Contents

Choosing the appropriate battery cell design is vital for addressing the power requirements of contemporary industries. This choice significantly influences applications such as uninterrupted power supply (UPS) systems and renewable energy storage solutions. Key trends underscore its significance:

Increasing demand for reliable power within industrial sectors.

The adoption of smart grids propelling advancements in renewable energy systems.

Consumer electronics necessitating high-performance lithium-ion batteries.

Emergency power systems depending on optimized battery designs.

Prismatic battery cells are integral to lithium battery pack manufacturing, providing customized solutions to meet the needs of various industries.

Key Takeaways

Prismatic battery cells store more energy, great for electric cars.

Cylindrical cells handle heat well and are safer for tools.

Pick a design based on energy, heat control, and cost.

Part 1: Overview of Cylindrical Battery Cells

1.1: Design and Structure of Cylindrical Battery Cells

Cylindrical cells are among the most widely used battery designs due to their robust structure and efficient manufacturing process. These cells feature a steel can that acts as the negative contact, while the top cap serves as the positive contact. Inside, a jelly roll structure comprises stacked electrodes and a separator, rolled tightly around a central axis. This design ensures consistent performance and mechanical stability.

The table below outlines the key components of cylindrical cells and their functions:

Component | Function |

|---|---|

Steel Can | Forms the negative contact of the cell. |

Top Cap | Forms the positive contact of the cell. |

Cover | Seals the top of the cell. |

Jelly Roll | Stacked electrodes and separator rolled around the central axis. |

End Tabs | Conduct current into and out of the electrodes. |

This design is particularly effective for applications requiring high thermal stability and safety, such as medical instruments and power tools.

1.2: Advantages of Cylindrical Battery Cells

Cylindrical cells offer several advantages that make them a preferred choice in various industries. Their mature manufacturing process ensures cost-effectiveness and scalability. The robust mechanical stability of these cells allows them to withstand physical stress, making them ideal for portable devices and industrial applications.

Additional benefits include:

High thermal stability, reducing the risk of overheating.

Longevity, with consistent performance over extended cycles.

Versatility, suitable for both high-drain and lower-drain applications.

1.3: Disadvantages of Cylindrical Battery Cells

Despite their advantages, cylindrical cells have some limitations. The space between individual cells in a battery pack reduces thermal buildup but also decreases energy density. This unoccupied space can limit the overall efficiency of the battery module.

The table below summarizes key disadvantages:

Disadvantage | Description |

|---|---|

Gap Between Cells | Reduces thermal buildup but decreases energy density due to unoccupied space. |

Performance in Cold | Cylindrical cells may underperform in colder environments compared to other geometries. |

These limitations should be considered when selecting cylindrical cells for specific applications, especially in environments with extreme temperatures.

Part 2: Overview of Prismatic Battery Cells

2.1: Design and Structure of Prismatic Battery Cells

Prismatic battery cells feature a rectangular prism shape, which allows for efficient stacking in battery packs. This design maximizes space utilization and simplifies assembly. You can find two primary construction types: the electrode sheet type, where anode, cathode, and separator layers are stacked, and the rolled and flattened type, which resembles cylindrical cells.

The table below highlights key characteristics of prismatic battery cells:

Characteristic | Description |

|---|---|

Shape | Rectangular prism shape, ideal for stacking multiple cells. |

Current Carrying Capacity | Stacked sheet type has higher capacity due to more surface contact. |

Common Applications | Used in Powerwall batteries and energy-intensive stationary power systems. |

Outer Casing Material | Typically made of steel or aluminum, providing strength similar to cylindrical cells. |

2.2: Advantages of Prismatic Battery Cells

Prismatic battery cells offer several advantages that make them appealing for various applications. Their energy density approaches that of lithium polymer pouch cells, allowing for longer driving ranges in electric vehicles. Additionally, innovative chemistries enhance thermal stability, improving safety and performance.

Key benefits include:

Higher energy capacity, supporting longer usage times.

Optimized design for efficient assembly and space utilization.

Increased market demand, with the prismatic lithium-ion battery cell market projected to grow from USD 99.98 million in 2023 to USD 342.5 million by 2033.

2.3: Disadvantages of Prismatic Battery Cells

Despite their advantages, prismatic battery cells have some drawbacks. Their manufacturing process can be more complex and costly compared to cylindrical cells. Additionally, while they offer high energy density, they may not perform as well in extreme temperatures.

Consider these disadvantages:

Higher production costs due to complex manufacturing.

Potential performance issues in very cold or hot environments.

Understanding these factors will help you make informed decisions when selecting battery cell designs for your applications.

Part 3: Comparative Analysis of Prismatic vs Cylindrical Battery Cells

3.1: Energy Density Comparison

Energy density plays a critical role in determining the performance and efficiency of battery cells, especially in applications like electric vehicles and energy storage systems. Prismatic cells generally offer higher energy density per cell compared to cylindrical cells. This advantage stems from their compact rectangular design, which minimizes unused space within battery packs.

