Contents

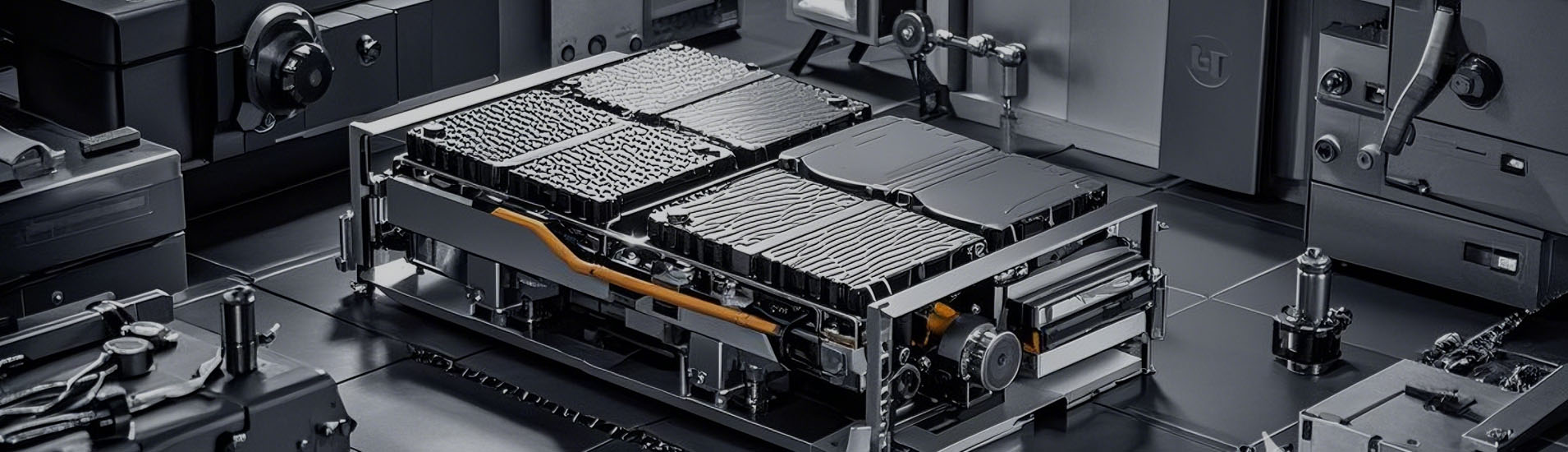

A well-planned 24V lithium battery design is vital for industrial and commercial applications. The increasing demand for lithium-ion batteries highlights their importance in sectors like electric vehicles and renewable energy. Modular and scalable designs demonstrate how advanced batteries meet diverse operational needs. Building a custom battery pack offers significant benefits. You can achieve cost efficiency by reducing capital expenditure fivefold per GWh, accelerate production by up to 25%, and unlock flexibility to manufacture various configurations on the same line. Addressing configuration, and safety ensures optimal battery performance while meeting your specific requirements.

Key Takeaways

Making your own 24V lithium battery pack can save a lot of money. DIY packs cost less than one-third of ready-made ones.

Choosing the right setup—series or parallel—is important. It helps your battery pack meet the needed voltage and power.

Adding a strong Battery Management System (BMS) is very important. It keeps the battery safe, balanced, and lasting longer.

Part 1: Core Design and Configuration Options for 24V Lithium Battery

1.1 Cell Chemistry Selection and Configuration

Designing a 24V lithium battery pack involves selecting a chemistry that aligns with specific application needs, balancing energy density, safety, and longevity.

Li-ion (Lithium-ion):

Voltage per Cell:

Nominal voltage: 3.6–3.7V (varies by chemistry, e.g., NMC, LCO).

Fully charged: 4.2V; discharged: 2.8–3.0V (per cell).

Advantages:

High energy density, Moderate cycle life (500–2,000 cycles), suitable for compact applications like portable electronics.

