Contents

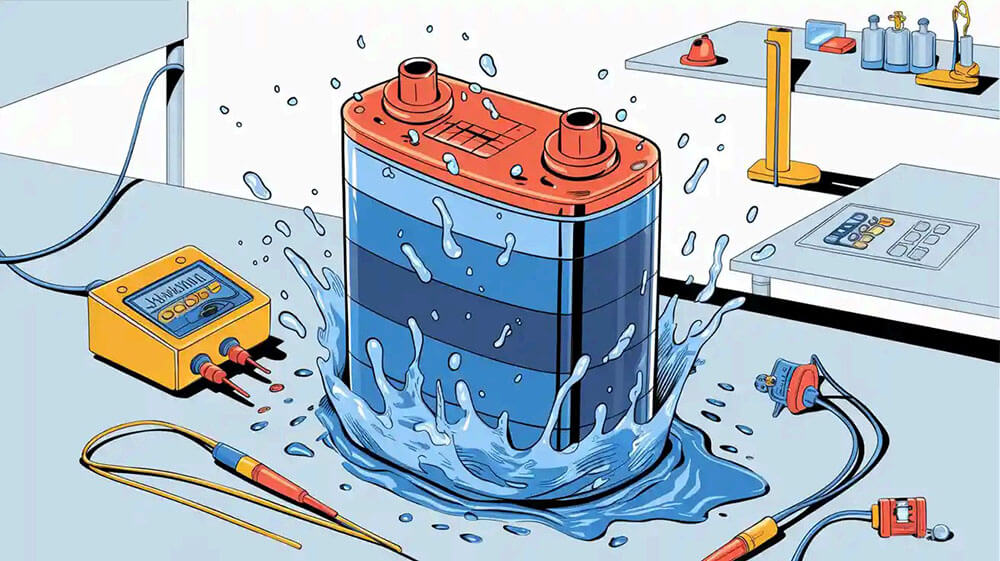

The waterproofing test of lithium battery ensures that these batteries remain safe and functional when exposed to water. This testing is crucial for lithium batteries used in essential systems such as medical devices, robots, alarms, and industrial machinery. Conducting a waterproofing test of lithium battery helps prevent malfunctions and extends the lifespan of the batteries.

Key Takeaways

Test batteries often to check if they stay safe in water. This stops problems and makes batteries last longer.

Use proper tools like a waterproof test box and pressure meter. Pick tools that follow safety rules for good results.

Be safe while testing by wearing safety gear and working in airy spaces. This lowers dangers and helps testing work well.

Part 1: Getting Ready for Waterproofing Tests

1.1 Tools You Need

To test if a lithium battery is waterproof, you need the right tools. These tools help get accurate results and keep the battery safe. Here’s what you’ll need:

Waterproof Testing Chamber: A closed box that mimics water exposure.

Pressure Gauge: Checks pressure during air-tightness testing.

Hydrophobic Barrier Sleeves: Keeps water away from the battery.

Battery Management System (BMS): Watches the battery’s performance for problems.

Conformal Coating Materials: Protects circuit boards from water damage.

Marine-Grade Waterproof Boxes: Great for testing bigger batteries.

Tip: Always pick tools that meet safety rules. For example, standards like GB 18384-2020 and GB 38031-2020 stress using good-quality tools for safe tests.

1.2 Staying Safe During Battery Tests

Safety is very important when testing lithium batteries. These batteries can be dangerous if not handled carefully. Follow these steps to stay safe:

Wear Safety Gear: Use gloves, goggles, and anti-static clothes to avoid accidents.

Work in Ventilated Areas: Test in open spaces to prevent harmful gas buildup.

Check Temperature: Keep the battery at the right temperature to stop overheating.

Use Certified Batteries: Pick batteries with safety labels like UN 38.3 to reduce risks.

Don’t Overcharge: Make sure the battery isn’t overcharged to avoid overheating.

Category | Details |

|---|---|

Testing Protocol | Runs multiple tests (T1-T8) to check battery safety over a week. |

Regulatory Environment | Batteries need a UN 38.3 test report to meet shipping rules like IATA standards. |

Compliance Responsibilities | Makers must test batteries for UN 38.3; shippers check certifications; logistics teams handle batteries safely to avoid fines. |

Certification Requirements | A third-party test report (UN 38.3) proves batteries passed all safety checks. |

Issuing Authority | Reports must come from approved testers and are reviewed by airlines and regulators. |

International Acceptance | Recognized worldwide as a key rule for safe battery transport. |

Note: Following these safety tips keeps you safe and ensures the test works well.

1.3 Getting the Battery Ready

Preparing the battery is key for a good waterproofing test. Follow these steps to get it ready:

Check the Battery: Look for cracks or leaks that might affect the test.

Clean It: Wipe off dirt or dust for a better seal.

Add Protective Coatings: Cover circuit boards to make them water-resistant.

Secure the Battery: Put it in a hydrophobic sleeve or waterproof box.

Test the BMS: Make sure the BMS works to track the battery during testing.

Tip: Use stable lithium battery types like LiFePO4 for better water resistance. These are great for medical devices, robots, and industrial tools.

