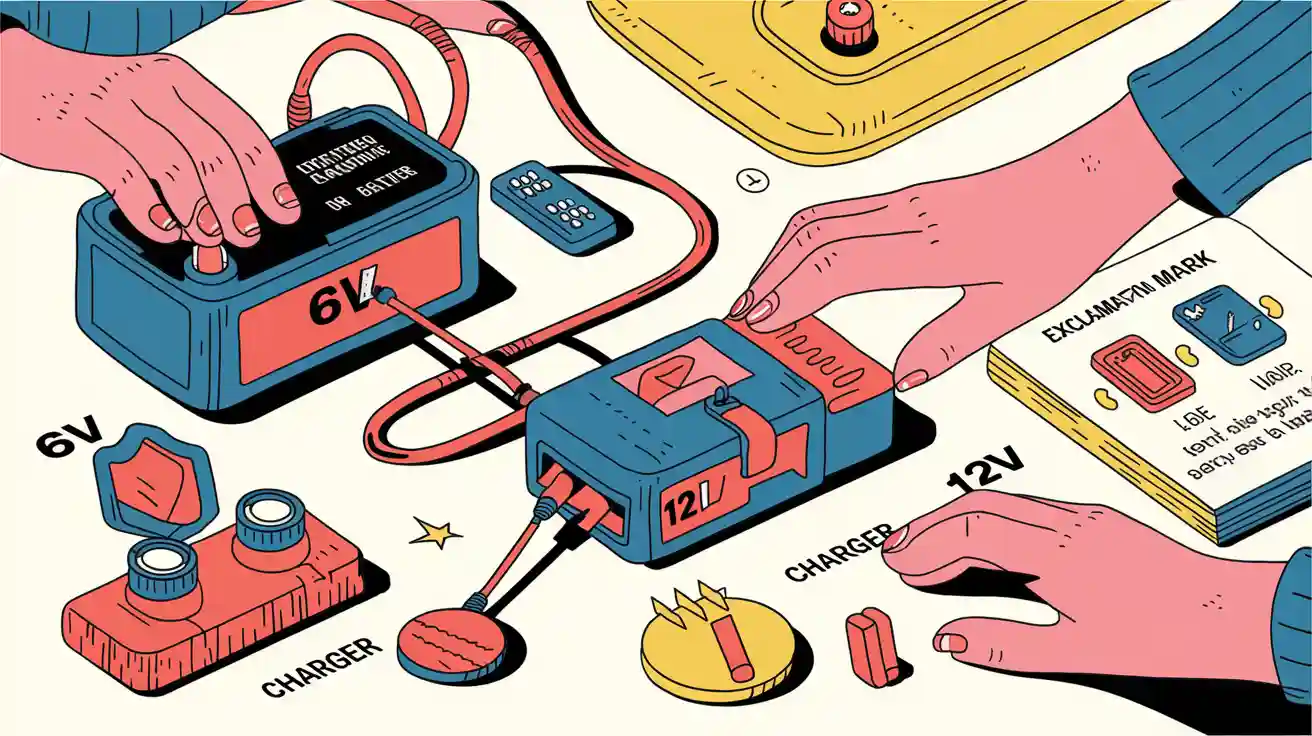

Charging 6V battery with 12V charger creates serious safety risks. When charging 6V battery with 12V charger, you expose the battery to dangers like overcharging, overheating, swelling, and even potential explosions. Common incidents from charging 6V battery with 12V charger include:

Charging 6V battery with 12V charger can deform the battery casing.

Charging 6V battery with 12V charger may cause electrolyte leakage.

Charging 6V battery with 12V charger often results in permanent capacity loss.

Charging 6V battery with 12V charger could trigger thermal runaway.

You must always match your charger voltage to your battery for safety. Charging 6V battery with 12V charger or using the wrong voltage endangers both the battery and your safety. Only consider series or parallel charging with proper precautions and compatible equipment.

Key Takeaways

Never charge a 6V battery directly with a 12V charger to avoid overheating, damage, and safety hazards like leaks or explosions.

