well in drones and wearable gadgets.

Li-ion batteries last longer and store more energy. They are perfect for electric cars and saving renewable energy.

Both types need careful use and care to stay safe and last long in factories.

Part 1: Overview of LiPo and Li-ion Batteries

1.1 What Is a Lithium Polymer Battery (LiPo)?

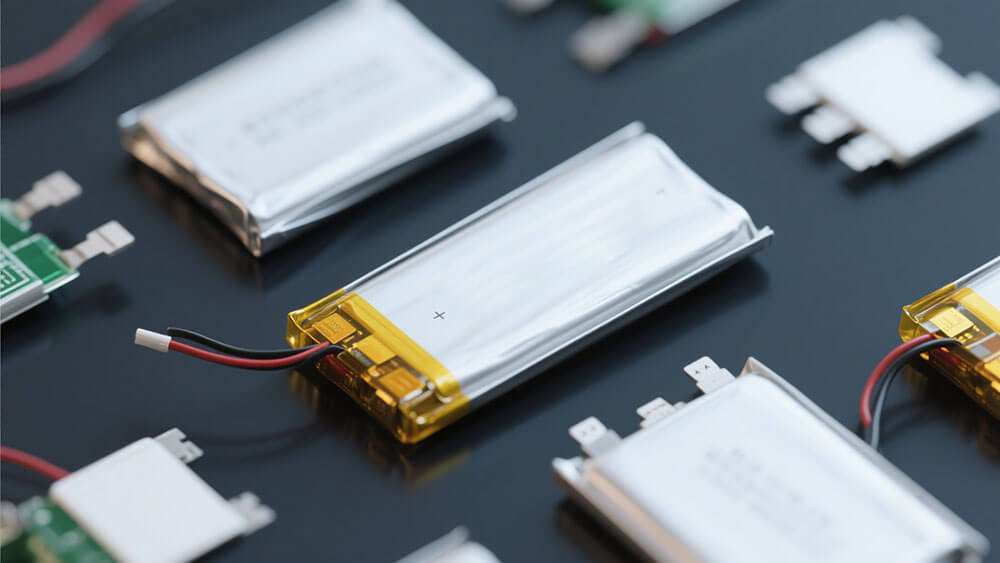

A lithium polymer battery, commonly referred to as LiPo, is a rechargeable battery that uses a gel-like polymer electrolyte instead of the liquid electrolyte found in traditional batteries. This unique composition enhances safety by reducing the risk of leakage and allows for greater flexibility in design. LiPo batteries consist of a positive electrode (cathode), a negative electrode (anode), and a polymer separator that prevents short circuits while enabling ionic movement. These batteries are widely used in applications requiring lightweight and customizable power solutions, such as drones, RC models, and wearable technology.

LiPo batteries also feature distinct charge and discharge curves, which help determine the State of Charge (SOC) and ensure safe operation. These characteristics make them ideal for industries prioritizing compact and high-performance energy storage.

1.2 What Is a Lithium-ion Battery (Li-ion)?

A lithium-ion battery is a high-energy-density rechargeable battery that has become the standard for powering modern devices. It operates by moving lithium ions between the anode and cathode through a liquid electrolyte during charge and discharge cycles. The small size of lithium ions enables high voltage and efficient charge storage, making these batteries suitable for applications like electric vehicles, consumer electronics, and large-scale energy storage systems.

Advancements in lithium-ion technology have significantly improved energy density, with current models achieving up to 300 Wh/kg. This progress has driven the widespread adoption of lithium-ion batteries, with global demand projected to exceed 3,100 GWh by 2030. Their robust design and fast-charging capabilities further enhance their appeal for industrial and commercial use.

1.3 Key Similarities Between LiPo and Li-ion Batteries

Despite their differences, LiPo and Li-ion batteries share several similarities. Both rely on lithium-ion chemistry to store and release energy, ensuring high efficiency and reliability. They are rechargeable, lightweight, and capable of delivering high power output, making them suitable for a wide range of applications.

