Contents

Lithium-ion battery recycling plays a pivotal role in advancing sustainability. As global demand for batteries grows, recycling technologies have become indispensable for reducing environmental impacts. The WEEE standard and lithium battery compliance address the mounting challenge of electronic waste, with only 22.3% of the 62 million tonnes of e-waste produced in 2022 formally recycled. By 2025, the lithium-ion battery recycling market is expected to grow at a compound annual growth rate of 38.3%, driven by end-of-life EV batteries and supportive policies.

Learn more about sustainability practices from Large Power.

Key Takeaways

Recycling lithium-ion batteries helps the planet by reusing materials. It also cuts down on waste and pollution.

New recycling methods, like using water-based processes and smart machines, make recycling better and faster.

Following WEEE rules is important for companies. These rules push them to take responsibility and create products that are easier to recycle.

Part 1: Current State of Lithium-Ion Battery Recycling

1.1 Market Growth and Demand for Battery Recycling

The lithium-ion battery recycling industry is experiencing unprecedented growth. This surge is driven by the increasing adoption of electric vehicles (EVs), renewable energy storage systems, and portable electronics. The global battery recycling market was valued at USD 35.50 billion in 2024 and is projected to reach USD 78.91 billion by 2032, growing at a CAGR of 10.50% from 2025 to 2032. Additionally, the base year market size of USD 12.55 billion is expected to double to USD 23.31 billion by 2033. These figures highlight the escalating demand for efficient recycling solutions to manage the growing volume of end-of-life batteries.

1.2 Challenges in Recycling Lithium Battery Packs

Recycling lithium-ion battery packs presents several challenges. The complex design of batteries, which often includes multiple layers of materials such as lithium, cobalt, and nickel, makes disassembly labor-intensive. Furthermore, the lack of standardized recycling processes across regions complicates efforts to scale operations. Safety concerns, including the risk of thermal runaway during handling, add another layer of difficulty. These challenges underscore the need for technological advancements and regulatory frameworks to streamline recycling processes.