Charge two 6V batteries connected in series with a 12V charger to match voltage safely and monitor the process closely to prevent overcharge.

Use chargers with automatic shut-off and protection features, keep battery terminals clean, and follow manufacturer guidelines to extend battery life and ensure safety.

Part 1: Charging 6V Battery with 12V Charger Risks

1.1 Battery Basics

To understand the risks of charging 6v battery with 12v charger, you first need to know how a 6v battery works. Every battery stores energy using chemical reactions between its internal parts. These parts include the anode, cathode, electrolyte, and separator. The table below shows the main components and their functions in a typical 6v battery:

Component | Role / Function | Example Materials / Details |

|---|---|---|

Anode | Negative electrode during discharging; supplies electrons to external circuit by oxidation | Metallic cadmium (Ni-Cd battery), metallic lead (lead-acid battery) |

Cathode | Positive electrode during discharging; accepts electrons from external circuit by reduction | Nickel oxyhydroxide (NiOOH) for Ni-Cd, lead dioxide (PbO2) for lead-acid |

Electrolyte | Completes internal circuit by allowing ion conduction; can be acidic or alkaline | Alkaline (KOH solution) in Ni-Cd; acidic (H2SO4 solution) in lead-acid; supplies OH- or H+ ions accordingly |

Separator | Physically isolates electrodes to prevent short circuits while allowing ionic flow | Porous plastic (Ni-Cd), porous glass-fiber (sealed lead-acid) |

Cell Connection | Multiple cells connected in series to increase voltage; 6v battery typically series of cells | Series connection adds voltages; e.g., 3 lead-acid cells in series for 6V |

When you use a 6v battery, the anode releases electrons during discharging, and the cathode accepts them. The electrolyte lets ions move between the electrodes, completing the circuit. The separator keeps the electrodes apart to prevent short circuits but still allows ions to flow. Most 6v batteries, like lead-acid or Ni-Cd, use several cells in series to reach the needed voltage.

Lithium-ion batteries, which you find in medical devices, robotics, security systems, infrastructure, consumer electronics, and industrial equipment, have a different structure. They use a graphite anode and a metal oxide cathode, such as LCO (LiCoO2), NMC (LiNiMnCoO2), LMO (LiMn2O4), LTO (Li4Ti5O12), or LiFePO4. Each chemistry has unique properties:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LCO | 3.7 | 150-200 | 500-1,000 |

NMC | 3.6-3.7 | 150-220 | 1,000-2,000 |

LMO | 3.7-4.0 | 100-150 | 300-700 |

LTO | 2.4 | 70-80 | 5,000-10,000 |

LiFePO4 | 3.2 | 90-160 | 2,000-5,000 |

Lithium-ion cells have higher platform voltages, so you need fewer cells to reach 6V. This makes lithium batteries lighter and more compact. Their design also supports efficient charging and discharging cycles, but they require strict protection to avoid overcharge, overheating, or short circuits.

1.2 Overcharging and Damage

Charging 6v battery with 12v charger creates a voltage mismatch. The 12v charger tries to push the battery up to 12 volts, which the 6v battery cannot handle. This causes several problems:

Overcharge leads to overheating, which can damage the battery inside and out.

The battery case may bulge, crack, or even burst.

Overcharge can cause the electrolyte to leak, releasing toxic substances.

Battery terminals may corrode quickly.

Internal short circuits can develop, making the battery unsafe to use.

Tip: If you notice corrosion on the terminals, a bulging case, or leaking fluid, stop charging right away. These are clear signs of overcharge and a serious safety hazard.

You may also see slow engine cranking, dimming lights, or frequent jump-starts. These signs mean the battery cannot hold a charge after repeated overcharge events. Overcharging dries out the electrolyte, increases internal resistance, and causes permanent damage. Gel and AGM batteries are especially sensitive to overcharge, and their lifespan drops sharply if you use the wrong charger.

