Contents

The difference between LiFePO4 robot batteries and traditional lithium-ion batteries is remarkable. LiFePO4 robot batteries can last for up to 10,000 cycles, while traditional lithium-ion batteries reach only 1,200 cycles. This stark contrast shows why choosing and maintaining the right battery determines your robot’s performance.

Your robot vacuum’s battery life can make or break its consistent operation. Battery chemistry plays a substantial role – LiFePO4 batteries resist thermal runaway and won’t combust. These features make them safer than standard Li-ion options for mobile robots.

Cool temperatures help batteries perform better and extend their lifespan. Research shows that batteries lose about 0.1V monthly when idle. Scientists are developing structural batteries that combine smoothly with robot frames. These innovations could double energy capacity and reduce weight at the same time.

The right knowledge can extend your robot’s operational life, whether you own an irobot or any battery-powered robot. This piece will teach you proven methods to boost your robot battery’s performance and help you direct your path through the changing world of robot power systems.

Battery Basics: How Are Robots Powered?

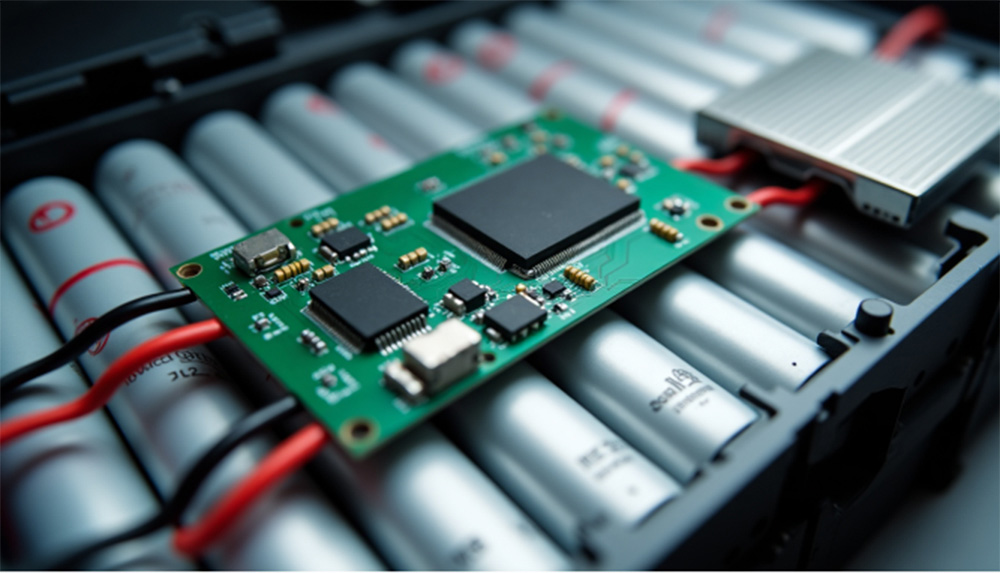

Image Source: Battery Power Tips

Batteries power the heart of modern robotics. They provide portable power that runs everything from robot vacuums to complex industrial machines. These power sources deliver instant electrical energy without emissions, moving parts, or hot components. This makes them perfect for most robot applications.

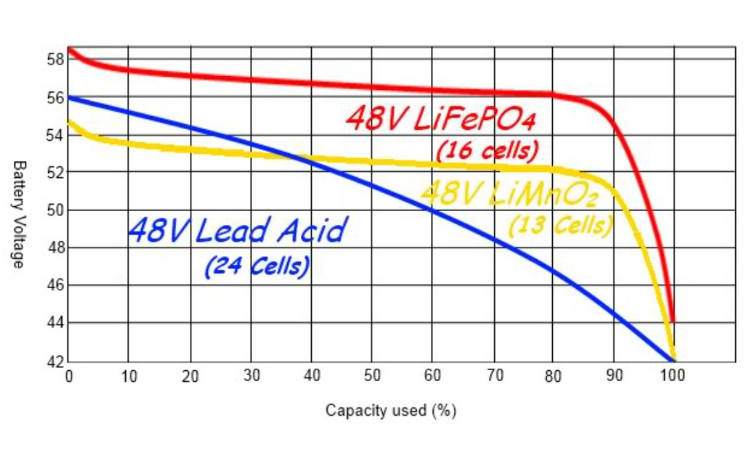

Understanding voltage, capacity, and discharge rates

Robot batteries combine multiple electrochemical cells that work together to deliver power. Each cell creates a specific voltage based on its chemistry. Lithium cells produce 3.7 volts per cell. Cells connected in series create higher voltages that match what robots need.

