High performance batteries provide portable power for devices ranging from medical equipment to electric vehicles. Performance characteristics extend beyond the basic energy storage function that consumers observe. Energy density represents a fundamental design parameter – the amount of power stored relative to physical size and weight constraints.

High performance batteries provide portable power for devices ranging from medical equipment to electric vehicles. Performance characteristics extend beyond the basic energy storage function that consumers observe. Energy density represents a fundamental design parameter – the amount of power stored relative to physical size and weight constraints.

Battery performance requirements encompass multiple technical specifications. Cycle life determines how many charge-discharge cycles a battery can withstand before capacity degradation occurs. Fast-charging capability requires specialized internal architecture that maintains battery integrity while reducing charging time. Safety mechanisms become increasingly critical as energy density increases and applications become more demanding.

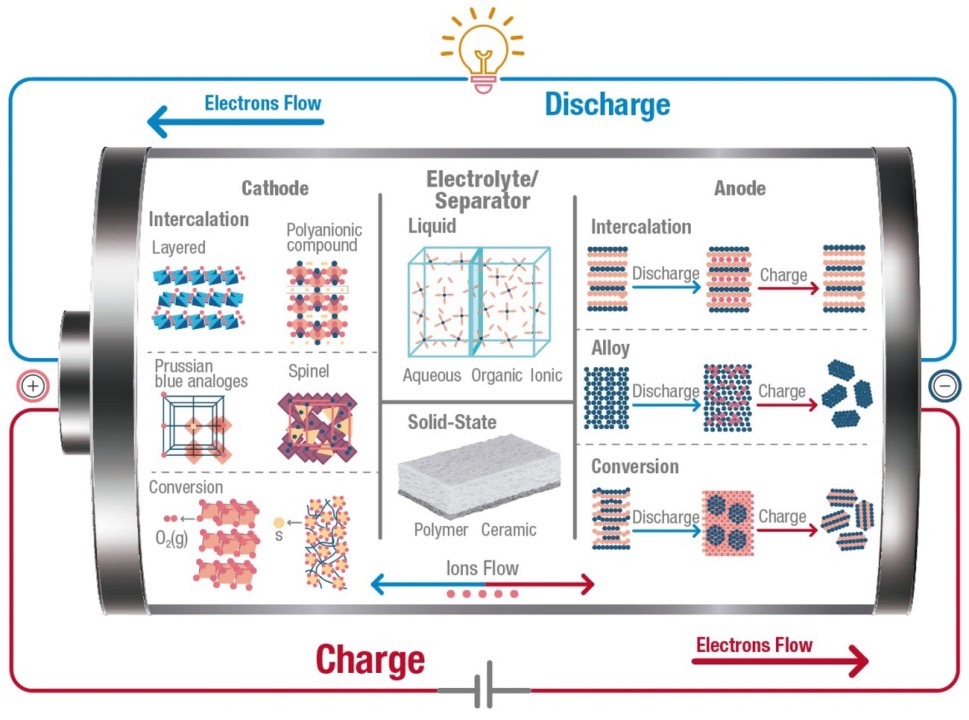

Advanced battery engineering addresses material selection, internal component design, and thermal management to extend operational lifespans. Terminal design, separator technology, and electrolyte formulation all influence performance outcomes. Solid-state battery technology offers significant improvements over conventional lithium-ion designs, representing the next generation of energy storage solutions.

This technical guide examines the engineering principles that define high performance battery systems. We will analyze component-level design considerations, testing protocols that validate performance under extreme conditions, and specialized applications where battery characteristics determine system success. The focus covers laboratory development through field deployment, addressing the engineering challenges that separate standard batteries from high performance power systems.

Internal Components That Determine Battery Performance

Image Source: Encyclopedia.pub

Image Source: Encyclopedia.pub

High performance battery systems depend on internal components that remain invisible during normal operation. Performance characteristics result from precise engineering of terminals, separators, and electrolyte formulations. These components work together to determine conductivity, safety margins, and cycle life performance across diverse applications.

