High energy density drives innovation in handheld medical device batteries. Device manufacturers seek batteries that deliver more energy with less weight and size. Engineers must balance performance, safety, and reliability. Advanced materials and nanotechnology play a key role. Innovative designs unlock new possibilities for lithium-ion battery packs in medical applications.

Key Takeaways

High energy density is crucial for handheld medical devices, enabling smaller, lighter designs that enhance portability for medical professionals.

Lithium-ion batteries are preferred for their long cycle life, low self-discharge rate, and high efficiency, making them ideal for medical applications.

Advanced materials and nanotechnology improve battery performance, allowing for faster charging and longer runtimes in compact devices.

Engineers must balance energy density with power density to ensure reliable performance during both routine use and emergencies.

Future trends in battery technology focus on sustainability and next-gen chemistries, promising higher energy density and improved safety for medical devices.

Part 1: High Energy Density in Medical Devices

1.1 Importance for Portability

High energy density plays a vital role in the design of handheld medical devices. Engineers strive to reduce the size and weight of these devices while maintaining long runtime. The development of high-energy-density batteries, such as advanced micro-combustors, has enabled significant reductions in device size and weight. These compact and lightweight features enhance portability, which is essential for medical professionals who need to carry devices during patient care. In robotics and security systems, portable devices allow for flexible deployment in various environments. Industrial and infrastructure sectors benefit from lightweight tools that improve worker mobility. Consumer electronics also rely on high energy density to deliver slim and efficient products.

Note: Compact battery packs with high energy density support extended use without frequent recharging, which is critical for field operations and emergency scenarios.

1.2 Impact on Performance

High energy density directly affects the operational lifespan and performance of handheld medical devices. Devices equipped with high-energy-density batteries can operate longer between charges and support advanced features, such as wireless connectivity and real-time monitoring. Increased energy density allows medical devices to deliver reliable performance during long shifts or emergency situations. However, engineers must consider the stress placed on batteries due to rapid charging and discharging cycles. This stress can shorten battery lifespan, making it important to balance energy density with durability.

Trade-Offs Between Energy Density and Power Density in Li-ion Batteries |

|---|

Increasing battery capacity often reduces power density. |

Batteries designed for long-lasting power may struggle with high bursts of energy. |

High power density batteries may have reduced capacity, leading to quicker depletion. |

Many medical devices require high-capacity batteries for prolonged operation. |

Some devices need quick power delivery during emergencies. |

Li-ion batteries must achieve a balance between energy density and power density to meet the demands of medical, industrial, and consumer applications. Engineers select battery chemistries and designs based on the specific needs of each device.

Part 2: Li-ion Batteries and Material Advances

2.1 Li-ion Battery Benefits

Lithium-ion batteries have become the preferred choice for handheld medical devices. Their high energy density allows device manufacturers to design compact products that deliver long runtimes. Medical professionals rely on these batteries for portable monitors, infusion pumps, and diagnostic tools. The following table highlights the key benefits of lithium-ion batteries compared to other chemistries:

Key Benefit | Description |

|---|---|

High Energy Density | Lithium-ion batteries store more energy per unit weight or volume, making them ideal for portable devices. |

Long Cycle Life | They can undergo many charge-discharge cycles, ensuring longevity and reliability in frequent-use applications. |

Low Self-Discharge Rate | They retain charge for extended periods, ensuring devices are ready for use without frequent recharging. |

High Efficiency | With 90-95% efficiency, they minimize energy loss during charging and discharging, enhancing performance. |

Low Maintenance Requirements | They require minimal upkeep, making them convenient for both consumer and industrial applications. |

Environmental Benefits | They are less harmful to the environment and can be recycled, reducing overall ecological impact. |

Cost-Effectiveness | Despite higher initial costs, their longevity and efficiency make them more economical over time. |

Note: In 2023, lithium-ion batteries held a 50.73% market share in the medical battery sector. Over 60% of portable medical devices now use lithium-ion batteries, and this dominance is expected to grow. The lithium batteries segment is projected to expand at a CAGR of 5.5% from 2024 to 2029.

