Contents

Understanding the distinctions between lithium-sulfur batteries and lithium-ion batteries is essential for selecting the right solution for your industrial needs. Lithium-sulfur batteries deliver an impressive energy density of approximately 550 Wh/kg, surpassing the 60–270 Wh/kg range of lithium-ion batteries. However, lithium-ion batteries excel in durability, supporting up to 5,000 cycles compared to the 500 cycles demonstrated by lithium-sulfur options. Safety, cost, and application suitability further differentiate these technologies, influencing their adoption in fields like robotics, infrastructure, and consumer electronics.

Choosing the optimal battery technology ensures efficiency and long-term value for your applications. Explore custom battery solutions tailored to your needs at Large Power.

Key Takeaways

Lithium-sulfur batteries store a lot of energy, up to 550 Wh/kg. They are great for lightweight uses like space tech and small gadgets.

Lithium-ion batteries last longer, up to 5,000 charge cycles. This makes them good for long-term use in factories and buildings.

Pick a battery based on your needs: lithium-sulfur for more energy and eco-friendliness, or lithium-ion for lasting power and better performance.

Part 1: Overview of Lithium-Sulfur and Lithium-Ion Batteries

1.1 Lithium-Sulfur Batteries: Working Principles

Lithium-sulfur batteries operate through a unique electrochemical process involving sulfur as the active material in the cathode. During discharge, lithium ions migrate from the anode to the cathode, reacting with sulfur to form lithium polysulfides. This reaction releases energy, which powers devices. Recent studies have highlighted the role of electrocatalysis in improving performance. By accelerating the sulfur reduction reaction and stabilizing intermediates like Li₂S₄, researchers have addressed challenges such as polysulfide shuttling, which causes energy loss. These advancements enhance the cycle life and efficiency of lithium-sulfur batteries, making them a promising option for applications requiring high energy density.

1.2 Lithium-Ion Batteries: Working Principles

Lithium-ion batteries rely on the movement of lithium ions between the anode and cathode through an electrolyte. The anode typically consists of graphite, while the cathode uses materials like NMC or LCO. During discharge, lithium ions flow from the anode to the cathode, generating electricity. Optimized designs have significantly improved their performance. For instance, advanced recycling-friendly designs reduce resource depletion by 23.5% and toxicity by 21.4%, while maintaining high energy efficiency. Despite higher initial costs, these designs lower life cycle costs, making lithium-ion batteries a cost-effective solution for long-term use.

1.3 Key Technological Differences

Energy Density: Lithium-sulfur batteries achieve up to 550 Wh/kg, surpassing the 60–270 Wh/kg range of lithium-ion batteries. This makes them ideal for applications requiring lightweight and high energy density solutions.

Cycle Life: Lithium-ion batteries excel in durability, supporting up to 5,000 cycles, compared to 300–500 cycles for lithium-sulfur batteries.

Environmental Impact: Sulfur’s abundance and lightweight nature make lithium-sulfur batteries more sustainable. In contrast, lithium-ion batteries rely on cobalt, which is resource-intensive to extract.

Recycling: Lithium-sulfur batteries have a simpler composition, potentially easing recycling processes.

For industrial applications, understanding these differences is crucial. Explore custom battery solutions tailored to your needs at Large Power.

Part 2: Performance Metrics Comparison

2.1 Energy Density and Weight

Energy density plays a critical role in determining a battery’s suitability for various applications. Lithium-sulfur batteries excel in this area, offering a high energy density of up to 550 Wh/kg. This makes them ideal for industries requiring lightweight and compact energy storage solutions, such as robotics. In contrast, lithium-ion batteries typically provide an energy density ranging from 60 to 270 Wh/kg, depending on the specific chemistry used, such as NMC or LCO.

Weight is another crucial factor. Lithium-sulfur batteries are lighter due to their sulfur-based cathodes, which contribute to their high energy-to-weight ratio. This advantage makes them a preferred choice for applications where weight reduction is essential, such as consumer electronics. However, lithium-ion batteries remain more versatile, offering a balance between weight, energy density, and durability.

