Contents

Lithium battery cell voltage serves as a key indicator of a battery’s health during charging and discharging cycles. It determines how efficiently energy flows, directly influencing applications like medical devices, robotics, and security systems. For instance, lithium-ion cells perform optimally at 25±2°C but experience voltage drops when discharging below 0°C, reducing capacity. Monitoring voltage behavior helps you prevent faults, as deviations often signal issues like reduced cycle life or potential system failures. Voltage sensors, more common than temperature sensors in battery management systems, enhance the detection of such anomalies, ensuring both safety and performance.

Key Takeaways

Check lithium battery voltage when charging or using to avoid problems like overheating or shorter life.

Use a battery management system (BMS) to keep it safe by controlling voltage, current, and heat.

Always check your battery’s normal voltage to match it with your devices.

Part 1: Lithium Battery Voltage Dynamics

1.1 Voltage behavior during charging

During charging, lithium-ion batteries exhibit distinct voltage characteristics that reflect their electrochemical processes. The charging cycle typically follows a constant current-constant voltage (CC-CV) protocol. Initially, the battery voltage rises steadily as current flows into the cell. Once the voltage approaches the full charge threshold, the charging mode transitions to constant voltage, allowing the battery to absorb energy at a slower rate until fully charged.

Statistical measurements provide valuable insights into voltage changes during charging cycles. These include variance, skewness, and excess kurtosis, which help analyze the distribution and stability of battery voltage. Below is a table summarizing these metrics:

Feature | Description |

|---|---|

Variance (Var) | Measures the spread of voltage values. |

Skewness (Ske) | Indicates the asymmetry of the voltage distribution. |

Maxima (Max) | The highest voltage recorded during the cycle. |

Minima (Min) | The lowest voltage recorded during the cycle. |

Mean (Mean) | The average voltage during the cycle. |

Excess Kurtosis (Kur) | Measures the tailedness of the voltage distribution. |

Experimental tests further demonstrate the behavior of lithium-ion batteries during charging. These tests use various charge multipliers, such as 0.02 C and 1 C, to evaluate performance under different conditions. Voltage and current data are recorded to assess capacity and coulombic efficiency, ensuring optimal battery operation.

Tip: Monitoring the lithium-ion battery voltage chart during charging helps identify anomalies, such as over-voltage conditions, which can lead to thermal runaway.

1.2 Voltage behavior during discharging

Discharging a lithium-ion battery involves a gradual reduction in voltage as stored energy is released. The voltage behavior during this process depends on the state of charge (SOC) and the load applied. Initially, the voltage remains stable, but as the SOC decreases, it begins to drop more rapidly.

Further analysis reveals three distinct stages of voltage behavior during discharging:

Stage I: Rapid voltage drop from 4.2 V to approximately 3.6 V, followed by stabilization at 3.6 V.

Stage II: Gradual rebound with minor fluctuations.

Stage III: Monotonic increase asymptotically to 0 V.

Overdischarge can lead to internal short circuits (ISCr), which compromise battery safety. Scanning electron microscopy (SEM) and X-ray diffraction (XRD) studies show that overdischarge causes Cu deposition on electrodes, indicating structural irregularities.

Note: Avoid over-discharging lithium-ion batteries to prevent irreversible damage and ensure long-term reliability.

1.3 Importance of voltage dynamics for battery packs

Understanding voltage dynamics is crucial for maintaining the performance and safety of lithium battery packs. Voltage anomalies, such as over-voltage or under-voltage conditions, can signal serious issues like thermal runaway or internal short circuits. Real-time monitoring of battery voltage ensures safe operation and helps predict potential faults.

Voltage dynamics also play a key role in fault diagnosis for applications like medical devices, robotics, and security systems. For example, in medical devices, voltage fluctuations can disrupt critical operations, while in robotics, they may impair mobility and precision. Accurate monitoring and prediction of voltage behavior enhance the reliability of these systems.

Call to Action: Explore custom battery solutions tailored to your industry needs: Custom Battery Solutions.