Also, use strong materials and advanced tech to prepare the battery. For example:

Pick lithium cells with barriers to block moisture.

Use a BMS to quickly find problems.

Try marine-grade waterproof boxes for bigger batteries.

By doing these steps, your battery will be ready for the waterproofing test.

Part 2: Types of Waterproofing Tests for Lithium Batteries

2.1 Hydrophobicity and Contact Angle Testing

Purpose: Evaluate the water-repellent properties of battery materials (e.g., electrode coatings, electrolytes).

Method: Place a water droplet on the material surface and measure the contact angle.

A contact angle >150° indicates superhydrophobicity (e.g., LiNbO3-coated electrodes or superhydrophobic electrolytes).

Application: Verify the moisture-blocking effectiveness of coatings.

2.2 Humidity Cycling Tests

Purpose: Assess battery stability under high-humidity conditions.

Method: Cycle batteries in fluctuating humidity environments (e.g., 45%~51% RH) while monitoring capacity fade, voltage changes, etc.

Example: Li-ion batteries with superhydrophobic electrolytes demonstrated stable cycling at 45% humidity.

Application: Simulate performance in real-world damp environments.

2.3 Water Immersion and Penetration Tests

Purpose: Test sealing integrity and resistance to water ingress.

Method: Partially or fully submerge batteries in water and observe for short circuits or performance degradation.

Supplementary technique: Use FeCl3 colorimetric method to trace water penetration paths.

Application: Critical for batteries used in marine or outdoor equipment.

2.4 Electrochemical Analysis in Humid Environments

Purpose: Analyze moisture-induced interference with electrochemical reactions.

Method:

Electrochemical Impedance Spectroscopy (EIS): Detect interfacial resistance changes.

Cyclic Voltammetry (CV): Identify side reactions caused by moisture (e.g., corrosion).

Application: Optimize electrode-electrolyte interface design.

2.5 Post-Test Material Characterization

Purpose: Reveal material degradation after moisture exposure.

Method:

SEM/TEM: Observe surface cracks or delamination.

XPS/XRD: Analyze compositional changes (e.g., LiOH formation).

Thermogravimetric Analysis (TGA): Evaluate thermal stability of waterproof materials (e.g., SHQSE membranes stable below 230°C).

2.6 Pressure and Thermal Shock Tests

Purpose: Validate waterproof structural reliability under extreme conditions.

Method:

Rapid temperature cycling (e.g., -40°C ↔ 85°C).

Pressure variation tests (simulating deep-sea or high-altitude environments).

Application: Ensure sealing integrity under drastic temperature or pressure changes.

Tip: To ensure the safety and reliability of lithium batteries in humid or water-exposed environments, rigorous waterproofing evaluations are essential.

Part 3: Understanding Waterproofing Test Results

3.1 Checking Pass or Fail

To understand test results, know the pass or fail rules. A battery passes if it stays strong and works after water exposure. Signs of passing include no water inside, steady voltage, and good performance after testing. Use a Battery Management System (BMS) to track these in real time.

For example, in medical tools, batteries must work well under strict conditions to keep patients safe. In robots, water resistance ensures they work smoothly in wet areas. Setting clear goals for each use helps decide if a battery meets the needed standards.

Tip: Write down all test results carefully. This makes safety checks easier and helps find repeated problems.

3.2 Fixing Common Test Problems

Common problems in waterproofing tests include small leaks, uneven pressure, or weaker performance. Leaks often happen due to bad seals or faulty materials. Fix this by checking the battery case and adding more protective layers.

Uneven pressure may mean the air-tightness test has issues. Adjust your tools and test again to confirm. If the battery loses power or overheats, it might have internal damage. Replace damaged parts and test it again.

Note: Regular care and testing lower the chances of these problems, keeping batteries reliable.

3.3 Following Industry Rules

Following industry rules is important for safety and approval. Standards like GB 18384-2020 and IP ratings explain what’s needed for waterproofing and safety. Meeting these rules ensures batteries are safe for important uses like electronics and buildings.

Key Points | Details |

|---|---|

Rules Overview | Explains laws and rules for the Waterproof Lithium Battery Market. |

Steps for Compliance | Key actions to meet rules and standards. |

Effects of Rule Changes | How new rules change the market and company plans. |

Knowing these rules helps match your tests with global needs. This not only makes products safer but also helps compete better in the market.

Call to Action: For custom solutions that follow industry rules, check out Large Power’s custom battery solutions.

Testing if a lithium battery is waterproof keeps it safe and reliable. Get ready by checking seals, using the right tools, and following safety steps. Testing often helps meet rules and keeps the battery working well. Focus on these steps to make it last longer and stay safe.

FAQ

1. How often should waterproofing tests be done on lithium batteries?

Do these tests once a year or after big repairs. This keeps batteries reliable for important uses like medical tools, robots, and buildings.

2. Can every lithium battery handle waterproofing tests?

No, not all batteries can be tested. Strong batteries like LiFePO4 are best for testing in gadgets and machines.

3. Why pick Large Power for custom battery solutions?

Large Power makes batteries that follow safety rules and waterproofing needs. Check out their custom solutions here.