Battery Terminal Design and Conductivity Performance

Battery terminals function as the critical interface between internal chemistry and external circuits. Terminal material selection directly affects conductivity, corrosion resistance, and power delivery capabilities. Copper terminals offer the highest conductivity among standard materials, with soldering and crimping compatibility for secure connections. Tinned copper terminals provide corrosion resistance while maintaining superior electrical properties.

Corrosive environments require brass terminals despite increased fabrication complexity compared to other materials. Marine applications benefit from brass terminals’ environmental degradation resistance. Lead terminals offer superior malleability for applications requiring field modifications.

Multi-port terminal configurations enhance performance in specialized applications by supporting multiple cable feeds while maintaining optimal conductivity. Terminal design influences charge efficiency and power delivery characteristics – critical factors for medical device and industrial equipment applications. The electrical interface between battery and load determines system performance under high-current demands.

Separator Technology and Safety Functions

Separators serve as critical safety barriers in high performance battery designs. These thin porous membranes prevent physical contact between cathode and anode while permitting ion transport. Commercial separator materials include polyethylene (PE), polypropylene (PP), or layered PE/PP combinations.

Separator failure creates internal short circuits that trigger thermal runaway conditions. Testing demonstrates that dry-processed polyolefin separators fail under relatively low mechanical loads. Ceramic-coated alternatives show significantly higher short-circuit load capacity (33% increase) and deformation tolerance (25% improvement).

Ceramic-coated separators provide superior thermal stability and wettability due to hydrophilic properties. These coatings reduce separator shrinkage at shutdown temperatures – essential for applications where failure creates safety hazards. Separator integrity must be maintained to prevent electrode contact that results in catastrophic failure modes.

Electrolyte Formulation and Performance Enhancement

Electrolyte composition fundamentally determines battery performance characteristics, functioning as the ion transport medium. Strategic electrolyte additives produce significant performance improvements with minimal cost impact. Small additive quantities (≤5% w/v) can substantially enhance electrochemical performance.

Key electrolyte additives provide specific performance benefits:

- Fluoroethylene carbonate (FEC) promotes LiF-rich, dense SEI film formation that enables uniform lithium deposition and inhibits dendrite formation

- Vinyl carbonate (VC) derivatives promote SEI formation at higher potentials, preventing ethylene carbonate reduction decomposition

- Boron-based additives function as anion receptors, facilitating salt dissociation and improving lithium-ion transport

Synergistic combinations of LiDFOB, TMSPi, and FEC create uniform, stable, ultra-thin (2.859 nm) CEI films with low impedance characteristics (1.623 Ω after 150 cycles). These protective films prevent particle pulverization and microcracking during high-speed charging while maintaining inter-particle conductivity.

Proper electrolyte formulation extends cycle life, improves charging rates, and enhances overall system reliability – essential considerations for mission-critical power applications. The chemical composition directly affects battery performance under demanding operating conditions.

Environmental Engineering for Battery System Reliability

Image Source: Weiss Technik

Image Source: Weiss Technik

Field applications impose environmental stresses that exceed controlled laboratory conditions. Battery system reliability depends on engineering solutions that address mechanical forces, environmental exposure, and temperature variations encountered in operational deployments. Custom battery manufacturer experience demonstrates that environmental engineering often determines the difference between successful field performance and premature system failure.

Mechanical Durability Under Vibration and Shock Loading

Automotive applications subject battery systems to continuous vibration frequencies and periodic mechanical shock events that degrade internal components. Vibration transmission from road surfaces and engine operation creates resonance effects within battery enclosures. Traditional lead-acid designs experience plate fracturing under sustained vibration exposure, resulting in electrolyte separation and increased internal resistance. Progressive plate displacement reduces current capacity and accelerates failure mechanisms.

AGM (Absorbent Glass Mat) construction provides enhanced vibration tolerance for lithium-ion battery applications in mobile platforms. These designs maintain structural integrity during extreme mechanical events, including vehicle rollover scenarios. Military-specification battery systems demonstrate exceptional durability, withstanding acceleration forces up to 50,000 gn and rotational stresses at 30,000 rpm.

