Battery pack design requires understanding both fundamental electrochemistry and application-specific engineering requirements. Custom battery pack applications have expanded significantly across electric vehicles, renewable energy systems, and portable electronic devices, each demanding precise technical specifications. Lithium-ion battery packs dominate these applications due to their high energy density characteristics, extended cycle life performance, and favorable weight-to-power ratios.

Battery pack design requires understanding both fundamental electrochemistry and application-specific engineering requirements. Custom battery pack applications have expanded significantly across electric vehicles, renewable energy systems, and portable electronic devices, each demanding precise technical specifications. Lithium-ion battery packs dominate these applications due to their high energy density characteristics, extended cycle life performance, and favorable weight-to-power ratios.

Battery chemistry fundamentals form the foundation of effective pack design. Lithium-ion technology serves as the primary electrochemical platform, with numerous variations available for specific applications. The anode typically consists of graphite-based materials capable of lithium intercalation, often incorporating silicon percentages to enhance capacity performance. Lithium-ion cells deliver high energy density in compact form factors while maintaining reliable power output for modern electronic systems. Power requirements are quantified in watts (W) or kilowatts (kW), while energy capacity is measured in watt-hours (Wh).

This guide addresses the essential technical aspects of battery pack design, from basic cell configuration principles to advanced thermal management implementation. Applications range from high-power discharge systems for electric vehicle starting operations to custom lithium-ion battery pack configurations designed for specific dimensional and performance requirements. The following sections provide systematic guidance for developing professional-grade battery pack solutions, covering electrical design, thermal management, safety systems, and regulatory compliance requirements. Our technical approach ensures that both emerging designers and experienced engineers can develop efficient, safe, and application-optimized power systems.

