Moisture and particulate contamination represent the primary failure modes for battery packs operating in demanding environments. Agricultural equipment, medical devices, industrial systems, and marine applications expose batteries to conditions that can compromise both safety and functionality. Effective waterproof battery pack design requires adherence to established protection standards rather than relying on general water resistance claims.

The Ingress Protection (IP) rating system provides the industry standard for measuring environmental protection in battery enclosures. The classification uses a two-digit format: the first digit (0-6) specifies solid particle protection levels, while the second digit (0-9) indicates liquid ingress resistance. Battery packs intended for outdoor installations typically require an IP rating of 65 or higher to ensure adequate protection against environmental exposure. Standard protection classifications for lithium battery applications include IP20, IP22, IP65, IP66, IP67, and IP68, each providing distinct protection characteristics for specific operating conditions.

Battery pack designers must understand these protection standards to select appropriate enclosure specifications for their applications. The IP rating directly influences enclosure design, sealing methods, and material selection throughout the development process.

This guide examines the technical requirements for waterproof battery pack design, explains IP rating classifications, analyzes protection technologies, and provides selection criteria for determining appropriate protection levels based on application requirements.

Waterproof Battery Pack Design Requirements

Waterproof battery pack design addresses multiple failure modes that can compromise system reliability and safety. Water intrusion creates direct paths for short circuits, accelerates electrochemical corrosion, and can result in thermal runaway conditions in lithium-ion systems. Electric vehicle battery packs, marine equipment, and industrial applications require robust protection against environmental exposure to maintain operational safety and performance standards.

Ingress Protection Standards vs. Water Resistance Claims

Ingress Protection (IP) ratings provide quantifiable protection measurements through standardized testing protocols, unlike general water resistance claims that lack specific performance criteria. Water resistance typically indicates basic splash protection without defined testing parameters for:

- Exposure duration limits under specific conditions • Maximum water immersion depth tolerance

• Pressure resistance thresholds for water jet exposure

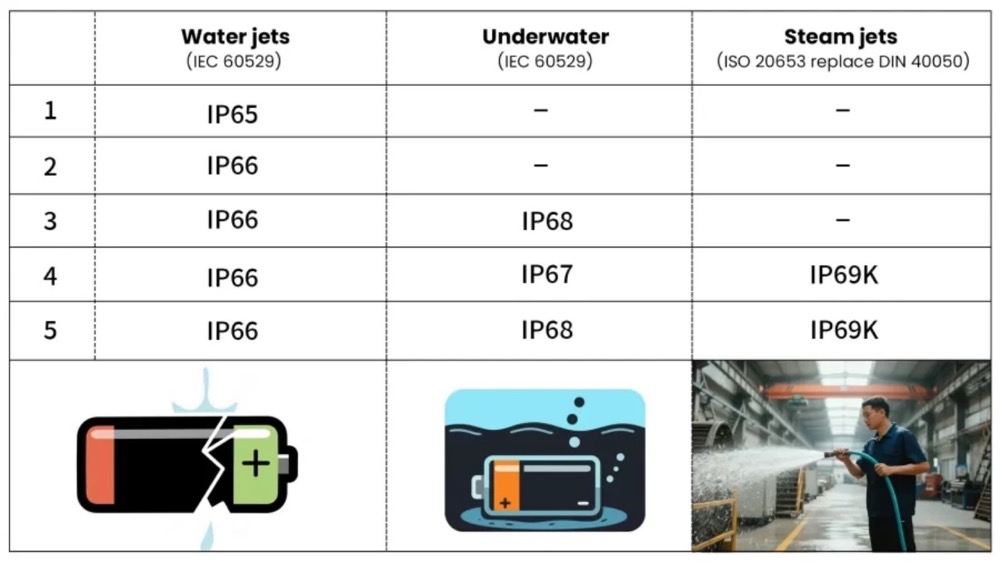

Ingress Protection (IP) ratings establish measurable performance criteria through internationally standardized test methods. An IP67 rating requires complete dust protection and survival of 1-meter water immersion for 30 minutes minimum. IP68-rated battery packs withstand continuous submersion under manufacturer-specified conditions, while IP69K-rated units resist high-pressure water jets at elevated temperatures.