Consequence | Explanation |

|---|---|

Reduced Battery Life | Overcharge increases internal resistance, reducing the number of charging cycles. |

Corrosion | Overcharge causes corrosion of battery components, damaging the internal structure. |

Electrolyte Loss | Excessive charging leads to higher gassing rates, causing loss of electrolyte fluid. |

Physical Damage | High voltage and heat can warp plates or melt separators inside the battery. |

Safety Hazards | Extreme overcharge may cause explosions or fires, posing risks to users. |

Industry standards require you to match the charger voltage to the battery voltage. For example, you must use a 6v charger for a 6v battery. Some smart chargers can detect battery type and adjust their charging program, but most 12v chargers will not protect a 6v battery from overcharge. Manufacturer guidelines warn against charging 6v battery with 12v charger directly. Instead, you should connect two 6v batteries in series to create a 12v bank if you must use a 12v charger. This method balances charging and provides protection for each battery.

Direct charging 6v battery with 12v charger is never safe. You risk overheating, leakage, corrosion, and even fire. Always follow manufacturer instructions and use the correct charger to ensure safety, protection, and long battery life.

Part 2: Charging 6 Volt Batteries Safely

Charging 6 volt batteries with a 12V charger requires careful planning and strict safety measures. You must use the correct arrangement and follow best practices to avoid overcharge, overheating, and physical damage. This section explains how to safely charge using series and parallel setups, and provides essential tips for lithium battery groups.

2.1 Series Arrangement

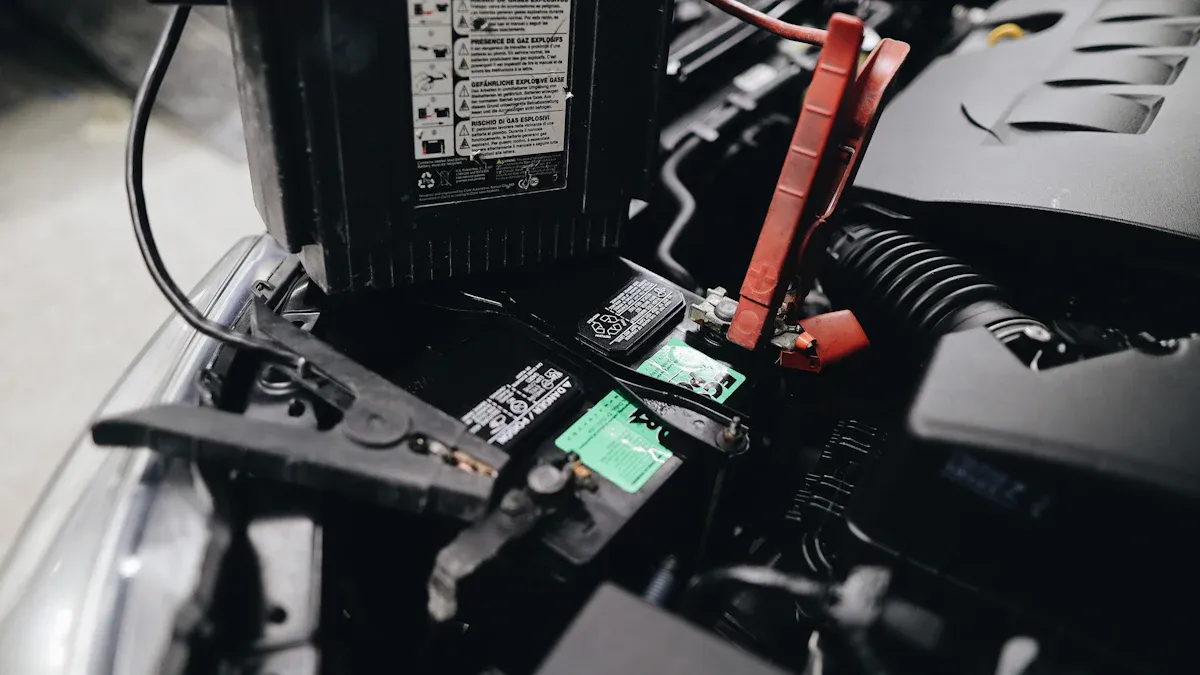

When you connect two 6V batteries in series, you create a 12V system. This method allows you to use a 12V charger safely. Follow these steps for proper charging:

Wire the two 6V batteries in series. Connect the positive terminal of the first battery to the negative terminal of the second battery.

