Contents

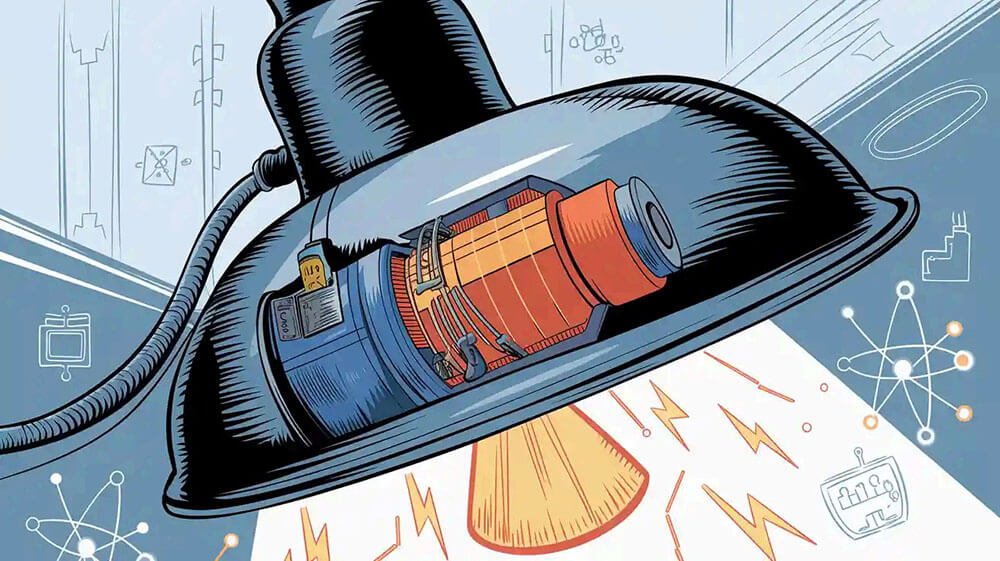

Explosion-proof lamps require power solutions that can withstand hazardous environments while maintaining optimal performance. Lithium batteries excel in these applications due to their exceptional energy density, which ensures efficient energy usage. They also provide long lifespans, enhancing the durability of lamps used in volatile industrial settings. Recent advancements, such as flame-retardant electrolytes, further enhance their safety and reliability. These features make the lithium battery of explosion-proof lamp lithium batteries for refinery operations indispensable.

Key Takeaways

Lithium batteries store a lot of energy, helping lamps work well in dangerous places.

Safety features in lithium batteries, like heat control, lower the chance of overheating, making them safer in risky areas.

Their light weight makes explosion-proof lamps easy to carry and use in factories or worksites.

Part 1: Requirements of Explosion-Proof Lamps in Hazardous Environments

1.1 Defining Hazardous Environments and Their Challenges

Hazardous environments are industrial zones where flammable gases, vapors, or combustible dust pose significant risks. These areas, such as oil refineries, chemical plants, and mining sites, demand specialized equipment to ensure safety. The primary challenge lies in preventing ignition sources from triggering explosions. Electrical devices, including lighting systems, must operate without emitting sparks or excessive heat. Additionally, the harsh conditions in these environments, such as extreme temperatures, vibrations, and corrosive substances, require robust and reliable solutions.

Explosion-proof lamps address these challenges by integrating advanced safety mechanisms. Their compatibility with lithium-ion batteries enhances their performance, offering high energy density and long operational life. This ensures uninterrupted illumination in critical settings, reducing the risk of accidents.

1.2 Key Features of Explosion-Proof Lamps

Explosion-proof lamps are engineered to meet stringent safety and performance standards. Key features include:

Construction: Encased in durable materials like aluminum, these lamps can withstand internal explosions without fracturing.

Durability: Shatter-resistant lenses prevent cracks, ensuring no leaks in hazardous zones.

Efficiency: LED technology provides over 50,000 hours of lifespan while consuming 20% less energy than traditional lighting.

Safety Classifications: Compliance with Class I, II, and III standards ensures suitability for environments with flammable gases or dust.

Mobility: Lightweight designs allow easy transport without compromising safety.

Environmental Impact: Free from harmful substances like mercury, these lamps align with sustainability goals.

1.3 Importance of Reliable Power Sources in Industrial Applications

In industrial settings, reliable power sources are critical for maintaining operational safety and efficiency. Lithium-ion batteries, with their high energy density and long cycle life, are ideal for powering explosion-proof lamps. Their lightweight design enhances portability, while advanced safety features prevent thermal runaway, even in volatile conditions. By integrating lithium-ion batteries, explosion-proof lamps deliver consistent performance, ensuring uninterrupted operations in hazardous environments.

For businesses seeking tailored solutions, exploring custom battery options can optimize performance for specific applications.

