Contents

Lithium-ion batteries drive innovation across industries, powering advancements in electric vehicles, energy storage systems, and consumer electronics. You benefit from their high energy efficiency, long lifespan, and minimal self-discharge. The market’s rapid growth, with revenue projected to reach USD 147.3 billion by 2030, highlights their importance. Understanding common lithium cell specifications ensures you optimize performance and energy density in these applications.

Key Takeaways

Lithium-ion batteries are important for many industries. They provide good energy use and last a long time. Knowing their details helps them work better.

Cylindrical, prismatic, and pouch cells are different types. Each type has special uses. Pick the right one based on your space and energy needs.

New lithium-ion technology, like silicon anodes and solid-state batteries, offers more energy and better safety. These changes will improve energy storage in the future.

Part 1: Overview of Lithium-ion Cell Models

1.1 What Defines a Lithium-ion Cell Model?

A lithium-ion cell model is defined by its physical dimensions, capacity, and performance characteristics. These models are standardized to meet the diverse requirements of industries such as consumer electronics, electric vehicles, and energy storage systems. For instance, cylindrical cells like the 18650 and 21700 are widely used due to their high energy density and robust design. Prismatic and pouch cells, on the other hand, offer flexibility in size and shape, making them ideal for applications where space optimization is critical.

The table below highlights some common lithium cell specifications and their typical applications:

Model | Capacity (mAh) | Dimensions (mm) | Typical Applications |

|---|---|---|---|

10440 | 250 – 350 | 10 x 44 | Mini electronic products |

14500 | 700 – 1200 | 14 x 50 | Consumer electronics |

18650 | 1500 – 4000 | 18 x 65 | Laptops, power tools |

21700 | 3000 – 6000 | 21 x 70 | E-bikes, solar lights |

26650 | 2400 – 6000 | 26 x 65 | High-powered flashlights |

1.2 Common Lithium Cell Specifications and Their Importance

Common lithium cell specifications include capacity, voltage, energy density, and cycle life. These parameters directly influence the performance and longevity of battery packs. For example, high energy density allows for compact designs, while a longer cycle life reduces replacement costs. Safety features, such as thermal stability and flame retardant properties, are equally critical, especially in high-demand applications like robotics and infrastructure.

The following table outlines key features that define lithium-ion cells:

Feature | Description |

|---|---|

High energy density | Enables compact designs and efficient energy storage. |

Long life | Ensures above 80% capacity retention after numerous cycles. |

Good safety | Incorporates thermal stability and fault isolation to prevent cascading failures. |

High voltage | Enhances efficiency and performance across applications. |

Good consistency | Ensures uniform performance, critical for battery pack reliability. |

1.3 Standardized Formats and Their Role in Industry

Standardized formats simplify the integration of lithium-ion cells into battery packs. Cylindrical cells like the 18650 and 21700 are preferred for their ease of assembly and mechanical strength. Prismatic and pouch cells, with their customizable dimensions, are often used in electric vehicles and industrial applications. Standardization also facilitates scalability, enabling manufacturers to produce battery packs efficiently while maintaining quality.

The adoption of standardized formats ensures compatibility across various devices and systems. This approach not only reduces production costs but also enhances the sustainability of lithium-ion batteries by streamlining recycling processes. For more insights into sustainability practices, visit Sustainability at Large Power.

