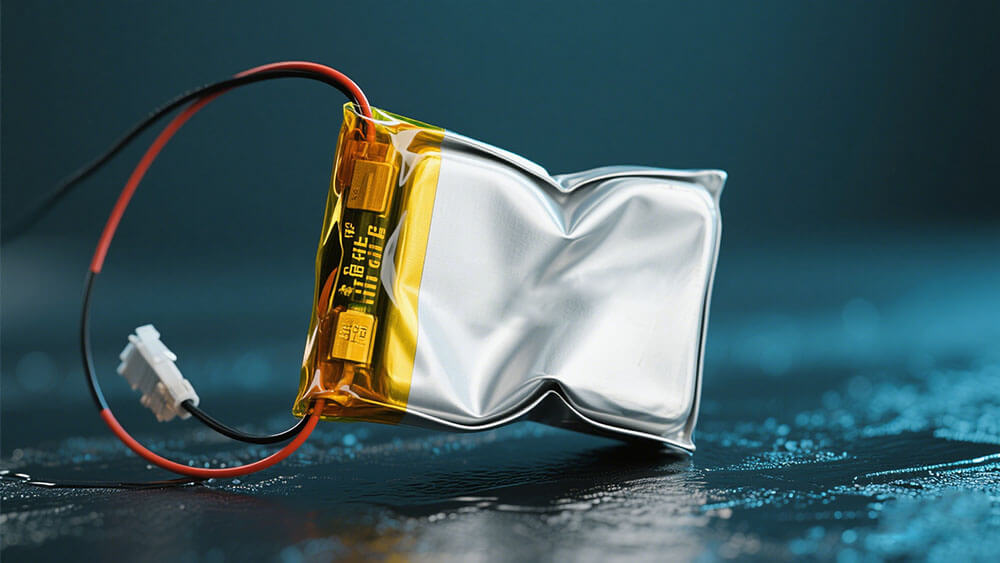

A short circuit in lithium battery systems occurs when unintended connections allow current to bypass its intended path, leading to excessive heat. This phenomenon threatens safety and performance, especially in critical applications like medical devices, robotics, and industrial equipment. Preventing short circuits about lithium battery systems is vital to avoid overheating, fires, and irreparable damage to battery packs. Proactive measures ensure reliability in demanding environments.

Key Takeaways

Learn what causes short circuits in lithium batteries. These include problems inside the battery or damage from outside. Knowing this helps spot dangers early.

Use safety circuits in battery packs to check voltage and heat. This makes batteries safer and stops them from overheating.

Charge batteries the right way by not overcharging them. Keep the charge under 4.20V per cell to make them last longer and avoid short circuits.

Part 1: Causes of Short Circuits in Lithium Batteries

1.1 Internal Causes of Short Circuits

Internal factors often play a significant role in causing short circuits within lithium battery systems. Manufacturing defects, such as impurities in the electrode materials or misaligned separators, can create pathways for unintended current flow. These defects compromise the integrity of the battery, leading to potential safety hazards.

The table below summarizes the internal mechanisms that lead to short circuits:

Type of Abuse | Description |

|---|---|

Mechanical Abuse | Causes mechanical deformation and partial rupture of the diaphragm, triggering internal short circuits. |

Electrical Abuse | Leads to lithium deposition and dendrite growth, connecting positive and negative parts through diaphragm pores. |

Thermal Abuse | High temperatures cause diaphragm shrinkage and collapse, resulting in short circuits. |

Stages of Short Circuit | Initial stage: slow voltage drop, minimal heat; Middle stage: significant voltage drop, heat accumulation; Final stage: rapid voltage drop to 0V, thermal runaway occurs. |

Understanding these internal causes is essential for industries like medical devices, robotics, and consumer electronics, where battery reliability is paramount.

1.2 External Factors Leading to Short Circuits

External factors, such as mechanical stress or improper handling, can also lead to short circuits in lithium battery packs. For instance, external impacts from drops or collisions may damage the battery casing, exposing internal components to potential shorting. In industrial applications, where batteries often face harsh conditions, these risks are particularly pronounced.

A study on lithium-ion batteries highlights the effects of micro short circuits caused by external mechanical stress. Testing methods, such as extrusion tests and charge/discharge cycling, reveal significant differences in capacity and resistance between damaged and undamaged batteries. These findings underscore the importance of proper handling and robust battery design to mitigate external risks.

1.3 Environmental Conditions and Their Impact on Short Circuits

Environmental conditions, such as temperature extremes and humidity, significantly impact the likelihood of short circuits in lithium batteries. High temperatures can accelerate chemical reactions within the battery, leading to thermal runaway. Conversely, low temperatures may cause lithium plating, which increases the risk of internal short circuits. Humidity and moisture can corrode battery components, further compromising their safety and performance.