From Cell to Pack: Building Blocks of Battery Design

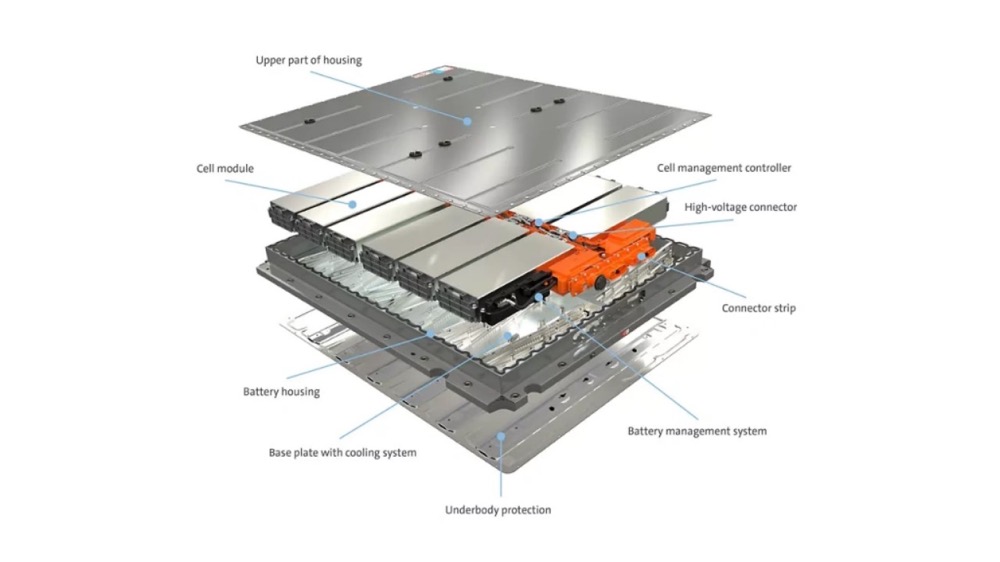

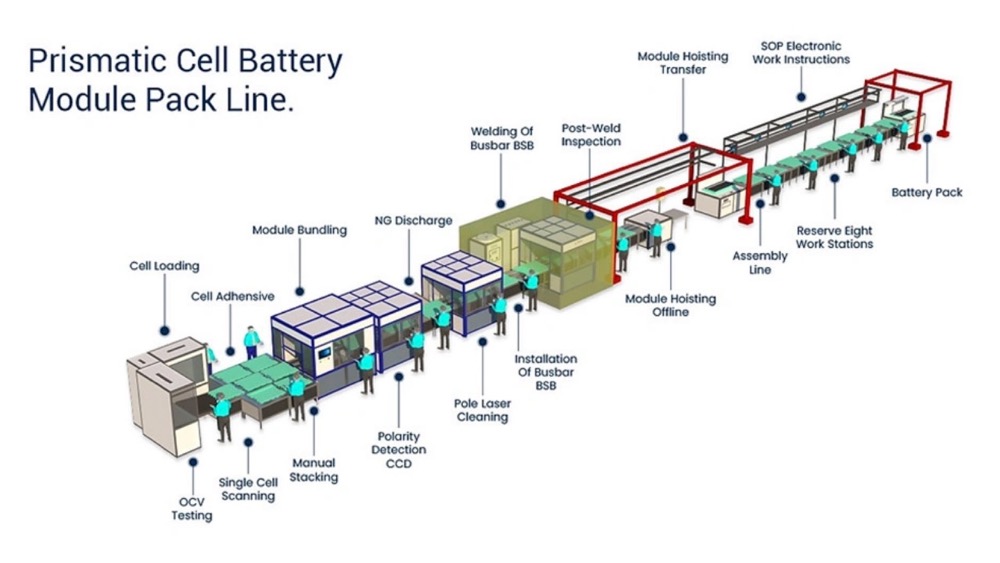

Image Source: semco infratech

Image Source: semco infratech

Battery pack development progresses through systematic integration of electrochemical cells, module assemblies, and pack-level components. Each component level contributes specific functionality to the complete energy storage system, with design decisions at the cell level directly impacting pack performance, safety, and manufacturing requirements.

Understanding lithium-ion cell types

Lithium-ion cells function as the basic electrochemical units providing energy storage capacity. Cell configuration determines both voltage and capacity characteristics, with individual cells connected in series to increase voltage or parallel to increase current capacity. The electrochemical reaction occurs between anode and cathode materials, with lithium ions moving through an electrolyte during charge and discharge cycles.

Three primary cell formats provide different performance characteristics:

- Cylindrical cells: These cylindrical form factor cells offer robust mechanical properties and proven thermal performance. Tesla’s implementation required between 6,000-9,000 cells per vehiclein their early electric vehicle designs. Cylindrical cells provide high power output capabilities but deliver lower energy density compared to alternative formats.

- Prismatic cells: The rectangular geometry maximizes space utilization efficiency within battery pack enclosures. Prismatic cells contain higher energy density per unit volume and demonstrate superior cycle life performance with enhanced safety characteristics. This format reduces the total number of electrical interconnections required, simplifying manufacturing and assembly processes.

- Pouch cells: Flexible aluminum foil packaging enables the highest energy density among available cell types. The flexible enclosure allows direct integration into device housings without requiring additional structural casings.

Cell chemistry variations include Lithium Cobalt Oxide (LCO), Lithium Manganese Oxide (LMO), Lithium Nickel Manganese Cobalt Oxide (NMC), and Lithium Iron Phosphate (LFP), each providing distinct performance, safety, and cost characteristics.

How modules form the foundation of packs

Battery modules comprise multiple cells configured to meet specific voltage and capacity requirements. Module-level integration incorporates several essential subsystems:

- Battery Management Systems (BMS) for voltage, temperature, and state of charge monitoring

- Thermal management systemsproviding heat dissipation capabilities

- Protective enclosures ensuring environmental protection

- Mechanical integration frameworks enabling module-to-pack connections

Modular design architecture provides measurable advantages for battery pack development. Testing data demonstrates that modular configurations reduce disassembly time by 60% and decrease service costs by 40% compared to monolithic pack designs. Module-level serviceability enables replacement of individual modules rather than complete pack replacement, reducing warranty costs and improving system maintainability.

General Motors’ Ultium platform demonstrates effective modular design implementation, utilizing large-format pouch cells arranged in serviceable modules within a scalable pack architecture.

The role of battery module design in performance

Module design directly influences pack-level performance, safety characteristics, and operational lifetime. Effective module design provides electrical isolation between individual cells, minimizing short circuit risks and containing thermal runaway propagation within single modules.

Thermal management integration at the module level determines operational performance limits. Properly designed thermal management systems enable continuous power discharge rates up to 60W per cell while maintaining safe operating temperatures. Temperature control prevents thermal runaway propagation and maintains cell performance within specified parameters.

Module architecture impacts both serviceability and end-of-life material recovery. Modular designs facilitate mechanical separation of materials during recycling processes, improving component recovery rates and supporting sustainable battery lifecycle management. This consideration becomes increasingly important as electric vehicle fleets expand and battery recycling infrastructure develops.