Environmental contamination causes predictable failure mechanisms in battery systems. Dust accumulation reduces insulation effectiveness between conductors, while moisture exposure increases self-discharge rates and promotes corrosion of current-carrying components. These degradation processes increase internal resistance and generate additional heat during charge and discharge cycles.

Technical Implementation of Waterproof Battery Enclosures

Waterproof battery enclosure design requires systematic protection against multiple ingress pathways. The implementation process addresses specific vulnerability points through:

Material Selection and Surface TreatmentsCorrosion-resistant thermoplastics and metal alloys provide the foundation for water-resistant enclosures. Hydrophobic surface treatments create additional moisture barriers on battery casing materials.

Sealing Technology Integration Multiple sealing approaches address different protection requirements:

- Compression sealing rings requiring consistent wall thickness and uniform pressure distribution

- Ultrasonic welding or structural adhesive bonding for permanent seals

- O-ring seals positioned at cover-to-casing interfaces

- Elastomeric sealants applied at mechanical joints

Precision Manufacturing Requirements Tight dimensional tolerances ensure consistent sealing performance across production quantities. Optimized mold designs maintain seal integrity while accommodating thermal expansion.

Electric vehicle applications present additional challenges due to high-voltage operation. Battery systems operating above 200V require enhanced sealing performance to prevent water ingress that could cause dangerous short-circuit conditions. Most automotive manufacturers specify IP67 as the minimum protection standard for EV battery enclosures.

Application-specific protection requirements vary significantly across industries. Outdoor battery installations typically require IP65 or higher protection levels. Marine applications demand IP67 or IP68 ratings due to water jet exposure, multi-directional splashing, and potential submersion events. Industrial environments with high-pressure cleaning operations require IP69K protection against pressurized water jets at elevated temperatures.

Lithium-ion battery packs offer inherent advantages for waterproof applications compared to lead-acid alternatives, providing better sealing compatibility and reduced maintenance requirements. This performance advantage has driven increased adoption in demanding environmental applications.

IP Rating Standards for Battery Pack Design

Battery pack designers require a comprehensive understanding of Ingress Protection standards to ensure reliable environmental protection. The International Electrotechnical Commission (IEC) established these standards under IEC 60529 to provide consistent protection classification across the electronics industry.

IP Code Structure and Classification

The IP rating follows a standardized two-digit format after the “IP” designation. The first digit ranges from 0-6, indicating solid particle protection effectiveness. The second digit ranges from 0-9, specifying liquid ingress resistance levels.

When testing has not been conducted for a specific protection type, the corresponding digit is replaced with “X.” An IPX7 rating indicates level 7 water protection without solid particle testing.

A critical design consideration: IP ratings are not cumulative across different test conditions. A battery pack meeting IPX7 immersion requirements may not satisfy IPX5 water jet specifications.

Solid Particle Protection Classifications

The first digit defines protection against solid object ingress according to these specifications:

| Level | Protection Against | Description |

| IP0X | None | No protection against contact or object ingress |

| IP1X | Objects >50mm | Protects against large body surfaces but not deliberate contact |

| IP2X | Objects >12.5mm | Prevents finger or similar-sized object entry |

| IP3X | Objects >2.5mm | Keeps out tools, thick wires |

| IP4X | Objects >1mm | Blocks most wires, screws, insects |

| IP5X | Dust Protected | Dust may enter but not enough to interfere with operation |

| IP6X | Dust-tight | Complete dust protection; no ingress permitted |

Battery applications in construction or industrial environments typically require IP6X classification to prevent dust particles from compromising internal components.

