Selecting the right Lithium Battery for lamps ensures your LED lamp operates safely and efficiently. Voltage compatibility and battery quality prevent damage and extend lifespan.

Aspect | Rechargeable LED Lights | Traditional Incandescent Bulbs |

|---|---|---|

Energy Consumption | Up to 80% less energy | Higher energy consumption |

Lifespan | 50,000 hours or more | Shorter lifespan |

Key Takeaways

Match the voltage of your lithium battery to your LED lamp’s requirements to ensure safe and efficient operation.

Calculate the right battery size based on your lamp’s power rating and desired runtime for optimal performance.

Consider environmental factors like temperature and humidity, as they can significantly affect battery performance and lifespan.

Part 1: Lamp Power Needs

1.1 Voltage and Current for LED Lights

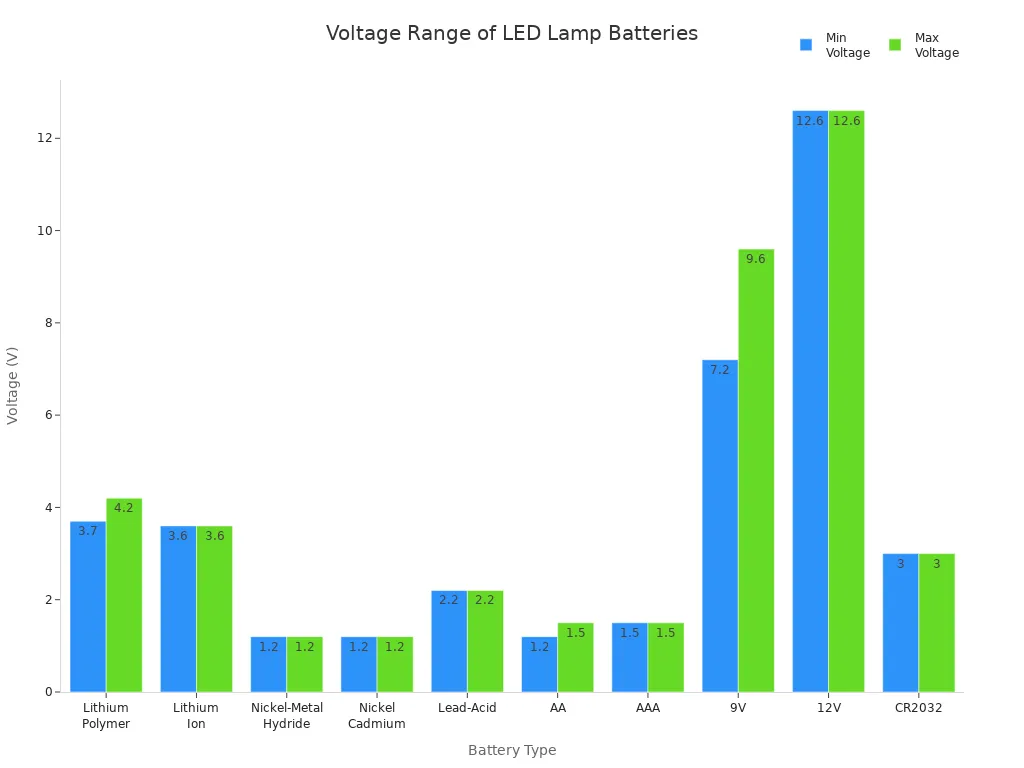

Selecting the correct voltage and current for your LED lamp is the foundation for safe and efficient operation. You must match the voltage of your lithium battery for led lights to the requirements of your lamp. Using the wrong voltage can cause flickering, reduced brightness, or even permanent damage. The following table outlines standard voltage ranges and their typical applications:

Voltage Range | Application Description |

|---|---|

Low Voltage (12V/24V) | Residential, small commercial areas; safer and easier to install |

120V – 277V | Urban and suburban street lighting; balances brightness and efficiency |

High Voltage (347V/480V) | Industrial areas, highways; supports high-intensity illumination |

Tip: Always check the lamp’s datasheet or technical label for voltage and current specifications before selecting a lithium battery for led lights.

Voltage mismatch can lead to several operational issues. The table below summarizes the impact of incorrect voltage and poor connections:

Issue | Effect on Performance and Lifespan |

|---|---|

Wrong driver voltage | |

Loose connections | Premature failures, unstable operation |

Voltage drop (wiring) | Dim lighting, increased power consumption |

Using an incorrect driver reduces LED output and efficiency.

Voltage drops from wiring cause dim, inefficient lighting.

Excessive voltage drops increase energy consumption and reduce lifespan.

