Selecting batteries for precision instruments demands your attention to stability, lifespan, and safety, especially in medical environments. Lithium batteries for medical devices set the standard for reliability in high-accuracy fields. You must recognize how battery failures—such as overcharging, over-discharging, exposure to temperature extremes, age, or physical damage—can cause overheating, swelling, reduced lifespan, and safety hazards. Monitoring for swelling or reduced performance keeps medical instruments dependable. Prioritize compliance with safety standards and built-in features from the start to protect your investment and maintain device integrity.

Common battery-related failures:

Overcharging

Over-discharging

Temperature extremes

Age

Physical damage

Key Takeaways

Prioritize stability when selecting batteries for precision instruments. Stable batteries ensure accurate results and reliable performance in medical and industrial applications.

Consider lifespan as a key factor. Lithium batteries offer longer operational lifespans compared to alkaline and nickel options, reducing the need for frequent replacements.

Choose lithium batteries for their high energy density and low self-discharge rates. These features make them ideal for portable medical devices and critical applications.

Ensure compliance with safety standards. Verify that your battery supplier meets necessary certifications to protect your devices and maintain regulatory compliance.

Implement regular maintenance practices. Schedule routine testing and inspections to monitor battery health and extend the lifespan of your precision instruments.

Selection Criteria

1.1 Stability Needs

You must prioritize stability when selecting batteries for precision instruments. Fluctuations in battery performance can cause unreliable measurements and compromise device reliability. High-resolution equipment detects minor changes in battery health, which is critical for medical and scientific applications.

Tip: Always choose batteries with proven thermal and mechanical stability for environments where temperature and physical stress vary.

Here is a table summarizing key stability requirements for batteries used in medical and scientific precision instruments:

Requirement Type | Specification |

|---|---|

Thermal Stability | Temperature tolerance without performance loss: -20ºC to 85ºC (rigid medical electronics), 0ºC to 45ºC (skin-worn sensors) |

Mechanical Stability | Retention of mechanical properties over time: < 70% modulus retention after 3–6 months in PBS or sweat |

Longevity (implants) | Total functional lifetime: 6 months – 2 years (research-grade flexible implants), 5–15 years (rigid cardiac/neurological implants) |

Longevity (wearables) | Operational time span: 3 days – 2 weeks (single-use sensors), > 6 months (reusable wearables) |

Fluctuations in battery stability can lead to inaccurate measurements and reduce the reliability of your results. Environmental factors, such as temperature, affect battery health and impact the accuracy of testing equipment. Traditional battery gauges may struggle with rapid fluctuations in load currents, which complicates predictions of remaining battery life. This inconsistency can directly affect the accuracy of precision instruments that rely on stable battery performance.

1.2 Lifespan Factors

You must consider lifespan as a primary factor when selecting batteries for precision instruments. The lifespan of a battery determines how long your medical devices and industrial systems can operate without interruption. Several factors influence battery lifespan:

Factor | Description |

|---|---|

Material Purity | Impurities in battery materials can accelerate degradation and reduce lifespan. |

Electrode Quality | The quality of the electrodes affects the battery’s ability to store and release energy efficiently. |

Cell Design | The design of the battery cell can impact its thermal management and overall lifespan. |

Degradation Mechanisms | Understanding complex chemical and physical processes that lead to battery degradation. |

State of Charge Management | Proper management of charge levels is crucial for extending battery lifespan. |

Charging Practices | Optimizing charging cycles and avoiding deep discharges can reduce stress on the battery. |

Temperature | Extreme temperatures can significantly accelerate degradation processes. |

Usage Patterns | How the battery is used can influence its overall lifespan. |

Manufacturing Quality | Choosing batteries from reputable manufacturers can help ensure higher quality and longer lifespan. |

When you select lithium batteries for medical devices, you benefit from longer operational lifespans compared to alkaline and nickel batteries. The table below compares average operational lifespans:

Battery Type | Average Lifespan in Precision Instruments |

|---|---|

Lithium | 10-15 years |

Alkaline | 5-10 years |

Nickel | Varies based on charge cycles |

Lithium batteries maintain charge longer than alkaline batteries.

They perform well in extreme temperatures, making them suitable for outdoor use.