Battery capacity shows how much energy a battery stores. It’s measured in milliamp-hours (mAh) or amp-hours (Ah). You can see capacity as your robot’s “fuel tank.” A 5000mAh battery delivers 5000mA (5A) of current for one hour before it runs out. Your robot vacuum’s battery life depends on this spec – bigger capacity means more runtime between charges.

C-rate tells you how fast a battery safely releases stored energy. A 1C rate means the battery drains in one hour, while 2C means it drains in 30 minutes. This spec is vital because it determines how well robot powers perform under load.

Robot batteries come with continuous and burst discharge rates. Continuous rates show sustainable current output. Burst rates last up to 10 seconds and allow brief high-power operations. Your robot battery pack can overheat and suffer permanent damage if you exceed these limits.

Two key factors determine battery performance: energy density and power density. Energy density shows stored energy per unit volume/weight. Power density reveals maximum power output. These specs help you choose between batteries for lightweight flying robots or heavy ground machines.

Batteries naturally lose charge during storage. Most batteries lose 0.5-5% charge monthly, depending on their chemistry. Robot dog batteries typically drop about 0.1V each month when not used.

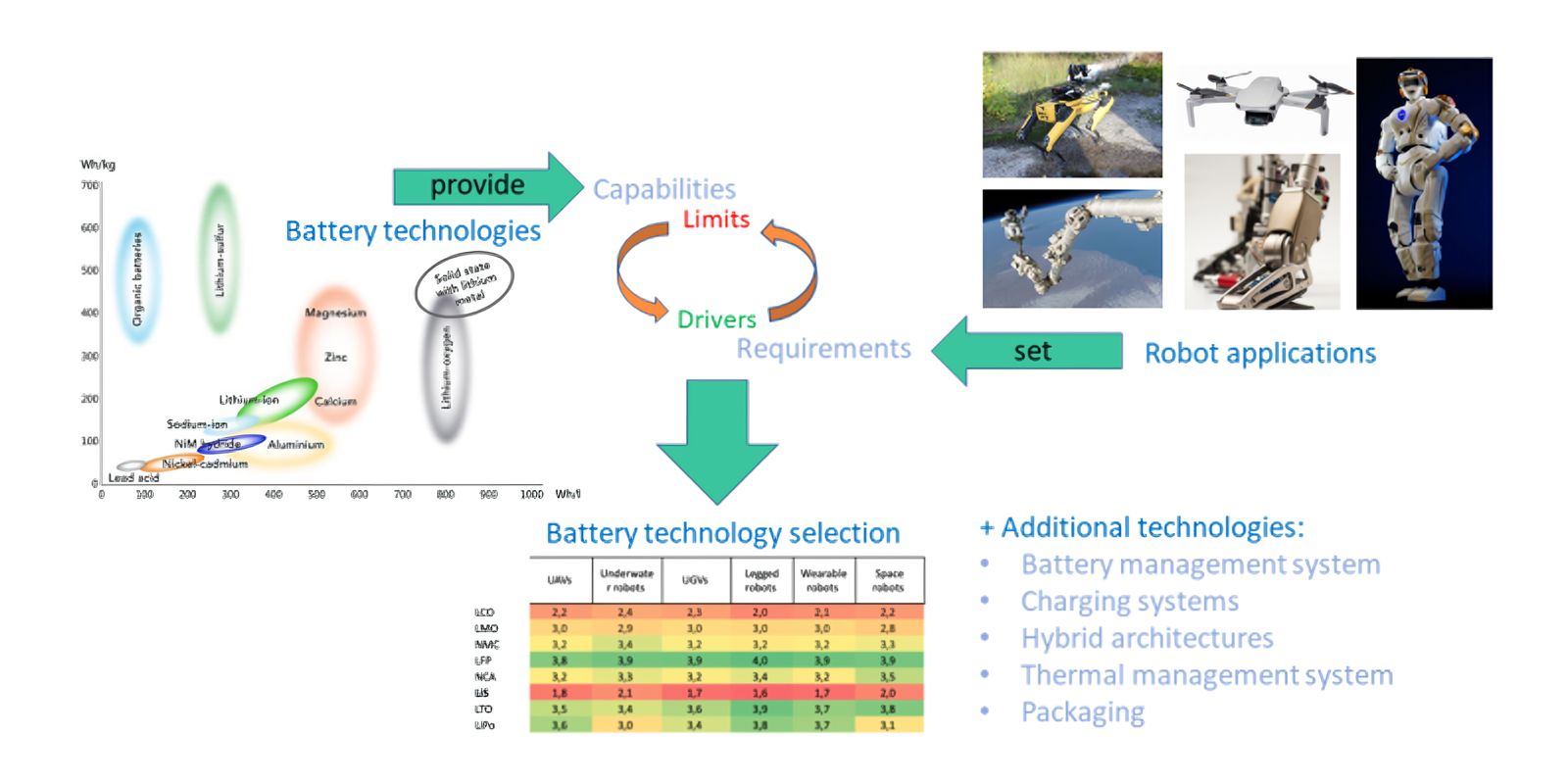

Different battery chemistries explained simply

Lithium-ion (Li-ion) batteries lead the pack in modern battery operated robots. They pack more energy per size, letting robots run longer between charges. This makes them great for drones and mobile robots. They need smart battery management systems to stay safe and avoid overheating.

Lithium Polymer (LiPo) batteries use a polymer electrolyte instead of liquid. This creates thin, flexible designs that fit tight spaces in robots. They deliver power fast enough for quick, precise movements but break more easily than other types.

Lead-acid batteries still work well in robotics despite their age. Stationary robots use them because they’re cheap and reliable when weight doesn’t matter. They’re too big and don’t last long enough for most modern mobile robots.

Nickel-Metal Hydride (NiMH) batteries balance cost and performance well. They offer safer, greener alternatives with decent power at good prices. Low internal resistance and great power-to-weight ratios make them perfect for robots that need steady performance.

Emerging technologies like solid-state batteries point to robotics’ future. These use solid electrolytes instead of liquids, which makes them safer and better performers with more energy density. They last longer and have lower thermal risks, but high costs limit their use today.

Each chemistry brings unique benefits. LiFePO4 batteries handle high temperatures without breaking down. They also deliver more power density and last longer than standard lithium-ion options. LiFePO4 can last through 3,500 charge cycles, while standard lithium-ion typically stops at 1,200 cycles.

Robot owners must balance energy needs, weight limits, environment, and budget when picking battery chemistry. The right choice helps your robot work efficiently throughout its life.