The table below compares common lithium battery chemistries used in medical and industrial applications:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Typical Applications |

|---|---|---|---|---|

LCO | 3.7 | 150-200 | 500-1000 | Portable monitors, imaging |

NMC | 3.6-3.7 | 150-220 | 1000-2000 | Infusion pumps, surgical tools |

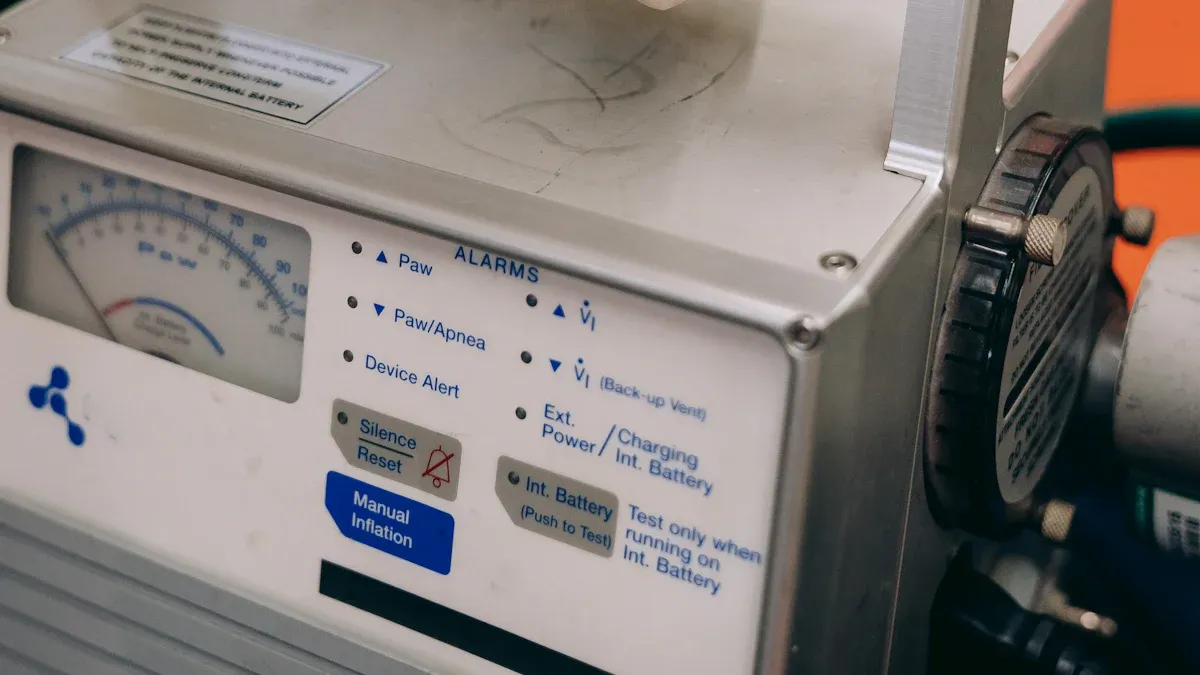

LFP (LiFePO4) | 3.2 | 90-160 | 2000-4000 | Defibrillators, ventilators |

LMO | 3.7 | 100-150 | 300-700 | Handheld scanners, sensors |

LTO | 2.4 | 70-80 | 5000-10000 | Backup power, rapid charge |

Solid-State | 3.2-3.8 | 250-350 | 1000-5000 | Next-gen medical devices |

Lithium Metal | 3.6-3.7 | 350-500 | 500-1000 | Research, high-density packs |

Medical device manufacturers select battery chemistries based on the required balance of energy density, cycle life, and safety. For example, NMC and LFP batteries offer a strong combination of safety and performance for critical care equipment.