Their long lifespan is particularly beneficial for precision instruments requiring reliability.

Lithium batteries retain their charge for a longer time than traditional batteries.

They are ideal for emergency equipment due to their reliability after long periods of inactivity.

1.3 Selecting Batteries for Precision Instruments

When selecting batteries for precision instruments, you must evaluate several criteria to ensure optimal performance and reliability. Focus on suppliers with a proven track record of delivering high-quality products. Assess the range of products offered to meet your specific needs in medical, robotics, security, infrastructure, and industrial fields. Confirm the supplier’s capacity to handle bulk orders and their reliability in on-time delivery.

Note: Always verify that your supplier adheres to safety standards and holds certifications that validate the quality of their batteries.

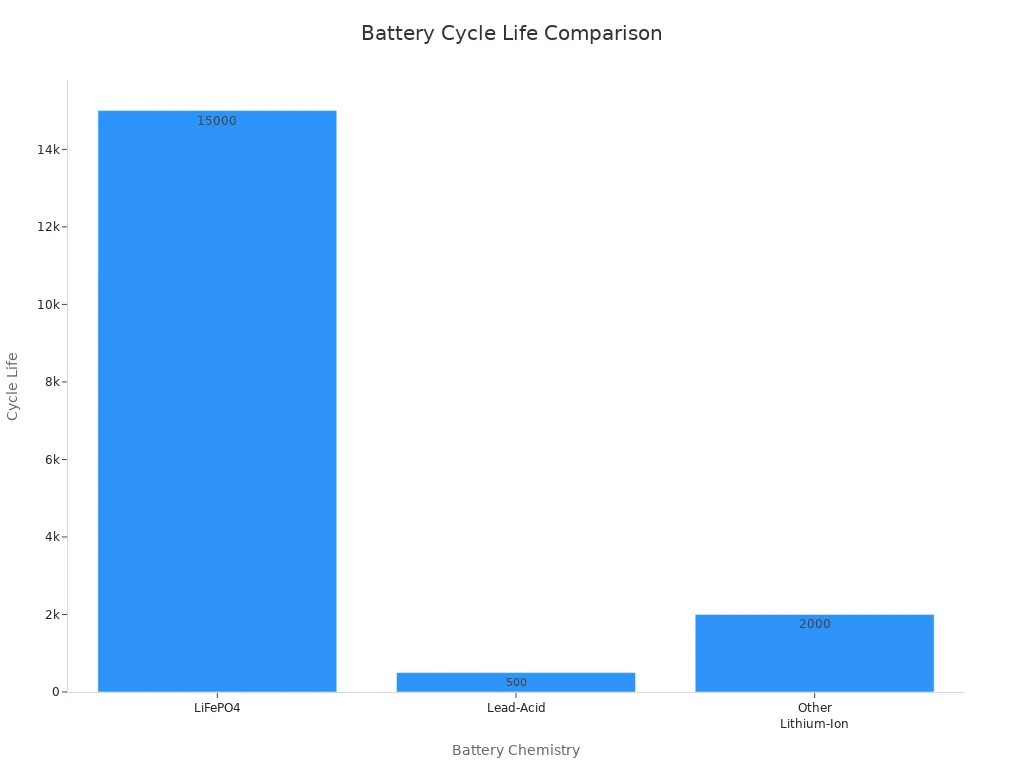

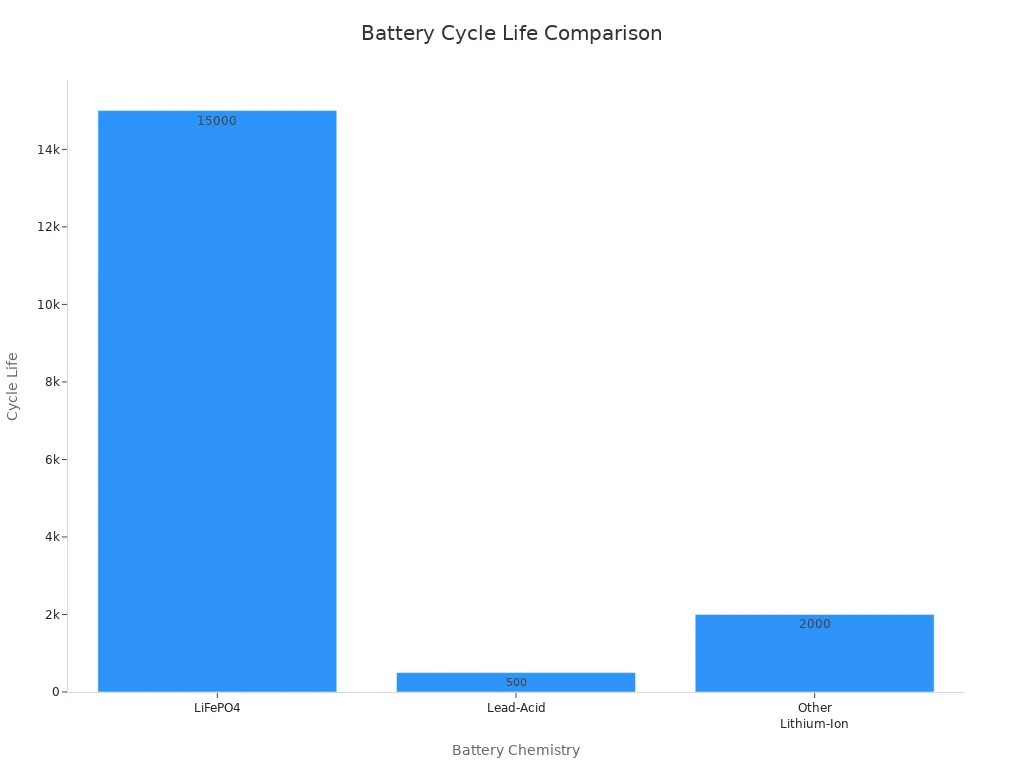

Selecting lithium batteries for medical devices offers distinct advantages. Lithium iron phosphate (LiFePO4) batteries provide high thermal stability and built-in battery management system (BMS) protection. They deliver up to 15,000 cycles, outperforming lead-acid and other lithium-ion chemistries. The chart below illustrates the cycle life comparison:

You should select lithium batteries for medical devices when you require consistent voltage during deep discharges and long-term reliability. These batteries excel in demanding environments, including medical, industrial, and security applications, where stability and lifespan are critical.

Battery Types

2.1 Lithium Batteries for Medical Devices

You need to understand why lithium batteries for medical devices set the standard in precision instrument applications. These batteries deliver high energy density and longevity, which means you get more power in a smaller, lighter package. Lithium-ion batteries offer longer cycle life and low self-discharge rates, so your medical equipment stays ready for use. You benefit from higher operating voltage, which reduces the number of cells needed in your device. Primary lithium medical batteries also provide lighter weight, making portable medical devices easier to handle.

Key advantages of lithium-ion batteries for medical devices:

Higher energy density and longevity

Longer cycle life for reliable performance

Low self-discharge rate for readiness

Lighter weight for portability

Higher operating voltage for efficient design

You see lithium batteries for medical devices in robotics, security systems, infrastructure monitoring, and industrial controls. These batteries excel in demanding environments where performance and reliability matter most.