Choosing the Right Robot Battery Pack

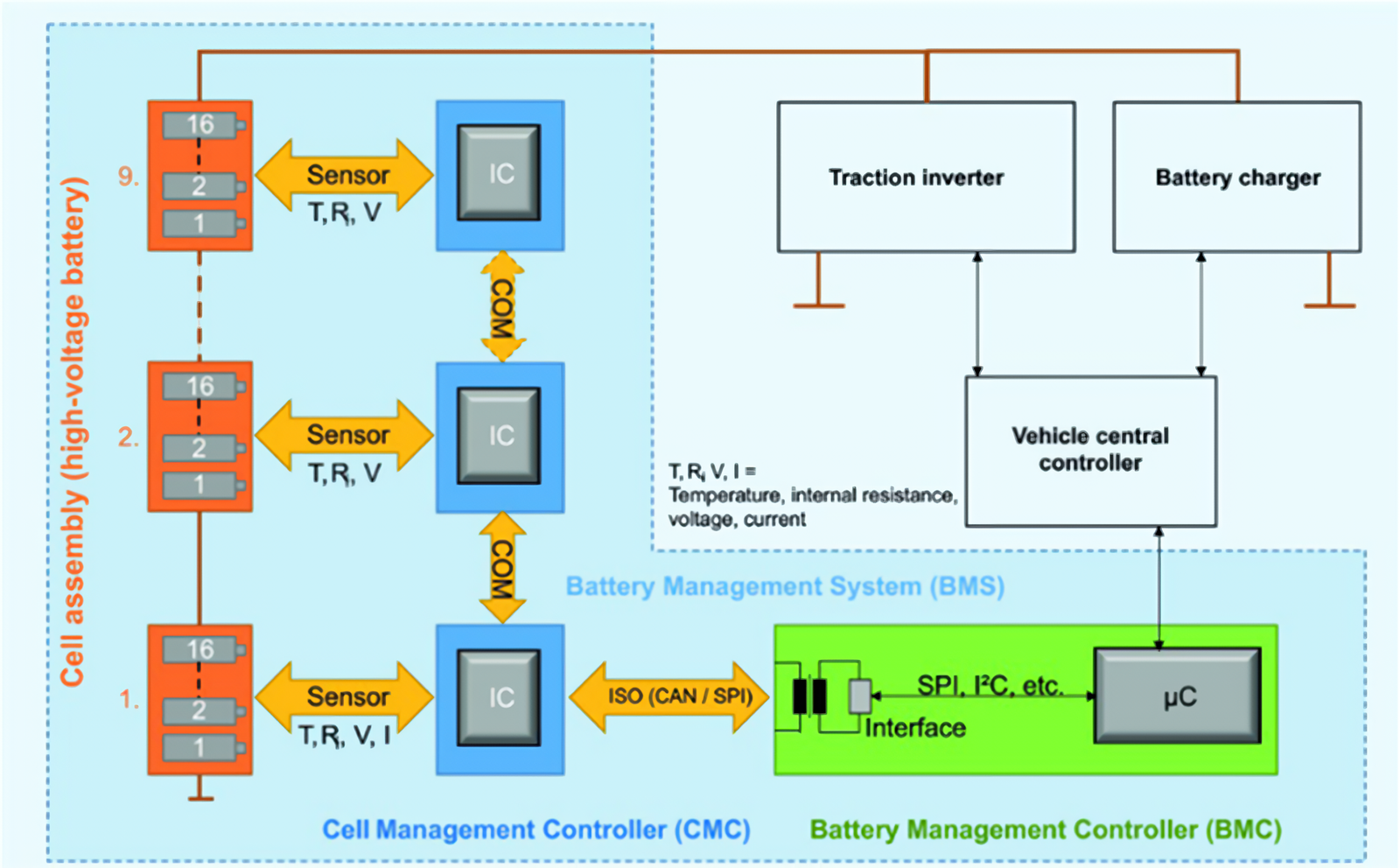

Image Source: MDPI

Your robot’s performance depends on choosing the right power source. Each robot needs a specific type of battery based on its unique requirements.

Factors to consider: size, weight, energy needs

Battery selection depends on your robot’s physical limits. Small robots like vacuum cleaners need compact batteries – usually under 300 cubic centimeters and lighter than 500 grams. Bigger autonomous robots have more room to work with. Industrial robots can use batteries up to 3500 cubic centimeters and 6 kilograms.

The way you distribute weight matters because batteries make up much of a robot’s total weight. Small automated guided vehicles (AGVs) that carry light loads have battery packs that take up most of their weight. This means high energy density batteries are vital to keep the weight low while running longer.

Different robots need different voltages. Small mobile robots usually run on 10-12V nominal voltage, while bigger autonomous systems might need 36V or more. To cite an instance, see the Spot robot dog that runs on 35-58.6V DC. Using the wrong voltage can make your robot run poorly or damage its electrical parts.

Your robot’s power needs should line up with its battery’s discharge abilities. You need to figure out both normal and maximum discharge currents based on your parts’ specs. Small robots might need 5.4A normal current, but industrial models could need 27A or more. The Spot robot dog can use up to 47A during peak use.

Battery capacity affects how long your robot runs – this is a big deal for practical use. Robot vacuum batteries need at least 6000mAh to run for 40-60 minutes at 6A average current. The Spot robot dog’s battery lasts about 90 minutes during normal use or four hours in standby mode.

The environment affects how well batteries work. Robots working in extreme temperatures need special batteries. The Spot robot’s battery works well between -20°C to 45°C, though batteries can heat up to 75°C while running. Some lithium-ion batteries keep 90% of their power even at -20°C.

The type of ground your robot moves on changes how much power it uses. Rough, uneven, or steep surfaces need more power. All-terrain robots need bigger batteries or better power management.

