Contents

NTC thermistors are critical components in lithium battery protection boards. These temperature-sensitive resistors help you monitor battery temperature accurately, ensuring operational safety. The NTC of Lithium Battery systems detects overheating risks, preventing potential damage. With reliable temperature monitoring, you can enhance the performance and lifespan of lithium batteries in demanding applications.

Key Takeaways

NTC thermistors help check battery temperature and stop overheating.

They send temperature data so systems can fix problems quickly.

Picking the right NTC thermistor means checking resistance and temperature range.

Part 1: What Are NTC Thermistors and Their Role in Lithium Battery Systems?

1.1 What is an NTC Thermistor?

An NTC thermistor, or Negative Temperature Coefficient thermistor, is a temperature-sensitive resistor. Its resistance decreases as the temperature rises, making it an essential component for temperature measurement and control. These thermistors are widely used in lithium battery systems due to their precision and reliability.

Characteristic | Description |

|---|---|

Precision | High accuracy in temperature sensing, with less than 1% error in detecting thermal runaway risks. |

Design | Compact and cost-efficient, ideal for integration into battery systems. |

Application | Used in battery thermal management systems for real-time monitoring. |

Operating Range | Effective in temperatures ranging from -40°C to 125°C. |

Market Growth | A 65% increase in EV battery production capacity between 2022 and 2023. |

NTC thermistors are indispensable for ensuring the safe operation of lithium-ion batteries, especially in applications like electric vehicles and consumer electronics. Their ability to monitor ambient temperatures ensures that batteries operate within safe charging and discharging conditions.

1.2 How Does an NTC Thermistor Work in Lithium Battery Systems?

NTC thermistors function by providing real-time temperature feedback to the battery management system (BMS). When the battery temperature changes, the thermistor’s resistance adjusts accordingly. This change is detected by the BMS, which then takes appropriate actions, such as reducing the charging current or shutting down the system to prevent overheating.

Key functions of NTC thermistors in lithium battery systems include:

Temperature measurement: Monitoring the temperature of individual cells or the entire battery pack.

Compensation: Adjusting system parameters based on temperature changes.

Inrush current suppression: Protecting the battery from sudden surges in current.

Source | Key Points |

|---|---|

Ametherm | NTC thermistors provide temperature feedback to the ADC, ensuring battery safety. |

Wevolver | They are used in BMS with voltage divider configurations, offering high sensitivity to temperature changes. |

Everexceed | NTC thermistors enable temperature measurement, compensation, and inrush current suppression. |

This mechanism ensures that lithium-ion batteries remain within their optimal operating range, preventing issues like thermal runaway or reduced performance.

1.3 Why Is the NTC of Lithium Battery Systems Critical for Safety?

The NTC of lithium battery systems plays a vital role in maintaining safety. Lithium-ion batteries are sensitive to temperature fluctuations, and excessive heat can lead to dangerous conditions such as thermal runaway. By continuously monitoring the temperature, NTC thermistors help prevent overheating and ensure the battery operates within safe limits.

Benefits of using NTC thermistors for safety:

Prevention of thermal runaway: Early detection of temperature spikes reduces the risk of catastrophic failures.

Enhanced reliability: Consistent temperature monitoring ensures stable battery performance.

Compliance with safety standards: Many industries, including medical and robotics, require strict adherence to safety regulations.

Recommended charging temperatures for lithium-ion batteries typically range from 0°C to 45°C for slow charging and 5°C to 45°C for quick charging. NTC thermistors ensure that these conditions are met, safeguarding both the battery and the end-user.

1.4 How to Choose the Right NTC for Lithium Battery Systems?

Selecting the appropriate NTC thermistor for a lithium battery system involves several critical factors. The thermistor must align with the specific requirements of the application to ensure optimal performance and safety.

Criteria | Description |

|---|---|

Base Resistance | Choose a base resistance that matches the application requirements or existing system. |

Resistance vs. Temperature Curve | Ensure the thermistor’s response aligns with the system’s temperature range. |

Thermistor Packaging | Select packaging that meets the environmental and mechanical demands of the application. |

For example, in electric vehicles, the thermistor must withstand extreme temperatures and vibrations. In consumer electronics, compact and cost-effective designs are preferred. Consulting with experts or manufacturers can help you identify the best NTC thermistor for your specific needs. For custom battery solutions, you can explore Large Power’s offerings.

Part 2: Benefits of NTC Thermistors in Lithium Battery Protection Boards

2.1 Accurate Temperature Monitoring for Battery Safety

NTC thermistors provide unparalleled accuracy in temperature measurement, making them essential for lithium battery protection. Their non-linear resistance characteristics allow them to detect even the slightest temperature changes, ensuring real-time monitoring. This capability is particularly critical in high-power applications like electric vehicles, where batteries are exposed to significant thermal loads. By integrating NTC thermistors, you can maintain precise control over battery temperatures, preventing overheating and ensuring operational safety.