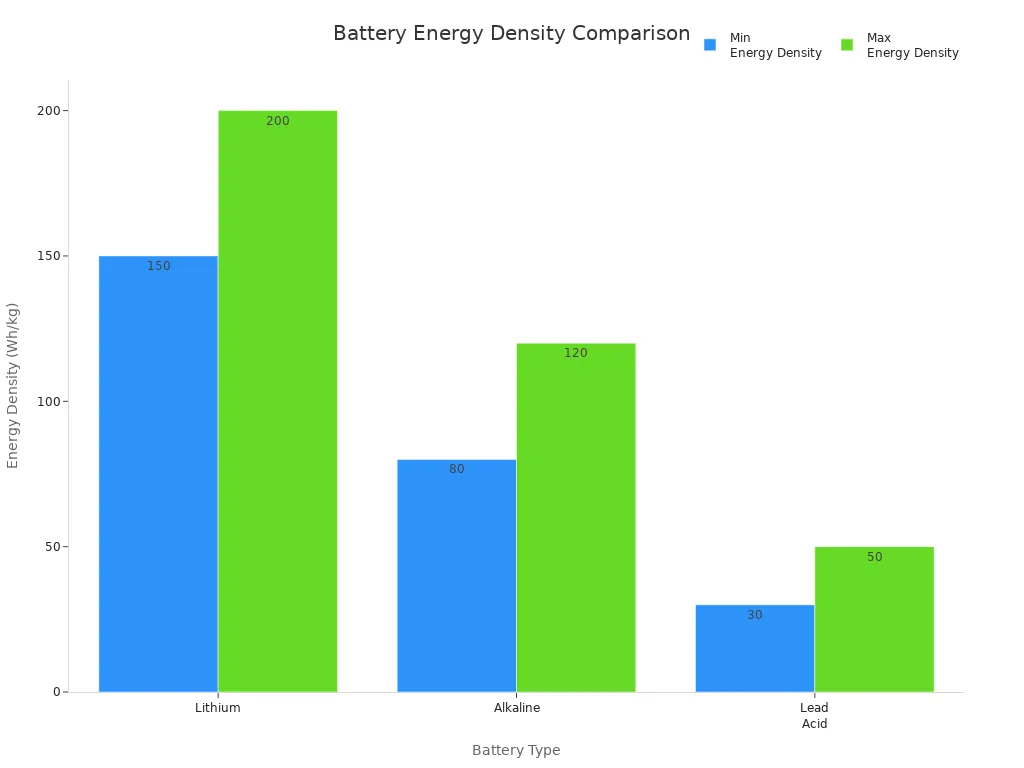

2.2 Alkaline and Nickel Options

When selecting batteries for precision instruments, you may consider alkaline or nickel chemistries. Alkaline batteries offer moderate energy density and are suitable for low-drain devices. Nickel-cadmium (NiCd) batteries provide strong endurance and minimal capacity loss during cycling. Nickel-metal-hydride (NiMH) batteries start losing capacity after about 300 cycles, with noticeable increases in resistance after 700 cycles and self-discharge after 1000 cycles. These options work in some consumer electronics and backup systems, but they do not match the performance of lithium-ion batteries in medical or industrial applications.

Battery Type | Energy Density (Wh/kg) | Typical Cycle Life | Suitability for Precision Instruments |

|---|---|---|---|

Lithium | 150–200 | 1000+ | Best for medical, robotics, security, industrial |

Alkaline | 80–120 | Single-use | Suitable for low-drain, consumer electronics |

Nickel-Cd | 45–80 | 1000+ | Good for backup, some industrial uses |

Nickel-MH | 60–120 | 300–1000 | Moderate, not ideal for high-accuracy devices |

2.3 Selecting Lithium Batteries

Selecting lithium batteries for medical devices requires you to match battery voltage and configuration to your project’s needs. You must choose the right lithium chemistry—such as NMC/NCA for automotive, LFP/LTO for industrial, or LCO/LMO for small mobile devices—based on energy density and longevity, discharge rate, and safety features. You should ensure the battery can handle your device’s current demands and fits within your design constraints.

Factor | Description |

|---|---|

Voltage and Configuration | Match battery voltage to your device requirements. |

Chemistry | Select lithium chemistry for optimal performance and safety. |

Discharge Rate | Ensure battery meets current demands. |

Cycle Life | Choose batteries with high cycle life for frequent use. |

Environmental Considerations | Consider temperature effects and management solutions. |

Safety Features | Look for built-in safety and certifications. |

Size and Form Factor | Ensure battery fits your device design. |

Supplier Reputation | Work with reputable suppliers for quality assurance. |

Primary lithium medical batteries must comply with IEC 60086-4 and ANSI/AAMI ES 60601-1 safety standards. You need to replace batteries showing swelling or overheating immediately and follow guidelines for safe handling and disposal. Selecting lithium batteries for medical devices ensures you meet strict safety and performance requirements in medical, industrial, and security fields.

Performance Factors

3.1 Energy Density

You need to understand energy density when selecting lithium battery packs for precision instruments. Energy density measures how much energy a battery stores in relation to its weight or volume. Higher energy density means you can power your medical, robotics, or security devices longer without increasing size or weight. This factor is critical for portable medical equipment and compact industrial sensors.