Here’s what to think about when picking a robot battery:

- Operational requirements: Daily run time, duty cycle, and standby periods

- Physical constraints: Available space and weight limitations

- Environmental conditions: Temperature ranges, humidity, and vibration exposure

- Safety requirements: Especially important for home-use robots

- Maintenance capabilities: Charging infrastructure and replacement accessibility

When to upgrade your irobot battery or robot dog battery

You’ll need to replace your battery based on several things. iRobot Roomba batteries usually last 1-2 years depending on how you use and maintain them. With good care, a single iRobot Roomba battery can handle hundreds of cleaning cycles.

Your robot battery needs replacement when you notice these warning signs:

The most obvious sign is shorter running time. Your battery needs replacement if your robot vacuum cleans for less time between charges. Having to recharge often after cleaning small areas means your battery is wearing out.

Bad charge retention is another red flag. Your battery might be failing if it loses power quickly when not in use. Roomba batteries turn off by themselves if they’re removed for more than 15 minutes.

Robot dog owners should watch their battery’s performance closely. A good Spot robot battery keeps its cell voltage difference under 0.1V when starting up. Higher voltage differences still work but aren’t ideal and might cause problems later.

Different batteries last for different amounts of time. The Spot robot battery should last 500 cycles before dropping to 80% capacity. Older Roomba models with NiCad batteries didn’t last as long as the new lithium ones.

Make sure you buy the right replacement battery for your model. The Roomba lithium-ion replacement battery works with e, i, and j series robot vacuums except j9+, Roomba Combo j7+, j9+, or 10 Max robots. Robot dog batteries must match your specific model – the CHiP robot dog uses two 18650 lithium-ion batteries.

Best Practices for Charging and Discharging

You can double or maybe even triple your robot’s battery life with the right charging habits. Modern robot batteries need specific care – forget the old advice about “running batteries down completely.”

Ideal charging cycles for robot vacuum battery life

Quality robot batteries typically last about 500 full charge-discharge cycles before they start losing power. The way you handle these cycles will affect how long your battery lasts.

Your robot battery works best when you recharge it at 20%-30% remaining power. Letting the battery run completely empty speeds up its wear and tear. Constant charging when the battery is almost full puts extra stress on the cells too.

Here’s what you should do to keep your robot vacuum battery healthy:

- Unplug when fully charged – Take your robot off the charger once it hits 100% to avoid overcharging

- Avoid deep discharges – Start charging before power drops below 20%

- Use smart charging systems – Newer iRobot models come with tech that makes charging more efficient

- Store at 50% charge – Keep the battery at half power during long breaks

Regular use helps your robot battery stay healthy. Robots left unused lose about 0.1V each month. This slow power drain can damage the battery if you ignore it too long.

Temperature control is vital for battery care. Heat and cold can quickly damage any type of battery. Keep your robot in a closet inside your house instead of an unheated garage or shed where temperatures swing up and down.

How to avoid battery memory effect

People often talk about “memory effect” in batteries, but many get it wrong. This issue mainly affects older nickel-cadmium (NiCd) batteries when crystals form inside after partial charging cycles.

The lithium-ion batteries in most robots today don’t have true memory effect. They can show signs of “voltage depression” though, which looks similar but happens for different reasons when you charge and discharge them the same way repeatedly.

Your robot vacuum will work better if you condition the battery now and then. Let it run until it’s almost empty (but not completely) before a full recharge. This helps the battery management system track power levels accurately.

Industrial robots with nickel-cadmium batteries need complete discharge cycles down to 0.6V to break up crystal buildup. For home robots, makers usually say to fully discharge NiCd batteries every three months.

Robot dogs and advanced robots often have smart systems that handle most maintenance. Still, manual fine-tuning helps, especially after using the robot the same way for a long time.

The best battery life comes from following the maker’s charging guidelines. iRobot wants you to keep the robot plugged in when it’s not cleaning and charge it right after use. Other robots need unplugging after a full charge, so check what your model needs.

Signs Your Robot Battery Needs Attention

Image Source: Redway Power

Early detection of battery deterioration protects you from unexpected robot downtime and safety risks. Robot batteries will show signs of wear that need quick attention, no matter how well you maintain them.

Reduced runtime and slow charging

Your first clue about battery problems usually comes from shorter operation time. A robot vacuum that once cleaned for an hour but now stops after 40 minutes clearly shows its battery capacity is dropping. ECOVACS robot vacuum owners often notice this runtime reduction as their batteries approach their typical 2-3 year lifespan.