Metric | Lithium-Sulfur Batteries | Lithium-Ion Batteries |

|---|---|---|

Energy Density | Up to 550 Wh/kg | 60–270 Wh/kg |

Weight | Lightweight | Moderate |

Tip: For industries prioritizing high energy density and lightweight solutions, lithium-sulfur batteries offer a significant advantage. However, consider the trade-offs in other performance metrics.

2.2 Cycle Life and Durability

Cycle life refers to the number of charge-discharge cycles a battery can endure before its capacity significantly degrades. Lithium-ion batteries dominate in this category, offering a longer cycle life of up to 5,000 cycles for NMC chemistries. This durability makes them suitable for applications requiring a longer lifespan, such as infrastructure and industrial operations.

Lithium-sulfur batteries, while offering high energy density, face challenges in achieving a long cycle life. Studies show that their cycle life typically ranges from 300 to 500 cycles. This limitation arises from issues like polysulfide shuttling and structural degradation of the sulfur cathode. Recent advancements, such as the use of nanostructured carbons and sulfur-amine chemistry, have shown promise in extending their lifespan. For instance, a sulfur-amine cathode demonstrated an initial discharge capacity of 970 mAh g-1, which reduced to 795 mAh g-1 after 200 cycles.

While lithium-sulfur batteries offer high energy density, their shorter cycle life may limit their use in applications requiring extended durability. Lithium-ion batteries provide a more reliable option for such scenarios.

2.3 Charging Speed and Efficiency

Charging speed and efficiency are critical for applications requiring quick energy replenishment. Lithium-ion batteries have made significant advancements in this area. Modern designs, such as Tesla’s Supercharger V4, can deliver up to 350 kW, enabling rapid charging. Similarly, the Hyundai Ioniq 6 can charge from 10% to 80% in just 18 minutes. These innovations make lithium-ion batteries highly efficient for electric vehicles and other applications requiring quick charging capability.

Lithium-sulfur batteries, on the other hand, are still in the early stages of optimizing their charging speed. Their unique chemistry poses challenges in achieving the same level of efficiency as lithium-ion batteries. However, ongoing research aims to address these limitations, focusing on improving the electrolyte and cathode materials to enhance charging performance.

Metric | Lithium-Sulfur Batteries | Lithium-Ion Batteries |

|---|---|---|

Charging Speed | Moderate | High |

Efficiency | Developing | Advanced |

Note: If your application demands quick charging and high efficiency, lithium-ion batteries currently offer the best solution. However, keep an eye on emerging advancements in lithium-sulfur technology.

Part 3: Cost Analysis

3.1 Production Costs of Lithium-Sulfur Batteries

Lithium-sulfur batteries offer a cost advantage due to the abundance and low cost of sulfur, a key cathode material. Unlike lithium-ion batteries, which rely on expensive metals like cobalt and nickel, lithium-sulfur technology reduces dependency on resource-intensive materials. However, challenges such as polysulfide shuttling and the need for advanced electrolytes increase production complexity. Research by Eroglu et al. (2015) highlights that while the material costs are lower, the manufacturing processes require further optimization to achieve cost parity with established lithium-ion technologies.