Part 2: Key Parameters of Lithium Battery Cell Voltage

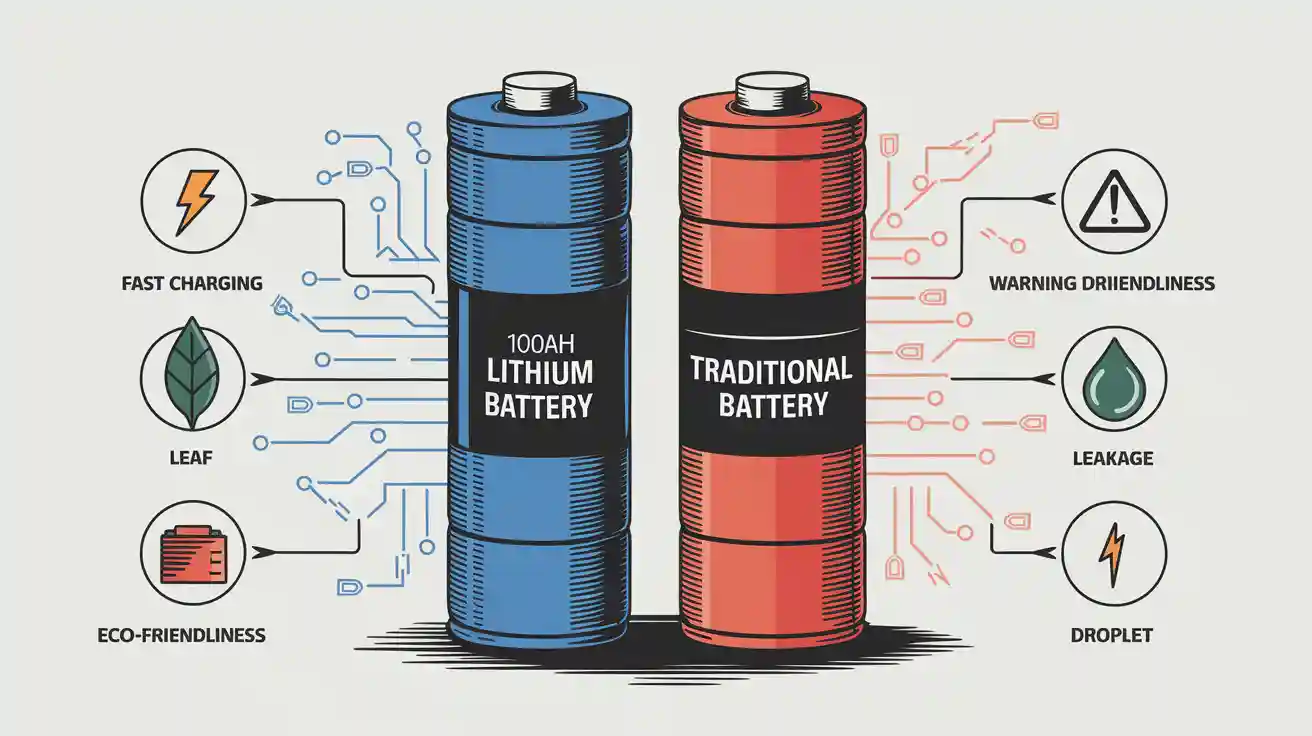

2.1 Nominal voltage and its significance

Nominal voltage represents the average voltage of a lithium-ion battery during its discharge cycle. It serves as a baseline for comparing different battery chemistries and is critical for designing battery packs for applications like medical devices, robotics, and security systems. For instance, the nominal voltage of LiFePO4 batteries is 3.2V, while NMC batteries typically range between 3.6V and 3.7V.

Understanding nominal voltage helps you ensure compatibility between the battery and the device it powers. It also provides insights into energy density and performance. Empirical measurements highlight the importance of nominal voltage in assessing battery consistency:

The relative standard deviation for capacities is 0.63%, while for median voltage, it is 0.43%.

Instant voltage at the end of charge: 0.015V (relative standard deviation: 0.09%).

Instant voltage at the end of discharge: 0.294V (relative standard deviation: 2.14%).

Voltage after 30 minutes post-discharge: 0.142V (relative standard deviation: 0.93%).

These metrics emphasize the role of nominal voltage in maintaining uniformity across cells in a battery pack. Variations in nominal voltage can lead to imbalances, reducing the overall efficiency and lifespan of the pack.

Tip: Always verify the nominal voltage of your lithium-ion battery to ensure it aligns with your device’s voltage requirements.