Charging problems usually come along with reduced runtime. A healthy robot battery takes 3-4 hours to charge fully from empty. Your robot battery pack probably needs replacement if charging becomes too slow—like one Roborock S7 owner who reported only 8% charge after 4.5 hours.

Temperature plays a big role in charging speed. Robots automatically slow down charging in temperatures below 0°C or above 40°C to protect their batteries. This safety feature is normal but people sometimes mistake it for battery failure. Your robot needs to operate within recommended temperature ranges for the best charging results.

Bad electrical connections can look like battery failure too. Dirty charging contacts between your robot and its charging station create resistance that slows down power transfer. You can fix apparent charging issues without replacing the battery by cleaning these contacts regularly with a dry cloth.

Swelling, overheating, and other warning signs

A swollen battery ranks among the most serious warning signs. You’ll notice the battery looks visibly bulged compared to how it started. This happens because of gas buildup inside from chemical breakdown, usually caused by overcharging or too much heat.

Physical signs include:

- Device deformation – Battery swelling creates gaps or bulges in your robot’s casing

- Uneven movement – Your robot tilts, moves unstably, or changes direction unexpectedly due to internal weight changes

- Difficulty fitting in charging dock – Physical changes stop proper contact with charging terminals

Heat warnings should raise immediate safety concerns. Batteries normally feel slightly warm during charging, but a battery that’s very hot to touch shows internal damage. Stop using the battery right away if you hear hissing, cracking, or popping sounds from lithium-ion batteries.

Strange performance often comes before total failure. Flying robots that pitch or roll erratically usually have battery problems, even when systems show normal operation. Your robot vacuum needs immediate battery attention if turning on features like headlights causes big power drops.

Chemical smells from your robot point to dangerous internal reactions. Stop using it immediately and dispose of it properly to prevent fires. You also need to act quickly if you see any leakage around battery compartments.

Regular battery checks help extend your robot’s life and prevent dangerous situations. Replacing declining batteries before they damage your robotics investment makes sense when you spot these warning signs early.

Advanced Tips to Maximize Battery Lifespan

Image Source: Planet Analog

Smart electronics and technology can extend your robot battery’s operational life well beyond simple charging practices. These systems work behind the scenes to protect your investment and optimize performance.

Using smart chargers and battery management systems

Battery management systems (BMS) are electronic control circuits that monitor and regulate charging and discharging cycles. They optimize your battery’s stored energy usage. These advanced systems guard against common battery issues like deep discharge and over-voltage that occur from extreme fast charging or high discharge currents.

BMS technology gives multi-cell robot batteries essential cell balancing capabilities. Your battery pack stays healthy because all cells charge and discharge uniformly, which prevents single cell failures from affecting the entire unit.

Smart chargers work alongside BMS to optimize voltage levels during charging. They prevent quick charging cycles that can damage robot batteries. The VEX Smart Charger v2 showcases this with its dual charge rates and automatic shutoff features designed specifically for robots.

Your device specifications should guide your choice of charging equipment. Cheap alternatives often lead to uneven charging and dangerous overheating. Quality chargers protect your robot vacuum battery and improve its safety and lifespan.

Calibrating your robot battery periodically

Regular calibration helps robots maintain accurate power readings and perform better. Daihen robot users discovered that calibration became crucial after battery replacement to restore accurate positioning.

The calibration process involves these steps:

- Fully charging your robot battery

- Running it until nearly depleted (but avoiding complete discharge)

- Recharging completely without interruption

This process resets your robot’s internal power monitoring system and ensures accurate capacity reporting. Roomba i7 users found that without proper calibration, their robots couldn’t use larger replacement batteries effectively. Their units ran for only 50 minutes with 3200mAh batteries that should last longer.

Calibration becomes crucial after long periods of consistent usage patterns to prevent voltage depression, which mimics memory effect in lithium batteries.

Future-Proofing: Preparing for New Battery Technologies

Robot battery technology is about to take a huge leap forward by solving many problems with current power systems. Traditional lithium-ion batteries don’t deal very well with advanced power needs as robots become more sophisticated. This creates opportunities for new breakthroughs.

Solid-state batteries and what they mean for robot powers

Solid-state batteries are one of the most exciting developments for future robot battery systems. These advanced power sources use solid alternatives instead of liquid electrolytes, unlike conventional lithium-ion batteries. This leads to remarkable improvements in several areas.