2.2 Advanced Electrode Materials

Electrodes play a central role in battery performance and energy storage. Recent research highlights lithium metal as a promising anode material for next-generation lithium-ion batteries. Lithium metal offers a theoretical capacity of 3860 mAh g−1 and a low electrochemical potential of −3.04 V versus the standard hydrogen electrode. This makes lithium metal a leading candidate for achieving high energy density in lithium batteries.

Engineers also explore advanced cathode materials, such as nickel-rich NMC and high-voltage LCO, to further boost battery performance. These materials enable higher energy storage and longer runtimes in compact medical devices. The design of electrodes, including their thickness and structure, directly affects both energy density and cycle life. Optimized electrodes allow for faster charging and discharging, which is essential for emergency medical equipment.

Tip: Selecting the right electrode materials and optimizing their design can significantly improve battery performance and reliability in demanding medical environments.

2.3 Nanotechnology Innovations

Nanotechnology has transformed the design of electrodes in lithium-ion batteries. By increasing the surface area of lithium metal at the nanoscale, engineers enhance lithium-ion interaction. This leads to improved energy storage capacity and faster charging and discharging. Layering active materials and maximizing surface area at the nanoscale also enhances reactivity and performance.

Nanostructured electrodes provide better energy transfer stability and efficiency.

Enhanced surface area and conductivity result in more efficient energy storage and transfer.

Medical device batteries with nanomaterial-based electrodes show longer cycle life and improved reliability.

Nanotechnology enables the design of electrodes that meet the strict requirements of medical, industrial, and infrastructure applications. These innovations support the development of high energy density lithium-ion batteries that power the next generation of portable medical devices.

Part 3: Electrode Design Strategies

3.1 Thin-Film Electrodes

Thin-film electrodes have transformed the design of lithium-ion batteries for medical devices. Engineers use these electrodes to achieve precise control over thickness and composition. This approach leads to significant improvements in electrochemical properties and cycling performance. Thin-film designs allow for enhanced charge storage and stable operation over many cycles.

Performance Aspect | Details |

|---|---|

Electrochemical Properties | Significant improvements in charge storage capabilities and cycling performance observed. |

Capacity Retention | Achieved 75.75% capacity retention after 300 cycles at a current density of 20 µA/cm². |

Li-ion Diffusion Coefficient | Ranged from 10⁻¹⁷ to 10⁻²⁰ cm²/s, indicating enhanced lithium ion movement in the thin film. |

Charge Transfer Resistance | Impedance measurements showed reduced resistance before and after cycling. |

Thin-film cathode materials enhance electrochemical performance without the need for binders or additives. Nanostructure modification increases the surface-to-volume ratio, which improves performance but may also lead to side reactions. Coating techniques help prevent these side reactions and boost conductivity.

Despite these advantages, thin-film electrodes present several manufacturing challenges:

The inability to increase electrode thickness limits effective areal energy density.

Difficulty in controlling geometry on a micrometer scale affects integration into miniaturized devices.

Low energy densities hinder applications requiring long periods between charging.

Tip: Thin-film electrodes work best in applications where precise control and high cycling stability matter more than maximum areal capacity.

3.2 Structured Architectures

Structured electrode architectures offer new ways to improve both energy and power density in lithium-ion batteries. Engineers design electrodes with two-dimensional (2D) and three-dimensional (3D) structures to optimize performance. These architectures increase the surface area available for electrochemical reactions and shorten the pathways for lithium ions.

Aspect | 2D Designs | 3D Architectures |

|---|---|---|

Charge Rates | Improved by maximizing surface area | Shorter diffusion pathways |

Energy Transport | Limited by compactness | Enhanced energy transport |

Electrolyte Infiltration | Compromised | Facilitated among active components |

Surface-to-Volume Ratio | Lower | Higher, improving energy density |

Mechanical Durability | Less flexible | More adaptable to deformation |

3D battery architectures can deliver high energy and power densities at the same time. These designs reduce the diffusion path for lithium ions, which allows for faster charge and discharge rates. The optimized microstructures in 3D electrodes also improve flexibility and mechanical performance. Medical device manufacturers benefit from these features, as devices require both high capacity and rapid power delivery.