Environmental Protection Through IP Rating Standards

The IP (Ingress Protection) rating system establishes standardized protection levels against environmental contamination. The two-digit classification system specifies protection thresholds for solid particle intrusion and liquid ingress:

- First digit (1-6): Solid particle protection, with level 6 indicating complete dust-tight sealing

- Second digit (1-9): Liquid protection, with level 8 specifying continuous submersion capability

Outdoor battery installations require minimum IP65 protection, while marine environments benefit from IP67 specifications. IP67-rated high performance battery systems resist dust infiltration and water immersion to 1-meter depth for 30-minute duration. These protection standards ensure consistent performance under variable environmental conditions without compromising electrical characteristics.

Temperature Range Engineering: -20°C to 60°C Operation

Temperature variation presents significant engineering challenges for battery electrochemical systems. Low-temperature conditions reduce battery capacity substantially – research indicates range can decrease by approximately 12% at 20°F (-6.7°C). This performance reduction occurs due to increased electrolyte viscosity, which limits ion mobility and reduces electrochemical reaction rates.

Specialized electrolyte formulations address extreme temperature operation requirements. Dibutyl ether compositions with lithium salt remain fluid at temperature extremes, with boiling points reaching 141°C/286°F. Acetonitrile-based electrolyte systems maintain functionality at -40°F (-40°C) while extending cycle life at elevated temperatures up to 140°F/60°C.

Molecular engineering of electrolyte-lithium ion interactions enables low-temperature performance optimization. Reduced molecular binding forces facilitate ion transport at sub-zero temperatures. Advanced formulations retain over 87% energy capacity at -40°C while maintaining Coulombic efficiencies of 98.2%.

Battery Testing Protocols: Validating Performance Under Extreme Conditions

Battery qualification requires comprehensive testing protocols that exceed standard laboratory conditions. Effective battery validation must simulate the extreme mechanical, electrical, and environmental stresses that batteries encounter during actual deployment. Our testing methodology addresses three critical areas: mechanical abuse scenarios, electrical stress conditions, and environmental exposure validation.

Mechanical Abuse Testing and Impact Resistance

Standardized mechanical testing evaluates battery response to physical damage scenarios. Testing protocols deliberately subject cells to conditions that exceed normal operating parameters. These validation procedures identify failure thresholds before batteries reach field applications.

Drop impact testing evaluates structural integrity by dropping complete battery assemblies from heights reaching 30 meters. Crush testing applies controlled hydraulic pressure to identify internal shorting risks under mechanical deformation. Nail penetration tests drive steel rods through fully charged cells to evaluate internal damage response mechanisms.

Automotive applications follow SAE J2464 protocols that include shock, penetration, roll-over, water immersion, and crush test scenarios. Military applications require even more stringent testing – battery assemblies must withstand acceleration forces up to 50,000 gn while maintaining electrical integrity.

Electrical Stress Validation and Safety Thresholds

Electrical abuse testing represents a critical validation dimension for high performance batteries. Overcharge conditions can trigger thermal runaway similar to external heating and short-circuiting scenarios. Testing data confirms that overcharge capacity thresholds typically reach around 1.78 Ah regardless of applied charge rate.

Overcharge testing monitors multiple parameters simultaneously: voltage stability, current flow characteristics, capacity degradation, and surface temperature distribution. Temperature measurements consistently show elevated readings near battery venting areas due to internal gas generation.

Over-discharge testing reveals equally important safety considerations. Discharge voltages below critical thresholds (0.5-0.0V) cause irreversible capacity losses between 12.56-24.88%. This degradation results from copper current collector dissolution and subsequent anode surface deposition.

Environmental Exposure and Corrosion Testing

Environmental testing validates battery performance across the temperature, humidity, and corrosive conditions encountered in field applications. Testing chambers simulate combined environmental stressors to identify potential failure mechanisms.