3.2 Production Costs of Lithium-Ion Batteries

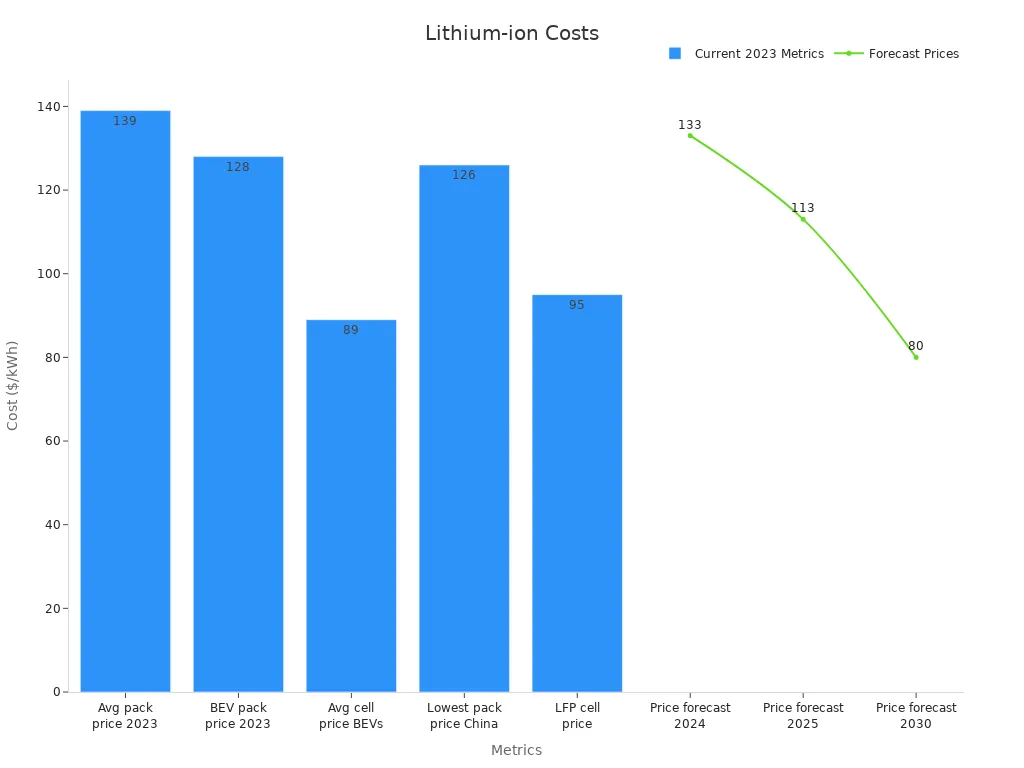

Lithium-ion batteries have seen significant cost reductions over the past decade. According to recent analyses, the average battery pack price in 2023 is $139/kWh, with lithium iron phosphate (LiFePO4) cells priced at $95/kWh. This decrease is driven by advancements in manufacturing efficiency and the adoption of lower-cost chemistries. However, regional factors, such as higher labor costs in Europe and the US, could offset these savings. Incentives like the $45/kWh production tax credit aim to mitigate these regional cost disparities.

Metric | Value |

|---|---|

Average battery pack price (2023) | $139/kWh |

BEV pack price (2023) | $128/kWh |

LiFePO4 cell price | $95/kWh |

3.3 Long-Term Cost Implications

When evaluating long-term costs, lithium-ion batteries benefit from their established safety record and longer cycle life, which reduces replacement frequency. For example, NMC lithium-ion batteries can last up to 2,000 cycles, making them ideal for industrial applications. In contrast, the shorter lifespan of lithium-sulfur batteries, typically 300–500 cycles, may lead to higher replacement costs over time. However, ongoing advancements in lithium-sulfur technology, such as improved cathode stability, could enhance their economic viability in the future.

Tip: For applications requiring high durability and cost efficiency, lithium-ion batteries remain the preferred choice. Explore custom battery solutions tailored to your needs at Large Power.

Part 4: Safety Considerations

4.1 Thermal Stability and Fire Risks

Thermal stability is a critical factor in evaluating battery safety. Lithium-ion batteries are prone to thermal runaway, a phenomenon where internal heat generation leads to uncontrollable fires. Damaged or counterfeit lithium-ion batteries exacerbate this risk, as they often lack proper safety mechanisms. Fires caused by these batteries are faster and more aggressive compared to other types.

Evidence Type | Description |

|---|---|

Report | Highlights safety risks of lithium-ion batteries in aviation, focusing on thermal runaway incidents and solutions for containment. |

Standard | UL 5800 provides testing and performance criteria for fire containment solutions for airline crew. |

Database | UL Standards & Engagement’s TRIP database collects voluntary reports of thermal runaway incidents from airlines. |

Lithium-sulfur batteries exhibit improved thermal stability due to their unique chemistry. Studies using small-angle X-ray scattering and pair distribution function analysis have shown that sulfur-based cathodes maintain structural integrity under high temperatures. A carbon–sulfur composite achieved a specific capacity of 1625 mAh g−1, demonstrating 97% of sulfur’s theoretical capacity, which contributes to better thermal performance.

Tip: Always source batteries from reputable manufacturers to minimize risks associated with counterfeit products.