Feature | 2D Electrode Designs | 3D Electrode Designs |

|---|---|---|

Flexibility | Limited | Enhanced flexibility and stretchability |

Mechanical Performance | Compromised during deformation | Maintains performance under stress |

Electrochemical Performance | Moderate | Improved due to optimized microstructures |

Note: Structured architectures support the development of batteries that meet strict requirements for reliability and performance in medical environments.

3.3 Surface Modifications

Surface modifications play a critical role in enhancing electrode performance. Engineers apply coatings and treatments to electrode surfaces to improve conductivity, reduce unwanted side reactions, and extend battery life. These modifications help stabilize the interface between the electrode and electrolyte, which is essential for maintaining high energy density and consistent capacity.

Common surface modification techniques include:

Atomic layer deposition to create uniform protective coatings.

Doping with conductive materials to increase electron mobility.

Application of nanocoatings to suppress dendrite formation and improve safety.

Surface modifications also enable the use of advanced materials that might otherwise degrade quickly. By improving the stability and conductivity of electrodes, these techniques support the production of batteries with higher capacity and better power density. Medical device manufacturers rely on these strategies to ensure reliable operation and long service life for portable equipment.

Callout: Surface engineering remains a key area of innovation for next-generation lithium-ion batteries in medical applications.

Part 4: Battery Pack Design

4.1 Compact Integration

Battery pack design for handheld medical devices demands compact integration without sacrificing high energy density. Engineers use several techniques to achieve this goal. They select advanced chemistries, such as silicon-anode lithium-ion cells, which provide 20–30% higher capacity than traditional graphite anodes. Solid-state batteries offer even greater energy density and stability. Optimal cell arrangement plays a key role. Stacking prismatic cells vertically saves space and increases output. Energy management systems use low-power electronics and software, including sleep modes, to optimize energy use. Smart Battery Management Systems (BMS) monitor cell voltage, temperature, and charge state. Calibrated BMS units prevent overcharging, balance cells, and initiate shutdowns during faults. Engineers also focus on thermal management by using phase-change polymers or graphene layers for heat dissipation. In critical applications, ceramic separators minimize combustion risks. Robust materials, such as aerospace-grade aluminum and PEEK polymers, absorb shock and protect the battery pack.

Technique | Description |

|---|---|

Advanced Chemistries | Silicon-anode Li-ion cells for higher capacity; solid-state batteries for stability and energy density. |

Optimal Cell Arrangement | Series/parallel combinations; vertical stacking of prismatic cells for space savings. |

Energy Management | Low-power electronics and sleep modes for energy optimization. |

Smart Battery Management Systems | BMS monitors and balances cells, prevents overcharging, and manages faults. |

Thermal Management | Phase-change polymers, graphene layers, and ceramic separators for heat dissipation and safety. |

Robust Materials | Aerospace-grade aluminum and PEEK polymers for shock absorption. |

4.2 Safety and Reliability

Safety and reliability remain top priorities in battery pack design for medical devices. High energy density batteries, especially lithium-ion, can pose risks of explosions and fires during charging. Engineers address these concerns by using protection circuit modules (PCM) to prevent overcharging and thermal instability. Incorrect chargers may cause battery failures, so manufacturers recommend using only approved charging equipment. Environmental conditions, such as extreme temperatures, can lead to swelling or cracking of the battery enclosure. Impurities in battery fabrication, like microscopic metal particles, may cause internal short circuits and thermal instability. Engineers rely on robust PCM and strict quality control to minimize these risks.

Concern | Explanation |

|---|---|

Battery explosions and fires | High energy density batteries risk explosions and fires during charging. |

Use of incorrect chargers | Non-approved chargers can cause improper charging and failures. |

Environmental conditions | Extreme temperatures may cause swelling and cracking. |

Protection Circuit Module (PCM) | PCM prevents overcharging and thermal instability. |

Impurities in battery fabrication | Metal particles can cause short circuits and explosions. |

Tip: Regular testing and strict manufacturing standards improve reliability and safety in lithium battery packs.

