Contents

Selecting the ideal battery for industrial or commercial applications ensures operational efficiency and longevity. Large Batteries power critical systems across industries, making it vital to evaluate factors like power demands, environmental conditions, and safety standards. Understanding how to choose batteries tailored to your needs minimizes risks and enhances system performance. For customized solutions, explore Large Power’s consultation services.

Key Takeaways

Figure out how much power your equipment needs. This helps you pick a battery that keeps things running smoothly.

Check the temperature and humidity where the battery will be used. Pick strong batteries that last longer in tough conditions.

Make sure the battery matches your equipment’s voltage, size, and connectors. This avoids problems and keeps the system working well.

Part 1: Define Your Application Requirements

1.1 Understand Your Power Needs

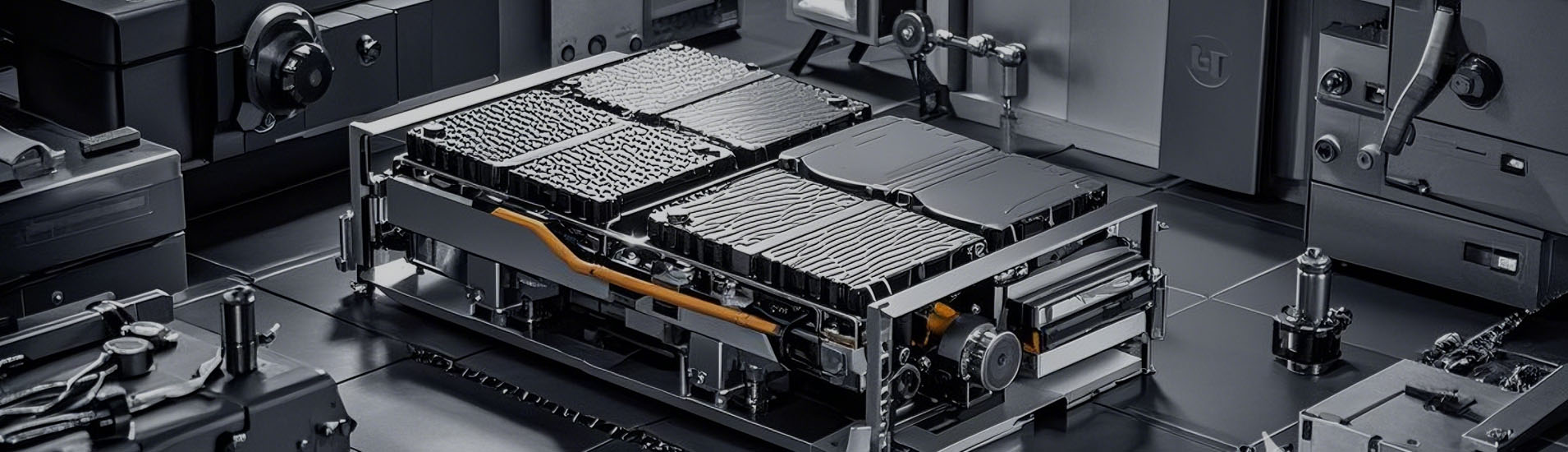

Identifying your power requirements is the first step in selecting the right type of battery. Begin by assessing the energy demands of your equipment or system. For industrial applications, this often involves calculating the total wattage or amperage needed to operate machinery, robotics, or infrastructure systems. For example, robotics applications may require batteries with high discharge rates to support dynamic movements and continuous operations.

Large batteries are designed to meet diverse power needs, ranging from low-power consumer electronics to high-performance industrial systems. Matching the battery’s capacity to your equipment ensures uninterrupted operation and prevents overloading. For systems requiring consistent power delivery, lithium-ion batteries are often preferred due to their stable voltage output and high energy density.

1.2 Determine Usage Duration and Load Profile

Usage duration and load profile are critical factors in battery selection. You need to evaluate how long your equipment will operate on a single charge and whether the load remains constant or fluctuates. For instance, medical devices often demand batteries with extended runtime and stable performance to ensure patient safety.

Load profiles vary significantly across applications. Industrial systems may experience peak loads during startup, while security systems require steady power for surveillance equipment. Batteries with high cycle life, such as LiFePO4 Lithium batteries, are ideal for applications with frequent charge-discharge cycles.