Lithium-ion batteries: 150 to 250 Wh/kg or 300 to 700 Wh/L

Lithium-polymer batteries: 100 to 200 Wh/kg or 200 to 400 Wh/L

Lithium Iron Phosphate (LiFePO₄) batteries: 90 to 160 Wh/kg or 220 to 350 Wh/L

A higher energy density allows you to store more energy in a compact battery pack. This leads to longer operational times for your precision devices. These batteries maintain voltage and power output under high-load conditions, which ensures reliable performance in demanding medical and industrial scenarios. The efficient energy conversion of lithium chemistries also minimizes energy loss during discharge. You benefit from smaller, lighter battery packs that extend device runtime—an essential advantage for portable medical and security equipment.

Lithium Battery Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Typical Cycle Life (cycles) |

|---|---|---|---|

Lithium-ion (NMC/NCA) | 3.6–3.7 | 150–250 | 1,000–2,000 |

Lithium-polymer | 3.7 | 100–200 | 500–1,000 |

LiFePO₄ (LFP) | 3.2 | 90–160 | 2,000–5,000 |

Tip: Choose lithium battery chemistries with higher energy density for applications where space and weight are limited, such as wearable medical monitors or portable diagnostic tools.

3.2 Voltage Stability

Voltage stability is essential for maintaining accuracy in precision instruments. You must ensure that your battery pack delivers a consistent voltage output, even as the battery discharges or faces temperature changes. Medical and industrial devices require stable voltage to avoid measurement errors and maintain reliable performance.

Temperature variation can impact voltage stability after initial production.

High stability over a wide temperature range is crucial for precision instruments.

Techniques like voltage compensation and oven stabilization help mitigate temperature effects.

Time stability measures device drift as voltage per unit of time, typically specified as 3 to 100 ppm/√1000 Hours.

You should select lithium battery packs with built-in battery management systems (BMS) to monitor and regulate voltage. A BMS helps maintain stability, protects against over-discharge, and ensures safety.

Note: Stable voltage output is especially important in medical imaging, laboratory analyzers, and robotics, where even minor fluctuations can affect results.

3.3 Cycle Life

Cycle life refers to the number of complete charge and discharge cycles a battery can undergo before its capacity drops below a usable level. You want a long cycle life for your medical, security, and industrial devices to reduce maintenance and replacement costs.

Lithium Battery Chemistry | Typical Cycle Life (cycles) | Application Scenarios |

|---|---|---|

Lithium-ion (NMC/NCA) | 1,000–2,000 | Medical devices, robotics, security systems |

Lithium-polymer | 500–1,000 | Portable medical monitors, consumer devices |

LiFePO₄ (LFP) | 2,000–5,000 | Industrial controls, infrastructure, backup |

You can extend the cycle life of lithium batteries by minimizing the depth of discharge (DoD). High DoD cycles cause greater degradation in LiFePO₄ batteries, leading to capacity loss and reduced state of health. The internal structure of the battery experiences more stress at higher DoD, which can cause micro-cracks and further reduce performance. To maximize lifespan, avoid deep discharges and recharge batteries before they reach very low levels.

Tip: Set your device’s BMS to limit the minimum allowable voltage. This practice helps prevent deep discharges and extends battery life.

3.4 Compatibility

Compatibility ensures that your lithium battery pack integrates seamlessly with your precision instrument’s design. Manufacturers use advanced measurement technologies and simulation tools to optimize battery design for specific applications. They monitor quality at every production stage, using high-precision measurement devices and laser sensors to ensure component accuracy. Rigorous quality control processes minimize variability among battery batches, which is crucial for medical and industrial applications.

You should always verify that your battery supplier uses simulation tools to match battery characteristics with your device’s requirements. This approach guarantees that your battery pack will deliver the expected performance and stability in your application, whether in medical diagnostics, robotics, or security monitoring.

Note: Consistent compatibility reduces the risk of device failure and supports long-term reliability in critical environments.