Cell-to-pack (CTP) design approaches eliminate traditional module structures entirely. CATL reports that CTP implementation increases volume utilization by 20-30%, reduces component count by 40%, and improves manufacturing efficiency by 50%. However, applications requiring enhanced safety margins and field serviceability continue to benefit from modular pack architectures in custom battery pack development.

Core Elements of a Battery Pack

“Often times, engineers say that the system needs 2 A to [perform], but what is often not understood is: Is there a peak current load at some point in the load regime? In this case, we have to make sure that the battery can handle not only an average current but a peak load current as well.” — George Cintra, Director of Engineering, Electrochem Solutions (battery technology expert)

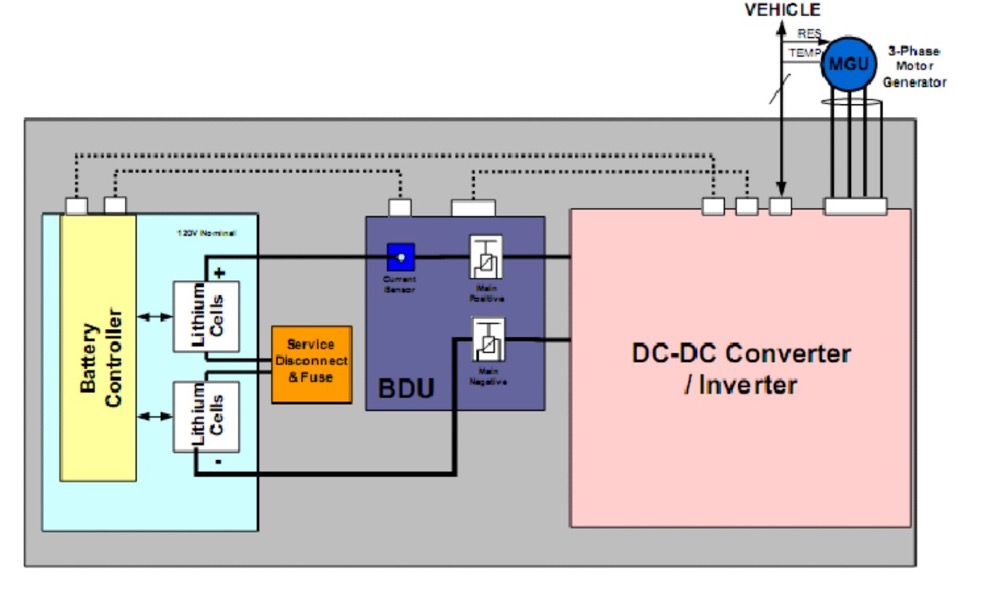

Image Source: ResearchGate

Image Source: ResearchGate

Battery pack performance depends on the precise integration of four essential components. Our experience developing custom battery solutions has demonstrated that each element must be optimized individually and as part of the complete system to achieve reliable operation.

Battery cells and their configuration

Battery cells function as the primary electrochemical units that store and deliver electrical energy. Custom battery pack design requires configuring multiple cells in series, parallel, or series-parallel combinations to meet specific voltage and current requirements.

Series connections multiply voltage while parallel connections increase capacity. A standard laptop battery using a 4s2p configuration (four cells in series, two in parallel) achieves 14.4V nominal voltage while doubling capacity from 2,400mAh to 4,800mAh. Cell matching becomes critical in custom lithium-ion battery packs, as the weakest cell determines overall pack performance.

Standard configurations include:

- 1S2P: Single series string, parallel capacity doubling

- 2S1P: Voltage doubling with original capacity

- 2S2P: Both voltage and capacity doubled

Battery Management System (BMS)

The BMS serves as the control center for battery pack operations, continuously monitoring electrical parameters and managing safety functions. Essential BMS functions include individual cell voltage monitoring, temperature sensing across multiple points, current measurement, and active cell balancing.

Advanced BMS designs for electric vehicle applications provide high-accuracy monitoring with voltage precision of ±15mV, current accuracy within ±1-2%, and temperature measurement accuracy of ±1°C. Additional capabilities include active cell balancing, contactor and fuse control, state of charge estimation, thermal management system coordination, and comprehensive fault detection.