1.3 Consider Environmental Conditions (e.g., temperature, humidity)

Environmental factors like temperature and humidity directly impact battery performance. Extreme temperatures can accelerate battery degradation, while high humidity increases the risk of water ingress. For outdoor applications, such as infrastructure systems, selecting batteries with robust enclosures and thermal management systems is essential.

Key considerations include:

Temperature: High temperatures can lead to thermal runaway, while low temperatures reduce battery efficiency.

Humidity: Moisture can compromise battery integrity, especially in environments with frequent exposure to rain or condensation.

Design choices, such as using corrosion-resistant materials and advanced battery management systems (BMS), mitigate these risks.

1.4 Evaluate Space and Weight Constraints

Space and weight constraints play a significant role in battery selection, particularly for portable or compact systems. Large batteries must balance capacity and size to fit within the available space without compromising efficiency. For example, industrial applications often require batteries with high volumetric and gravimetric efficiency to maximize energy density while minimizing footprint.

Aspect | Details |

|---|---|

Objective | Develop large format lithium-ion cells and batteries with capacities over 1 MWh and improved safety. |

Efficiency | Lithium-Ion systems are more volumetric and gravimetrically efficient than other rechargeable systems. |

Safety Concerns | Larger batteries have increased risk of failure propagation, affecting installation and operational safety. |

Size and Capacity | Targeting cell sizes from 100 Ah to 500 Ah or larger, with specific energy and energy density requirements. |

Cycle Life | Targeting over 200 cycles and 5 years of wet life. |

Selecting the right type of battery for your application ensures optimal performance and safety. For tailored solutions, consult Large Power’s experts.

Part 2: Match Battery Specifications to Your Needs

2.1 Battery Capacity (Ah or Wh) and Its Importance

Battery capacity, measured in ampere-hours (Ah) or watt-hours (Wh), determines how much energy a battery can store and deliver. Selecting the right capacity ensures your equipment operates efficiently without interruptions. For instance, large batteries used in industrial applications must support extended operations, especially for systems like robotics or infrastructure. Underestimating capacity can lead to frequent recharging, reducing productivity and increasing downtime.

When evaluating capacity, consider:

Energy Demand: Calculate the total energy consumption of your equipment over a specific period.

Reserve Capacity: Account for unexpected surges or prolonged usage.

Application Type: High-capacity batteries are essential for energy-intensive applications like medical devices or industrial machinery.

Tools like the Power.Match.® system help match battery capacity to your specific requirements, ensuring optimal performance. Additionally, pairing the battery with a compatible charger that matches its voltage and amperage prevents undercharging or overcharging, which can degrade battery life.

2.2 Voltage Requirements for Your Equipment

Voltage compatibility is critical for the safe and efficient operation of your equipment. Each type of battery chemistry has a specific nominal voltage range, which must align with your system’s requirements. For example, lithium-ion batteries typically operate at a nominal voltage of 3.6 volts, making them suitable for high-performance applications.

The table below highlights the voltage characteristics of different battery chemistries:

Battery Chemistry | Nominal Voltage | Fully Charged Voltage | Fully Discharged Voltage |

|---|---|---|---|

NiCad | 1.2 volts | 1.4 volts | 1.0 volts |

NiMH | 1.4 volts | 1.4 volts | 1.0 volts |

Lithium-ion | 3.6 volts | 4.2 volts | 2.8-3.0 volts |

Lead-acid | 2 volts | 2.1 volts | 1.75 volts |

Matching the voltage ensures your equipment operates within its designed parameters, preventing issues like overheating or inefficiency. For tailored voltage solutions, consult Large Power’s experts.

2.3 Cycle Life and Expected Battery Longevity

Cycle life refers to the number of charge-discharge cycles a battery can complete before its capacity significantly declines. This specification is crucial for applications requiring frequent usage, such as industrial systems or security systems.

Different battery chemistries offer varying cycle lives:

LiFePO4 Lithium batteries: 2,000–5,000 cycles, ideal for long-term applications.

NMC Lithium batteries: 1,000–2,000 cycles, suitable for moderate usage.

LCO Lithium batteries: 500–1,000 cycles, often used in consumer electronics.

Selecting a battery with a higher cycle life reduces replacement frequency, lowering long-term costs. For applications requiring extended longevity, prioritize chemistries like LiFePO4 or NMC.