Humidity control remains critical for lithium battery performance, with optimal operating range between 40-60% relative humidity. Excessive moisture accelerates chemical degradation as water reacts with lithium salts like LiPF₆ to form corrosive hydrofluoric acid.

Salt spray testing evaluates corrosion resistance under marine conditions. Thermal cycling between temperature extremes (-40°C to +85°C at 95% humidity) simulates seasonal environmental variations. These combined stress protocols reveal failure points in sealing systems, insulation materials, and structural components before field deployment.

Testing protocols must validate battery performance under systematic abuse scenarios to ensure reliable operation in demanding applications. These comprehensive validation procedures enable confident deployment of custom battery manufacturer solutions across medical, industrial, and consumer applications where performance reliability cannot be compromised.

Specialized Applications for LiPo Battery Technology

LiPo batteries excel in applications requiring high power-to-weight ratios and compact form factors. These lithium polymer cells provide unique advantages for specialized equipment where conventional battery chemistries cannot meet performance requirements.

Aerial Applications: Optimizing Weight and Power Parameters

UAV performance depends on careful battery selection to balance flight time against payload capacity. LiPo batteries deliver exceptional power density, making them the standard choice for aerial platforms. Battery capacity increases extend flight duration but add system weight that reduces agility and efficiency. Weight considerations become critical as each additional gram directly impacts flight characteristics. Quality LiPo cells maintain performance through 300+ charge cycles, requiring lifecycle management protocols for commercial operations.

Cell configuration significantly affects platform capabilities. Higher voltage increases motor RPM and thrust output while simultaneously adding battery mass. Smaller aerial platforms benefit from 4S configurations that prioritize maneuverability, while larger payload-carrying systems require 6S arrangements for adequate power delivery.

High-Performance RC Applications: Current Draw and Thermal Considerations

Remote control vehicles demand sustained high-current discharge capability that only advanced LiPo technology can provide. The C-rating specification defines maximum safe current draw limits for each battery design. Exceeding rated discharge current damages cells, reduces service life, and creates thermal runaway risks.

Temperature management becomes essential since LiPo cells operate optimally between 30°C-60°C. Excessive heat causes cell expansion or fire hazards, while cold temperatures reduce voltage stability and available capacity. High-performance RC applications require active cooling systems to maintain safe operating temperatures during peak discharge periods.

Medical Device Integration: Size Constraints and Safety Requirements

Medical applications demand compact battery solutions while maintaining strict safety standards. LiPo technology enables battery thickness under 1mm, allowing integration into wearable medical devices with minimal size impact. ANSI/AAMI ES 60601-1 establishes fundamental safety requirements for medical battery systems, mandating compliance with international safety standards.

Battery failure analysis shows that 80% of incidents occur during charging operations, making protection circuit design critical for medical applications. Medical device batteries must pass comprehensive testing protocols including IEC 62133, validating safe operation under normal use and foreseeable misuse conditions.

Battery Lifecycle Management and Reliability Engineering

Image Source: ResearchGate

Image Source: ResearchGate

Battery lifecycle management addresses the complete operational span from manufacturing through material recovery. The battery industry faces increasing pressure to maximize resource utilization while maintaining performance standards throughout extended service periods. Structured lifecycle planning enables both economic optimization and environmental responsibility.

Lifecycle Management Framework

Battery lifecycle management encompasses four distinct phases: initial production, operational deployment, secondary applications, and material recovery. Each phase requires specific technical considerations and performance monitoring protocols. For custom lithium ion batteries, implementing systematic lifecycle oversight involves establishing clear performance thresholds, monitoring protocols, and transition criteria between lifecycle phases.

The operational phase demands continuous performance monitoring to identify degradation patterns and optimize charging protocols. Secondary applications extend useful battery life by deploying cells at 70-80% original capacity in less demanding applications. Material recovery operations focus on extracting valuable elements including lithium, cobalt, and nickel for reuse in new battery production.