Disadvantages:

Thermal sensitivity (prone to thermal runaway if damaged or overcharged), aging during storage (degrades faster when stored at full charge), moderate safety (Requires strict BMS oversight compared to LiFePO4).

Configuration:

Requires 7 cells (e.g.,3.6V per cell) in series (7S) to achieve a nominal voltage of 25.2V (closest to 24V systems).

LiFePO4 (Lithium Iron Phosphate):

Voltage per Cell:

Nominal voltage: 3.2V.

Fully charged: 3.65V; discharged: 2.5V (per cell).

Advantages:

Superior thermal stability, longer cycle life (2,000–5,000 cycles), and safer operation (less prone to thermal runaway), Low self-discharge (~2–3% per month), ideal for long-term storage. Nominal voltage: ~3.2V per cell.

Disadvantages:

Lower energy density (~100–180 Wh/kg vs. Li-ion’s up to 300 Wh/kg), Higher weight and volume for the same capacity compared to Li-ion.

Configuration:

Requires 8 cells in series (8S) to reach 25.6V. Ideal for industrial or automotive applications.

LiPo (Lithium Polymer):

Voltage per Cell:

Nominal voltage: ~3.6V (similar to Li-ion).

Fully charged: 4.2V; discharged: 3.0V (per cell).

Advantages:

Flexible packaging for custom shapes, lightweight. Nominal voltage: ~3.6V.

Disadvantages:

Lower energy density than Li-ion (but better than LiFePO4), Sensitive to physical damage (e.g., punctures, swelling), Shorter cycle life (~300–500 cycles at 80% depth of discharge).

Configuration:

Requires 7 cells in series (7S) to achieve a nominal voltage of 25.2V.

Comparison of Configurations

Parameter | LiFePO4 (8S) | Li-ion (7S) | LiPo (7S) |

|---|---|---|---|

Voltage | 25.6V | 25.9V | 25.9V |

Energy Density | Low (~100–180Wh/kg) | High (up to 270Wh/kg) | Moderate (~150–200Wh/kg) |

Typical Use Case | Long-term, high-safety | Portable, high-energy | Custom, high-power |

Cycle Life | 2,000–5,000 cycles | 500–2,000 cycles | 300–500 cycles |

Understanding these battery cell chemistry performance from Large Power helps you select and design suitable 24V battery pack.

1.2 Series-Parallel Configuration About Your 24V Lithium Battery Design

Designing a 24V lithium battery pack requires careful planning of series and parallel cell arrangements to achieve the desired voltage, capacity, and power output. Series connections define the pack voltage, while parallel connections determine capacity and current capability. By carefully balancing series-parallel configurations with application needs, you can optimize a 24V lithium battery pack for efficiency, safety, and durability.

To build a 24V nominal system (Take Li-ion as an example) :

Series Calculation:

Nominal voltage per cell: 3.6–3.7V (use 3.6V for conservative design).

Required cells in series (S):

Nominal voltage: 7×3.6V=25.2V7×3.6V=25.2V (standard for 24V systems).

Fully charged voltage: 7×4.2V=29.4V7×4.2V=29.4V.

Capacity Expansion (Parallel):

Parallel connections (P) increase capacity (Ah).

Example:

7S2P = 7 cells in series + 2 in parallel.

If each cell is 3Ah, total capacity = 2×3Ah=6Ah.

Total energy: 25.2V×6Ah=151.2Wh.

While DIY solutions provide series-parallel configuration, you require careful planning to ensure performance and power for your equipment. Customization from Large Power enhance capabilities for your 24V lithium battery packs, making them a preferred choice for businesses seeking tailored solutions.

1.3 Accounting for Additional Design Components: Mechanical Design, Current and Power Requirements

Mechanical robustness and precise alignment with power demands are equally critical to ensure safety, longevity, and performance.