4.2 Safety Features of Lithium-Sulfur Batteries

Lithium-sulfur batteries incorporate advanced safety features to address potential risks. Their solid-state design enhances damage tolerance and eliminates fire hazards. This design also reduces the likelihood of thermal runaway, making them a safer option for applications requiring high energy density.

Safety Feature | Description |

|---|---|

Solid-State Design | Provides high damage tolerance and eliminates fire risks. |

These features make lithium-sulfur batteries suitable for industries prioritizing safety, such as robotics and medical applications.

4.3 Safety Features of Lithium-Ion Batteries

Lithium-ion batteries include multiple safety mechanisms to mitigate risks. Battery management systems (BMS) monitor and regulate voltage, temperature, and current, ensuring stable operation. Additionally, manufacturers implement thermal cutoffs and pressure-sensitive vents to prevent overheating. Despite these measures, the reliance on flammable electrolytes remains a challenge.

For industrial applications, consider consulting experts to customize battery solutions that align with your safety requirements. Learn more about custom solutions here.

Part 5: Environmental Impact

5.1 Resource Extraction and Sustainability

The environmental impact of resource extraction for batteries is a critical concern. Lithium-ion batteries rely heavily on materials like cobalt and nickel, which are resource-intensive to mine. These processes often lead to habitat destruction and significant greenhouse gas (GHG) emissions. Studies on lithium-ion batteries highlight that resource extraction contributes up to 15% of their total GHG emissions, depending on the mining method.

In contrast, lithium-sulfur batteries use sulfur, an abundant and low-cost material. This reduces their dependency on rare metals, making them a more sustainable option. However, the production of lithium sulfur batteries still involves lithium extraction, which contributes to environmental degradation. Life-cycle assessment (LCA) studies emphasize the need for comprehensive data to accurately evaluate the sustainability of these rechargeable battery technologies.

Battery Type | GHG Emissions Source | Contribution to GHG Emissions |

|---|---|---|

Lithium Hydroxide | Brine | 5% |

Lithium Hydroxide | Mining | 15% |

Lithium-Sulfur | Mixed (Brine & Mining) | Assumed evenly split |

For businesses prioritizing sustainability, lithium-sulfur batteries offer a promising alternative. Learn more about sustainable practices here.

5.2 Recycling Challenges and Opportunities

Recycling remains a challenge for both lithium-ion and lithium-sulfur batteries. Lithium-ion batteries contain complex chemistries, including cobalt and nickel, which complicate recycling processes. Despite advancements, only 5% of lithium-ion batteries are currently recycled globally.

Lithium-sulfur batteries, with their simpler composition, present fewer recycling challenges. Their lack of cobalt and nickel simplifies material recovery. However, the technology for recycling lithium sulfur batteries is still in its infancy. Developing efficient recycling methods will be crucial for their widespread adoption in practical applications.

Recycling innovations can significantly reduce environmental impact. Businesses can explore custom battery solutions tailored to their needs at Large Power.

5.3 Carbon Footprint of Lithium-Sulfur vs Lithium-Ion Batteries

The carbon footprint of batteries varies based on their materials and production processes. Lithium-ion batteries have a higher carbon footprint due to the energy-intensive extraction of cobalt and nickel. In contrast, lithium-sulfur batteries generate fewer emissions because of their reliance on sulfur.

However, the carbon footprint of lithium-sulfur batteries can increase if lithium extraction methods are not optimized. Companies must consider these factors when selecting a battery for industrial or consumer applications. By choosing the right battery, you can align your operations with sustainability goals while maintaining efficiency.

Tip: Partnering with experts like Large Power ensures you receive environmentally conscious battery solutions. Explore options Large Power.

Part 6: Application Suitability

6.1 Industrial Applications for Lithium-Sulfur Batteries

Lithium-sulfur batteries are gaining traction in industries that prioritize lightweight energy storage and high energy density. Their ability to achieve energy densities close to 500 Wh/kg makes them ideal for applications requiring compact and efficient power solutions.

Aerospace Sector: The lightweight nature of lithium-sulfur batteries reduces payload weight, making them suitable for satellites and unmanned aerial vehicles (UAVs). Their high energy density ensures extended operational times, a critical factor in aerospace applications.