Liquid Ingress Protection Standards

The second digit specifies water resistance through progressively rigorous test conditions:

| Level | Protection Against | Testing Method |

| IPX0 | None | No protection |

| IPX1 | Dripping water | Vertical drops for 10 minutes |

| IPX2 | Dripping water at 15° angle | Four positions, 10 minutes total |

| IPX3 | Spraying water | Water spray up to 60° from vertical |

| IPX4 | Splashing water | Water splashing from any direction |

| IPX5 | Water jets | Water Protection Ratings Water Protection Rating |

| IPX6 | Powerful water jets | Water Protection Ratings Water Protection Rating |

| IPX7 | Temporary immersion | Up to 1m depth for 30 minutes |

| IPX8 | Continuous immersion | Beyond 1m depth, manufacturer-specified conditions |

Outdoor battery installations generally require minimum IPX5 protection. Marine applications demand IPX7 or IPX8 ratings for submersion resistance. IPX9K provides essential protection against high-pressure cleaning systems operating at 180°F and pressures reaching 1450 PSI.

Testing Protocol Requirements

Each IP classification requires specific testing procedures with defined parameters. IPX7 testing mandates 30-minute submersion with the product’s lowest point positioned 1000mm below the water surface. These precise specifications ensure consistent protection standards across manufacturers and applications.

Battery pack designers must select appropriate IP ratings based on specific environmental exposure rather than assuming higher ratings provide universal protection. The testing methodology varies significantly between protection levels, making application-specific selection critical for optimal performance and cost efficiency.

Waterproof Battery Pack Technologies and Materials

Image Source: CM Batteries

Waterproof battery pack design requires specific material selection and sealing technologies based on the target IP rating and operating environment. Different protection levels demand different approaches to achieve reliable long-term performance.

Encapsulation Resin vs Laser Welding for Maximum Protection

Two primary technologies dominate the design of battery packs requiring IP68/IP69K protection levels: encapsulation resin and laser welding.

Encapsulation resin involves filling the battery assembly with a curing compound such as epoxy, polyurethane, or silicone to create a monolithic sealed unit. This approach provides excellent immersion protection and increases vibration resistance. The trade-offs include significant weight increase, poor thermal management due to reduced heat dissipation, and complete elimination of serviceability.

Laser welding creates hermetically sealed enclosures through precision metal-to-metal bonding. This technology achieves IP68/IP69K ratings while maintaining a compact profile and superior mechanical integrity. The higher production cost reflects the precision equipment requirements and specialized tooling needed for consistent weld quality.

Sealing Materials and Implementation Methods

Material selection for waterproof seals depends on the specific environmental conditions and chemical exposure requirements:

Silicone rubber operates effectively across temperature ranges from -80°C to 250°C while maintaining flexibility and providing inherent flame resistance. Fluororubber offers superior chemical resistance, making it suitable for medical device applications where disinfectants are used regularly. EPDM provides excellent weathering and UV resistance for outdoor applications.

Implementation methods include O-ring sealing, which provides cost-effective solutions but requires periodic replacement due to wear. Form-in-place gaskets (FIPG) and cure-in-place gaskets (CIPG) offer custom sealing solutions for complex geometries. Proper compression ratios typically range from 15-30% for planar seals to prevent both leakage and permanent gasket deformation.

Application-Specific Enclosure Design

Environmental conditions dictate enclosure material and construction requirements:

Marine applications require stainless steel construction to resist saltwater corrosion while maintaining IP68 protection levels. Industrial environments utilize ABS plastic for IP65 applications, with specialized high-temperature, high-pressure resistant enclosures for IP69K applications involving cleaning at 80°C and 10 MPa pressure. Medical device batteries must combine IP68 protection with chemical-resistant materials capable of withstanding repeated disinfection cycles.

Electric vehicle battery enclosures present unique challenges due to high voltage levels potentially exceeding 200V, requiring IP67 protection as the minimum standard. Design considerations include minimizing potential leak paths, incorporating proper gasket compression channels, and maintaining seal integrity across the battery’s operational temperature range.

Testing validation includes pressure decay testing, immersion testing under specified conditions, and thermal shock evaluation to confirm protection levels. Compliance verification requires certification to standards such as IEC 60529 for international applications and MIL-STD-810G for military specifications.

Application-Specific IP Rating Requirements

Image Source: CM Batteries

Battery pack protection requirements vary significantly based on the specific operating environment and exposure conditions. Each application presents unique challenges that dictate minimum acceptable IP ratings for reliable performance.