Part 2: Advantages of Lithium Battery of Explosion-Proof Lamp

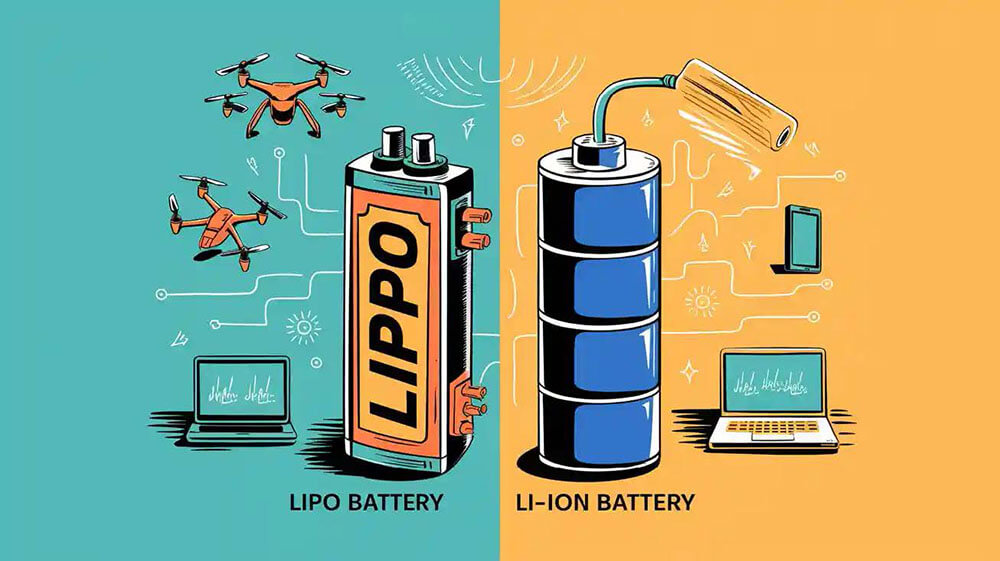

2.1 High Energy Density and Long Cycle Life

Lithium-ion batteries stand out due to their high energy density, making them ideal for explosion-proof lamps in refinery and industrial applications. These batteries store significantly more energy compared to other rechargeable options, ensuring prolonged operation in critical environments. Their long cycle life further enhances their value, allowing you to rely on them for extended periods without frequent replacements.

These attributes make lithium-ion batteries indispensable for explosion-proof lamps, ensuring uninterrupted illumination in hazardous environments. Explore custom battery solutions tailored to your needs.

2.2 Lightweight Design for Enhanced Portability

Lithium-ion batteries offer a lightweight design that significantly improves the portability of explosion-proof lamps. In industrial settings, where mobility is crucial, this feature allows you to transport and position lamps with ease. Despite their reduced weight, these batteries maintain high energy density, ensuring optimal performance without compromising safety.

The lightweight nature of lithium-ion batteries also reduces the strain on equipment, minimizing wear and tear over time. This makes them a cost-effective choice for businesses seeking durable and efficient power solutions. Whether you need portable lighting for refinery operations or industrial maintenance, lithium-ion batteries provide the perfect balance of performance and convenience.

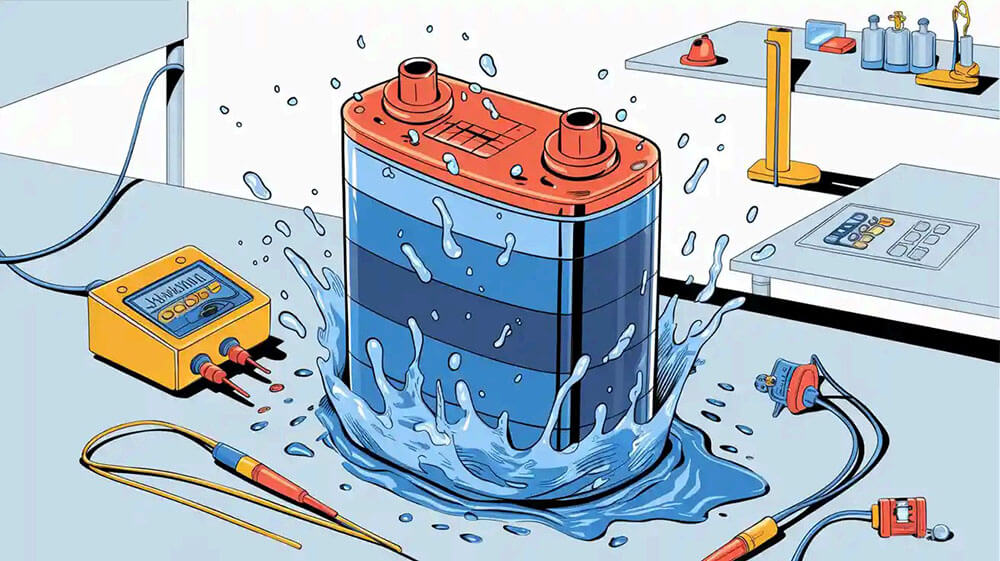

2.3 Advanced Safety Features to Prevent Thermal Runaway

Safety is paramount in hazardous environments, and lithium-ion batteries excel in this regard. Advanced safety mechanisms, such as the integration of a safety reinforced layer (SRL), significantly reduce the risk of thermal runaway. This innovative feature interrupts current flow during voltage drops or overheating, ensuring the battery remains stable under extreme conditions.