For example, in security system, where batteries often operate in diverse environmental conditions, maintaining optimal storage and operating environments is crucial. You should store lithium batteries in dry, temperature-controlled environments to minimize these risks. Additionally, using batteries with advanced thermal management systems can help maintain stability under varying conditions.

By understanding and addressing these environmental factors, you can enhance the safety and reliability of lithium battery packs across various applications, from robotics to medical devices.

Part 2: Effective Methods to Prevent Short Circuits

2.1 Use of Protective Circuits in Lithium Battery Packs

Protective circuits play a crucial role in ensuring the safety and reliability of lithium battery packs. These circuits monitor and regulate the voltage, current, and temperature of the battery, preventing conditions that could lead to short circuits or thermal runaway. By integrating protective circuits, you can enhance the safety of lithium battery systems used in critical applications like medical devices, robotics, and security systems.

To illustrate the effectiveness of protective circuits:

The GB 38031-2020 standard requires batteries to remain non-flammable for at least five minutes after a warning, allowing sufficient time for evacuation.

Fireproof insulation products have been tested at 1,500°C for 30 minutes, demonstrating their ability to protect battery systems under extreme conditions.

Incorporating these advanced protective measures into your battery packs can mitigate risks and ensure compliance with industry safety standards. This is especially critical in infrastructure applications, where battery packs power essential systems like transportation networks.

2.2 Best Practices for Charging and Discharging Lithium Batteries

Adopting proper charging and discharging practices is essential to maintain the safety and longevity of lithium battery packs. Overcharging or discharging beyond recommended limits can lead to internal damage, increasing the risk of short circuits.

The following table outlines safe charging levels and their impact on battery performance:

Charge Level (V/cell) | Discharge Cycles | Available Stored Energy |

|---|---|---|

4.30 | 150–250 | 110–115% |

4.25 | 200–350 | 105–110% |

4.20 | 300–500 | 100% |

4.13 | 400–700 | 90% |

4.06 | 600–1,000 | 81% |

4.00 | 850–1,500 | 73% |

3.92 | 1,200–2,000 | 65% |

3.85 | 2,400–4,000 | 60% |

To ensure safety during charging, avoid exceeding 4.20V per cell. Lowering the charge voltage can significantly extend the battery’s cycle life. For instance, maintaining a 50% state of charge (SOC) can increase the lifespan by 44–130%. These practices are particularly beneficial for consumer electronics and industrial applications, where battery reliability is paramount.

2.3 Environmental and Storage Guidelines for Lithium Battery Safety

Proper environmental and storage conditions are vital to protect lithium battery packs from short circuits. Extreme temperatures, humidity, and improper storage can compromise battery safety and performance.

Follow these guidelines to minimize risks:

Avoid short-circuiting the positive and negative poles to prevent thermal runaway.

Insulate battery terminals using materials like electrical tape or plastic caps to prevent accidental short circuits.

Cover discarded batteries with insulating paper before storage or disposal to avoid accidental short circuits.

For example, in security systems, where batteries often operate in diverse environmental conditions, maintaining optimal storage environments is critical. Store batteries in dry, temperature-controlled areas to reduce the risk of corrosion and thermal instability. Additionally, using advanced thermal management systems can help stabilize battery performance under varying conditions.

By adhering to these guidelines, you can enhance the safety and reliability of lithium battery packs across various applications, from robotics to medical devices.