Part 2: Detailed Specifications of Popular Models

2.1 Cylindrical Cell: Specifications, Features, and Applications

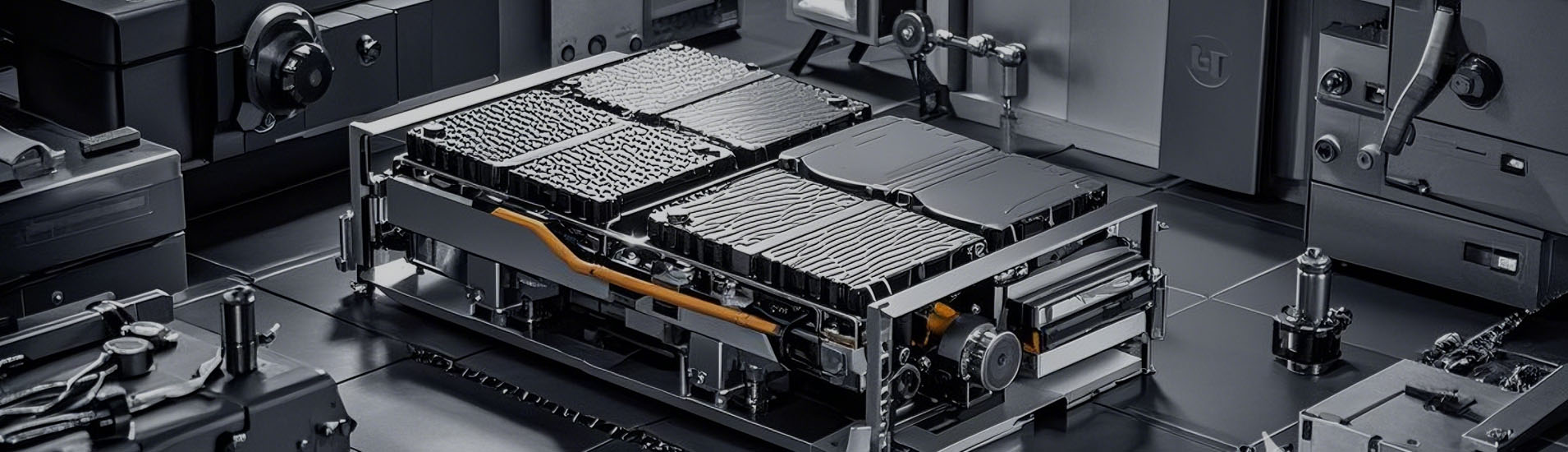

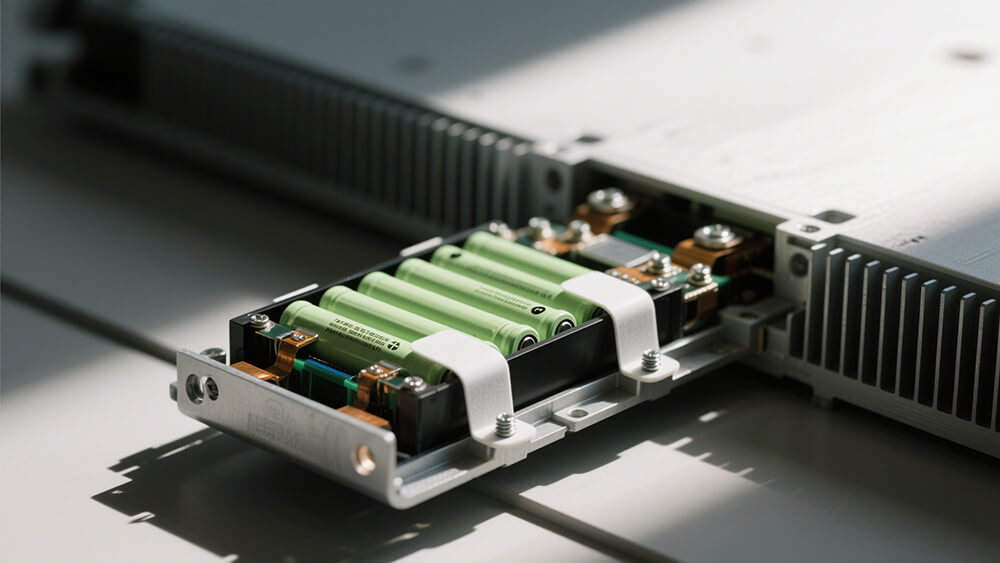

Cylindrical lithium-ion batteries are among the most widely used cell types due to their standardized design and robust mechanical stability. These cells, such as the 18650 and 21700 models, are manufactured using automated processes, ensuring consistency and cost efficiency. Their high energy density and effective cooling management make them ideal for applications requiring reliable performance over extended periods.

Key Features:

High Specific Energy: Cylindrical cells offer a specific energy of up to 248Ah/kg, outperforming other formats in energy storage capacity.

Mechanical Stability: The cylindrical design provides excellent structural integrity, reducing the risk of deformation under pressure.

Automated Manufacturing: Automation ensures uniformity, scalability, and lower production costs.

Safety Features: Built-in safety mechanisms, such as pressure relief vents, enhance reliability in high-demand environments.

Applications:

Cylindrical cells are commonly used in:

Electric Vehicles (EVs): Models like the 21700 are integral to EV battery packs, offering high energy density and long cycle life.

Consumer Electronics: Devices such as laptops and power tools benefit from the compact and efficient design of 18650 cells.

Industrial Equipment: Their durability makes them suitable for high-power applications in industrial settings.

