Contents

Storing lithium-ion batteries at the Optimal Storage State of Charge (SOC) for Lithium-Ion Batteries between 40% and 60% protects their chemical integrity and maintains long-term performance. This range reduces chemical stress, minimizing degradation caused by high voltage or deep discharge. For industrial applications, cycling batteries between 40%-60% SOC at rates such as C/2 or 2C ensures reliability over extended storage periods.

Key Takeaways

Keep lithium-ion batteries charged between 40%-60% to stay healthy. This level reduces chemical wear and damage over time.

Check the battery charge every three months. Recharge to 40%-60% if it falls below 20% to avoid permanent harm.

Store batteries in a place between 15°C and 25°C. This temperature helps prevent heat damage and makes them last longer.

Part 1: Why 40%-60% SOC Is the Optimal Storage State of Charge for Lithium-Ion Batteries

1.1 Chemical stability and reduced degradation at mid-level SOC

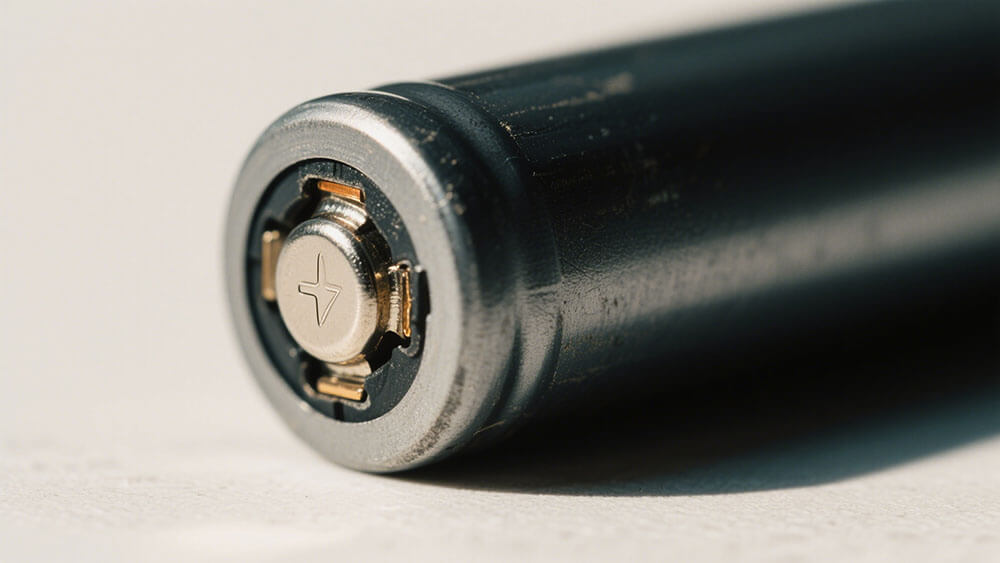

Storing lithium-ion batteries at a mid-level state of charge, specifically between 40% and 60%, ensures chemical stability. At this range, the battery’s internal components, such as the cathode and electrolyte, experience minimal stress. High states of charge, such as 100%, place the cathode under significant voltage stress, accelerating the breakdown of materials like cobalt oxide in LCO Lithium batteries. Conversely, deep discharge below 20% can lead to irreversible chemical damage, such as lithium plating, which reduces capacity and increases the risk of failure.

Maintaining a mid-level SOC minimizes these risks by keeping the lithium ions in a balanced state. This balance reduces side reactions, such as electrolyte decomposition, which are more likely to occur at extreme SOC levels. For industrial applications, where lithium-ion battery storage often involves large-scale systems, this stability translates to fewer maintenance requirements and longer operational lifespans.

Tip: Disconnect batteries from devices during storage to prevent parasitic drain, which can push the SOC outside the optimal range.

1.2 Scientific basis for the 40%-60% SOC recommendation

The recommendation to store lithium-ion batteries at 40%-60% SOC is backed by extensive research. Studies have shown that batteries stored at this range exhibit the lowest annual capacity loss, often less than 5%. In contrast, batteries stored at full charge can lose up to 20% of their capacity annually due to heightened chemical activity.

This optimal storage state of charge aligns with the voltage range of 3.6V to 3.8V per cell, where the electrochemical reactions inside the battery are most stable. For example, NMC Lithium batteries, with a platform voltage of 3.6-3.7V, perform best when stored within this range. The International Electrotechnical Commission (IEC) also recommends a storage voltage of 3.7-3.85V per cell, further supporting the 40%-60% SOC guideline.