1.2 Right Battery Size and Capacity

To ensure your battery operated led lights meet operational demands, you must calculate the right battery size. This involves determining the battery capacity required for your application. The following formulas help you calculate battery size based on your lamp’s power rating and desired runtime:

Formula Description | Formula | Example Calculation |

|---|---|---|

Battery Capacity (Ah) based on power and time | Battery capacity (Ah) = (LED power (W) × Usage time (hours)) / Battery voltage (V) | For a 10W LED light running for 5 hours on a 12V battery, you’ll need a 4.17Ah battery. |

Battery Capacity (Ah) based on runtime and current | Battery Capacity (Ah) = Runtime (hours) x Current Draw (A) | With a runtime of 5 hours and a current draw of 0.83A: Battery Capacity = 5 hours × 0.83A = 4.15Ah |

Final Battery Capacity considering DoD | Final Battery Capacity = Adjusted Capacity/DoD | For a 10W LED light operating at 12V for 5 hours, considering a DoD limit of 50%, you will need a battery with a capacity of at least 10.8Ah. |

Note: Depth of Discharge (DoD) is critical for lithium batteries. For longer battery life, avoid discharging below 50% of total capacity.

The right battery size depends on your application. For example, medical devices, robotics, security system installations, and infrastructure projects all require precise calculations to ensure uninterrupted operation. The table below shows typical battery types and their applications:

Types Of LED Batteries | Voltage (V) | Applications |

|---|---|---|

Lithium Polymer (Li-Po) | 3.7 – 4.2 | Mobile LED lights, camera-mounted LEDs, drones |

Lithium Ion (Li-Ion) | 3.6 | Portable power banks, LED flashlights, consumer electronics |

Nickel-Metal Hydride (NiMH) | 1.2 | Emergency lighting, hybrid vehicles |

Nickel Cadmium (NiCd) | 1.2 | Power tools, emergency lighting |

Lead-Acid | 2.2 | Emergency lights, off-grid solar systems |

AA | 1.2-1.5 | Remote controls, small LED lights |

AAA | 1.5 | Remote controls, small LED lights |

9V | 7.2 – 9.6 | Smoke detectors, small LED devices |

12V | 12.6 | Larger LED systems, automotive, industrial lighting |

CR2032 | 3 | LED lights, car key fobs |

When you select the best battery to use for led lights, always consider the right battery size for your specific use case. For battery operated led lights in industrial or infrastructure settings, you may require higher capacity lithium batteries to support longer runtimes and higher power demands.

1.3 Usage Patterns and Environment

Your usage patterns and installation environment play a significant role in determining the right battery size and chemistry. Continuous operation, such as in security system lighting or infrastructure projects, demands larger battery capacity and robust lithium battery for led lights. Intermittent use, common in consumer electronics or portable medical devices, may allow for smaller, lighter battery packs.

Environmental factors such as temperature and humidity directly affect lithium battery performance. The table below summarizes key environmental impacts:

Factor | Effect on Battery Performance |

|---|---|

Low Temperature | Reduces real capacity, increases internal resistance; charging slows or stops below 0°C; capacity drops to ~70% at -10°C. |

High Temperature | Accelerates aging, shortens battery life, increases risk of chemical instability. |

High Humidity | Causes corrosion and damage; batteries must be protected from moisture and condensation. |

High temperatures increase internal resistance and cause capacity loss, reducing charging and discharging efficiency.

Low temperatures slow chemical reactions, lowering capacity and efficiency.

Operating within -4°F to 140°F maximizes lithium battery performance and lifespan.

Tip: For critical applications in medical, robotics, or industrial sectors, always specify environmental requirements when consulting with your battery supplier. This ensures you select the best battery to use for led lights in any environment.

By understanding your lamp’s voltage and current needs, calculating the right battery size, and accounting for usage and environmental factors, you can confidently choose the best lithium battery for led lights. This approach guarantees efficiency, safety, and reliability for your B2B projects.

Part 2: Lithium Battery Options and Compatibility

2.1 Best Battery to Use for LED Lights

Selecting the best lithium battery for led lights requires a clear understanding of the available battery chemistries and their performance characteristics. You need to consider energy density, cycle life, weight, and application requirements. The most common types for LED lamp applications include Lithium-ion (Li-ion), Lithium Polymer (LiPo), Lithium Iron Phosphate (LiFePO4), and cylindrical cells like 18650 and 21700.

Battery Type | Energy Density (Wh/kg) | Cycle Life (cycles) | Key Advantages | Typical Applications |

|---|---|---|---|---|

Li-ion | 150-250 | 300-1000 | High energy density, low self-discharge, reliable | Portable LED lamps, emergency lighting, power banks |

LiPo | 300-400 | 300-500 | Flexible design, lightweight, high energy density | Slim LED panels, wearable lighting, drones |

LiFePO4 | 90-160 | 3000-7000 | Long cycle life, high safety, stable chemistry | Industrial LED lamps, solar street lights |

18650 | ~200 | 300-500 | Standardized size, widely available | Flashlights, modular LED systems |

21700 | ~250 | 500-800 | Higher capacity, improved energy density |

Tip: For applications requiring long operating time and high reliability, LiFePO4 and 21700 cells offer superior cycle life and stability.