Safety and Compliance

4.1 Compliance with Safety Standards

You must ensure compliance with safety standards when selecting lithium battery packs for medical and industrial precision instruments. These standards protect your devices from failures and help you meet regulatory certifications required in global markets. The following table summarizes key international safety standards for lithium batteries:

Standard | Description |

|---|---|

IEC 62133 | Safety requirements for rechargeable lithium batteries used in medical devices. |

IEC 62619 | Safety standards for secondary lithium cells and batteries in industrial applications. |

UL 1642 | Safety requirements for primary and secondary lithium battery cells in electronic products. |

UN/DOT 38.3 | Regulations for the safe transportation of lithium batteries classified as dangerous goods. |

You should always verify that your supplier provides documentation for these certifications. This step helps you avoid compliance issues and supports risk mitigation in your supply chain. For more information on responsible sourcing, review our conflict minerals statement.

4.2 Built-in Safety Features

Built-in safety features in batteries play a critical role in preventing failures and protecting your medical and industrial devices. You benefit from advanced battery management systems that monitor and control key safety parameters. The table below lists essential safety features in batteries for precision instruments:

Safety Feature | Description |

|---|---|

Under-Voltage Protection (UVP) | Prevents cells from discharging below minimum safe voltage (~2.5V). |

Over-Current Protection (OCP) | Detects sustained current beyond safe limits and disconnects the pack. |

Short-Circuit Protection (SCP) | Responds to instantaneous spikes, safely isolating the pack within microseconds. |

Over-Temperature Protection (OTP) | NTC sensors monitor heat; BMS disconnects the pack if unsafe temperatures are reached. |

Under-Temperature Protection (UTP) | Blocks charging at low temperatures to prevent lithium plating, while allowing controlled discharging. |

Passive Balancing | Bleeds excess energy from high-voltage cells to equalize the pack. |

Active Balancing | Transfers energy from fully charged cells to lower-charged ones, improving efficiency and usable capacity in large systems. |

Tip: You should select lithium battery packs with robust built-in safety features to reduce the risk of overheating, short circuits, and voltage instability in medical, robotics, and industrial applications.

4.3 Regulatory Requirements

You must meet strict regulatory requirements and obtain the necessary certifications for lithium battery packs in medical and industrial fields. These rules ensure your devices operate safely and reliably. The table below highlights important regulatory certifications and requirements:

Regulation | Description |

|---|---|

IEC 62133 | Ensures rechargeable batteries can withstand overcharging, short circuits, and physical stress without failure. |

IEC 60086-4 | Guarantees non-rechargeable lithium batteries do not leak or explode under stress. |

ISO 13485 | Mandates strict quality control in battery manufacturing to prevent defects. |

FDA EMC Rules | Requires testing to ensure devices do not interfere with other medical equipment. |

UN 38.3 | Ensures batteries can withstand transport conditions without risk of failure. |

UL 1642 | Ensures individual lithium cells are safe before assembly into battery packs. |

You must also consider certifications such as RTCA DO-311A for aviation, UL certification for safety and performance, CE certification for EU compliance, and UN38.3 for shipping. These regulatory certifications help you avoid legal issues and maintain high safety standards in medical, security, and industrial environments.

Environmental Factors

5.1 Temperature Tolerance

You must consider temperature tolerance when selecting batteries for precision instruments. Batteries perform best at room temperature. Cold conditions can reduce capacity and efficiency, which impacts medical, robotics, and industrial devices. For example, at -18°C (0°F), a battery may deliver only half its rated capacity compared to 27°C (80°F). Internal resistance increases in cold environments, which can lower power output and affect the accuracy of medical equipment.

Batteries operate best at room temperature.

Cold temperatures increase internal resistance and reduce efficiency.

Extreme heat can accelerate battery aging and cause safety risks.

Nickel batteries offer strong performance in extreme cold and heat, making them suitable for outdoor medical monitoring and industrial sensors. Lithium battery packs, especially those with advanced thermal management, provide reliable operation in most medical and security applications.

Battery Chemistry | Temperature Range (°C) | Performance in Extreme Cold | Application Scenarios |

|---|---|---|---|

Lithium-ion (NMC/NCA) | -20 to 60 | Moderate | Medical, robotics, security |

Lithium Iron Phosphate | -20 to 60 | Good | Industrial, infrastructure |

Nickel-Cadmium | -40 to 60 | Excellent | Medical, outdoor, backup systems |

Tip: Choose batteries with proven temperature tolerance for medical devices used in field or outdoor environments.