The energy density advantage is a big deal as it means solid-state batteries deliver two to three times more energy density than traditional lithium-ion batteries. Robots can now run longer between charges or keep the same runtime with smaller, lighter battery packages.

The safety improvements stand out too. Solid-state designs resist leakage or short circuits better by design, which makes robot operations and user safety more reliable. These batteries reduce fire risks in manufacturing environments, making them ideal for industrial use.

Battery life is another key advantage. All-solid-state batteries in encoders work well at temperatures up to +125°C and last around 20 years. This is much longer than typical electronic components that usually work for about 5 years. The extended lifespan cuts down maintenance needs and overall ownership costs.

How emerging tech will affect battery operated robots

Several other breakthroughs are changing robot power systems among solid-state technology. Zinc batteries (also called biomorphic batteries) solve many problems with lithium-ion technology through recyclable, affordable designs. These batteries work by moving hydroxide ions through a zinc electrode while air moves through an electrolyte membrane.

Robotics and battery research work together to create better results. Robotics pushes battery chemistry forward through high-throughput experiments and data analysis. Better power sources then lead to more capable robots, creating an ongoing cycle of improvement.

AI and machine learning speed up battery innovation. AI algorithms look at massive amounts of data during manufacturing and testing to make production processes better in real time. Machine learning models can predict how well batteries will work and how long they’ll last based on manufacturing details. This helps create more efficient and durable batteries.

Robot owners who want to protect their investments should learn about these emerging technologies. The next wave of battery operated robots will run longer, charge faster, and need less maintenance. They’ll also be much safer to use.

Conclusion

Good battery maintenance is the life-blood of keeping your robot running reliably. This piece explores how battery chemistry, charging practices, and environmental factors affect your robot’s operational lifespan by a lot. LiFePO4 batteries offer high advantages for most robotic applications with their impressive 10,000-cycle potential. Each chemistry type comes with unique benefits based on what you need.

Taking care of your battery goes beyond just charging it right. Your robot’s battery can last months or years depending on how well you calibrate, manage temperature, and watch for warning signs. Cool batteries perform better, and you should pay special attention to temperature control. Heat speeds up degradation in all battery types.

Smart chargers and battery management systems add extra protection by optimizing charging cycles automatically and stopping harmful deep discharges. Keeping up with state-of-the-art technology like solid-state batteries helps you prepare for next-gen robot power sources that promise better energy density, safety, and longevity.

Each robot application comes with its own power challenges. Our experts can help design the best power systems that match your exact needs. Feel free to reach out to us about any custom battery solutions.

Note that consistent and informed battery maintenance gets real results. These practical tips come from robotics professionals who use them every day. Your robot will need a new battery someday, but these guidelines help you get the most performance and life from your current one.

FAQs

Q1. How often should I charge my robot vacuum?

For optimal battery life, charge your robot vacuum when the battery level drops to 20-30%. Avoid letting it fully deplete or constantly topping it off when nearly full. Most high-quality robot batteries can handle about 500 full charge-discharge cycles before performance declines.

Q2. What are the signs that my robot’s battery needs replacement?

Key indicators include significantly reduced runtime, slow charging, physical swelling of the battery, overheating during operation, and erratic robot behavior. If your robot vacuum struggles to complete tasks it once handled easily, it may be time for a battery replacement.

Q3. Can I use any charger for my robot?

It’s crucial to use manufacturer-recommended chargers that match your device specifications. Low-quality alternatives can cause uneven charging and dangerous overheating. Quality chargers not only protect your robot’s battery but also improve overall safety and lifespan.

Q4. How does temperature affect my robot’s battery performance?

Temperature significantly impacts battery performance. Extreme heat or cold can accelerate battery degradation. For optimal performance, store and operate your robot in temperature-controlled areas, avoiding unheated garages or outdoor sheds that subject batteries to harmful temperature fluctuations.

Q5. What are solid-state batteries, and how will they impact robotics?

Solid-state batteries are an emerging technology that replaces liquid electrolytes with solid alternatives. They offer 2-3 times the energy density of traditional lithium-ion batteries, improved safety, and longer lifespans. For robotics, this means longer operation times between charges, reduced fire risks, and potentially smaller, lighter battery packages.