2.2 Full charge voltage and its impact

The full charge voltage of a lithium-ion battery indicates the maximum voltage it can safely reach during charging. This parameter directly affects the battery’s energy capacity and overall performance. For most lithium-ion chemistries, the full charge voltage ranges between 4.2V and 4.4V.

The table below illustrates the relationship between nominal voltage and full charge voltage for various lithium battery models:

Nominal Cell Voltage | Max Charge Voltage |

|---|---|

3.6V | 4.2V |

3.7V | 4.2V |

3.8V | 4.35V |

3.85V | 4.4V |

A fully charged lithium-ion battery achieves its peak energy storage capacity, making it ideal for high-demand applications like industrial equipment and consumer electronics. However, exceeding the full charge voltage can lead to overcharging, which may cause thermal runaway or permanent damage to the battery.

Note: Regularly monitor the lithium-ion battery voltage chart during charging to prevent overcharging and ensure safe operation.

2.3 Cutoff voltage for safe operation

Cutoff voltage defines the minimum and maximum voltage limits for the safe operation of a lithium-ion battery. It prevents over-discharging and overcharging, both of which can degrade battery performance and pose safety risks.

For a 3.6V lithium-ion battery, the typical cutoff voltage is:

3.0V for discharge.

4.2V to 4.35V for full charge.

Maintaining these voltage ratings ensures the longevity and reliability of the battery. Over-discharging can lead to internal short circuits, while overcharging increases the risk of thermal runaway. Both scenarios can compromise the safety of devices like medical equipment, robotics, and infrastructure systems.

Call to Action: Consult with experts to design custom battery solutions that meet your specific voltage requirements: Custom Battery Solutions.

Part 3: Factors Influencing Lithium Battery Voltage

3.1 Temperature effects on voltage

Temperature significantly impacts lithium-ion battery voltage and overall performance. Operating temperatures between 25°C and 55°C are ideal for maintaining optimal battery voltage. However, extreme heat accelerates degradation, particularly at the LCO cathode, while cold temperatures reduce the state of charge and discharge capacity. A comprehensive study highlights that elevated temperatures lead to the formation of surface films on electrodes, increasing cell impedance and reducing battery life. This degradation is especially critical in applications like medical devices, where consistent battery voltage is essential for reliability.

For lithium iron phosphate batteries, temperature fluctuations can alter the battery voltage chart, affecting performance in robotics and infrastructure systems. Monitoring and controlling temperature during charging LiFePO4 batteries or discharging LiFePO4 batteries can mitigate these effects.

Tip: Use temperature sensors in conjunction with battery management systems to maintain safe operating conditions and extend battery life.

3.2 Battery health and aging

Battery aging directly influences voltage stability. Over time, lithium-ion batteries experience capacity loss and increased internal resistance, leading to voltage drops. Statistical analyses, such as semi-empirical and machine-learning-assisted models, help predict these changes.

Analysis Type | Description |

|---|---|

(Semi-)empirical models | Use empirical data to derive relationships between battery aging and voltage changes. |

Electrochemical/physics-based models | Focus on the physical and chemical processes occurring in the battery. |

Machine-learning-assisted models | Utilize machine learning techniques to analyze data and predict voltage changes. |

For industrial applications, understanding these aging effects ensures consistent battery performance and prevents unexpected failures. Regular monitoring of the battery voltage chart can help identify early signs of aging, enabling timely maintenance.

3.3 Load conditions and voltage fluctuations

Load conditions play a crucial role in determining battery voltage behavior. Controlled experiments reveal that high discharge currents cause significant voltage fluctuations, impacting the state of charge and thermal stability. For instance, discharging to 0 V reduces the voltage rebound effect, while negative end voltages further stabilize the battery. These findings are vital for consumer electronics, where stable battery voltage ensures uninterrupted operation.

In robotics and security systems, voltage fluctuations can impair functionality. By optimizing discharge capacity and controlling load conditions, you can enhance battery performance and extend battery life.

Note: Implementing a robust battery management system can minimize voltage fluctuations and improve the reliability of lithium-ion and LiFePO4 batteries.

Part 4: Safety Precautions for Lithium Battery Voltage

4.1 Avoiding overcharging and over-discharging

Overcharging and over-discharging lithium batteries can severely impact their performance and safety. You should always monitor the battery voltage to ensure it stays within the recommended range. For most lithium-ion batteries, the charging voltage peaks at 4.2V, while the cutoff voltage during discharge is typically 3.0V. Exceeding these limits can lead to overheating, capacity loss, or even thermal runaway.