5.2 Durability

You need batteries that withstand harsh conditions and maintain long-term durability. In medical, industrial, and infrastructure fields, batteries face humidity, salt spray, and frequent cycling. These factors accelerate aging and reduce lifespan. Manufacturers enhance durability by using advanced thermal management, insulation, and robust chemistries.

Life expectancy for batteries in electric vehicles and grid storage can exceed ten years.

Humidity and salt spray environments speed up degradation.

Battery design and material choices affect durability.

Strategies include insulation, predictive analytics, and improved charging infrastructure.

Nickel batteries excel in environments with extreme temperature swings and high humidity. Lithium battery packs with protective features and optimized design deliver reliable performance for medical and security systems.

Environmental Stress | Impact on Battery | Durability Solutions |

|---|---|---|

Humidity | Accelerates aging | Insulation, sealed enclosures |

Salt spray | Corrosion, degradation | Corrosion-resistant materials |

Temperature extremes | Capacity loss | Advanced thermal management |

Note: You should evaluate battery durability benchmarks for medical and industrial applications to ensure long-term reliability.

5.3 Storage and Transport

Proper storage and transport practices protect battery lifespan and safety. You should store lithium-ion batteries in cool, dry environments to prevent corrosion and extend service life. Avoid exposing batteries to moisture or extreme temperatures. Handle battery packs carefully to prevent physical damage, especially in medical and robotics supply chains.

Avoid moisture and temperature extremes.

Handle with care to prevent damage.

Comply with local transportation regulations and use secure packaging.

For medical and industrial shipments, follow all safety guidelines and regulatory requirements. Sustainable battery management reduces environmental impact. You can learn more about sustainability practices on our Sustainability Approach page.

Tip: Implement best practices for battery storage and transport to maintain safety and extend the lifespan of medical devices.

Cost and Quality

6.1 Cost Analysis

Battery Chemistry | Initial Cost | Replacement Frequency | Maintenance Cost | Application Scenario |

|---|---|---|---|---|

Lithium-ion (NMC/NCA) | High | Low | Medical, robotics, security | |

Lithium Iron Phosphate | Moderate | Very Low | Very Low | Industrial, infrastructure |

Nickel-Cadmium | Low | Moderate | Moderate | Backup, outdoor |

Tip: You should factor in long-term savings from reduced replacements and maintenance when evaluating battery costs for medical devices.

6.2 Quality vs. Budget

You must balance quality and budget to achieve reliable performance in precision instruments. High-quality lithium battery packs deliver consistent voltage, extended cycle life, and superior durability. These features are essential for medical, security, and industrial applications. Lower-cost batteries may seem attractive, but they often compromise on durability and reliability. You should prioritize quality over short-term savings, especially for devices that require stable operation and long lifespan.

High-quality batteries reduce risk of device failure.

Superior durability ensures longer service intervals.

Consistent performance supports accurate results in medical and robotics fields.

Note: Investing in quality batteries protects your reputation and reduces long-term costs.

6.3 Supplier Evaluation

You need to evaluate suppliers carefully before purchasing lithium battery packs for medical and industrial use. Reliable suppliers provide documentation for safety certifications, quality control processes, and warranty terms. You should request test reports and references from other B2B clients in medical, robotics, and security sectors. Assess the supplier’s ability to deliver consistent quality and durability across large orders. Look for transparent communication and support for technical questions.

Evaluation Criteria | Why It Matters |

|---|---|

Safety Certifications | Ensures compliance for medical and industrial |

Quality Control | Guarantees consistent battery performance |

Warranty Terms | Protects your investment |

Technical Support | Assists with integration and troubleshooting |

References | Validates supplier reliability |

You should choose suppliers who demonstrate a strong commitment to quality and durability in every aspect of their lithium battery packs.

Testing and Maintenance

7.1 Battery Test Equipment

You need reliable battery test equipment to ensure the performance and safety of lithium battery packs in medical and industrial applications. Accurate testing helps you detect early signs of degradation and prevent unexpected failures. Modern battery analysis tools measure voltage, current, temperature, and internal resistance. These tools support routine testing and validation, which are essential for maintaining high standards in medical, robotics, and security devices.