Research highlights the effectiveness of NTC thermistors in improving temperature monitoring accuracy. For instance, studies show that these sensors achieve a sensitivity of 0.0367V/ºC and a non-linearity as low as 0.16%. This level of precision is vital for applications requiring stringent safety standards, such as medical devices and robotics. Additionally, advanced NTC thermistor probes, like those from VETENG, offer a tolerance of ±1%, ensuring reliable performance in demanding environments.

Accurate temperature monitoring not only enhances safety but also ensures compliance with industry regulations. Whether you’re managing a single lithium-ion battery or a multi-cell pack, NTC thermistors provide the reliability needed to safeguard your systems.

2.2 Prevention of Overheating and Thermal Runaway

Overheating is one of the most significant risks in lithium battery systems. Excessive heat can lead to thermal runaway, a dangerous chain reaction that compromises battery integrity and poses safety hazards. NTC thermistors play a crucial role in mitigating this risk by providing continuous temperature feedback to the battery management system (BMS). When temperatures rise beyond safe limits, the BMS can take corrective actions, such as reducing the charging current or shutting down the system.

The real-time monitoring capabilities of NTC thermistors are particularly valuable in preventing thermal runaway. In high-power applications like EV charging stations, these sensors detect temperature spikes early, allowing for immediate intervention. This proactive approach not only protects the battery but also prevents damage to surrounding components, ensuring the longevity of the entire system.

By incorporating NTC thermistors into your battery protection strategy, you can effectively manage thermal risks. This is especially important in industries like consumer electronics and industrial automation, where overheating can lead to costly failures or safety incidents.

2.3 Enhanced Battery Performance and Longevity

NTC thermistors contribute significantly to the performance and lifespan of lithium batteries. By maintaining optimal operating temperatures, these sensors help prevent the degradation of battery materials. This ensures that your batteries deliver consistent performance over their lifecycle, reducing the need for frequent replacements.

Temperature regulation is a key factor in extending battery longevity. For example, lithium-ion batteries perform best within a specific temperature range. NTC thermistors ensure that this range is maintained, even under varying environmental conditions. This is particularly beneficial in applications like LiFePO4 battery systems, where temperature stability directly impacts cycle life and energy efficiency.

Moreover, the integration of NTC thermistors into battery management systems enhances overall system efficiency. By providing accurate temperature data, these sensors enable the BMS to optimize charging and discharging processes. This not only improves energy utilization but also minimizes wear and tear on the battery.

Incorporating NTC thermistors into your battery systems is a cost-effective way to enhance performance and reliability. Whether you’re designing batteries for medical devices, robotics, or infrastructure projects, these sensors offer the precision and durability needed to meet your requirements.

Part 3: Applications of NTC Thermistors in Lithium Battery Systems

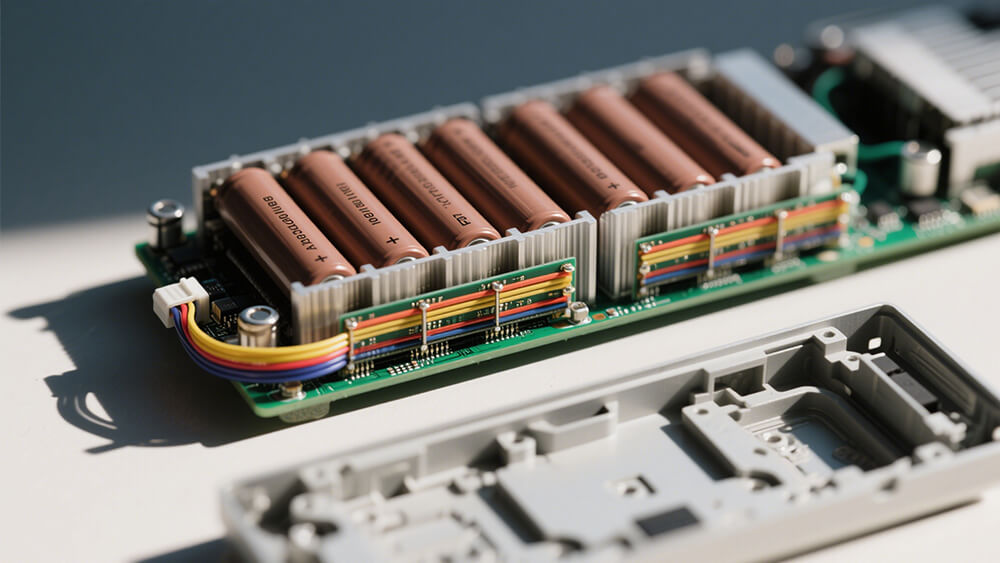

3.1 Integration in Battery Management Systems (BMS)

NTC thermistors are integral to battery management systems, ensuring the safety and stability of lithium batteries. These thermistors provide real-time temperature sensing, enabling the BMS to monitor and regulate battery conditions effectively. By detecting temperature fluctuations, the BMS can adjust charging and discharging rates, preventing overheating and extending battery life.

Key applications of NTC thermistors in BMS include:

Automotive Systems: In electric vehicles, 10k PTC thermistors monitor battery temperatures, reducing overheating risks and enhancing vehicle reliability.