4.3 Balancing Energy and Power

Engineers must balance energy density and power output in battery packs for portable medical equipment. They select lithium cobalt oxide (LCO) and nickel manganese cobalt (NMC) chemistries for their combination of safety and energy density. A robust Battery Management System (BMS) includes overcharge and over-discharge protection, temperature monitoring, and short-circuit protection. Fast charging capabilities, such as QC3.0, allow quick recharging and enhance usability. The design supports continuous operation and remains lightweight, which suits various medical applications. Active cell balancing in the BMS improves performance and safety. Real-time energy indication helps users track battery life and optimize performance. These strategies support optimization for both energy and power, ensuring efficient battery packs for medical devices.

LCO and NMC chemistries balance safety and energy density.

BMS features include overcharge/discharge protection, temperature monitoring, and short-circuit protection.

Fast charging (QC3.0) enables quick recharging for portable devices.

Active cell balancing and real-time energy indication optimize battery pack performance.

Callout: Optimization of battery pack design ensures reliable, safe, and efficient operation in demanding medical environments.

Part 5: Simulation and Testing

5.1 Modeling for Optimization

Simulation plays a vital role in designing lithium battery packs for handheld medical devices. Engineers use advanced modeling techniques to predict battery behavior and optimize performance. Observer-based fault diagnosis helps identify potential issues before they affect device operation. Kalman filters provide robust fault diagnosis, which is crucial for applications that demand high energy density. Adaptive methods adjust to process and measurement noise, improving the accuracy of battery state estimations. These approaches allow engineers to simulate real-world conditions and refine battery designs for maximum reliability and efficiency.

Observer-based fault diagnosis enhances reliability.

Kalman filters support robust fault detection in lithium-ion batteries.

Adaptive methods improve accuracy by adjusting to noise.

Tip: Simulation tools help engineers optimize battery pack design, reducing development time and improving product quality.

5.2 Reliability Testing

Reliability testing ensures that lithium battery packs meet strict safety and performance standards for medical devices. Engineers conduct a series of tests to validate battery durability and consistency. Performance testing verifies that batteries deliver expected results under normal conditions. Functional testing checks primary functions, while reliability testing confirms consistent operation. Stress testing exposes batteries to extreme temperatures and peak power demands. Biocompatibility testing ensures materials are safe for human contact.

Capacity testing measures discharge time at a constant current.

Stress testing evaluates battery performance under harsh conditions.

Lifecycle testing simulates real-world usage to assess long-term capacity.

Overcharge and over-discharge testing prevent unsafe operation.

External short circuit, crush, puncture, and thermal abuse testing address physical and thermal risks.

Vibration and shock testing confirm durability during transport and use.

During these tests, engineers monitor metrics such as voltage and current. Batteries must meet criteria like no deformation or leakage, even when exposed to temperatures from -40°C to 75°C. These protocols ensure that medical devices powered by lithium battery packs deliver reliable energy and maintain high energy density throughout their service life.

Note: Comprehensive reliability testing protects patient safety and supports regulatory compliance for medical device manufacturers.

Part 6: Future Trends

6.1 Next-Gen Chemistries

Battery technology continues to evolve as manufacturers seek higher performance for lithium battery packs in medical systems. Next-generation chemistries promise to deliver even greater high energy density, longer cycle life, and improved safety for critical applications. Researchers focus on several innovative directions:

Silicon-based anodes offer much higher energy storage than traditional graphite, supporting compact systems with extended runtimes.

Solid-state batteries (SSBs) replace liquid electrolytes with solid materials, reducing risks and enabling denser, safer systems.

Novel electrode materials, including those using ionic liquids and high salt content electrolytes, enhance stability and performance in demanding applications.

Bespoke batteries are tailored for specific medical systems, optimizing energy delivery and reliability.