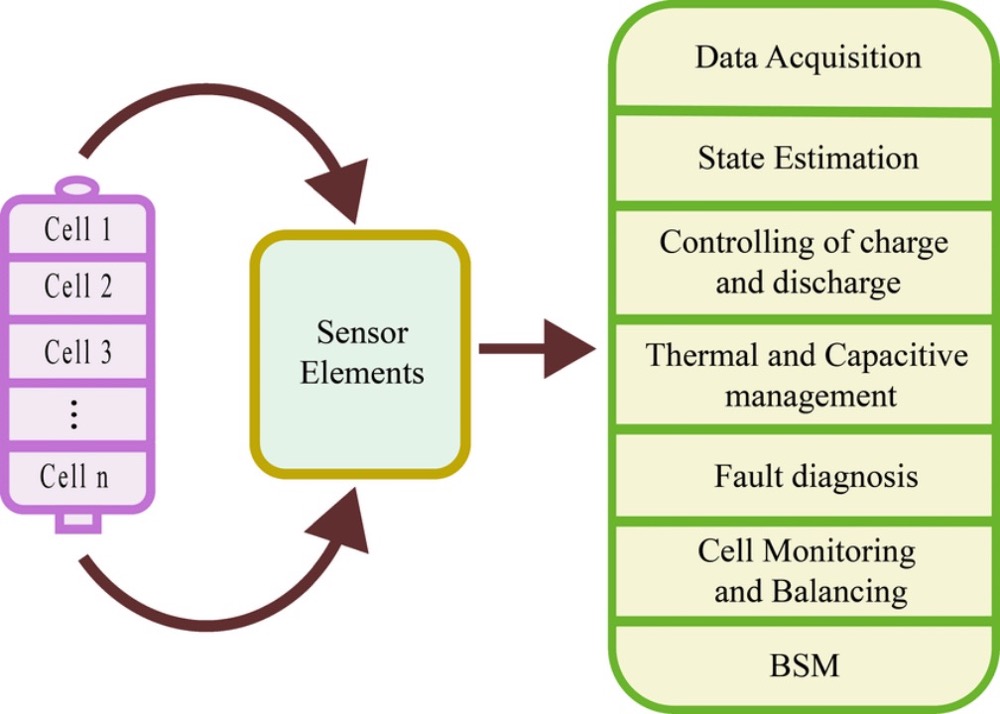

Embedded Sensor Systems for Predictive Maintenance

Smart monitoring systems provide real-time battery health assessment through embedded sensor networks. These systems monitor voltage stability, temperature profiles, and internal impedance changes to predict failure modes before they occur. Acceleration data and vibration analysis identify mechanical stress patterns that could compromise battery integrity. Predictive maintenance systems enable proactive intervention rather than reactive replacement strategies.

Battery management systems equipped with predictive capabilities demonstrate significant lifecycle extensions. Properly implemented monitoring systems can extend operational lifespans from 10 years to 20 years, representing a 30% improvement in total lifecycle value while reducing ownership costs by over 30%. State-of-charge (SOC) and state-of-health (SOH) calculations prevent overcharging and overdischarging conditions that accelerate capacity degradation.

Secondary Applications and Material Recovery

Batteries maintaining 70-80% of original capacity retain substantial value for secondary applications. These repurposed systems perform effectively in applications with lower power density requirements:

- Energy storage systems supporting renewable power generation

- Backup power systems for commercial and residential facilities

Material recovery operations extract critical elements from end-of-life batteries. Recycling processes can potentially supply 60% of global cobalt demand, 53% of lithium requirements, 57% of manganese needs, and 53% of nickel requirements by 2040. This material recovery reduces dependence on raw material mining while supporting sustainable battery production.

Battery pack engineering requires systematic attention to component-level design, testing protocols, and application-specific requirements. High performance battery systems demonstrate superior field reliability when terminal materials, separator technology, and electrolyte formulation address the specific demands of the intended application.