Attach the positive lead of the 12V charger to the free positive terminal of the first battery.

Attach the negative lead of the charger to the free negative terminal of the second battery.

Ensure all connections are clean and tight. Dirty or loose terminals can cause resistance, heat, and poor charging.

Apply a thin layer of grease or petroleum jelly to the terminals to prevent corrosion.

Use a quality 12V charger designed for lead-acid batteries, such as the CTEK MULTI US 7002.

Monitor the charging process. Check electrolyte levels regularly and top up with distilled water if needed.

Treat the two batteries as a single 12V unit during charging. Do not disconnect them until charging is complete.

Replace both batteries as a matched set to maintain balance, since batteries self-discharge at different rates.

Note: Charging time depends on battery capacity and charger output. For example, a 25 amp charger may take about 6 hours to recharge half-discharged batteries. Avoid deep discharging to reduce charging time and extend battery life.

Advantages of Series Arrangement:

You get higher amperage capacity, which means more reserve power for your system.

Both batteries share current equally during charging and discharging, improving reliability.

6V deep cycle batteries often have more lead content, which increases capacity and lifespan.

You can service each 6V battery individually, which may lower long-term costs.

Disadvantages:

You face higher initial costs because you need two batteries and extra equipment.

The setup is heavier and bulkier, requiring more space.

If one battery fails, you may need to replace both to maintain balance.

Maintenance becomes more complex, especially if you need to keep both batteries matched.

Aspect | Series Configuration |

|---|---|

Failure Impact | One failing cell can cause entire pack failure; voltage imbalance reduces efficiency and runtime. |

Overcharging Risk | Requires balanced charging to avoid overcharge; equalizing charge needed to maintain balance. |

Overheating Risk | Less heat accumulation; risk mainly from imbalance or failing cells. |

Physical Damage Risk | Replacement difficult; mismatched cells cause imbalance; welded packs complicate repair. |

Best Practices:

Always use matched batteries for charging 6 volt batteries in series.

Monitor individual battery voltages to prevent overcharge and imbalance.

Use a battery monitor, such as the Victron Smart Shunt, for accurate state-of-charge information.

Avoid charging overnight unless your charger has an automatic cutoff feature.

2.2 Parallel Arrangement

Parallel charging is less common for 6V batteries with a 12V charger, but you may encounter it in maintenance or balancing scenarios. In parallel, you connect all positive terminals together and all negative terminals together. This keeps the voltage at 6V but increases the available current.

Steps for Parallel Charging:

Use batteries of the same age, brand, voltage, and amp-hour rating to avoid imbalance.

Connect all positive terminals together and all negative terminals together.

Use a charger that matches the combined amp-hour rating at 12 volts.

Set the charger to a low current (around 2 amps) to avoid overcharge.

Monitor the batteries during charging. Check for boiling, swelling, or leaks.

Ensure proper ventilation to prevent hydrogen gas buildup.

Do not leave the charger unattended unless it has an automatic cutoff.

Avoid mixing old and new batteries, as this can cause premature failure.

Warning: Charging in parallel can take longer than series charging. Uneven charging may cause imbalance and shorten battery life. Always use matched batteries and monitor the process closely.

Aspect | Parallel Configuration |

|---|---|

Failure Impact | A weak cell reduces capacity but does not affect voltage; shorted cells can cause excessive heat/fire risk. |

Overcharging Risk | Protection circuits and fuses needed to isolate faulty cells and prevent overcharge or thermal runaway. |

Overheating Risk | Heat dissipation is challenging; risk of thermal runaway higher due to multiple current paths. |

Physical Damage Risk | More connections increase failure points; short circuits can cause fire hazards; fuses mitigate risks. |

Best Practices:

Charge each 6V battery individually before connecting in parallel for maintenance charging.

Use a quality charger with smart features to prevent overcharge.

Check each cell with a density tester for accurate health assessment.