Mechanical Design Considerations

Housing Design:

Material Selection:

Use flame-retardant plastics (e.g., ABS+PC blends) or metal casings (aluminum for lightweight, steel for ruggedness) to contain thermal events and resist impacts.

For LiPo packs, semi-flexible enclosures with puncture-resistant layers (e.g., Kapton tape) are essential.

Environmental Protection:

Select enclosures rated for dust/water resistance (e.g., IP65 for outdoor solar storage, IP67 for marine use). Incorporate rubber mounts or foam padding for 24V lithium battery packs.

Cell Arrangement and Spacing:

Cylindrical Cells (e.g., 18650):

Arrange in rigid modules with cell holders or honeycomb trays to prevent movement.

Leave 1–2mm gaps between cells for airflow and thermal expansion tolerance.

Prismatic/Pouch Cells:

Apply compression plates or fixtures to manage swelling (common in LiFePO4 and LiPo).

Use thermally conductive pads between cells to distribute heat evenly.

Understanding these cost contributions helps you allocate resources effectively and design a battery pack that balances performance and budget.

Current and Power Requirements

Current Demand Analysis:

Continuous Current:

Calculate based on the application’s peak power draw (e.g., 30A for an e-bike motor).

Ensure cells and BMS can handle this current without overheating (e.g., LiFePO4 cells rated for 1C–3C).

Peak Current:

Account for short-term surges (e.g., 100A for power tool startups) and select cells with high pulse ratings (e.g., LiPo at 50C).

Power Capacity Sizing:

Energy (Wh):

Total energy = Nominal voltage × Capacity (e.g., 25.6V × 20Ah = 512Wh for solar storage).

Runtime Estimation:

Runtime (hours) = Total energy (Wh) ÷ Average power draw (W).

By harmonizing mechanical robustness with precise power handling, a 24V lithium battery pack can deliver reliable performance across diverse applications, from portable electronics to industrial systems.

By understanding these configuration options, you can design a 24V lithium battery pack that meets your specific voltage and capacity requirements while ensuring optimal performance and safety.

Part 2: Safety and Performance Optimization

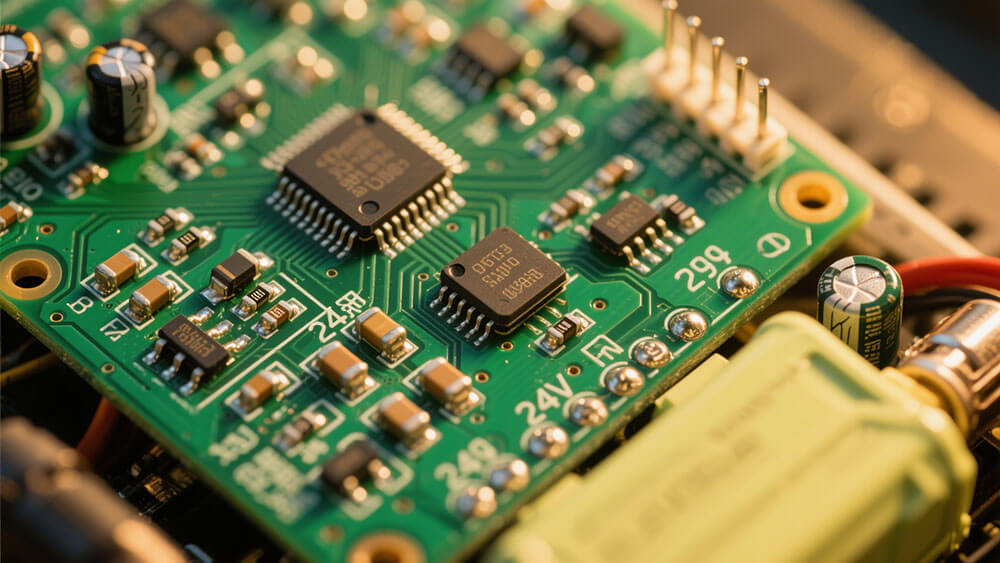

2.1 Selecting High-Quality Components for Safety

Choosing high-quality components is essential for ensuring the safety and reliability of your battery pack. Rigorous quality assurance practices help identify potential issues early and maintain consistent performance. These practices include material testing, cell testing, and module compatibility assessments.