The table below compares cylindrical cells with other formats:

Feature | Cylindrical Cell | Prismatic Cell | Pouch Cell |

|---|---|---|---|

Specific Energy | High | Moderate | Moderate |

Mechanical Stability | Good | Moderate | Low |

Manufacturing | Automated | Manual | Manual |

Safety Features | Yes | Limited | Limited |

Energy Density | 248Ah/kg | 140Ah/kg | 140Ah/kg |

Calendar Life | Long | Moderate | Moderate |

Cost | Low | Moderate | Moderate |

Packaging Density | Less Ideal | Better | Better |

Cooling Management | Effective | Limited | Limited |

2.2 Prismatic Cells: Specifications, Features, and Applications

Prismatic cells are designed for applications requiring compact and space-efficient battery packs. These cells feature a rectangular aluminum casing, which optimizes space utilization and enhances safety. Their robust structure and longer lifespan make them a preferred choice for electric vehicles and energy storage systems.

Key Features:

Safety: Prismatic cells exhibit strong resistance to thermal runaway, minimizing fire or explosion risks.

Longevity: Their extended lifespan reduces replacement frequency, making them cost-effective over time.

Energy Density: These cells strike a balance between power and energy, ensuring consistent performance.

Efficiency: They maintain stable output even under high temperatures or heavy usage.

Environmental Safety: Non-toxic materials enhance sustainability and align with eco-friendly practices.

Applications:

Prismatic cells are widely used in:

Electric Vehicles: Their compact design and high energy density make them suitable for EV battery modules.

Energy Storage Systems: These cells are ideal for renewable energy storage, ensuring reliable power supply.

Infrastructure Projects: Their durability supports applications in transportation and other critical infrastructure.

The table below highlights the advantages of prismatic cells:

Specification | Advantage |

|---|---|

Safety | Robust resistance to thermal runaway, reducing fire or explosion risks. |

Longevity | Longer lifespan, making them cost-effective over time. |

Energy Density | Outstanding balance of power and energy for reliable performance. |

Efficiency | Consistent output maintained even under high temperatures or heavy usage. |

Material Safety | Made with non-toxic materials, enhancing environmental safety. |

2.3 Pouch Cells: Specifications, Features, and Applications

Pouch cells, also known as lithium-polymer batteries, are lightweight and flexible, making them ideal for applications where weight and shape customization are critical. These cells use aluminum-plastic film packaging, which reduces weight and allows for higher energy density.

Key Features:

Customizable Design: Pouch cells can be tailored to fit specific dimensions, maximizing space efficiency.

High Energy Density: Their lightweight structure enables higher energy storage per unit weight.

Low Weight: The absence of a rigid casing reduces overall weight, enhancing portability.

Flexible Applications: These cells are suitable for both single-layer and multi-layer configurations.

Applications:

Pouch cells are commonly used in:

Consumer Electronics: Devices like smartphones and tablets benefit from their lightweight and compact design.

Medical Devices: Their customizable shape supports specialized medical applications.

Drones and Robotics: Pouch cells provide the high energy density required for drones and robotic systems.

The table below outlines key performance factors for pouch cells:

Performance Factor | Description |

|---|---|

Electrode Alignment | Critical for both single-layer and multi-layer cells; misalignment tolerance is very small. |

Electrolyte Wetting | Time must be controlled for complete diffusion, influenced by viscosity and evaporation rates. |

Dryness Factor | Larger surface area and longer fabrication time lead to moisture absorption; immediate usage is advised. |

External Pressure Influence | Affects cell impedance and current distribution, impacting cycling performance in pouch cells. |

Additionally, pouch cells demonstrate impressive performance under varying conditions:

At -20°C, the average discharge capacity at a 1C rate is 68.5% of that at 25°C.

At a lower rate of 0.04C, the discharge capacity improves to 80% of that at 25°C.

The coefficient of variation (COV) at 0.04C under 25°C is 0.35%, indicating low variability.

For custom battery solutions tailored to your specific needs, explore Large Power’s Custom Battery Solutions.

Part 3: Comparison of Models Based on Key Parameters

3.1 Capacity and Energy Density

Capacity and energy density are critical factors when evaluating lithium-ion batteries. Capacity, measured in ampere-hours (Ah) or milliampere-hours (mAh), determines the total charge a battery can store. Energy density, expressed in Wh/kg, reflects how much energy a battery can deliver per unit weight. High energy density ensures compact designs without compromising performance.