Outdoor Battery-Powered Lighting: IP65 Requirements

Battery-powered lighting systems installed outdoors face continuous exposure to environmental conditions. For reliable outdoor battery lights with timers, an IP65 rating establishes the minimum protection threshold. This specification ensures complete dust protection and resistance to water jets from any direction, including wind-driven rain.

Outdoor battery installations offer operational advantages beyond weather protection. These systems eliminate indoor space requirements while providing superior ventilation characteristics that prevent thermal buildup during charging cycles. The IP65 classification specifically addresses dust ingress prevention and low-pressure water jet resistance, both critical for equipment exposed to variable weather patterns.

Marine Applications: IP67 vs IP68 Considerations

Marine environments create demanding conditions for battery enclosures due to saltwater exposure and potential submersion events. IP67 provides temporary immersion protection up to 1 meter depth for 30 minutes, meeting requirements for most recreational boating applications. This rating has become the baseline standard for marine battery applications.

IP68 offers extended protection for continuous submersion beyond 1 meter depth, necessary for applications with sustained saltwater contact. Saltwater exposure accelerates terminal corrosion, reducing electrical conductivity and creating potential for short circuits or electrochemical reactions. Marine batteries for trolling motors and similar applications benefit from IP68 ratings to maintain reliability during unexpected immersion scenarios.

Medical Device Applications: IP68 for Disinfection Protocols

Medical device batteries require IP68 protection to withstand both liquid immersion and chemical disinfection procedures. This rating ensures dust-tight construction and extended water immersion resistance, critical for maintaining safety and operational reliability in healthcare environments. Medical battery enclosures must function reliably through repeated sterilization cycles, as contamination control in healthcare settings allows no margin for failure.

Industrial Sensor Systems: IP69K for High-Pressure Environments

Industrial applications involving frequent high-pressure cleaning require the maximum IP protection level available. IP69K rating provides protection against high-temperature, high-pressure water jets, with specific test parameters including:

- Water temperature: 176°F (80°C) • Pressure levels: 1,450 PSI (10 MPa) • Flow rate: 14-16 liters per minute

This protection level becomes essential in food processing facilities, pharmaceutical manufacturing, and automotive production where regulatory sanitization protocols mandate aggressive cleaning procedures.

IP Rating Selection for Battery Pack Applications

Determining the appropriate IP rating for your waterproof battery pack requires systematic analysis of environmental exposure conditions rather than selecting maximum protection levels. Proper rating selection balances operational requirements against cost and design constraints.

Environmental Hazard Analysis

Battery pack designers must evaluate specific operating conditions to establish minimum protection requirements. Critical assessment factors include:

- Particulate exposure levels (construction dust, agricultural debris, industrial contaminants)

- Liquid contact patterns (intermittent splashing, continuous humidity, direct immersion)

- Temperature operating ranges (sub-zero conditions, elevated heat environments)

- Pressure variations (altitude changes, high-pressure cleaning exposure)

Industry applications have established standard minimum requirements: agricultural equipment typically specifies IP65 protection, medical devices require IP68 for disinfection compatibility, and marine equipment demands IP67 or IP68 for saltwater environments.

Protection Level Cost Analysis

IP67 provides optimal cost-performance balance for most battery applications, offering temporary immersion protection without premium manufacturing costs. Higher protection levels such as IP68 or IP69K require specialized sealing technologies and manufacturing processes that significantly increase production costs while addressing only specific application requirements like continuous submersion or high-pressure jet exposure.

Budget-conscious applications can utilize IP54 protection for basic dust and splash resistance suitable for covered outdoor installations. Battery enclosures requiring higher IP ratings necessitate precision sealing methods, advanced materials, and quality control processes that directly impact final product pricing.

Testing Verification Requirements

Battery pack specifications must include certified test documentation from accredited laboratories. Third-party verification provides measurable competitive advantages in markets where environmental protection represents a critical performance parameter. Manufacturer self-certification offers limited market recognition, while independent testing compliance enables premium product positioning and establishes technical credibility with customers.

Testing documentation should specify the exact test conditions, duration parameters, and pass/fail criteria used to validate the claimed IP rating. This verification process ensures that protection claims match actual performance capabilities under specified environmental conditions.