Factor | Prismatic Cells | Cylindrical Cells |

|---|---|---|

Energy Density | Higher per cell, ideal for EVs | Lower per cell, but consistent output |

Applications | EVs, energy storage systems | Power tools, laptops, e-bikes |

Prismatic cells excel in applications requiring high energy density, such as electric vehicles, where maximizing driving range is essential. However, cylindrical cells remain a reliable choice for devices needing consistent energy output over extended periods.

3.2: Thermal Management in Prismatic and Cylindrical Cells

Thermal management is a crucial factor in battery performance and safety. Cylindrical cells outperform prismatic cells in this area due to their uniform design, which facilitates efficient heat dissipation. The cylindrical shape allows for better airflow and cooling, reducing the risk of overheating.

Evidence Type | Description |

|---|---|

Heat Generation | Prismatic cells generate more heat on the backside, requiring advanced cooling. |

Temperature Variation | Thermal profiles vary based on airflow direction and cell location in the pack. |

Cooling Efficiency | Cylindrical cells exhibit better cooling, especially in high-performance setups. |

Prismatic cells often require additional cooling systems to manage heat effectively, which can increase the complexity and cost of battery pack designs. In contrast, cylindrical cells’ inherent thermal stability makes them suitable for high-drain applications like power tools and robotics.

3.3: Durability and Longevity of Prismatic vs Cylindrical Cells

Durability and longevity are vital for ensuring the reliability of battery systems in industrial and energy storage applications. Cylindrical cells are known for their robust mechanical stability, which makes them resistant to physical shocks and vibrations. This durability contributes to their long lifecycle and consistent performance.

Prismatic Cells:

Larger size and high energy capacity make them ideal for energy storage systems and EVs.

Durable enough to eliminate the need for a module step in cell-to-pack designs, reducing production costs.

Suitable for applications requiring substantial power output.

Cylindrical Cells:

Rigid structure enhances mechanical stability and safety.

Long lifecycle ensures reliable energy management in various applications.

Commonly used in high-energy-density applications like portable devices and robotics.

Both designs offer excellent durability, but the choice depends on the specific requirements of your application. For instance, prismatic cells are better suited for stationary energy storage systems, while cylindrical cells excel in portable and high-performance devices.

3.4: Cost Implications of Prismatic and Cylindrical Cells

Cost considerations are a significant factor when selecting a battery cell design. Prismatic cells generally have higher production costs due to their complex manufacturing process. However, they offer cost advantages in large-scale applications like EVs, where their high energy density reduces the number of cells required.

Battery Type | Cost ($/kWh) | Location |

|---|---|---|

LiFePO4 Prismatic | 49 | China |

NMC-811 Prismatic | 60 | China |

NMC-811 Cylindrical | 67.1 | South Korea |

LiFePO4 prismatic cells in China are approximately 25% cheaper than NMC-811 cylindrical cells produced in South Korea.

Prismatic cells’ cost-effectiveness makes them advantageous for EVs and energy storage systems, where high energy density is critical.

While cylindrical cells remain cost-competitive, their slightly higher costs may impact large-scale applications. Both designs, however, demonstrate minimal cost differences (<1%) in specific use cases, highlighting their overall cost-effectiveness.

For tailored battery solutions that align with your cost and performance needs, explore Large Power’s custom battery solutions.

Part 4: Suitability for Different Industries

4.1: Renewable Energy Storage Systems and Cylindrical Cells

Renewable energy storage systems demand reliable and efficient battery solutions to store power generated from solar and wind sources. Cylindrical cells, particularly cylindrical LiFePO4 cells, have emerged as a preferred choice in this sector due to their safety, performance, and cost-effectiveness. These cells discharge energy rapidly, making them ideal for applications requiring consistent power output. For instance, they are widely used in grid energy storage systems and rural electrification projects.

The global shift towards renewable energy has further accelerated the adoption of cylindrical cells. Governments worldwide are implementing policies such as tax credits and rebates to promote solar energy storage systems. This trend aligns with the broader goal of reducing carbon emissions and transitioning to a low-carbon economy.

Drivers | Opportunities | Challenges |

|---|---|---|

Deployment of grid energy storage systems | Adoption in rural electrification projects | Installation difficulties in remote areas |

Use of lithium-ion batteries in renewables | Demand for continuous power in data centers | Overheating due to abnormal discharges |

Renewable energy revolution | Price reduction of lithium-ion batteries | Aging of lithium-ion batteries |

Cylindrical cells also play a crucial role in modernizing energy infrastructure. Their robust design ensures durability and longevity, making them suitable for long-term energy storage applications. To explore custom battery solutions tailored for renewable energy systems, visit Large Power’s custom battery solutions.

4.2: Consumer Electronics and Battery Cell Design

Consumer electronics rely heavily on advanced battery technology to meet the growing demand for longer-lasting and faster-charging devices. Prismatic cells and cylindrical cells both cater to this sector, but their suitability depends on the specific application. Prismatic cells, with their high capacity and compact design, are commonly used in smartphones, laptops, and wearables. These cells maximize space utilization within devices, enabling manufacturers to create slimmer and more efficient products.