Note: For long-term lithium-ion battery storage, maintaining a controlled environment with temperatures between 15°C and 25°C is equally important to prevent thermal degradation.

1.3 Benefits for industrial lithium-ion battery packs

For industrial applications, adhering to the 40%-60% SOC range offers several advantages. First, it reduces the risk of thermal runaway, a critical safety concern in large-scale lithium-ion battery storage systems. Batteries stored at full charge are more prone to overheating, especially in high-temperature environments. By maintaining a mid-level SOC, you can significantly lower this risk.

Second, this practice extends the lifespan of industrial battery packs. For example, LiFePO4 Lithium batteries, commonly used in industrial settings, already offer impressive cycle life (2,000-5,000 cycles). Proper storage further enhances their longevity, reducing replacement costs and downtime. Additionally, maintaining the optimal SOC ensures consistent performance, which is crucial for applications like robotics, infrastructure, and security systems.

Lastly, storing batteries at 40%-60% SOC aligns with sustainability goals. By minimizing degradation, you reduce waste and the need for frequent replacements. This approach supports a more sustainable energy ecosystem, as highlighted in our sustainability initiatives.

Call to Action: For tailored solutions to optimize your industrial lithium-ion battery storage, explore our custom battery solutions.

Part 2: Risks of Storing Lithium-Ion Batteries Outside the Optimal SOC Range

2.1 Impact of full charge (100% SOC) on battery lifespan

Storing lithium-ion batteries at 100% SOC significantly accelerates their degradation. High voltage levels at full charge increase chemical activity within the battery, leading to faster breakdown of the electrolyte and electrode materials. Over time, this results in capacity loss and reduced lifespan. For instance, batteries stored at 100% SOC can lose capacity at a much higher rate compared to those stored at 40% SOC.

Aging Condition | Capacity Loss Rate | Temperature |

|---|---|---|

100% SOC | Increases after 85% nominal capacity | 25°C, 40°C |

90% SOC | Capacity fade dominant | 40°C |

Lower SOC | Change rate relaxes over time | Various |

To avoid these issues, you should store batteries at mid-level SOC, where chemical reactions remain stable. This practice ensures the longevity of your lithium ion battery storage systems.

2.2 Consequences of deep discharge (below 20% SOC)

Deep discharge below 20% SOC poses severe risks to lithium-ion batteries. Low SOC conditions can cause electrolyte decomposition, leading to increased internal resistance and heat generation. Additionally, structural strain from deep discharges may create micro-cracks in the active material, reducing the battery’s ability to store charge.

Effect | Description |

|---|---|

Capacity Loss | High depth of discharge cycles cause significant capacity fade over time. |

Increased Internal Resistance | Thickening of the SEI layer increases resistance and heat generation. |

Structural Damage | Micro-cracks in active material reduce charge storage capacity. |

Voltage Drop | Sharp declines in voltage reduce system efficiency. |

BMS Shutdown | Low voltage triggers battery management system shutdown. |

Inverter Shutdown | Inverters shut down to protect themselves, interrupting power supply. |

To prevent these consequences, you should avoid letting the SOC drop below 20%, especially in industrial lithium ion battery storage setups.

2.3 Long-term risks for bulk storage in industrial applications

Storing lithium-ion batteries outside the 40%-60% SOC range in bulk industrial applications introduces long-term risks. At full charge, batteries are more prone to thermal runaway, especially in high-temperature environments. This can lead to safety hazards, including fires. On the other hand, storing batteries at low SOC increases the likelihood of entering sleep mode or forming copper shunts, which can cause self-discharge and instability.

Storing batteries at full charge results in higher capacity losses compared to mid-level SOC.

Low SOC conditions risk permanent damage, reducing the reliability of large-scale lithium ion battery storage systems.

Maintaining the optimal SOC range minimizes these risks, ensuring safety and reliability for industrial applications.

Part 3: Practical Tips for Maintaining the Optimal SOC During Storage

3.1 Using battery management systems (BMS) for SOC monitoring

A battery management system (BMS) is the cornerstone of effective lithium-ion battery storage. It monitors the state of charge (SOC) with precision, ensuring batteries remain within the optimal 40%-60% range. Advanced BMS technologies, such as those developed by Stanford researchers, utilize electrochemical models to estimate SOC and State of Health (SOH) in real-time. This capability allows you to operate batteries within safe limits, extending their lifespan and improving reliability.