2.2 Lithium Battery for Lamps: Types and Comparison

You must compare lithium battery types based on your LED lamp’s requirements. Li-ion batteries provide a balance of energy density and safety, making them a reliable choice for most devices. LiPo batteries offer higher energy density (300-400 Wh/kg), which allows for lighter and thinner lamp designs. However, they have a higher self-discharge rate and typically last 300-500 cycles. Li-ion batteries, with 150-250 Wh/kg, deliver longer lifespan and lower self-discharge, but less design flexibility.

Battery Type | Energy Density (Wh/kg) | Cycle Life (cycles) | Self-Discharge Rate | Design Flexibility |

|---|---|---|---|---|

Li-ion | 300-1000 | Low | Moderate | |

LiPo | 300-400 | 300-500 | Higher | High |

Cylindrical cells like 18650 and 21700 also play a significant role in LED lighting. The 21700 cell provides higher energy density and longer cycle life compared to the 18650, making it suitable for high-capacity, long-duration lighting.

Battery Type | Cycle Life (cycles) | Energy Density (Wh/L) |

|---|---|---|

18650 | 300-500 | ~500 |

21700 | 500-800 | ~700 |

The weight of your lithium battery for led lights impacts the design and portability of your LED lamp. Lighter batteries, such as Li-ion and LiPo, improve transport and installation efficiency, especially for portable or modular lighting systems.

2.3 Rechargeable Lithium Battery: Safety and Quality

You should always prioritize safety and quality when selecting a lithium battery for led lights. High-quality, rechargeable lithium batteries reduce the risk of thermal runaway, fires, and explosions. Low-quality batteries may contain manufacturing defects, increasing the likelihood of hazardous incidents, especially under physical stress or high temperatures.

Certification | Description | Test Content |

|---|---|---|

MSDS | Provides safety information and handling guidelines for batteries. | Chemical Composition Analysis, Safe Handling Guidelines |

UN38.3 | Ensures safety during transportation of lithium batteries. | Altitude Simulation Test, Temperature Cycling Test, Vibration Test, Shock Test |

CNCA | Certification for safe transportation of chemicals in China. | Chemical Composition Analysis, Safe Transportation Test |

RoHS | Restricts hazardous substances in electrical and electronic equipment. | Chemical analysis of restricted substances, Material identification |

Note: Always request documentation for MSDS, UN38.3, and RoHS certifications from your supplier to ensure compliance and safety.

Common safety risks with low-quality batteries include:

Thermal runaway, which can cause rapid temperature increases and fires.

Increased risk of fires and explosions due to physical damage or electrical abuse.

Higher likelihood of hazardous incidents from manufacturing defects.

To maximize battery lifespan and safety:

Charge batteries at a slow rate.

Avoid overnight charging.

Use chargers rated for about 1/4 of the battery capacity.

Store batteries in cool, shaded areas at around 50% charge.

Regularly check and clean battery terminals.

2.4 Lithium Battery for LED Lights: Compatibility Factors

You must ensure full compatibility between your lithium battery for led lights and the lamp system. Voltage compatibility is critical. The battery pack voltage must match the LED lamp’s rated voltage to prevent underperformance or damage.

Compatibility Factor | Description |

|---|---|

Voltage Compatibility | Ensures the battery pack voltage matches the LED lamp’s rated voltage to prevent underperformance or damage. |

Wiring and Connection Interface | Proper connection interfaces compatible with battery packs ensure easy assembly and maintenance, reducing installation time and potential technical issues. |

Other key factors include:

Size and Connector Type: The battery must fit the lamp’s housing and use compatible connectors for safe, efficient installation.

Efficiency: Choose batteries with at least 80% efficiency for optimal performance.

Discharge Current: A higher discharge rate enables the battery to provide more current, essential for high-drain LEDs to achieve intended brightness. Insufficient discharge current can result in dim lighting or failure to power the LED.

Weight: Lighter batteries improve portability and ease of installation, especially for mobile or modular lighting systems.