3.2 Size and Weight Considerations

The size and weight of lithium-ion batteries directly impact their performance and usability. Factors such as capacity, chemistry, and construction influence weight. For instance, LiFePO4 batteries are heavier but offer superior cycle life, while NMC batteries provide higher energy density at a lighter weight.

Battery weight depends on capacity and energy density.

The formula for weight calculation:

Battery Weight (g) = Battery Capacity (Ah) x Energy Density (Wh/kg)Packaging materials and internal components also contribute to weight.

These considerations are vital for industries like robotics and infrastructure, where weight optimization enhances efficiency.

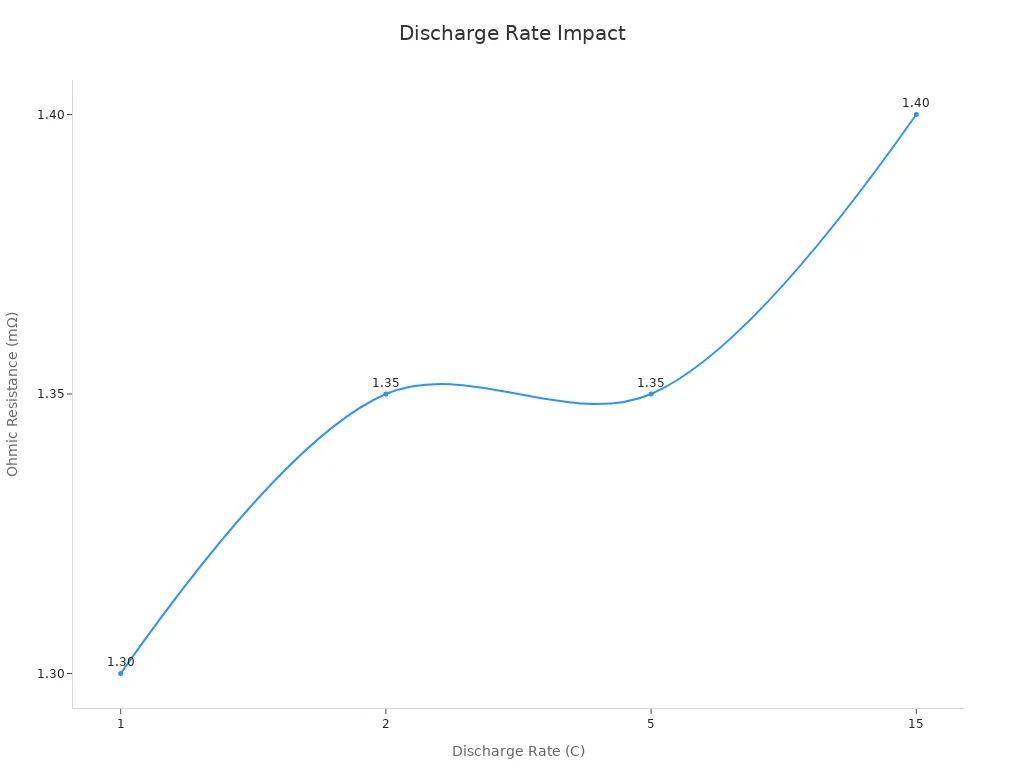

3.3 Discharge Rate and Performance

Discharge rate, measured in C-rate, affects battery performance by determining how quickly energy is delivered. Higher discharge rates increase internal resistance, leading to voltage drops and reduced efficiency.

Discharge Rate (C) | Pure Ohmic Resistance (mΩ) |

|---|---|

1 | 1.30 |

2 | 1.35 |

5 | 1.35 |

15 | 1.40 |

At a 15C pulse rate, a 4.2% change in state of charge (SoC) can cause significant voltage variations, impacting applications like medical devices and security systems.

3.4 Cycle Life and Longevity

Cycle life measures how many charge-discharge cycles a battery can endure before its capacity drops below 80%. Dynamic cycling enhances longevity compared to constant current cycling. For example:

Dynamic discharge profiles increase equivalent full cycles by up to 38%.

Constant current protocols may underestimate lifetime mileage by 195,000 miles.

LiFePO4 batteries excel in cycle life, offering 2,000–5,000 cycles, making them ideal for industrial and energy storage applications.

3.5 Cost and Scalability

Cost and scalability are pivotal for large-scale deployment. Cylindrical cells like 18650 and 21700 are cost-effective due to automated production. Prismatic and pouch cells, while more expensive, offer better space utilization and energy density.

Factors influencing cost include:

Raw material prices (e.g., cobalt and lithium).

Manufacturing processes.