Automotive Industry: Electric vehicles (EVs) benefit from the high theoretical capacity of lithium-sulfur batteries. These batteries enable longer driving ranges while reducing the overall weight of the vehicle.

Portable Electronics: Devices like laptops and smartphones can leverage the compact design and improved safety features of lithium-sulfur batteries. The use of non-flammable electrolytes enhances safety, especially in consumer electronics.

Medical Equipment: Lithium-sulfur batteries are increasingly adopted in medical devices due to their lightweight design and ability to provide reliable power for extended periods. Learn more about medical battery applications.

The lithium-sulfur battery market is projected to reach USD 11.3 billion by 2033, driven by advancements in nanomaterials and improved cycle life. These batteries are particularly attractive for industries prioritizing sustainability and safety.

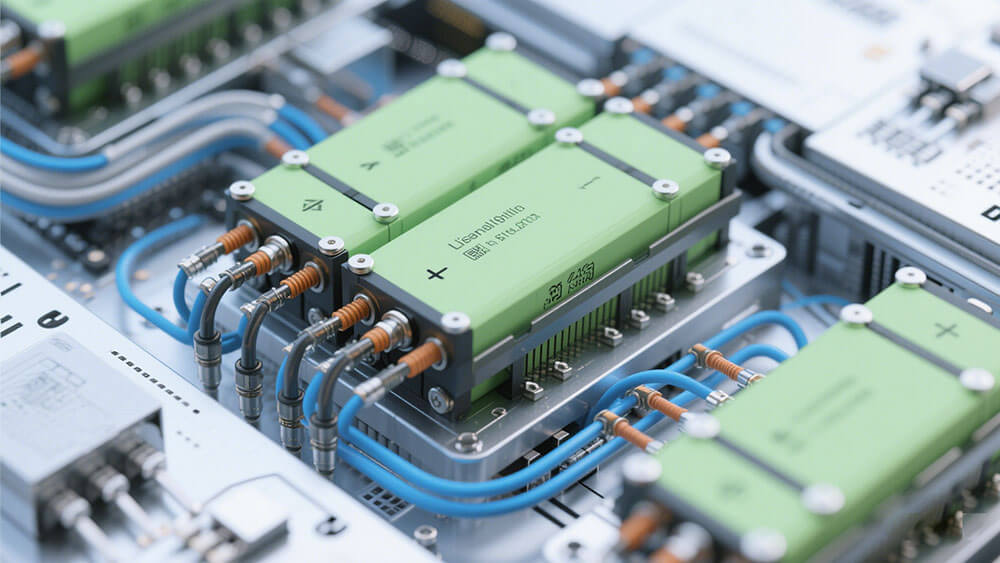

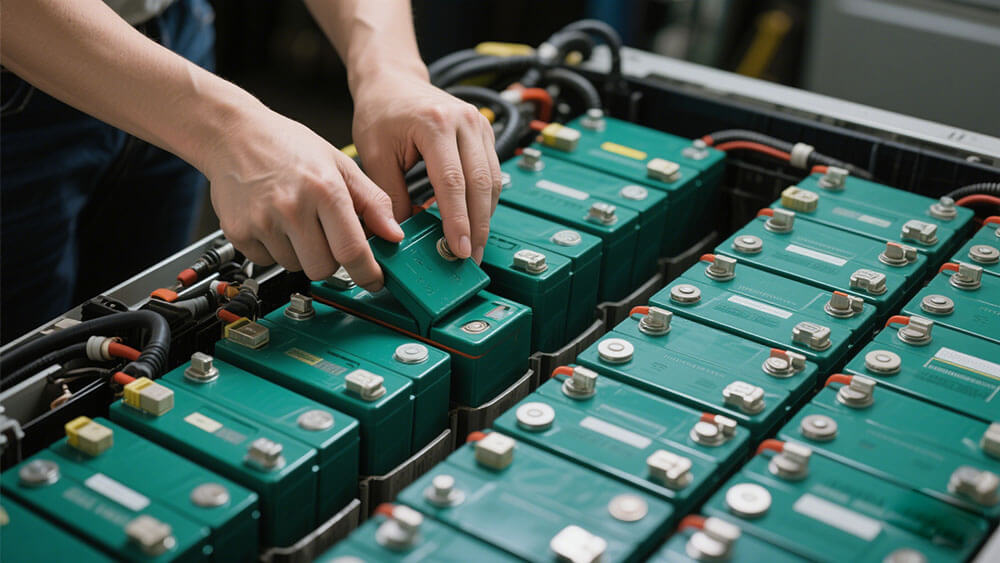

6.2 Industrial Applications for Lithium-Ion Batteries

Lithium-ion batteries dominate industrial applications due to their versatility, durability, and established performance metrics. Their ability to support up to 2,000 cycles makes them a reliable choice for long-term use.

Infrastructure: Lithium-ion batteries are widely used in transportation systems, including electric buses and railways. Their high cycle life and energy efficiency ensure consistent performance in demanding environments. Explore infrastructure applications.

Robotics: Robotics applications benefit from the balance between energy density and weight offered by lithium-ion batteries. These batteries provide the power needed for extended operational times without compromising mobility. Learn more about robotics applications.

Security Systems: Lithium-ion batteries are integral to security systems, offering reliable backup power for surveillance cameras and alarm systems. Their advanced battery management systems (BMS) ensure stable operation. Discover security system applications.

Industrial Equipment: Heavy machinery and industrial tools rely on lithium-ion batteries for their durability and ability to deliver consistent power. Their longer cycle life reduces replacement costs, making them a cost-effective solution. Explore industrial applications.

Application | Key Benefits of Lithium-Ion Batteries |

|---|---|

Infrastructure | High cycle life and energy efficiency |

Robotics | Balance between energy density and weight |

Security Systems | Reliable backup power and advanced BMS |

Industrial Tools | Durability and cost-effectiveness |