1.3 Gaps in Material Recovery and Recycling Efficiency

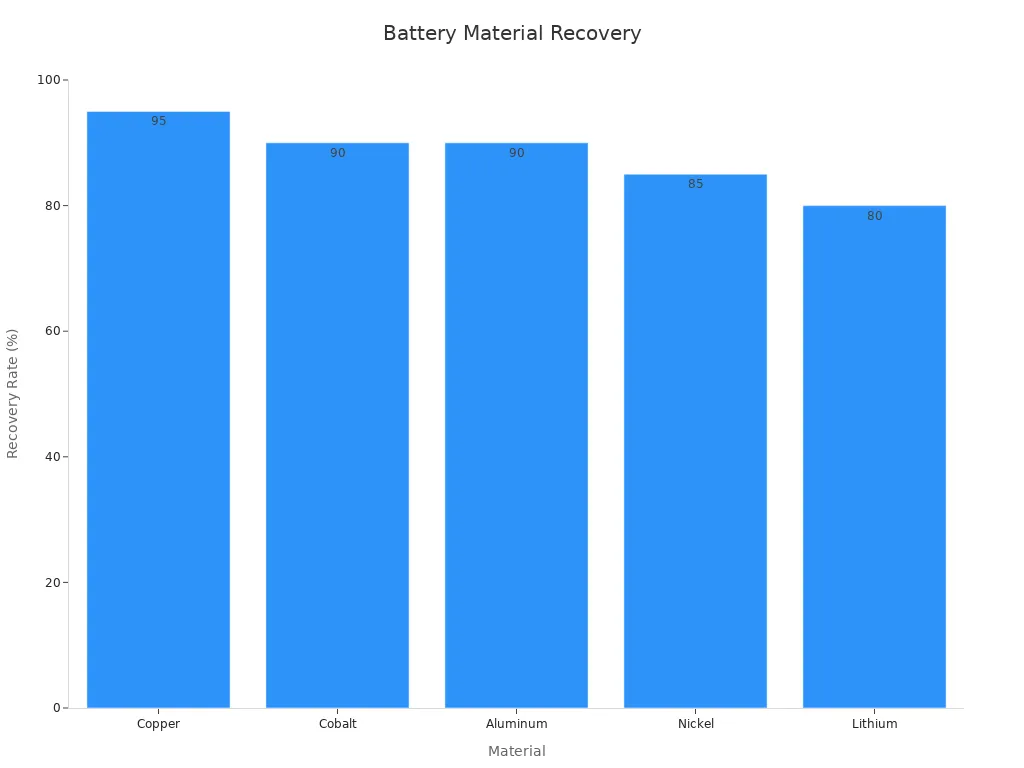

Despite advancements, significant gaps remain in material recovery rates during lithium-ion battery recycling. While materials like copper and cobalt achieve recovery rates of 95% and 90%, respectively, lithium lags at 80%. This disparity highlights inefficiencies in current recycling technologies. The chart below illustrates the recovery rates for key materials:

The chart emphasizes the potential for improvement in lithium recovery, which is critical for reducing dependence on virgin raw materials. Enhanced recovery methods could significantly boost the overall recycling efficiency and support the circular economy.

For businesses navigating these challenges, adopting innovative recycling technologies and collaborating with industry leaders like Large Power can provide tailored solutions. Explore custom battery solutions at Large Power.

Part 2: Technological Advancements in Recycling

2.1 Innovations in Lithium-Ion Battery Recycling Technologies

Recycling technology innovation has transformed how you approach lithium-ion battery recycling. Advanced recycling practices now focus on improving efficiency and profitability while addressing environmental concerns. For instance, direct recycling methods have shown remarkable economic performance, especially for NMC batteries. These methods recover valuable materials like nickel, manganese, and cobalt without degrading their quality.

Hydrometallurgical recycling, on the other hand, has proven highly effective for LiFePO4 batteries. This process uses chemical solutions to extract critical metals, ensuring minimal waste and high recovery rates. The state of health (SOH) of batteries plays a crucial role in determining the efficiency of these methods. As SOH increases, direct recycling becomes more profitable, making it a preferred choice for NMC batteries.

Key benefits of innovative recycling technologies include:

Enhanced recovery rates for critical materials.

Reduced environmental impact through sustainable practices.

Improved economic outcomes based on battery type and condition.

These advancements highlight the importance of selecting the right technology for efficient recycling processes. By adopting cutting-edge methods, you can maximize material recovery and contribute to a circular economy.

2.2 Material Recovery for Critical Metals

Recovering critical metals like lithium, cobalt, and nickel is essential for sustainable battery recycling. These metals are not only valuable but also finite, making their recovery a priority for the industry. Current technologies focus on improving recovery rates to reduce dependence on virgin raw materials.

For example, hydrometallurgical processes achieve high recovery rates for cobalt and nickel, often exceeding 90%. However, lithium recovery still lags behind at approximately 80%. This gap underscores the need for further innovation in recycling technologies.

Metal | Recovery Rate (%) | Key Process Used |

|---|---|---|

Lithium | 80 | Hydrometallurgical |

Cobalt | 95 | Pyrometallurgical/Hydro |

Nickel | 90 | Hydrometallurgical |

Improving lithium recovery rates is critical for reducing the environmental footprint of battery production. By investing in advanced recycling practices, you can ensure a steady supply of critical metals while minimizing waste.

2.3 Automation and AI in Recycling Processes

Automation and artificial intelligence (AI) are revolutionizing the recycling industry. These technologies streamline operations, reduce costs, and enhance safety. For lithium battery recycling, AI-powered systems can identify and sort battery components with unparalleled precision.