Thermal and voltage regulation systems

Temperature control directly affects battery safety, performance, and lifespan. Lithium-ion cells operate optimally between 15-35°C, with performance degradation occurring outside this range. Sub-zero temperatures reduce discharge capacity and increase internal resistance, while temperatures above 50°C accelerate capacity fade. Operating beyond 60°C significantly increases thermal runaway probability.

Thermal management approaches vary by application requirements: passive air cooling using heat sinks and ventilation channels, forced air cooling with integrated fans, liquid cooling systems utilizing coolant jackets or microchannels, phase change materials for thermal buffering, and thermoelectric cooling for precise temperature control. Dual-PCM thermal management systems can reduce peak temperatures by 1.3°C compared to single-PCM designs.

Voltage regulation protects batteries from overcharge and deep discharge conditions. Voltage monitoring circuits disconnect the battery when operating parameters exceed safe limits, extending operational life and preventing damage.

Enclosure and mechanical protection

Battery enclosures provide mechanical protection, structural integrity, thermal management pathways, electrical isolation, and environmental sealing. Material selection typically involves aluminum alloys for superior thermal conductivity or engineered plastic compounds for weight reduction.

Advanced enclosure materials offer enhanced safety characteristics. Specialized thermoplastic materials can withstand exposure to 1100°C flames for over five minutes while maintaining internal pack temperatures below 200°C, eliminating the need for additional thermal blankets required with conventional metal housings. Integrated protection systems like FyreJacket 1650 provide thermal runaway containment while facilitating streamlined assembly processes.

Designing with Purpose: Matching Pack to Application

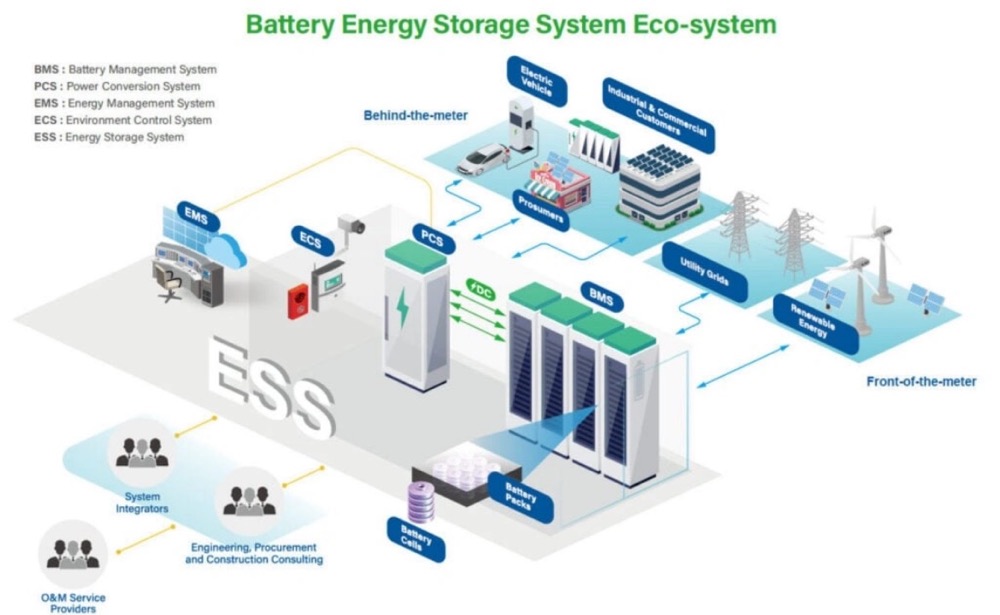

Image Source: Energy-Storage.News

Image Source: Energy-Storage.News

Effective battery pack design requires matching technical specifications to application requirements. Each application presents unique challenges in power delivery, environmental conditions, and operational parameters. Our experience developing custom battery manufacturer solutions across diverse industries has demonstrated that application-specific design determines both performance outcomes and long-term reliability.

Designing for Electric Vehicles

Electric vehicle applications demand high energy density combined with robust thermal management capabilities. Multi-domain modeling methodologies enable electro-thermal evaluation of different cell arrangements through numerical and geometrical models. Lithium manganese or lithium iron phosphate chemistries typically provide optimal safety and performance characteristics for EV applications. These battery packs must withstand mechanical vibration, impact forces, and temperature variations while maintaining structural integrity throughout the vehicle’s operational life.