Scalability of production lines.

For custom battery solutions tailored to your needs, explore Large Power’s Custom Battery Solutions.

Part 4: Emerging Trends and Future Prospects

4.1 Advances in Lithium-ion Cell Technology

The lithium-ion battery industry continues to evolve, driven by the demand for higher performance and sustainability. Recent advancements include the development of silicon anodes, which significantly enhance energy density and battery lifespan. These innovations address the growing need for compact, high-capacity batteries in sectors like consumer electronics and electric vehicles. For example, silicon anodes can store up to ten times more lithium ions than traditional graphite anodes, enabling longer runtimes and improved efficiency.

In the automotive sector, manufacturers are focusing on increasing energy density to extend the driving range of electric vehicles. Smart battery management systems (BMS) are also being integrated into industrial applications to optimize energy utilization and reduce downtime. Additionally, advancements in cathode materials, such as NMC and LiFePO4, are improving the performance and safety of lithium-ion batteries. These developments highlight the industry’s commitment to innovation and reliability.

Sector | Advances in Lithium-Ion Technology |

|---|---|

Automobile | Enhancements in energy density and driving range, facilitating electric vehicle adoption. |

Industrial | Integration of smart battery management systems for optimized energy utilization and reduced downtime. |

Consumer Electronics | Innovations aimed at achieving higher energy density and longer battery life for slimmer devices. |

Energy Storage Systems | Deployment of large-scale projects to stabilize the grid and support renewable energy integration. |

Medical Devices | Focus on miniaturization and increased energy density for portable healthcare applications. |

4.2 Challenges in Recycling and Sustainability

Recycling lithium-ion batteries presents significant challenges due to the presence of heavy metals and organic compounds. Studies reveal that reusing 1,000 lithium battery packs could recover 200,000 megajoules of energy, equivalent to avoiding the production of 11 new EV battery packs. However, the recycling rate remains low, with only 10% to 40% of lithium-ion batteries being recycled in the U.S. and Europe. This highlights the urgent need for improved waste management practices to mitigate environmental impacts.

Efforts to enhance sustainability include the development of eco-friendly recycling technologies and the use of non-toxic materials in battery production. These initiatives align with global sustainability goals and emphasize the importance of responsible resource management. For more insights into sustainability practices, visit Sustainability at Large Power.

4.3 Innovations in Solid-State and Next-generation Batteries

Solid-state batteries represent a transformative leap in battery technology. These batteries eliminate the need for liquid electrolytes, reducing safety risks such as leakage and thermal runaway. Solid-state batteries are lighter, more compact, and offer higher energy density, making them ideal for applications requiring high performance and reliability. Recent advancements in solid electrolytes, including ceramic and polymer materials, have enhanced conductivity and made this technology more feasible.

The benefits of solid-state batteries extend to their longer lifespan and slower capacity degradation. This makes them a sustainable choice for industries like robotics and medical devices. Additionally, the absence of liquid components allows for greater design flexibility, enabling innovative configurations for various applications. As the industry moves toward next-generation technologies, solid-state batteries are poised to play a pivotal role in shaping the future of energy storage.

For custom battery solutions tailored to your specific needs, explore Large Power’s Custom Battery Solutions.

Understanding the specifications and applications of lithium-ion batteries ensures you select the right model for your industry. Cylindrical, prismatic, and pouch cells cater to diverse needs, from consumer electronics to industrial systems. Explore custom battery solutions to optimize performance and align with your operational goals. Visit Large Power’s Custom Battery Solutions for tailored options.

FAQ

1. What factors should you consider when selecting a lithium-ion battery model?

Tip: Focus on capacity, energy density, cycle life, and application-specific requirements. For tailored solutions, explore Large Power’s Custom Battery Solutions.

2. How do lithium-ion batteries differ from LiFePO4 batteries?

Feature | Lithium-ion Batteries | LiFePO4 Batteries |

|---|---|---|

Energy Density | Higher energy density, suitable for compact devices | Lower energy density but safer and longer-lasting |

Cycle Life | 500–2000 cycles depending on chemistry | 2000–5000 cycles, ideal for industrial and energy storage applications |

Safety | Moderate safety; requires robust Battery Management Systems (BMS) | Excellent safety, resistant to thermal runaway |

3. Why are cylindrical cells like 18650 and 21700 widely used?

Cylindrical cells offer high energy density, mechanical stability, and cost efficiency. Their standardized design simplifies integration into battery packs for consumer electronics, EVs, and industrial systems.