Performance metrics validate the benefits of integrating AI into recycling processes:

Metric | AI Systems | Human Operators |

|---|---|---|

Average Production Time | 119.10 minutes | 528.64 minutes |

Blueprinting Efficiency | 0.5 minutes | 23.5 minutes |

AI systems significantly outperform human operators in terms of speed and accuracy. They also minimize risks associated with handling hazardous materials. Automation further enhances efficiency by enabling continuous operation, reducing downtime, and optimizing resource utilization.

By leveraging AI and automation, you can achieve efficient recycling processes that meet both economic and environmental goals. These technologies represent the future of battery recycling, offering scalable solutions for a growing industry.

Part 3: WEEE Standard and Lithium Battery Compliance

3.1 Updates to the WEEE Directive for 2025

The European WEEE directive continues to evolve, with significant updates planned for 2025. These changes aim to address the growing challenges of waste electrical and electronic equipment, particularly in the context of lithium-ion batteries. The directive emphasizes stricter collection targets, improved treatment standards, and enhanced administrative harmonization.

Aspect | Description |

|---|---|

Mandates the separate collection of waste electrical and electronic equipment to improve recycling rates. | |

Treatment Standards | Sets stringent standards for the proper treatment of WEEE to ensure environmental safety. |

Collection Targets | Establishes specific targets for the collection, recovery, and recycling of WEEE. |

Combat Illegal Exports | Aims to prevent illegal waste exports by making it harder to disguise shipments as legitimate. |

Administrative Harmonization | Reduces administrative burdens by unifying national EEE registers and reporting formats. |

The principle of Extended Producer Responsibility (EPR) underpins these updates. This principle requires producers to finance the collection and recycling of their products, ensuring accountability throughout the lifecycle. By adhering to these supportive regulations, you can align with the polluter-pays principle, which promotes environmental compliance and sustainability.

3.2 Global Compliance and Cross-Border Collaboration

Global compliance with the WEEE directive demands coordinated efforts across borders. As lithium-ion batteries power industries worldwide, their recycling and disposal require international collaboration. Countries adopting the European WEEE directive as a benchmark can streamline their policies, ensuring consistency in managing waste electrical and electronic equipment.

Cross-border collaboration also plays a crucial role in combating illegal exports. By sharing data and harmonizing reporting formats, nations can track the movement of recyclable lithium batteries more effectively. This approach not only reduces environmental risks but also fosters a circular economy by recovering valuable materials like cobalt, nickel, and lithium.

To support these efforts, you can leverage partnerships with industry leaders like Large Power. Their expertise in custom battery solutions ensures compliance with global standards while optimizing recycling processes. Explore custom solutions at Large Power.

3.3 Implications for Manufacturers and Recyclers

The updates to the WEEE directive have far-reaching implications for manufacturers and recyclers. For manufacturers, the directive necessitates designing products with recyclability in mind. This includes using materials that are easier to recover and ensuring compliance with EPR requirements. Recyclers, on the other hand, must invest in advanced technologies to meet the directive’s stringent recovery targets.

Study | Findings |

|---|---|

The Influence of Eco-Investment on E-Waste Recycling | Identifies gaps in logistics and legal frameworks affecting recycling rates in Serbia. |

Favot et al. (2022) | Highlights the positive impact of competition on economic performance. |

Apostolescu et al. (2022) | Demonstrates economic and environmental benefits of recycling, including cost-effective recovery of metals. |

Cialani and Mortazavi (2020) | Suggests that increased recycling rates do not significantly raise costs for municipalities. |

By aligning with the WEEE directive, you can unlock economic opportunities while contributing to sustainability goals. Investing in innovative recycling technologies and fostering cross-border collaboration will position your business as a leader in environmental compliance.

