Solid-state battery technology can handle 8,000 to 10,000 charge cycles, which is a big deal as it means that conventional batteries, like traditional lithium-ion batteries, only last 1,500 to 2000 cycles. Our latest breakthrough uses a silicon interface that doubles charging speed and maintains this exceptional longevity. Traditional lithium-ion batteries have almost reached their physiochemical limits. Solid-state batteries provide a revolutionary solution with 50% higher energy density through advanced composite cathodes. Additionally, solid-state batteries offer higher energy density compared to traditional lithium-ion batteries, enabling longer driving ranges.

These batteries are much safer, unlike conventional batteries, because they eliminate thermal runaway risks and electrolyte leakage concerns. This makes them ideal for everything from consumer electronics to electric vehicles. Toyota already plans EVs that can travel up to 750 miles on one charge and need just 10 minutes to charge. Ultrathin composite polymer electrolytes have reduced internal resistance and enhanced the battery’s overall performance. Solid-state batteries are much safer than lithium-ion batteries due to the absence of a liquid electrolyte.

Our groundbreaking silicon interface speeds up solid-state battery development. Hybrid solid electrolytes blend the best features of inorganic and polymer materials to create superior ionic conductivity with mechanical flexibility.

Breakthrough Overview: Silicon Interface in Solid-State Battery Tech

Image Source: Assembly Magazine

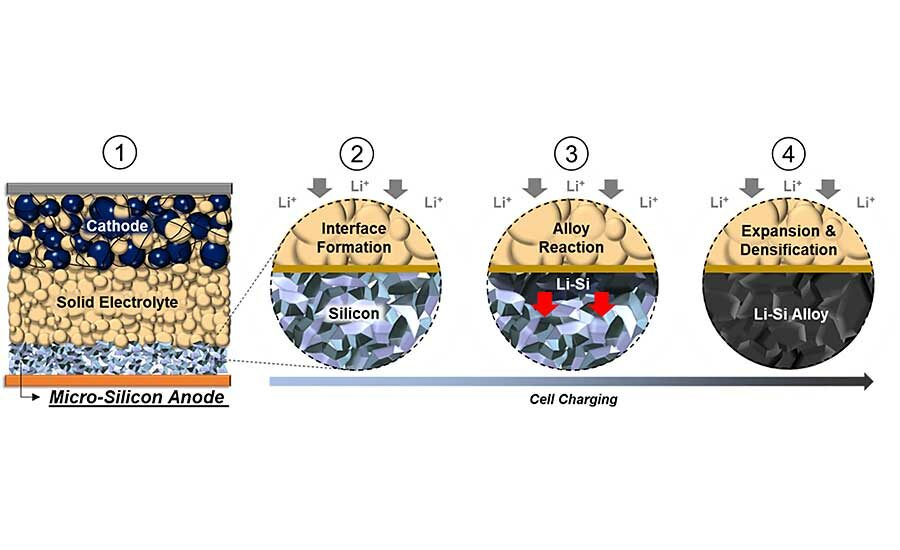

Silicon anodes mark a radical alteration in semi solid state batteries technology. This represents a significant advancement, offering improved energy density, enhanced safety features, and faster charging times compared to traditional lithium-ion batteries. These anodes have a theoretical specific capacity reaching 4200 mAh g−1 and a relatively low oxidation-reduction potential of 0–0.45 V (vs Li/Li+). Silicon provides exceptional energy storage capabilities. Traditional electrode materials are nowhere near as effective, making silicon the life-blood of next-generation energy storage systems.

What Makes the Silicon Interface Unique?

Silicon interface’s alloying process takes place at approximately 0.3V versus Li+/Li, which prevents lithium dendrite formation and short circuits. This feature becomes crucial because dendrites pose a major safety risk in battery technology, especially in batteries using liquid electrolyte . Silicon anodes store lithium ions in their bulk phase through an alloying mechanism instead of surface plating. This allows them to achieve substantially higher critical current density than lithium metal anodes.

Scientists have recently created a Li21Si5 layer that evens out the electric field at the anode surface. This state-of-the-art development helps create uniform and rapid lithium ion transport, which doubles the charging speed. The layer spreads expansion stress and keeps both the anode bulk and interface structure stable.