Chemistries beyond lithium, including sodium, magnesium, calcium, and aluminum, are under investigation for specialized applications and improved resource availability.

Chemistry Type | Typical Use in Systems | |

|---|---|---|

Silicon-based anode | Portable diagnostic systems | |

Solid-state battery | Enhanced safety, compactness | Implantable medical systems |

Li-air/Li-sulfur | Ultra-high energy density | |

Sodium/Magnesium | Resource availability | Backup and auxiliary systems |

Note: These advances will shape the future of medical device systems, enabling new applications and supporting the growing demand for reliable, portable energy.

6.2 Sustainability

Sustainability remains a central concern for the production and deployment of high energy density lithium battery packs in medical systems. The extraction of lithium can cause habitat loss, soil erosion, and water pollution, which impacts both ecosystems and communities. Harmful chemicals from lithium extraction may contaminate water sources, posing risks to human health and the environment. The carbon footprint of battery production also presents challenges, requiring manufacturers to adopt mitigation strategies.

Manufacturers must address social responsibility in their supply chains. Workers need safe conditions and fair wages. Human rights concerns, such as child labor and forced labor, require ongoing attention. Supply chain transparency helps companies identify and manage social and environmental risks, ensuring responsible sourcing for all systems and applications.

Extraction of lithium affects habitats and water quality.

Battery production increases carbon emissions.

Safe labor conditions and fair wages are essential.

Human rights issues must be addressed.

Transparent supply chains support responsible sourcing.

For more on sustainable practices in battery systems, visit Our Approach to Sustainability.

Callout: Sustainable battery systems will drive the next wave of innovation in medical applications, supporting both performance and environmental stewardship.

Medical device manufacturers achieve high energy density by implementing advanced design strategies. The table below highlights actionable strategies that improve efficiency and energy density improvements in lithium battery packs:

Strategy | Description |

|---|---|

Electrode Design | Optimizes energy and power density through innovative concepts. |

Microstructure Optimization | Uses 3D modeling to enhance efficiency in energy storage systems. |

Mass Loading Increase | Raises theoretical capacity for better energy storage systems. |

Laser Perforation | Improves lithium ion transport and fast charging in energy storage systems. |

Leading brands prioritize safety and reliability by integrating leak-proof designs, fail-safe mechanisms, and strict quality control. Technology advancements, including solid-state batteries and silver-oxide cells, drive efficiency and support continuous operation. B2B stakeholders should evaluate solutions based on compliance, reliability, and long-term support to maximize efficiency in energy storage systems.

FAQ

What factors most influence energy density in lithium battery packs for medical devices?

Engineers select advanced electrode materials, optimize cell architecture, and use compact integration techniques. These factors increase energy density. Battery management systems also help maintain performance and safety.

How do manufacturers ensure safety in high energy density lithium battery packs?

Manufacturers use protection circuit modules, robust battery management systems, and strict quality control. They test batteries for thermal stability, overcharge protection, and mechanical durability. These steps reduce risks in medical environments.

Which lithium battery chemistries offer the best balance of energy density and cycle life?

Chemistry | Energy Density (Wh/kg) | Cycle Life (cycles) | Typical Use |

|---|---|---|---|

NMC | 150–220 | 1000–2000 | Infusion pumps, surgical tools |

LFP | 90–160 | 2000–4000 | Defibrillators, ventilators |

NMC and LFP chemistries provide strong energy density and long cycle life.

What role does nanotechnology play in lithium battery pack design?

Nanotechnology increases electrode surface area and conductivity. These improvements boost energy storage, enhance charge rates, and extend cycle life. Medical device batteries benefit from greater reliability and efficiency.

How do manufacturers test reliability in lithium battery packs for medical devices?

Manufacturers conduct capacity, stress, lifecycle, and safety tests. They monitor voltage, current, and physical integrity. Batteries must pass tests for temperature extremes, vibration, and shock to ensure consistent performance.