Part 4: Environmental and Economic Impacts of Recycling

4.1 Sustainability Benefits of Lithium-Ion Battery Recycling

Recycling lithium-ion batteries offers significant environmental advantages. By reusing critical materials, you can reduce environmental impacts by at least 58% compared to traditional mining methods. This includes lower greenhouse gas emissions, reduced water consumption, and decreased energy usage. For example, electricity consumption during recycling plays a pivotal role in determining environmental performance. Using renewable energy sources for recycling can lower greenhouse gas emissions by up to five times.

Adopting eco-friendly recycling practices also minimizes the ecological footprint of battery production. As the demand for electric vehicles grows, sustainable recycling solutions become essential for reducing waste and conserving resources. By prioritizing lithium-ion battery recycling, you contribute to a cleaner environment and support global sustainability goals.

4.2 Economic Opportunities in the Circular Economy

The circular economy for lithium battery recycling presents lucrative opportunities for businesses. Clean energy applications are expected to account for 90% of global lithium demand by 2030, creating a robust market for recycled lithium. Manual disassembly costs for commercial battery assemblies range from $85 to $106, highlighting the economic feasibility of recycling operations.

Evidence Type | Description |

|---|---|

Recovery Potential | Clean energy uses will dominate lithium demand, driving recycling markets. |

Cost Analysis | Manual disassembly costs demonstrate the economic viability of recycling. |

Future Projections | Spent batteries in the U.S. may reach 2 million tonnes by 2040. |

Current Recycling Challenges | Facilities focus on cobalt and nickel recovery, leaving room for lithium optimization. |

Government incentives, such as grants and tax breaks, further enhance the profitability of circular practices. By investing in recycling technologies, you can capitalize on these opportunities while reducing lifecycle emissions and disposal costs.

“Investors focusing on ESG integration can enhance the circularity of real assets, ensuring renewable energy infrastructure can be recycled to lower lifecycle emissions.”

4.3 Reducing Dependence on Virgin Raw Materials

Lithium battery recycling significantly reduces reliance on virgin raw materials. High recovery efficiencies for critical materials, such as cobalt, nickel, and manganese, ensure a steady supply for manufacturing.

Nickel recovery rate: 98%

Manganese recovery rate: 98%

Lithium recovery rate: 90%, requiring additional processes for optimization.

Copper and steel recovery rates: 90%

Aluminum and graphite recovery rates: 90%

By 2050, recycled materials will account for 65% of cobalt and 77% of lithium in the EU. These resources will primarily come from end-of-life batteries and manufacturing scrap. Recycling not only conserves finite resources but also supports the circular economy by transforming waste into valuable inputs for production.

Explore custom battery solutions at Large Power.

The future of lithium battery recycling and WEEE compliance lies in innovation and collaboration. Key trends, such as advancements in recycling technologies and stricter WEEE directives, highlight the growing importance of sustainable practices. Projections show that the lithium-ion battery recycling market will grow at a CAGR of 18.9% by 2034, driven by electric vehicle adoption and the demand for critical minerals.

Adopting sustainable recycling practices is essential to meet regulatory demands and market expectations. For instance, the EU’s Waste Framework Directive mandates strict waste categorization and reporting standards. International cooperation can further enhance recycling infrastructure and prevent waste mismanagement.

Lithium battery recycling plays a pivotal role in fostering a circular economy. By recovering valuable materials, you can reduce environmental impact and support sustainable development. Large Power offers custom solutions to help you align with these goals. Explore custom solutions at Large Power.

FAQ

1. What are the key benefits of recycling lithium-ion batteries?

Recycling lithium-ion batteries reduces environmental impact, conserves critical materials, and supports the circular economy. It also minimizes dependence on virgin raw materials.

2. How does the WEEE directive impact battery manufacturers?

The WEEE directive requires manufacturers to design recyclable products and comply with Extended Producer Responsibility (EPR) rules. This ensures accountability and promotes sustainable practices.

3. Why should you choose Large Power for custom battery solutions?

Large Power offers tailored solutions for lithium battery recycling and compliance. Their expertise ensures efficiency and adherence to global standards. Explore custom solutions at Large Power.