Comparison with Previous Interface Materials

Lithium metal anodes led solid-state battery research over the last several years, despite their problems with dendritic growth and volume fluctuations. The transition from traditional liquid-based batteries to semi solid solutions marks a significant advancement, as solid-state technology does not utilize any liquids, gels, or hazardous chemicals, making it more eco-friendly and suitable for various electronic devices. Silicon anodes show better resistance to dendrite formation during cycling processes. All the same, silicon comes with its challenges – it can expand up to 300-400% during lithiation.

Solid electrolytes paired with silicon create different interface characteristics. Sulfide solid electrolytes show better mechanical properties than oxide electrolytes when dealing with silicon’s volume changes. Room temperature sulfide electrolytes with high ionic conductivity show the most promise for silicon-based solid-state batteries.

Performance Metrics: Conductivity and Stability

The Li21Si5/Si interface shows these impressive performance metrics:

- Critical current density of 10 mA cm−2 at 45°C

- High original Coulombic efficiency of 97% with 2.8 mAh cm−2 areal capacity

- Low expansion rate of 14.5% after 1000 cycles

Monitoring battery performance and safety is crucial to ensure the longevity and reliability of these metrics.

Silicon-based solid-state batteries achieve ionic conductivity of approximately 1.5 × 10−3 S cm−1 and electronic conductivity of 4.4 × 10−4 S cm−1. These properties enable quick ion/electron transport that powers fast charging capabilities. Silicon anodes in solid-state configurations maintain higher specific capacity (3,400 mAh g−1) compared to composite alternatives (2,600 mAh g−1).

Advancements in Battery Technology from Interface Engineering

Image Source: ResearchGate

Interface engineering is the life-blood of advancing solid-state battery technology. Semi solid state batteries represent a significant advancement in battery technology, offering superior safety and energy density compared to traditional lithium-ion batteries. Recent studies show how strategic interface changes can dramatically improve performance in many ways.

Improved Cycle Life and Energy Density

Battery performance and long-term stability depend heavily on interface architecture in oxide-based solid-state batteries. Li7P3S11 nanocomposite electrodes maintain discharge capacities of 421 mAh g−1 even after 1000 cycles at high current densities of 1.27 mA cm−2 thanks to innovative interfacial designs that help keep track of energy density. Factorial’s verified 77Ah FEST® cells show energy densities of 375Wh/kg and last over 600 cycles for automotive qualification. These cells charge quickly from 15% to 90% in just 18 minutes at room temperature.

Interface Resistance Reduction Techniques

Scientists have found several ways to minimize interfacial resistance:

- Surface modification – Modified LAGP solid electrolyte surfaces with gel-polymer electrolytes cut interfacial resistance from 366410 Ω to just 3767 Ω. This big improvement lets solid-state batteries work at room temperature.

- Annealing treatment – Battery cells annealed at 150°C for one hour show reduced interface resistance of 10.3Ωcm2. This removes protons from the LiCoO2 structure and restores optimal performance.

- Structural design – Architectural lithium anodes and three-dimensional oxide solid-state electrolytes create more contact area. This improves ion movement across interfaces.

Integration with Lithium Metal Anodes

Interface engineering offers budget-friendly solutions for lithium metal anode implementation. The health of the battery, particularly in terms of performance and longevity, is crucial for ensuring safety and durability over extended use. Lithium metal’s theoretical capacity (3860 mAh g−1) is about ten times higher than graphite. All-solid-state lithium-metal batteries can boost specific energy density by 35% and volumetric energy density by 50% compared to regular lithium-ion batteries at pack levels.

Trifluoromethanesulfonic acid treatment of Ta-doped Li7La3Zr2O12 creates a lithiophilic layer with LiCF3SO3 and LiF components. This change helps control lithium metal negative electrode thickness from 0.78 μm to 30 μm. Symmetric Li||Li cells with these interfaces work steadily for up to 800 hours at 1.0 mA cm−2.

Solid-State Battery Development for Real-World Applications

Image Source: FOM Technologies

Solid-state battery technology proves its worth beyond laboratories through ground applications in challenging environments. These practical implementations show how theoretical benefits solve real industry challenges. Solid-state batteries offer longer lasting power due to their advanced energy density and increased lifespan, making them ideal for consumer electronics and electric vehicles.