Power calculations determine battery capacity requirements for EV applications. A vehicle component drawing 50 watts over 4 hours requires battery capacity of 200 watt-hours minimum. EV batteries represent approximately one-fourth of total vehicle weight, making lightweight design critical for range optimization. The challenge lies in balancing energy density requirements with thermal management needs and safety considerations.

Designing for Portable Electronics

Portable device applications prioritize maximum energy density within constrained physical dimensions. Custom lithium-ion battery packs provide superior output characteristics and extended operational life compared to standard solutions. Design optimization focuses on achieving maximum power-to-weight ratios while ensuring precise dimensional compatibility with device requirements.

Portable electronics typically operate under constant power discharge conditions where current increases as voltage decreases to maintain power output (P=V*I). This operational characteristic accelerates voltage decay and affects runtime predictions. Even powered-down devices require minimal current for memory retention and component functionality, which must be considered when specifying shelf-life performance characteristics.

Designing for Stationary Energy Storage

Stationary energy storage applications have become essential for grid stability and renewable energy integration. These systems prioritize operational longevity and reliability over weight considerations, unlike portable applications. Lithium-ion batteries prove most suitable for low and medium-sized installations requiring both high power and energy density.

Battery management systems for stationary applications must comply with IEEE 2686-2024 standards, which specify design, configuration, and security requirements. Advanced designs utilizing Li4Ti5O12 (LTO) anodes paired with LiMn2O4 (LMO) cathodes offer critical-material-free solutions for behind-the-meter storage applications. Stationary systems benefit from intermittent discharge patterns, allowing electrode rest periods that improve utilization efficiency compared to continuous discharge requirements in electric vehicles.

Advanced Techniques for Pro-Level Designers

Image Source: Nature

Image Source: Nature

Professional battery pack design requires sophisticated analytical tools and systematic methodologies to achieve optimal energy storage performance. Advanced design techniques enable precise prediction of battery behavior and systematic optimization of pack architecture.

Using AI and deep learning in battery design

Artificial intelligence transforms battery development through systematic data analysis and predictive modeling capabilities. Machine learning models process extensive datasets to predict critical parameters including ion conductivity and volume changes. The U.S. Army has demonstrated Large Quantitative Models (LQMs) that reduce lithium-ion battery end-of-life prediction times by 95%—from months to days—achieving 35x greater accuracy while requiring 50x less data. These algorithms automatically generate equation components that can identify relevant physical equations without predetermined assumptions.

Thermal simulation and crash analysis

Computer-aided simulation provides cost-effective methods for evaluating battery pack enclosure crashworthiness. Nonlinear dynamic finite element models enable designers to assess how material properties and thickness variations affect safety performance. Thermal management analysis remains critical for ensuring optimal battery performance while preventing thermal runaway conditions. Multi-physics simulations provide detailed analysis of current distribution, ion transport mechanisms, and potential failure modes within battery systems.

Optimizing for weight, space, and efficiency

Weight reduction directly impacts electric vehicle range, with every 10% weight decrease providing 6-8% range improvement. Topology optimization techniques using tools such as Altair OptiStruct enhance structural integrity while minimizing material requirements. Computer-aided engineering technology combined with machine learning algorithms enables cost-effective optimization of thermal management systems and crashworthiness performance. Integrated software platforms like Synera combine design tools with real-time KPI evaluation, reducing battery pack development timelines.

Practical Tools and Resources for Designers

Image Source: 3Dnatives

Image Source: 3Dnatives

Professional battery pack development requires specialized software platforms and validation methodologies to ensure design accuracy and regulatory compliance. Our technical team utilizes specific tools that address the complex requirements of custom lithium ion battery development.

Interactive battery pack design tools

Simscape Battery provides comprehensive pack structure definition capabilities, enabling designers to establish pack configurations with minimal code requirements while generating automated geometry and topology visualization. The MATLAB-based framework establishes direct integration between individual cell parameters and system-level performance characteristics. PyBaMM offers open-source electrochemical modeling for detailed cell-level analysis and simulation. BatPac combines financial modeling capabilities with electrical simulation for complete design evaluation.

CAD integration and 3D modeling

Battery packaging design requires integrated CAD platforms for thermal and mechanical analysis. Simcenter FLOEFD enables computational fluid dynamics simulations within native CAD environments, eliminating platform switching requirements. Multi-domain modeling methodologies support battery module development through integrated numerical and geometrical analysis frameworks. These platforms facilitate rapid spatial configuration evaluation while providing thermal performance predictions.