Maintain fluid levels above the plates to avoid irreversible damage.

Use fuses and protection diodes to prevent short circuits and overcurrent.

2.3 Lithium Battery Group Tips

Lithium battery groups, such as LiFePO4, NMC, LCO, LMO, and LTO, are common in medical devices, robotics, security systems, infrastructure, consumer electronics, and industrial equipment. These batteries offer high energy density and long cycle life, but require strict protection during charging and discharging.

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LCO | 3.7 | 150-200 | 500-1,000 |

NMC | 3.6-3.7 | 150-220 | 1,000-2,000 |

LMO | 3.7-4.0 | 100-150 | 300-700 |

LTO | 2.4 | 70-80 | 5,000-10,000 |

LiFePO4 | 3.2 | 90-160 | 2,000-5,000 |

Key Safety Tips for Lithium Battery Groups:

Recharge lithium batteries when they reach 20-30% capacity. Avoid full discharging, as it stresses the battery and shortens lifespan.

Do not leave devices plugged in after full charging. Overcharge can cause heat buildup and damage.

Charge only within the recommended temperature range (32°F to 113°F or 0°C to 45°C). Extreme temperatures reduce efficiency and can cause irreversible damage.

Always use chargers that match the battery’s voltage, amperage, and connector type. Incompatible chargers can cause overheating and reduce performance.

Perform regular maintenance. Check connections and clean terminals to ensure proper charging and discharging.

Use smart chargers with built-in overcharge, overheat, and short-circuit protection.

Monitor charging cycles and avoid charging overnight without intelligent protection.

Install fuses and protection circuits to isolate faulty cells and prevent thermal runaway.

Tip: Never mix lithium batteries of different ages or chemistries in a group. Always use matched sets to maintain balance and safety.

Charging Speed Comparison:

Series charging is faster because the charger supplies current through both batteries equally.

Parallel charging is slower, as the current divides between batteries, and balancing takes more time.

Summary Table: Recommended Charging Limits

Configuration | Recommended Charging Voltage | Current Limit / Charge Rate | Notes |

|---|---|---|---|

6V Batteries in Series (to form 12V) | ~14.3 volts (wet-cell) | Up to 5 amps during equalizing charge | Float voltage: 13.65-13.8V; equalizing up to 16.5V for 6V batteries |

6V Batteries in Parallel | Must be matched batteries | Careful monitoring required | Risk of imbalance; defective or mismatched batteries can cause damage |

Standard 12V Wet-cell | ~14.3 volts | N/A | Gel and sealed batteries require ~14.1V max |

Float Charging (all types) | 13.65-13.8 volts | N/A | Sustained float charging to avoid overcharge or undercharge |

Essential Safety Devices:

Use chargers with reverse polarity, overcharge, short-circuit, and overheat protection.

Temperature compensation adjusts charging voltage based on ambient temperature.

Fuses and diodes add extra protection against faults.

By following these guidelines, you can ensure safe charging, maximize battery life, and reduce the risk of overcharge, overheating, or physical damage. Always prioritize safety and use the right equipment for your battery type and application.

Charging a 6V battery with a 12V charger presents serious safety risks, including overheating, loss of protection, and damage during discharging. You must use proper charging arrangements and monitor protection features. Always follow manufacturer guidelines and consult experts before charging. Certified chargers with automatic shut-off enhance safety and prevent overcharging.

Remember: Careful charging and protection ensure battery safety and reliable discharging.

FAQ

Can you use a 12V charger for charging a 6V battery directly?

You should never use a 12V charger for charging a 6V battery directly. This creates a major safety hazard and can cause overcharge, overheating, or permanent damage.

What is the safest way to start charging 6 volt batteries with a 12V charger?

You should connect two 6V batteries in series before charging. This method matches the voltage and improves safety. Always monitor charging and use chargers with automatic protection features.

How do you avoid overcharge and ensure safety during charging?

You must use a charger with automatic shut-off and temperature monitoring. Check battery condition before charging. Never leave batteries unattended. Proper protection prevents overcharge and improves safety.