Extreme Environment Applications: Oil Field and Hazard Field

The oil and gas industry faces some of the world’s toughest operating conditions with extreme weather and remote locations. Artificial intelligence plays a crucial role in enhancing battery technology, particularly through battery health monitoring algorithms and optimizing the battery value chain from resource extraction to recycling. Solid-state batteries shine in these scenarios because of their thermal stability and safety features. Hitachi Zosen Corporation created a solid-state battery that achieved one of the highest capacities in the industry with better temperature tolerance.

NASA’s upcoming science missions need advanced energy storage systems that work at temperatures reaching 500°C for Venus missions. Scientists are developing all-solid-state Na-ion batteries (ASSNiBs) specifically for these missions. These batteries deliver high ionic conductivities and remain stable at extreme temperatures.

Consumer Electronics: Safer and Smaller Batteries

Solid-state batteries revolutionize consumer electronics through:

- Wearable devices – Samsung’s solid-state batteries come with non-flammable features, flexibility, and smaller size compared to Li-ion versions. These qualities make them perfect for Galaxy Watches, with possible launch by 2026. Additionally, they offer a significant improvement in energy density, enhancing the performance and efficiency of wearable devices.

- IoT applications – TDK’s CeraCharge, a chip-sized solid-state battery at just 4.5mm × 3.2mm × 1.1mm, works safely between -20°C and 80°C

These batteries eliminate any risk of leakage, which matters greatly for devices worn on the body. CookPerfect’s first “true wireless” thermometer employs solid-state technology that handles temperatures up to 85°C while fitting into a tiny 3.7mm-diameter unit.

Renewable Energy Storage: Long-Term Efficiency Gains

Solid-state batteries excel at storing renewable energy because of their durability and efficiency. Semi solid state battery technology offers improved safety and energy capacity, making it an ideal choice for renewable energy storage. The growing renewable energy sector needs these batteries to store power from solar or wind sources, creating reliable energy storage solutions and contributing to cost reduction . Their high energy density and stability suit grid regulation, peak-valley tariff usage, and remote area power supply. These batteries handle temperature changes that would damage regular batteries, delivering steady performance across different weather conditions.

Future of Solid-State Battery Research and Commercialization

Solid-state battery technology breakthroughs are moving faster from labs to commercial applications. Achieving comparable reliability to traditional lithium-Polymer batteries remains a challenge, despite the advantages of better safety and energy density. Major industry players build production infrastructure and create mutually beneficial alliances to speed up deployment.

Ongoing Research in Composite Electrolytes

Composite electrolytes show promise to solve practical challenges in solid-state batteries. These electrolytes blend organic polymers with inorganic materials to maximize performance benefits. Solid-state batteries can achieve substantial driving distances, often exceeding 1,000 kilometers on just a single charge, showcasing advancements in energy density and efficiency. Scientists classify them as ceramic-in-polymer (CIP) or polymer-in-ceramic (PIC) based on their composition. PIC electrolytes stand out because their inorganic phase maintains primary ion migration channels while the organic binder adds essential viscoelastic properties.

Scientists now focus on three main composite methods:

- Filler blending

- Embedded skeleton structures

- Multilayer bonding approaches

These techniques substantially improve ion transport capacity, interface stability, and electrolyte safety when researchers select appropriate methods.

Pilot Production Lines and Industry Partnerships

Leading battery manufacturers now set up dedicated production facilities to improve manufacturing processes. Solid ceramic separators are crucial in advanced battery technology, particularly for solid-state lithium-metal batteries, as they enhance efficiency and reduce manufacturing costs compared to traditional lithium-ion batteries. Nissan runs a pilot line at its Yokohama Plant that develops innovative manufacturing technologies. ION Storage Systems opened a pilot facility in Maryland that will produce 1 MWh of cells in 2024 and scale up to 10 MWh by 2025. Companies like CATL are significantly boosting investments in battery technology.

Mutually beneficial alliances play a crucial role. Stellantis put $75 million into Factorial Energy in 2021, which led to successful validation of 77Ah FEST® solid-state cells. SK On and Solid Power created a $50 million partnership covering research licensing, manufacturing equipment, and electrolyte supply.

Large Power has leading technology in semi solid state technology and starting mass production in 2026.