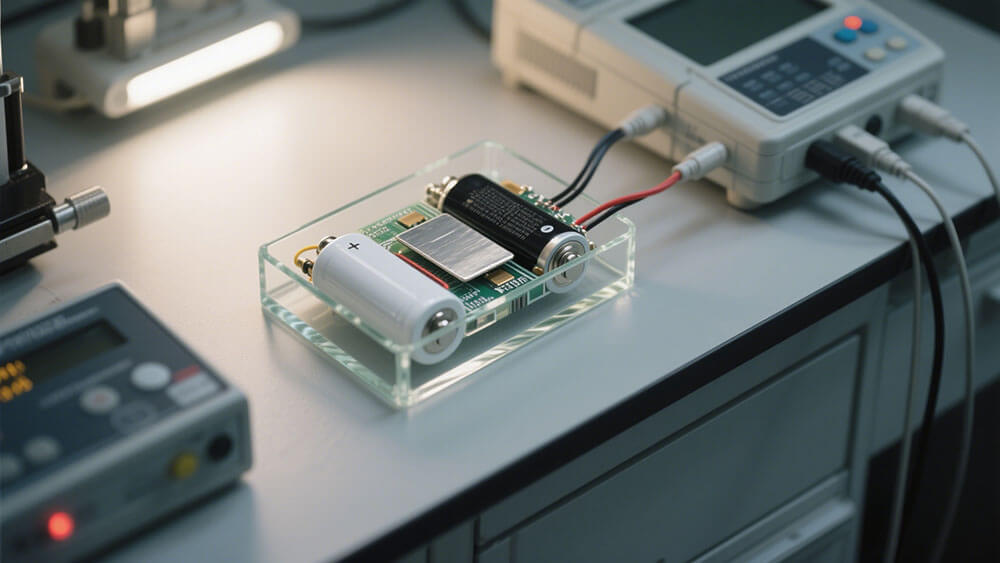

2.4 Charging Speed and Efficiency

Charging speed impacts operational efficiency, especially for applications requiring quick turnaround times. Fast-charging batteries, such as lithium-ion, are ideal for minimizing downtime. However, the charger must match the battery’s specifications to ensure safe and efficient charging.

Key factors to consider include:

Charger Voltage and Amperage: These must align with the battery’s requirements to prevent undercharging or overcharging.

Thermal Management: High-speed charging generates heat, necessitating advanced cooling systems.

Energy Efficiency: Efficient chargers reduce energy loss during the charging process, lowering operational costs.

For industrial users, selecting the right charger is as important as choosing the battery itself. A guide on industrial battery chargers highlights the importance of voltage, amperage, and safety features in ensuring compatibility and performance.

Matching charging speed and efficiency to your application needs enhances productivity and prolongs battery life. For customized charging solutions, explore Large Power’s consultation services.

Part 3: Compare Different Types of Large Batteries

3.1 Lithium-Ion (Li-ion): Features and Applications

Lithium-Ion batteries are widely recognized for their high energy density and efficiency, making them a preferred choice for various applications. These batteries offer energy densities of up to 270 Wh/kg, enabling compact designs without compromising performance. Their cycle life typically reaches 2,000 cycles at 80% depth of discharge, ensuring longevity in demanding environments.

Applications for Lithium-Ion batteries include:

Frequency regulation and peak shifting in energy storage systems.

Integration with renewable energy sources, such as solar and wind power.

Power management in consumer electronics and industrial systems.

These batteries also excel in fast-charging capabilities, with energy efficiencies exceeding 95%. However, their thermal management systems are critical to prevent overheating during high-power operations.

3.2 Lithium Iron Phosphate (LiFePO4): Features and Applications

LiFePO4 Lithium batteries are known for their exceptional safety and durability. With a cycle life of 2,000–5,000 cycles, they outperform many other chemistries in longevity. Their thermal stability minimizes risks of thermal runaway, making them ideal for high-power applications like electric vehicles and industrial systems. Learn more about LiFePO4 batteries.

Key features include:

Energy Density: 100–180 Wh/kg, lower than Lithium-Ion but sufficient for stationary and industrial uses.

Safety: Superior thermal stability ensures reliable performance in extreme conditions.

Lifespan: Up to 5,000 cycles under optimal conditions.

Applications span across electric vehicles, renewable energy storage, and industrial systems requiring consistent power delivery. Their lower environmental impact and extended lifespan make them a sustainable choice for businesses prioritizing long-term value.

3.3 Key Differences Between Li-ion and LiFePO4

Understanding the differences between Lithium-Ion and LiFePO4 batteries helps you select the best option for your application. While Lithium-Ion batteries offer higher energy density, LiFePO4 batteries excel in safety and longevity.