Lithium-ion batteries remain the preferred choice for industries requiring long-term reliability and versatility. Their established safety features and performance metrics make them indispensable across various sectors.

6.3 Emerging Trends in Battery Technology

The battery industry is witnessing rapid advancements, with both lithium-sulfur and lithium-ion technologies evolving to meet growing demands.

Lithium-Sulfur Batteries: The market for lithium-sulfur batteries is projected to grow from $0.68 billion in 2024 to $2.09 billion by 2029, reflecting a CAGR of 24.9%. Government investments in EVs and advancements in sulfur cathode chemistry are driving this growth. Researchers are focusing on increasing sulfur mass loading to improve practical applications.

Lithium-Ion Batteries: Innovations in lithium-ion technology include the development of solid-state designs and recycling-friendly chemistries. Experimental studies validate their effectiveness in reducing degradation and enhancing energy efficiency. For example, model-based methodologies refine specific dependencies to optimize performance.

Trend | Lithium-Sulfur Batteries | Lithium-Ion Batteries |

|---|---|---|

Market Growth | CAGR of 24.9% by 2029 | Established dominance |

Technological Advances | Sulfur mass loading | Solid-state designs |

Sustainability Focus | Reduced reliance on rare metals | Recycling-friendly chemistries |

Emerging trends highlight the potential for both battery types to address evolving industrial needs. Partnering with experts like Large Power ensures access to cutting-edge solutions tailored to your applications. Explore custom solutions.

Lithium-sulfur batteries and lithium-ion batteries offer distinct advantages tailored to different industrial needs. Lithium-sulfur batteries excel in energy density and sustainability, while lithium-ion batteries provide unmatched durability and charging efficiency. Selecting the right battery depends on your application’s priorities, whether it’s lightweight design, long cycle life, or cost-effectiveness.

Partnering with experts like Large Power ensures you receive customized solutions that align with your operational goals.

FAQ

1. What are the main advantages of lithium-sulfur batteries over lithium-ion batteries?

Lithium-sulfur batteries offer higher energy density (up to 550 Wh/kg) and use abundant sulfur, making them lightweight and more sustainable.

2. Are lithium-sulfur batteries suitable for industrial applications?

Yes, their high energy density and lightweight design make them ideal for aerospace, robotics, and medical applications.

3. How does Large Power support businesses in choosing the right battery?

Large Power provides tailored battery solutions, ensuring optimal performance, safety, and sustainability for your specific industrial needs.