Summary

Waterproof battery pack development requires systematic application of IP rating standards and precise understanding of environmental protection requirements. IP ratings provide quantifiable protection levels against solid particle ingress and liquid intrusion, enabling engineers to specify appropriate enclosure designs for demanding applications.

The technical distinction between basic water resistance claims and certified IP protection remains critical for reliable battery pack performance. Standardized IP testing protocols ensure measurable protection against specific environmental conditions, unlike general resistance specifications that lack verification standards. Enclosure technologies—including encapsulation resin, laser welding, and precision gasket systems—address distinct waterproofing requirements based on application parameters and cost constraints.

Application requirements determine necessary protection specifications. Outdoor battery installations require IP65 minimum ratings for dust-tight protection and water jet resistance. Marine applications demand IP67 or IP68 ratings due to saltwater exposure and potential submersion conditions. Medical device batteries need IP68 certification for disinfection compatibility and immersion protection. Industrial applications with high-pressure cleaning requirements benefit from IP69K protection against heated water jets at pressures reaching 10 MPa.

Effective IP rating selection follows established engineering practices. Environmental risk assessment identifies specific protection requirements based on dust exposure, moisture contact frequency, temperature ranges, and pressure conditions. Cost analysis balances protection specifications against manufacturing constraints—IP67 provides optimal cost-performance for most applications without premium pricing associated with higher ratings. Supplier verification through certified testing documentation ensures compliance with specified protection levels.

The objective for battery pack design is to match protection requirements to actual environmental conditions rather than selecting maximum available ratings. IP67 certification addresses temporary immersion requirements for most demanding applications while maintaining cost-effectiveness. Higher protection levels add significant manufacturing complexity and expense without providing additional benefit unless specific application conditions require enhanced protection capabilities.

For any custom battery pack inquiry, please contact Large Power, a leading battery pack maker.

Key Takeaways

Understanding IP ratings is essential for designing reliable waterproof battery packs that perform consistently in challenging environments.

- IP ratings provide standardized protection levels: The two-digit system measures dust protection (0-6) and water resistance (0-9), with higher numbers indicating superior protection against environmental threats.

- Application determines required protection level: Outdoor lighting needs IP65+, marine applications require IP67/IP68, medical devices need IP68 for disinfection, and industrial sensors benefit from IP69K.

- IP67 offers optimal cost-performance balance: This rating handles temporary immersion up to 1 meter for 30 minutes without premium pricing, making it suitable for most applications.

- Verify supplier claims with certified testing: Request third-party IP testing documentation rather than relying on self-declared ratings to ensure genuine protection capabilities.

- Environmental risk assessment guides selection: Evaluate dust exposure, moisture contact frequency, temperature extremes, and pressure conditions before choosing an IP rating rather than defaulting to the highest level.

The key to successful waterproof battery design lies in matching protection requirements to actual environmental challenges while balancing performance needs with cost constraints.

FAQs

Q1. What does IP rating mean for battery packs? IP (Ingress Protection) rating is a standardized system that measures a battery pack’s protection against solid particles and liquids. The first digit (0-6) indicates dust protection, while the second digit (0-9) represents water resistance.

Q2. Which IP rating is recommended for outdoor battery applications? For outdoor battery applications, an IP rating of 65 or higher is generally recommended. This ensures protection against dust and water jets from any direction, making it suitable for exposure to rain and other outdoor elements.

Q3. How does IP68 differ from IP67 for marine batteries? While IP67 protects against temporary immersion up to 1 meter for 30 minutes, IP68 offers superior protection for continuous immersion beyond 1 meter. IP68 is more suitable for marine batteries facing consistent saltwater exposure.

Q4. What IP rating is necessary for medical device batteries? Medical device batteries typically require an IP68 rating. This ensures dust-tight protection and resistance to extended water immersion, allowing the batteries to withstand both disinfection procedures and potential liquid exposure in healthcare settings.

Q5. How do manufacturers achieve high IP ratings for battery packs? Manufacturers use various techniques to achieve high IP ratings, including specialized casing materials, sealing technologies like O-rings and gaskets, protective coatings, and precision mold designs. For maximum protection (IP68/IP69K), methods such as encapsulation resin or laser welding are often employed