To avoid overcharging, use chargers specifically designed for your battery type. Charging within the recommended temperature range, usually between 0°C and 45°C, also minimizes risks. Over-discharging, on the other hand, can cause irreversible damage to the battery’s internal structure. For instance, discharging a LiFePO4 battery below its cutoff voltage can lead to reduced cycle life and safety hazards.

Aspect | Details |

|---|---|

Recommended Voltage Range | 3.0 to 4.2 V for short-term storage; 3.8 V to 3.9 V for prolonged storage |

Precautions | Avoid replacing individual cells, short-circuiting, overcharging, or exposing to high temps |

Tip: Regularly check the battery voltage and avoid using damaged or incompatible chargers to maintain safety and extend battery life.

4.2 Role of battery management systems (BMS)

A battery management system (BMS) plays a critical role in regulating lithium battery voltage and ensuring safe operation. It continuously monitors voltage, current, and temperature, preventing overcharging or over-discharging. By employing cell-to-cell balancing, the BMS ensures that all cells in a battery pack maintain consistent voltage levels. This not only optimizes the battery’s capacity but also prolongs its lifespan.

For LiFePO4 batteries, a BMS is particularly essential due to their unique voltage characteristics. It protects the battery from aggressive usage, such as high discharge rates, which could otherwise lead to voltage instability. Additionally, the BMS includes safety features like short-circuit protection and thermal monitoring, reducing the risk of fires or damage.

Note: Investing in a high-quality BMS is crucial for maintaining the safety and performance of your lithium battery packs.

4.3 Best practices for charging battery packs

Adhering to best practices when charging lithium battery packs ensures maximum performance and longevity. Always use the charger recommended by the manufacturer, as different lithium chemistries, such as LiFePO4, have specific voltage and current requirements. Charging at room temperature is ideal, as extreme temperatures can affect battery voltage and compromise safety.

Avoid letting the battery voltage drop too low before charging. For example, charging a LiFePO4 battery when its state of charge (SoC) is low helps maintain its cycle life. Terminate the charge once the battery reaches full capacity, as continuous charging can lead to voltage stress and potential damage.

Alert: Never use trickle or float charging methods for lithium batteries, as these can cause overheating and instability.

By following these guidelines, you can ensure the safe and efficient operation of your lithium battery packs, whether they power consumer electronics or industrial equipment.

Understanding lithium battery voltage during charging and discharging is essential for ensuring optimal performance and safety. Voltage consistency maximizes energy efficiency, while monitoring tools help prevent risks like thermal runaway or reduced lifespan. Adopting best practices, such as using a battery management system, safeguards your battery packs in applications like robotics and consumer electronics.

Aspect | Evidence |

|---|---|

Performance | Higher voltage leads to increased output power and energy storage capacity. |

Voltage consistency is crucial for maximizing the overall energy efficiency of a battery pack. | |

Safety | High voltage raises the risk of thermal runaway, which can lead to battery explosions or fires. |

Voltage imbalances can cause overcharging or over-discharging, increasing safety risks. | |

Life Impact | Operating at high voltage can shorten the cycle life of lithium batteries due to accelerated aging. |

Voltage imbalance significantly contributes to reduced lifespan of battery packs. |

Tip: Consult with experts to design custom battery solutions tailored to your needs: Custom Battery Solutions.

FAQ

1. What happens if you overcharge a lithium battery?

Overcharging can cause overheating, capacity loss, or thermal runaway. Always monitor voltage and use chargers designed for your battery type to prevent damage.

Tip: Invest in a charger with built-in overcharge protection for added safety.

2. How does temperature affect lithium battery voltage?

High temperatures accelerate degradation, while cold temperatures reduce capacity and voltage stability. Maintaining an ideal operating range of 25°C to 55°C ensures optimal performance.

3. Why is a battery management system (BMS) essential?

A BMS monitors voltage, current, and temperature, preventing overcharging or over-discharging. It ensures cell balancing, prolonging battery life and enhancing safety.

Note: A high-quality BMS is critical for industrial and consumer applications. For professional guidance on BMS, visit Large Power.