The SRL reduces battery explosions from 63% to 10%, as demonstrated in impact testing on 3.4-Ah pouch cells.

It enhances battery safety without negatively impacting performance, making it ideal for explosion-proof applications.

These mechanisms address safety concerns effectively, providing peace of mind in volatile industrial settings.

By incorporating these advanced features, lithium-ion batteries ensure reliable and safe operation, even in the most demanding environments. Their robust design and cutting-edge technology make them the preferred choice for powering explosion-proof lamps. Learn more about sustainability in lithium battery solutions.

Part 3: Mitigating Risks of Lithium Batteries for Refinery and Industrial Use

3.1 Designing Explosion-Proof Battery Packs for Safety

Designing explosion-proof battery packs requires a meticulous approach to ensure safety in hazardous environments. You must consider multiple factors, including thermal management, structural integrity, and resistance to environmental stressors. Advanced testing methods validate the reliability of these designs, ensuring they meet the rigorous demands of refinery and industrial applications.

Testing Method | Purpose |

|---|---|

Thermal Runaway Testing | Evaluates the battery’s response to overheating, reducing fire risks. |

Heat Dissipation Testing | Assesses the battery’s ability to manage heat during high-load operations. |

Vibration Testing | Simulates transportation impacts to ensure structural durability. |

Shock and Impact Testing | Measures resilience to sudden impacts, preventing internal damage. |

Crush Testing | Tests the battery’s behavior under extreme compression forces. |

Humidity Testing | Determines performance in high-humidity environments. |

Altitude Testing | Assesses functionality in low-pressure conditions. |

Salt Fog Testing | Evaluates resistance to corrosion caused by saltwater exposure. |

These tests ensure that lithium battery packs can withstand the harsh conditions of industrial environments. Standards like ANSI/CAN/UL 9540A further enhance safety by assessing thermal runaway susceptibility and informing necessary fire protection measures. By adhering to these protocols, you can mitigate risks and ensure the reliability of explosion-proof battery systems.

3.2 Compliance with Industry Standards and Certifications

Compliance with industry standards is critical for ensuring the safety and performance of lithium batteries in hazardous settings. Certifications like UL and IEC validate the reliability of battery packs, instilling confidence in their use across refinery and industrial applications.

UL certification guarantees that lithium batteries meet stringent safety requirements, reducing the risk of fire or explosion.

International standards, such as IEC 62660 and UL 2580, ensure consistent performance and reliability across various battery systems.

EPL classifications (Ga, Gb, Da) provide additional assurance by categorizing equipment based on its protection level in explosive atmospheres.

Battery testing programs also play a vital role in compliance. These programs evaluate mechanical and climatic shock resistance, exposure to temperature extremes, and abuse response. Organizations like Eurofins E&E conduct these tests, ensuring that lithium batteries perform safely under hazardous conditions. By prioritizing compliance, you can enhance operational safety and align with global regulatory requirements.

3.3 Addressing Potential Failures with Advanced Engineering

Advanced engineering techniques are essential for mitigating potential failures in lithium batteries. Risk assessments and safety guidelines, such as NFPA 855 and the International Fire Code, provide a framework for designing robust energy storage systems. These standards focus on preventing hazards like thermal runaway and explosions, ensuring safe operation in industrial environments.

Guideline/Standard | Focus Area | Description |

|---|---|---|

NFPA 855 | Installation of Energy Storage Systems | Establishes safety measures to prevent failures and hazards in battery systems. |

International Fire Code | Electrical Energy Storage Systems | Provides regulations for safe operation and risk management. |

NFPA 69 | Explosion Prevention Systems | Outlines requirements for preventing explosions in hazardous environments. |

NFPA 68 | Explosion Protection by Deflagration Venting | Details methods for venting gases to mitigate explosion risks. |

Incorporating these guidelines into battery design minimizes risks and enhances reliability. For example, integrating safety mechanisms like reinforced layers and thermal barriers can prevent thermal runaway. Additionally, using advanced materials that resist corrosion and withstand extreme temperatures further improves battery performance.

By leveraging cutting-edge engineering and adhering to established safety standards, you can address potential failures effectively. This approach ensures that lithium batteries remain a safe and reliable power source for explosion-proof lamps in refinery and industrial applications. For tailored solutions, consider exploring custom battery options.

Lithium batteries redefine safety and efficiency in explosion-proof lamps. Their high energy density, long cycle life, and advanced safety features make them essential for hazardous environments.

Investing in lithium-powered lamps ensures uninterrupted operations and reduces risks. Explore custom battery solutions to meet your unique industrial needs.

FAQ

1. What makes lithium-ion batteries ideal for explosion-proof lamps?

Lithium-ion batteries offer high energy density, long cycle life, and advanced safety features. These attributes ensure reliable performance in hazardous industrial environments.

2. How do lithium battery packs ensure safety in hazardous environments?

Explosion-proof battery packs integrate thermal management, reinforced layers, and compliance with UL standards to prevent thermal runaway and ensure operational safety.

3. Why choose Large Power for custom lithium battery solutions?

Large Power specializes in tailored lithium battery solutions, ensuring optimal performance and safety for industrial applications.