In terms of safety, both battery types require careful handling to prevent damage. While Li-ion batteries incorporate protection circuits to mitigate risks like thermal runaway, LiPo batteries are designed to minimize leakage. Additionally, both types exhibit durability, with Li-ion batteries offering longer lifespans and LiPo batteries excelling in high-discharge scenarios. These shared characteristics make them indispensable in industries requiring advanced energy solutions.

Part 2: Detailed Comparison Between Lithium Polymer and Lithium-ion Batteries

2.1 Composition and Design: Gel Polymer vs. Liquid Electrolyte

The composition and design of lithium polymer and lithium-ion batteries significantly influence their performance and applications. While both rely on lithium-ion chemistry, their electrolyte materials differ:

Lithium-ion batteries use liquid electrolytes, which allow ions to move smoothly between the anode and cathode. This design ensures efficient energy transfer and contributes to their high energy density. However, the liquid electrolyte requires a rigid casing to prevent leakage, adding to the battery’s weight.

Lithium polymer batteries, on the other hand, utilize gel-like polymer electrolytes. These semi-solid materials are denser, resulting in slightly less efficient ion movement. However, the flexible nature of the polymer allows for lightweight and customizable designs, making these batteries ideal for applications where form factor is critical.

The difference between lithium polymer and lithium-ion battery designs also impacts their safety. The gel polymer in LiPo batteries reduces the risk of leakage, while the liquid electrolyte in Li-ion batteries necessitates robust containment measures. This distinction highlights the importance of selecting the right battery type based on your specific industrial requirements.

2.2 Performance Metrics: Energy Density, Power Output, and Lifespan

Performance metrics such as energy density, power output, and lifespan are critical when evaluating lithium polymer and lithium-ion batteries. The table below summarizes these differences:

Metric | LiPo | Li-ion |

|---|---|---|

Energy Density | Higher than Li-ion | Lower than LiPo |

Power Output | Generally higher | Varies, but often lower |

500-800 cycles | up to 5,000 cycles (depends on charge voltage) |

Lithium polymer batteries offer higher energy density, enabling longer runtimes in compact devices. Their superior power output makes them suitable for high-discharge applications like drones and RC models. However, their lifespan may decline rapidly after 450 cycles due to dendritic salt formation.

Lithium-ion batteries, while slightly lower in energy density, excel in durability. Charging them at lower voltages, such as 4.1V instead of 4.2V, can extend their lifespan to over 1,000 cycles. This makes them a reliable choice for applications requiring endurance and consistent performance.

2.3 Safety Considerations: Thermal Runaway and Durability

Safety remains a top priority when selecting a battery for industrial use. Both lithium polymer and lithium-ion batteries have unique safety profiles:

Lithium-ion batteries are prone to thermal runaway, a chain reaction triggered by overheating or internal short circuits. Incidents like the Moss Landing fire in California (January 2025) underscore the importance of advanced thermal management systems and regular safety assessments.

Lithium polymer batteries are less likely to experience leakage due to their gel-like electrolyte. However, they may swell under extreme conditions, necessitating proper handling and monitoring.

Durability also plays a role in safety. Lithium-ion batteries benefit from robust designs that withstand mechanical stress, while lithium polymer batteries require careful packaging to maintain their structural integrity. Implementing safety measures, such as emergency response planning and compliance with industry standards, can mitigate risks and enhance battery reliability.

2.4 Cost and Maintenance: Long-term Investment Analysis

When evaluating the cost and maintenance of lithium polymer and lithium-ion batteries, consider their long-term performance and operational expenses:

Lithium polymer batteries, while initially more expensive, offer significant advantages in applications requiring lightweight and flexible designs. However, their capacity may fade after 800 cycles if used between 20%-100% state of charge (SOC).

Lithium-ion batteries provide a cost-effective solution for applications demanding durability and low self-discharge rates. For instance, LiFePO4 variants can achieve up to 5,000 cycles with minimal capacity fade, making them a sustainable choice for long-term use.