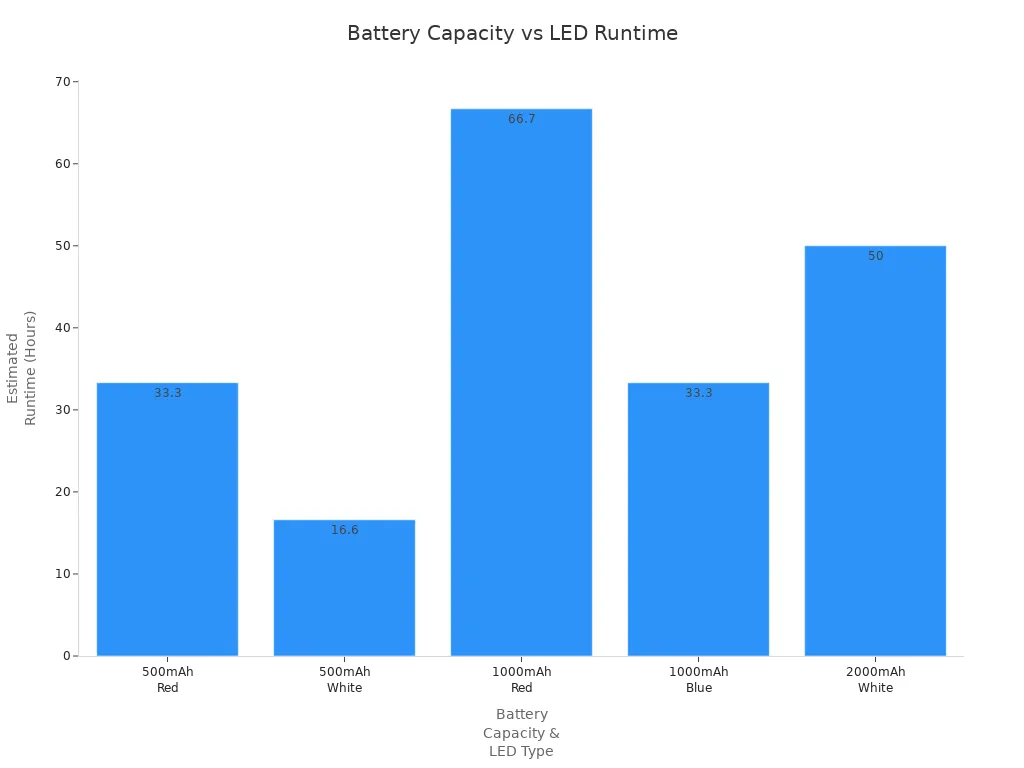

Manufacturers test battery compatibility by matching battery capacity, LED type, and current draw to estimate operating time. For example:

Battery Capacity (mAh) | LED Type | Current Draw (mA) | Estimated Runtime (Hours) |

|---|---|---|---|

500 | Red | 15 | 33.3 |

500 | White | 30 | 16.6 |

1000 | Red | 15 | 66.7 |

1000 | Blue | 30 | 33.3 |

2000 | White | 40 | 50 |

Quick Reference Checklist for Selecting the Best Lithium Battery for LED Lights:

Confirm voltage and power compatibility.

Select battery capacity based on required operating time.

Ensure efficiency is at least 80%.

Choose high energy density for compact designs.

Verify safety certifications (MSDS, UN38.3, RoHS).

Check size, weight, and connector compatibility.

Consider environmental impact and handling requirements.

Consult with your battery supplier for customized solutions.

By following these guidelines, you can ensure your lithium battery for led lights delivers reliable performance, long operating time, and full compatibility with your LED lamp systems.

You can select the best lithium battery for LED lamps by focusing on battery specifications, voltage compatibility, and final battery capacity. Review the table below for key steps:

Factor | Description |

|---|---|

Capacity | Calculate final battery capacity for required runtime. |

Voltage | Match voltage to lamp needs. |

Cycle Life | Choose batteries with a long life span. |

Use the battery capacity formula and online calculators to confirm final battery capacity.

Always consult suppliers to verify final battery capacity and compatibility.

FAQ

What factors should guide your choice of lithium battery for LED lamps?

You should base your choice on voltage compatibility, battery capacity, and safety certifications. Large Power offers custom battery solutions for specialized B2B needs. Click here for customized consultation.

How does your choice of lithium battery chemistry impact LED lamp performance?

Your choice of lithium battery chemistry affects energy density, cycle life, and safety. Refer to the table below for a quick comparison of standardized battery types:

Battery Chemistry | Energy Density (Wh/kg) | Cycle Life (cycles) | Key Application |

|---|---|---|---|

Li-ion | 150-250 | 300-1000 | Portable LED systems |

LiPo | 300-400 | 300-500 | Slim LED panels |

LiFePO4 | 90-160 | 3000-7000 | Industrial LED lamps |

Why should B2B users consult Large Power for their lithium battery pack choice?

Large Power provides expert guidance for your battery pack choice, ensuring optimal compatibility and performance. Their custom solutions address unique operational requirements. Request a custom battery consultation.