Consumer Electronics: In smartphones, these thermistors manage thermal conditions, preventing thermal runaway and improving user safety.

The integration of NTC thermistors in BMS not only enhances safety but also optimizes the performance of high-energy lithium-ion batteries. This makes them indispensable for industries like transportation and consumer electronics.

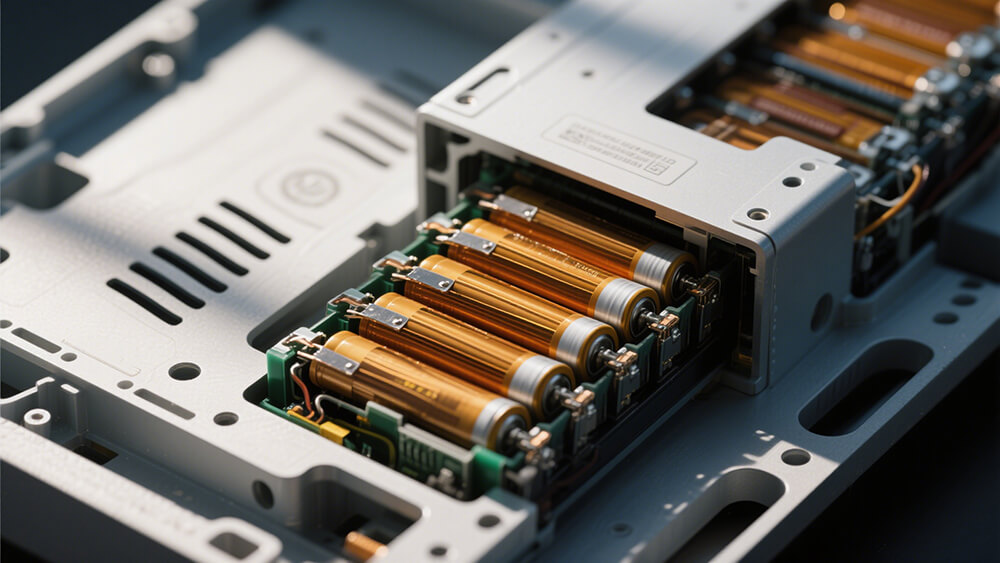

3.2 Temperature Sensing for Multi-Cell Lithium Battery Packs

Accurate temperature sensing is critical for multi-cell lithium battery packs. NTC thermistors excel in this role due to their high sensitivity and fast response time. They ensure uniform temperature distribution across cells, preventing hot spots and reducing the risk of thermal runaway.

Advantage/Function | Description |

|---|---|

High Sensitivity | Ensures precise battery temperature measurement. |

Fast Response Time | Quickly detects temperature changes in dynamic conditions. |

Overheat Protection | Identifies overheating during charging or discharging. |

Temperature Monitoring | Enables optimized charging and discharging algorithms. |

Cell Balancing | Maintains uniform temperature across cells, enhancing safety. |

Early Warning System | Alerts for potential faults, ensuring proactive thermal management. |

By leveraging these features, you can design lithium battery systems with improved safety and extended cycle life. This is particularly beneficial for applications requiring high reliability, such as medical devices and robotics.

3.3 Role in Overcharge and Overcurrent Protection Mechanisms

NTC thermistors play a vital role in circuit over-current protection and overcharge prevention. When a battery experiences excessive current or voltage, the thermistor detects the resulting temperature rise. This triggers the BMS to take corrective actions, such as reducing the current flow or shutting down the system.

In high-energy lithium-ion batteries, this functionality is crucial for maintaining safety and stability. The thermistor acts as an early warning system, preventing damage to the battery and surrounding components. This ensures the longevity of the battery and reduces the risk of catastrophic failures.

By incorporating NTC thermistors into your lithium battery systems, you can achieve a robust thermal management strategy. This not only enhances safety but also improves the overall performance of your battery packs.

NTC thermistors are indispensable for ensuring the safety and performance of lithium battery systems. Their precise temperature monitoring capabilities prevent overheating, thermal runaway, and other risks, making them a cornerstone of modern battery management systems. Industries like automotive electronics and consumer electronics rely heavily on these thermistors to meet stringent safety standards and enhance battery longevity.

Future advancements in thermistor technology, such as improved accuracy and integration with AI-driven systems, promise to revolutionize lithium battery safety. To explore custom battery solutions tailored to your needs, visit Large Power.

FAQ

1. How do NTC thermistors improve lithium-ion battery safety?

NTC thermistors monitor temperature changes in real time. They prevent overheating by signaling the battery management system (BMS) to adjust charging or discharging rates. Learn more about BMS operation.

2. Can NTC thermistors be used in robotics applications?

Yes, NTC thermistors ensure thermal stability in robotics systems, preventing overheating during high-performance tasks. Explore robotics battery solutions.

3. Why choose Large Power for custom lithium battery solutions?

Large Power offers tailored battery solutions with advanced NTC thermistor integration for optimal safety and performance. Start your consultation here.