Benchmarking and validation checklists

Battery pack design validation requires systematic comparison against established industry parameters. Standard benchmarking parameters include total energy capacity (Wh), usable energy capacity (Wh), peak power output (W), nominal voltage (V), amp-hour capacity (Ah), total weight (kg), and volume specifications (liters). Key performance metrics derive from these parameters: specific energy (Wh/kg), energy density (Wh/liter), and cost effectiveness ($/kWh). Validation protocols encompass capacity and voltage measurement during complete charge/discharge cycles, combined with extreme condition testing to verify safety compliance.

Conclusion

Battery pack design integrates electrical, mechanical, and thermal engineering disciplines into cohesive energy storage solutions. This guide has addressed the progression from individual cell selection through complete system implementation, covering application-specific design considerations across multiple market sectors.

The battery industry presents ongoing challenges in balancing performance specifications against safety requirements. Successful battery pack development requires systematic approaches that combine theoretical understanding with empirical validation. Cell chemistry selection, electrical configuration, and thermal management implementation determine both operational lifespan and performance characteristics.

Application requirements dictate design priorities: electric vehicles require high energy density with robust thermal control systems, portable electronics demand compact configurations with optimized power-to-weight characteristics, and stationary storage systems prioritize reliability and service life over weight considerations. Each application category requires specific engineering approaches tailored to operational parameters.

Engineering tools have advanced significantly, with simulation software and computer-aided design platforms enabling performance prediction, thermal analysis, and structural optimization before prototype development. These capabilities reduce development timelines while improving design reliability.

Battery technology continues to evolve through materials science advances and manufacturing process improvements. Cell-to-pack architectures offer improved energy density, while enhanced thermal management techniques provide better safety characteristics.

The principles outlined in this guide establish the foundation for professional battery pack development. Applications spanning medical devices, electric vehicles, and grid storage systems all benefit from the systematic design approach presented here. These engineering fundamentals will support the development of energy storage solutions that meet increasingly demanding performance and safety requirements across all application sectors.

Large Power is a leading battery pack designer, please contact us for any custom battery pack design request.

Key Takeaways

Master the fundamentals of battery pack design to create efficient, safe, and application-specific energy storage solutions that meet modern performance demands.

- Start with the right cell configuration: Choose between cylindrical, prismatic, or pouch cells based on your application’s power, energy density, and space requirements.

- Design application-specific thermal management: EV packs need robust cooling systems, portable devices prioritize compact designs, while stationary storage focuses on longevity over weight.

- Leverage AI and simulation tools early: Use advanced modeling software to predict performance, optimize thermal distribution, and reduce development time by up to 95%.

- Balance the four core elements: Properly integrate cells, BMS, thermal systems, and protective enclosures to ensure optimal performance and safety.

- Apply modular design principles: Modular architectures reduce service costs by 40% and enable easier maintenance compared to monolithic pack designs.

The key to professional battery pack design lies in understanding that each application demands a unique balance of power, safety, and efficiency considerations.

FAQs

Q1. What are the key components of a battery pack? A battery pack consists of four core elements: battery cells configured in series or parallel, a Battery Management System (BMS) for monitoring and control, thermal and voltage regulation systems, and a protective enclosure. These components work together to ensure optimal performance, safety, and longevity.

Q2. How does battery pack design differ for various applications? Battery pack design varies significantly based on the application. Electric vehicles require high energy density and robust thermal management. Portable electronics prioritize compact designs with optimal power-to-weight ratios. Stationary storage applications focus on reliability and longevity rather than weight considerations.

Q3. What advanced techniques are used in professional battery pack design? Professional designers use AI and deep learning for predicting battery properties and optimizing designs. They also employ thermal simulations and crash analysis to evaluate safety and performance. Additionally, advanced optimization techniques are used to minimize weight and maximize space efficiency.

Q4. What tools are available for battery pack designers? Designers have access to interactive design tools like Simscape Battery and PyBaMM for modeling and simulation. CAD integration tools like Simcenter FLOEFD enable seamless 3D modeling and CFD simulations. Benchmarking tools and validation checklists are also crucial for ensuring design quality and compliance with industry standards.

Q5. How can modular design improve battery pack performance? Modular battery pack designs offer several advantages. They can reduce disassembly times by up to 60% and lower service costs by approximately 40% compared to monolithic layouts. Modular configurations also allow for isolated module replacement, substantially reducing warranty costs and improving overall serviceability and recyclability.