Both battery types require regular maintenance to ensure optimal performance. Monitoring the charging process and adhering to recommended usage guidelines can extend their lifespan and reduce overall costs. For tailored solutions that align with your operational needs, explore Large Power custom battery solutions.

Part 3: Practical Recommendations for Choosing the Right Battery

3.1 When to Choose Lithium Polymer Batteries

LiPo batteries are ideal for industries requiring lightweight, flexible, and high-discharge power solutions. Their gel-like polymer electrolyte allows for customizable designs, making them suitable for applications where compactness and adaptability are critical. For example, drone manufacturers often prefer LiPo batteries due to their ability to deliver high power output in a lightweight package. Similarly, wearable technology and remote-controlled devices benefit from the flexibility and energy density of LiPo batteries.

You should also consider LiPo batteries for applications that demand rapid bursts of energy. Their high discharge rates make them a reliable choice for powering devices that require quick and consistent energy delivery. However, proper handling and monitoring are essential to prevent swelling and ensure battery safety and durability.

If your project prioritizes form factor and performance over extended lifespan, LiPo batteries provide an excellent solution. For tailored configurations that meet your specific needs, explore Large Power custom battery solutions.

3.2 When to Choose Lithium-ion Batteries

Li-ion batteries excel in applications requiring high energy density, durability, and long-term reliability. Their robust design and liquid electrolyte enable efficient energy transfer, making them the preferred choice for industries like logistics, renewable energy, and healthcare.

In logistics, Li-ion-powered automated guided vehicles (AGVs) have demonstrated a 30% reduction in downtime and a 40% improvement in productivity compared to traditional lead-acid batteries.

Solar energy projects benefit from Li-ion technology, with a reported 20% increase in energy storage efficiency in California-based installations.

In healthcare, Li-ion batteries power critical devices such as portable ventilators, ensuring reliable performance during power outages.

Li-ion batteries are also suitable for applications requiring extended lifespans. For instance, LiFePO4 variants can achieve up to 2,000 cycles with minimal capacity fade, making them a cost-effective solution for long-term use. If your operations demand consistent performance and durability, Li-ion batteries offer a dependable option.

To ensure optimal performance, consider integrating advanced thermal management systems and adhering to recommended charging practices. For customized solutions tailored to your industrial requirements, visit Large Power custom battery solutions page.

3.3 Ensuring Battery Safety and Longevity in Industrial Applications

Battery safety and durability are critical in industrial environments. Implementing best practices and leveraging advanced technologies can significantly enhance operational safety and extend battery lifespan.

Advanced diagnostic models like WOA-LSTM improve safety performance by 90.1% within six months, compared to 30.4% for EMD models and 19.7% for traditional FDM systems.

Maintenance costs can be reduced to 20.3% of the original with WOA-LSTM, while compliance rates for high-temperature safety indicators reach 98%.

The probability of safety incidents, such as thermal runaway, drops to nearly 0% with these advanced systems.

To maximize battery longevity, monitor charging cycles and avoid extreme discharge levels. Regular maintenance and adherence to safety standards are essential. Additionally, selecting batteries with proven safety records and certifications ensures reliability in demanding industrial applications.

By choosing the right battery type and implementing robust safety measures, you can optimize performance and reduce operational risks. For expert guidance and custom battery solutions, consult with Large Power team.

Understanding the differences between LiPo and Li-ion batteries is essential for selecting the right solution for your applications. Each type offers unique advantages and disadvantages. LiPo batteries excel in lightweight, flexible designs, while Li-ion batteries provide durability and high energy density. Evaluating these characteristics ensures optimal performance and safety.

1. What are the key industrial applications of LiPo and Li-ion batteries?

LiPo batteries power drones and robotics, while Li-ion batteries excel in electric vehicles, renewable energy storage, and medical devices.

2. How can you ensure the safety of lithium-based batteries in industrial use?

Implement advanced thermal management systems, monitor charging cycles, and follow safety standards. Learn more about sustainability initiatives here.

3. Why choose Large Power for custom battery solutions?

Large Power offers tailored battery designs, ensuring optimal performance and safety for industrial needs.