Quality Assurance Practice | Description |

|---|---|

Rigorous Testing Protocols | Detects and resolves potential issues early, enhancing safety. |

Material Testing | Ensures battery cell materials meet quality standards. |

Aging Tests | Simulates long-term effects to assess durability and performance degradation. |

High-quality components reduce the risk of thermal runaway and improve the lifespan of your battery pack. For industrial applications, investing in reliable materials and testing protocols ensures operational stability and minimizes downtime.

Tip: Prioritize components that undergo aging tests to ensure durability under demanding conditions.

2.2 Preventing Overcharging and Overdischarging

Preventing overcharging and overdischarging is critical for maintaining the safety and efficiency of your battery pack. Advanced mechanisms like precise voltage threshold control and multi-level hardware protection safeguard against these risks.

Mechanism | Description |

|---|---|

Precise Voltage Threshold Control | Monitors cell voltage in real-time, cutting off charging when thresholds are exceeded. |

Multi-level Hardware Protection | Includes MOSFET control and hardware fuses to isolate faults during abnormal conditions. |

Graded Voltage Threshold Management | Manages power levels to prevent overdischarge, extending battery life through energy-saving modes. |

The DeltaS streetlight project in Saudi Arabia demonstrated the effectiveness of these measures. Under extreme conditions, the battery system achieved a failure rate of less than 0.3%, far below the industry average. This highlights the importance of robust Battery Management Systems (BMS) in preventing overcharging and overdischarging.

Note: Implementing adaptive wake-up technology can further enhance efficiency by reducing maintenance needs.

2.3 Implementing Proper Ventilation and Thermal Management

Effective ventilation and thermal management prevent overheating and ensure consistent performance across applications. Venting mechanisms reduce internal pressure buildup, preserving the lifespan of lithium-ion batteries.

Application | Efficiency Impact | Energy Output |

|---|---|---|

Enhanced reliability | Stable discharge | |

Improved precision | Consistent power | |

Reduced heat buildup | Prolonged cycles |

Research shows that maintaining battery temperatures between 25 ℃ and 40 ℃ optimizes output and minimizes capacity degradation. Heat pipe systems improve temperature uniformity, enhancing energy density and extending battery life. These systems are particularly beneficial for electric vehicles, where efficient thermal management boosts range and performance.

Block Quote: Efficient heat dissipation provided by heat pipe systems significantly enhances battery lifespan and charging performance, making them indispensable for high-demand applications.

By integrating proper ventilation and thermal management solutions, you can ensure the safety and reliability of your battery pack, even in challenging environments.

Building a 24V lithium battery pack requires careful attention to cost, configuration, and safety. Proper maintenance, high-quality materials, and adherence to best practices ensure reliability. Thorough planning and safety measures protect your investment and enhance operational efficiency.

Tip: Prioritize regulatory compliance and comprehensive testing to meet safety benchmarks and build customer trust.

FAQ

1. What is the ideal operating temperature for a 24V lithium battery pack?

The ideal operating temperature ranges between 25°C and 40°C. This range optimizes performance, minimizes degradation, and ensures the battery’s longevity in various applications.

2. How do I choose the right Battery Management System (BMS)?

Select a BMS that matches your battery’s voltage and capacity. Look for features like real-time monitoring, fault detection, and thermal management for enhanced safety and efficiency.

Tip: For professional guidance on battery configurations, visit Large Power.

3. Can I use different types of lithium cells in one battery pack?

No, mixing lithium cell types can cause imbalances and safety risks. Always use cells with identical specifications to ensure consistent performance and prevent potential failures.