Forecast for Mass Adoption by 2030

Industry experts expect substantial commercial adoption this decade. Capacity compared to traditional lithium-ion batteries shows significant advancements, particularly with innovations like Enovix’s 3D cell architecture. Toyota and Nissan plan to launch solid-state battery-equipped EVs by 2027-2028, aiming for a longer life span than current models . Samsung SDI will start mass production by 2027 through its S-Line facility. Hyundai targets partial production by 2027 and full-scale operations by 2030. The solid-state battery market is projected to reach approximately $6 billion by the end of the decade.

Market growth looks set for exponential expansion. Valuations reached $1 billion in 2023 with projected CAGR of 30-35% through 2031. Experts predict solid-state batteries will capture 3-5% of the market by 2030.

Conclusion

Solid-state battery technology is about to reshape the scene, thanks to breakthrough silicon interface developments. The potential for widespread adoption of solid-state battery technology is significant, as advancements continue to overcome technical challenges and reduce costs. This article shows how this new interface doubles charging speeds and lasts an impressive 8,000-10,000 charge cycles. The Li21Si5 layer creates a homogeneous electric field that enables uniform lithium ion transport and keeps the anode structure stable during cycling. The global solid-state battery market is expected to grow at a CAGR of 28% from 2022 to 2030.

The numbers tell an impressive story. Silicon-based solid-state batteries show conductivity of approximately 1.5 × 10−3 S cm−1 and deliver better critical current density and Coulombic efficiency. Interface engineering has cut resistance by two orders of magnitude in some cases. These theoretical benefits are now becoming real-life applications.

These batteries already work in a variety of sectors. You’ll find them powering equipment in tough environments like oil fields and space missions. They also make consumer electronics smaller and safer. Their use in renewable energy storage proves their versatility and long-term value.

Toyota, Nissan, and Samsung have set clear plans to start mass production between 2027-2030. The market should grow fast, with projections suggesting a CAGR of 30-35% through 2031. Research in composite electrolytes and mutually beneficial industry alliances will speed up this timeline as manufacturing scales up.

This silicon interface breakthrough isn’t just a small step forward – it’s a fundamental change in battery technology that fixes the main problems of traditional lithium-ion systems. These technologies will grow from lab experiments into commercial products and alter the map of energy storage for decades.

FAQs

Q1. How quickly can solid-state batteries be charged?

Solid-state batteries with the new silicon interface technology can be charged from 15% to 90% in just 18 minutes at room temperature, potentially reducing the overall weight of electric vehicles . Some manufacturers are targeting even faster charging times of 10-15 minutes for a full charge in future electric vehicles.

Several leading battery manufacturers like Large Power, particularly in China, have developed semi-solid-state battery technology for electric vehicles, focusing on achieving mass production capabilities and the potential of these batteries as a transitional technology between liquid and solid-state batteries.

Q2. What are the main advantages of solid-state batteries over traditional lithium-ion batteries? Solid-state batteries offer several advantages, including 50% higher energy density, improved safety with no risk of thermal runaway or electrolyte leakage, and significantly longer lifespan of 8,000 to 10,000 charge cycles compared to 1,500 to 2,000 cycles for traditional lithium-ion batteries.

Q3. How do silicon anodes improve solid-state battery performance?

Silicon anodes in solid-state batteries provide a theoretical specific capacity of up to 4200 mAh g−1, which is significantly higher than traditional electrode materials. They also prevent lithium dendrite formation and enable higher critical current density, leading to faster charging and improved safety.

Q4. When can we expect to see solid-state batteries in consumer products?

Several major manufacturers, including Toyota, Nissan, and Samsung, are targeting mass production of solid-state batteries between 2027 and 2030. Some applications, like wearable devices and IoT sensors, may see earlier adoption, with potential implementation in products like Samsung’s Galaxy Watches as early as 2026.

Q5. What impact will solid-state batteries have on renewable energy storage?

Solid-state batteries are expected to significantly enhance renewable energy storage capabilities due to their high energy density, long lifespan, and ability to withstand temperature fluctuations. They are particularly suitable for grid regulation, peak-valley tariff utilization, and powering remote areas, offering more efficient and reliable energy storage solutions for solar and wind power systems.