Feature | Lithium-Ion (Li-ion) | Lithium Iron Phosphate (LiFePO4) |

|---|---|---|

Energy Density | 160–270 Wh/kg | 100–180 Wh/kg |

Safety | Prone to thermal runaway | Greater thermal stability |

Lifespan | 500–2,000 cycles | 2,000–5,000 cycles |

Applications | Consumer electronics, portable | EVs, industrial, stationary |

LiFePO4 batteries are ideal for high-power, long-term applications, while Lithium-Ion batteries suit compact, energy-dense systems. For tailored recommendations, consult Large Power’s experts.

Part 4: Evaluate Battery Quality, Safety, and Compatibility

4.1 Look for Safety Certifications (e.g., UL, CE, UN38.3)

Safety certifications validate the quality and reliability of batteries, ensuring they meet industry standards. When selecting large batteries, prioritize those with certifications like UL, CE, and UN38.3. These certifications confirm that the batteries have undergone rigorous testing for performance, safety, and environmental compliance.

Certification | Description |

|---|---|

UL Certification | Ensures performance, reliability, and safety of battery cells. |

UN38.3 Certification | Tests for mechanical, electrical, and thermal safety during transportation. |

CE Certification | Indicates conformity to EU health, safety, and environmental standards. |

RoHS Certification | Regulates hazardous substances in battery manufacturing. |

MSDS Report | Provides safety information for handling battery chemicals. |

For global trade, UN38.3 certification is essential, as it ensures safe transportation of lithium-ion batteries through tests like altitude simulation and thermal cycling. Additionally, compliance with IEC 62133 guarantees environmental, mechanical, and electrical safety. These certifications not only protect your investment but also ensure operational safety.

4.2 Ensure Compatibility with Your Equipment

Battery compatibility with your equipment is critical for seamless operation. Mismatched batteries can lead to inefficiencies, overheating, or even system failures. Start by verifying the voltage, capacity, and connector type of the battery. For example, lithium-ion batteries with a nominal voltage of 3.6V are ideal for high-performance systems.

Consider the following steps to ensure compatibility:

Match the battery’s voltage and capacity with your equipment’s requirements.

Verify the physical dimensions and connector types.

Check for compatibility with the Battery Management System (BMS) to optimize performance and safety.

Proper compatibility reduces downtime and enhances the lifespan of both the battery and your equipment. For tailored solutions, consult Large Power’s experts.

4.3 Consider Warranty and After-Sales Support

A robust warranty and reliable after-sales support reflect the manufacturer’s confidence in their product. Analyze warranty terms to understand coverage for defects, performance issues, and lifespan guarantees. Manufacturers offering extended warranties often use higher-quality materials and production processes.

Effective after-sales support ensures you receive assistance for troubleshooting, maintenance, and replacements. Proper maintenance, as outlined in warranty guidelines, can significantly extend battery life and reduce claims. For instance, customers who align their usage with warranty terms report fewer issues and enjoy longer battery performance.

“Crown’s reliability eliminated about 95% of our warranty batteries – and made a huge impact on our bottom line. We’re spending less time testing batteries and more time selling them.” – Ben Sverdlow, Jeffrey Allen’s President.

Partnering with manufacturers that prioritize customer support ensures long-term value and operational efficiency. Explore Large Power’s customized solutions for reliable batteries and exceptional service.

Selecting the right rechargeable batteries for your application ensures optimal performance and safety. You must evaluate your specific requirements, including power needs, environmental conditions, and equipment compatibility. Prioritize high-quality rechargeable options with proven safety certifications. Collaborate with reputable suppliers and consult experts to tailor solutions for your needs. This approach guarantees long-term reliability and efficiency.

Tip: For customized rechargeable battery solutions, consult Large Power’s experts.

FAQ

1. What is the best lithium battery type for industrial applications?

LiFePO4 Lithium batteries are ideal for industrial applications due to their long cycle life, thermal stability, and high safety standards. Explore industrial battery solutions.

2. How do I ensure my battery is compatible with my equipment?

Match the battery’s voltage, capacity, and connector type with your equipment. Verify compatibility with the Battery Management System (BMS). Learn more about BMS technology.

3. Why should I choose Large Power for custom battery solutions?

Large Power offers tailored solutions, expert consultation, and reliable after-sales support. Their batteries meet industry standards for safety and performance. Consult Large Power’s experts.