Different SOC estimation methods offer varying levels of accuracy and applicability. For industrial lithium-ion battery storage, methods like the Extended Kalman Filter (EKF) provide high accuracy and real-time monitoring, making them ideal for large-scale systems. Below is a comparison of SOC estimation techniques:

SOC Estimation Method | Accuracy | Speed | Complexity | Real-time Applicability |

|---|---|---|---|---|

Coulomb Counting (CC) | Low | Fast | Low | No |

Open-Circuit Voltage (OCV) | High | Slow | Medium | No |

Extended Kalman Filter (EKF) | High | Medium | High | Yes |

Unscented Kalman Filter (UKF) | Highest | Slowest | Highest | No |

Tip: Implement a BMS with real-time SOC monitoring to prevent overcharging or deep discharge, especially in industrial applications. Learn more about BMS technologies here.

3.2 Importance of temperature and humidity control

Temperature and humidity play a critical role in lithium-ion battery storage. High temperatures accelerate chemical reactions, leading to faster degradation, while low temperatures can cause electrolyte freezing. Maintaining a stable environment between 15°C and 25°C ensures optimal performance and longevity. Humidity levels below 50% reduce the risk of corrosion on metal components, further safeguarding the battery’s integrity.

For industrial setups, sophisticated infrastructure is essential to regulate these conditions. Temperature-controlled storage rooms and dehumidifiers can help maintain stability. Additionally, thermal management systems integrated with battery packs provide real-time adjustments to prevent overheating.

Callout: A controlled environment not only preserves battery health but also minimizes safety risks like thermal runaway. Explore sustainable storage solutions here.

3.3 Periodic SOC checks and recharging protocols

Periodic SOC checks are vital for maintaining the health of lithium-ion batteries during storage. Batteries naturally lose charge over time due to self-discharge. If the SOC drops below 20%, irreversible damage may occur. To prevent this, you should inspect the SOC every three months and recharge the battery to 40%-60% if necessary.

Avoid frequent charging cycles during storage, as this can increase wear on the battery. Instead, focus on maintaining a stable SOC within the recommended range. For industrial lithium-ion battery storage, automated systems can streamline this process, ensuring consistent monitoring and recharging.

Tip: Before using a battery after long-term storage, perform a full charge-discharge cycle to recalibrate the BMS and restore optimal performance.

3.4 Best practices for storing lithium-ion battery packs in bulk

Bulk storage of lithium-ion battery packs requires adherence to industry benchmarks to ensure safety and reliability. The best way to store lithium-ion battery packs involves maintaining a cool, dry environment and keeping the SOC within the manufacturer-recommended range. For large-scale setups, infrastructure must include temperature and humidity controls, as well as systems for SOC monitoring.

Key practices for bulk storage include:

Optimal Conditions: Store batteries in a stable environment to prevent degradation.

State of Charge (SOC): Maintain SOC levels between 40%-60% to minimize stress on cells.

Infrastructure Requirements: Use advanced systems to manage environmental factors and SOC levels effectively.

Callout: Proper bulk storage practices reduce safety risks and extend battery lifespan. For customized industrial solutions, visit Large Power.

Maintaining the optimal storage state of charge (SOC) for lithium-ion batteries between 40% and 60% is crucial for preserving their health and performance. This range minimizes chemical stress, reduces degradation, and ensures long-term reliability. For industrial applications, adopting proper SOC management practices enhances operational efficiency and extends battery lifespan.

Tip: Implementing these strategies not only improves battery performance but also supports sustainability goals. Learn more about sustainable storage practices here.

For tailored solutions to optimize your lithium-ion battery storage, explore our custom battery solutions.

FAQ

1. How often should you check the SOC of stored lithium-ion batteries?

You should check the SOC every three months. Recharge the battery to 40%-60% if the SOC drops below 20%.

Tip: Use automated systems for consistent SOC monitoring in industrial setups.

2. Can lithium-ion batteries be stored at temperatures below 0°C?

No, storing lithium-ion batteries below 0°C risks electrolyte freezing, which can damage the battery. Maintain storage temperatures between 15°C and 25°C for optimal performance.

3. Is it safe to store lithium-ion batteries fully charged?

Storing batteries at 100% SOC accelerates degradation and increases safety risks like thermal runaway. Always store them at 40%-60% SOC to minimize chemical stress.

Alert: Avoid high-temperature environments to reduce the risk of overheating.