Comprehensive testing validates battery performance under conditions that exceed normal operating parameters. Drop tests, overcharge protocols, and environmental exposure evaluations identify potential failure modes before field deployment. Custom battery packs engineered for automotive applications must withstand vibration and shock loads, while systems designed for outdoor use require appropriate IP ratings and temperature stability from -40°C to 85°C.

Application requirements determine optimal battery chemistry and configuration. Unmanned aerial systems prioritize power-to-weight ratios and discharge characteristics. Remote control vehicles require high burst discharge capabilities with effective thermal management. Medical device applications demand compact form factors with multi-stage protection systems that comply with IEC 62133 and ANSI/AAMI ES 60601-1 standards.

Battery management systems provide essential monitoring and control functions that extend operational lifespans. State-of-charge and state-of-health monitoring prevent overcharging and over-discharge conditions that cause permanent capacity loss. Predictive maintenance capabilities can extend battery service life from 10 years to 20 years, reducing total ownership costs by over 30%.

Second-life applications maximize resource utilization when batteries reach 70-80% of original capacity. Grid storage and backup power systems represent significant opportunities for battery redeployment before recycling recovers lithium, cobalt, and nickel for new battery production.

High performance battery development continues advancing with solid-state technology and improved electrolyte formulations. The engineering principles remain consistent: systematic component selection, comprehensive testing validation, and lifecycle management determine whether battery systems meet reliability requirements for mission-critical applications where failure is not acceptable.

Key Takeaways

Understanding the hidden engineering behind high-performance batteries reveals why some power sources excel while others fail in demanding real-world applications.

- Hidden components matter most: Terminal materials, ceramic-coated separators, and strategic electrolyte additives (like FEC and VC) dramatically improve conductivity, safety, and charge retention with minimal cost impact.

- Real-world testing prevents field failures: Drop tests, overcharge protocols, and environmental exposure simulations reveal critical failure points before deployment, ensuring batteries survive actual operating conditions.

- Application-specific design is essential: Drones need power-to-weight optimization, RC vehicles require burst discharge capability, and medical devices demand compact safety—one-size-fits-all approaches fail.

- Lifecycle management doubles battery value: Embedded sensors enable predictive maintenance that can extend lifespans from 10 to 20 years, while second-life applications and recycling maximize resource utilization.

- Environmental engineering determines durability: Proper IP ratings, vibration resistance, and temperature management (-40°C to 85°C) separate batteries that merely function from those that excel under stress.

The difference between adequate and exceptional battery performance lies in meticulous attention to these often-overlooked engineering details, comprehensive testing protocols, and strategic lifecycle planning that ensures reliable operation when failure isn’t an option.

FAQs

Q1. What are the key components that define high-performance battery performance? High-performance batteries rely on several hidden components, including advanced battery terminals for optimal conductivity, internal separators for safety, and electrolyte additives that enhance charge retention. These elements work together to improve overall battery efficiency and lifespan.

Q2. How are high-performance batteries engineered to withstand real-world conditions? High-performance batteries are designed with features like vibration and shock resistance for automotive use, ingress protection (IP) ratings for outdoor applications, and the ability to function in extreme temperatures ranging from -20°C to 60°C. These engineering considerations ensure reliability in diverse environments.

Q3. What types of tests are conducted to simulate real-world battery use? Batteries undergo rigorous testing beyond standard lab measurements, including drop tests and mechanical abuse scenarios, overcharge and deep discharge cycle testing, and humidity and corrosion resistance validation. These tests help predict how batteries will perform under extreme conditions in actual use.

Q4. How are LiPo batteries used in different applications? LiPo (Lithium Polymer) batteries are used in various applications due to their high power-to-weight ratio. They’re popular in drones for their lightweight properties, in RC vehicles for their high burst discharge rates, and in medical devices where compact size and safety are crucial.

Q5. What strategies are used to ensure long-term battery reliability? Long-term battery reliability is achieved through comprehensive lifecycle management plans, the use of embedded sensors for predictive maintenance, and exploring second-life applications before recycling. These strategies help extend battery life, reduce costs, and maximize resource efficiency.