Part 3: Safety Measures and Advanced Technologies for Lithium Battery Packs

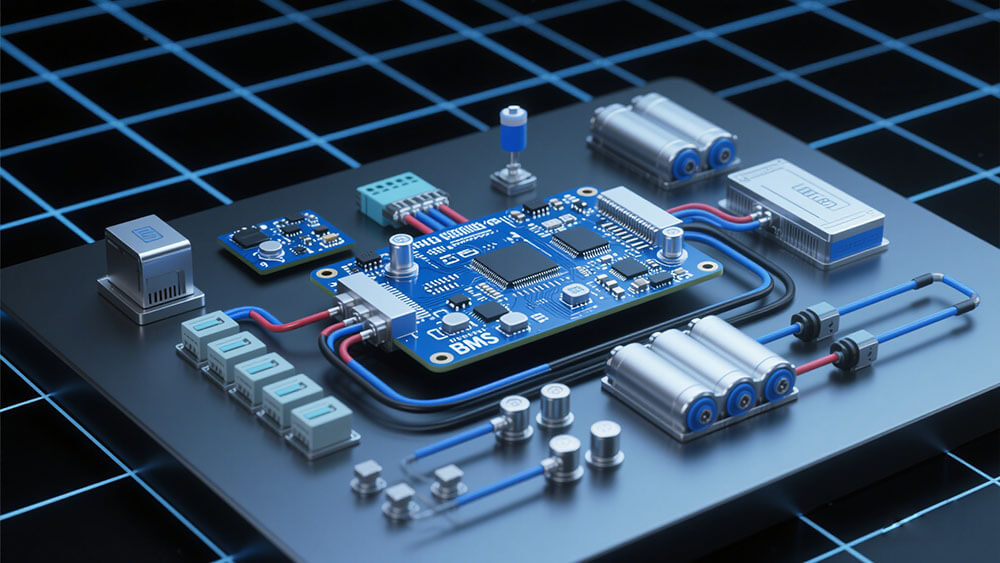

3.1 Role of Battery Management Systems (BMS) in Preventing Short Circuits

A Battery Management System (BMS) serves as the brain of lithium-ion batteries, ensuring their safe and efficient operation. By continuously monitoring voltage, current, and temperature, the BMS prevents conditions that could lead to short circuits or thermal runaway. For instance, if the current exceeds safe thresholds, the BMS disconnects the circuit to protect the battery pack. Similarly, it halts discharging when undervoltage occurs, safeguarding against potential damage.

In industrial applications, where battery packs power heavy machinery, the BMS plays a critical role in maintaining operational safety. Sophisticated sensor networks integrated into the BMS provide real-time data on battery health, enabling early detection of internal shorts. Distributed temperature sensors and voltage probes enhance this capability, ensuring reliability in demanding environments like robotics and infrastructure. By leveraging cloud-based analytics, the BMS also facilitates continuous monitoring, making it indispensable for modern lithium-ion battery systems.

3.2 Importance of Fuses and Circuit Breakers in Lithium Battery Safety

Fuses and circuit breakers act as frontline defenses against electrical faults in lithium battery packs. These components interrupt the flow of excessive current, preventing overheating and potential fires. For example, a 400 Ah battery bank can supply up to 40,000 Amps momentarily during a short circuit. Without a properly rated circuit breaker, such currents could cause catastrophic failures.

In medical devices, where uninterrupted power is critical, layered fuse designs ensure safety at multiple levels—cell, module, and pack. This approach isolates faults, minimizing the impact on the overall system. Similarly, in security systems, circuit breakers protect against external electrical surges, enhancing the reliability of battery-powered operations. By incorporating these safety measures, you can significantly reduce risks and ensure compliance with industry standards.

3.3 Emerging Research and Innovations in Lithium Battery Safety

Advancements in lithium battery technology continue to enhance safety and performance. For example, the development of solid-state batteries, which use solid electrolytes, offers improved thermal stability and eliminates risks associated with liquid electrolytes. These batteries are particularly promising for applications in consumer electronics and robotics, where compact and safe energy storage is essential.

Innovative materials like ceramic membranes and flame-retardant electrolytes further mitigate risks by suppressing dendrite growth and reducing internal short circuits. Real-time monitoring systems now analyze gas emissions during battery operation, providing insights to adjust electrolyte composition and minimize harmful reactions. Additionally, intumescent thermal barriers and flame-resistant materials enhance safety by containing fire spread and maintaining structural integrity under extreme conditions.

These advancements underscore the importance of adopting cutting-edge technologies to improve lithium battery safety. By staying informed about emerging trends, you can ensure your battery systems meet the highest safety and performance standards.

Short circuits in lithium batteries often result from internal defects, external impacts, or environmental factors. Preventing these issues requires robust safety measures, including protective circuits, proper charging practices, and optimized storage conditions.

Key Prevention Methods:

Incorporate safety-reinforced layers (SRL) to reduce explosion risks by 53%.

Conduct regular safety tests to identify vulnerabilities in battery systems.

For businesses, implementing these strategies ensures operational safety and compliance. Consulting experts like Large Power for custom battery solutions can further optimize performance and reliability.

FAQ

1. What is the role of a Battery Management System (BMS) in lithium battery safety?

A BMS monitors voltage, current, and temperature, preventing overcharging, overheating, and short circuits. It ensures safe operation in critical applications like robotics and infrastructure.

2. How can you safely store lithium battery packs?

Store batteries in dry, temperature-controlled environments. Insulate terminals with tape or caps to prevent accidental short circuits. Avoid exposure to extreme temperatures or humidity.

3. Why should you consult experts for custom lithium battery solutions?

Experts like Large Power provide tailored solutions, ensuring safety, compliance, and optimal performance for your specific industrial or commercial needs.