Test Equipment Type | Function | Application Scenario |

|---|---|---|

Battery Analyzers | Measure capacity, cycle life, and efficiency | Medical, robotics, security |

Environmental Chambers | Simulate temperature and humidity extremes | Medical, industrial |

Impedance Testers | Assess internal resistance and health | Infrastructure, industrial |

Data Loggers | Track performance trends over time | Medical, infrastructure |

Tip: Use advanced battery analysis systems with AI integration to identify performance trends and schedule proactive maintenance.

7.2 Validation Protocols

You must follow strict validation protocols to guarantee the reliability of lithium battery packs in precision instruments. Comprehensive design validation checks performance under different environmental conditions. Cycle life testing evaluates how batteries perform after repeated charging and discharging. Thermal management testing ensures batteries stay within safe temperature ranges. Safety testing checks for risks like overcharging, short circuits, and physical impacts. Many companies now use AI and data analytics for battery analysis, which helps you spot patterns and predict maintenance needs.

Key steps for effective testing and validation:

Conduct comprehensive design validation for all new battery packs.

Perform cycle life testing to estimate operational lifespan.

Test thermal management systems to prevent overheating.

Complete safety testing to meet industry standards.

Use AI-driven battery analysis for ongoing monitoring.

Note: Validation protocols are especially important in medical and security fields, where device failure can have serious consequences.

7.3 Maintenance Best Practices

You should implement best practices for ongoing maintenance to extend the lifespan of lithium battery packs in medical and industrial environments. Regular testing helps you monitor battery health and plan timely replacements. Set up a maintenance schedule that includes periodic battery analysis, visual inspections, and performance reviews. Replace batteries that show signs of swelling, overheating, or reduced capacity. Use a battery management system (BMS) to automate monitoring and alerts. For more details, visit our Battery Management System (BMS) page.

Maintenance checklist:

Schedule routine testing and validation.

Track battery analysis data for trends.

Inspect for physical damage or swelling.

Replace batteries before critical failure.

Train staff on safe handling and storage.

Regular maintenance reduces downtime and supports the reliability of medical, robotics, and industrial devices.

When you select batteries for precision instruments, focus on stability, compliance, and long service life. Lithium battery packs, especially rechargeable lithium medical batteries, deliver reliable power for medical devices and other demanding applications. You gain long service life and consistent performance in medical environments. Prioritize safety, quality, and regular maintenance to keep your medical instruments operating at peak efficiency. Make informed choices to ensure your medical equipment meets strict standards and supports critical operations.

FAQ

What makes lithium-ion batteries ideal for precision instruments in medical and industrial fields?

Lithium-ion batteries offer high energy density and long cycle life. You get reliable power for medical, robotics, security, and industrial devices. These batteries meet strict standards for safety and performance. Their compatibility with advanced battery management systems ensures stable operation.

How do you ensure compatibility between lithium-ion battery packs and your precision instruments?

You should check voltage, size, and connector type. Review manufacturer specifications for compatibility. Confirm standards compliance for medical, robotics, and security applications. Use simulation tools to match lithium-ion battery packs with device requirements. Test integration before deployment.

What standards must lithium-ion batteries meet for medical and industrial use?

Lithium-ion batteries must comply with IEC 62133, UL 1642, and UN 38.3 standards. These standards cover safety, transport, and performance. You should request certification documents from suppliers. Standards ensure batteries operate safely in medical, robotics, security, and industrial environments.

How do lithium-ion batteries compare to nickel and alkaline options for cycle life and durability?

Chemistry | Typical Cycle Life | Durability in Harsh Conditions | Application Scenario |

|---|---|---|---|

Lithium-ion | 1,000–2,000 | Excellent | Medical, robotics, security |

Nickel-Cadmium | 1,000+ | Good | Backup, outdoor |

Alkaline | Single-use | Moderate | Consumer electronics |

Lithium-ion batteries provide superior cycle life and durability for precision instruments.

What maintenance practices extend the lifespan of lithium-ion battery packs in industrial and medical devices?

You should schedule regular testing and validation. Monitor battery health using advanced analysis tools. Replace lithium-ion batteries showing swelling or reduced capacity. Follow standards for safe handling and disposal. Train staff on compatibility and maintenance procedures.