Cylindrical cells, on the other hand, are favored for devices requiring rapid energy discharge and consistent performance. Their robust structure ensures safety and reliability, making them ideal for power tools and portable electronics. The increasing demand for consumer electronics highlights the importance of selecting the right battery cell design to enhance user experience and device performance.

Key trends in consumer electronics:

Rising demand for improved battery life and efficiency in smartphones and laptops.

Advancements in battery technology focusing on safety and performance.

Growing preference for lightweight and compact battery packs.

For more insights into battery solutions for consumer electronics, refer to Large Power’s consumer electronics battery solutions.

4.3: Industrial Applications of Prismatic and Cylindrical Cells

Industrial applications require battery solutions that can withstand harsh environments and deliver consistent power output. Prismatic cells and cylindrical cells both serve this sector effectively, but their applications vary based on specific requirements. Prismatic cells, with their high energy capacity and efficient design, are ideal for heavy-duty equipment and stationary power systems. These cells are commonly used in industrial automation, robotics, and infrastructure projects.

Cylindrical cells, known for their mechanical stability and rapid energy discharge, are better suited for portable industrial tools and equipment. Their robust design ensures durability, even under extreme conditions. For example, cylindrical LiFePO4 cells are widely used in industrial-grade power tools and backup power systems.

Benefits of prismatic cells in industrial applications:

High capacity supports prolonged usage in heavy machinery.

Compact design simplifies integration into battery packs.

Enhanced safety features reduce operational risks.

Advantages of cylindrical cells for industrial use:

Superior thermal management ensures consistent performance.

Long lifecycle minimizes maintenance costs.

Versatility makes them suitable for a wide range of tools and devices.

To learn more about battery solutions for industrial applications, visit Large Power‘s industrial battery solutions.

Understanding the key differences between prismatic and cylindrical cells is crucial for optimizing energy storage solutions. Prismatic cells offer higher energy density, while cylindrical cells excel in thermal management and safety characteristics. You should consider industry-specific needs, such as safety concerns and application requirements, when selecting lithium-ion batteries. Consulting experts for custom battery solutions can enhance performance and reliability. Explore Large Power’s custom battery solutions for tailored advice.

FAQ

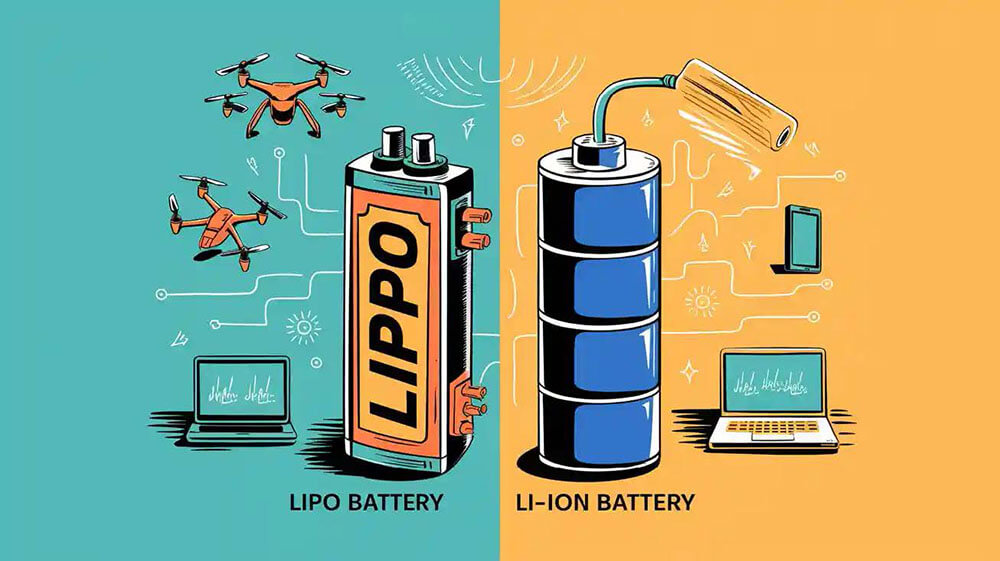

1. What are pouch cells, and how do they differ from cylindrical and prismatic cells?

Pouch cells are lithium-ion batteries encased in flexible aluminum laminate. Unlike cylindrical and prismatic cells, they offer lightweight designs and customizable shapes for space-constrained applications.

2. How do pouch cells benefit industrial applications?

Pouch cells provide high energy density and design flexibility, making them ideal for industrial automation and robotics. Their lightweight structure reduces equipment weight, enhancing operational efficiency.

3. Why should you consider Large Power for custom pouch cell solutions?

Large Power specializes in tailored pouch cell designs for diverse industries. Their expertise ensures optimal performance and reliability. Explore Large Power’s custom battery solutions for more details.