High temperatures can drastically impact lithium battery performance, lifespan, and safety. For instance, studies show that as temperatures rise from 25°C to 55°C, the degradation rate of maximum charge storage increases from 4.22% to 13.24% after 260 cycles. Elevated temperatures also accelerate chemical instability, increasing the risk of overheating risks and reducing battery safety. These effects highlight the importance of managing high temperature performance about lithium battery systems effectively.

Key Takeaways

Hot temperatures can lower how long lithium batteries last. Keeping them cool helps them work better.

Use good cooling systems to stop overheating and keep them safe. Check and fix these systems often.

Keep lithium batteries in cool, airy places to avoid heat. Don’t leave them fully charged for too long to prevent damage.

Part 1: Mechanisms of Heat’s Impact on Lithium Battery Performance

1.1 Thermal Degradation and Chemical Instability in Battery Packs

High temperatures accelerate thermal degradation in lithium-ion batteries, leading to chemical instability. This process occurs when elevated temperatures cause the electrolyte to decompose, generating gas and increasing internal pressure. Over time, this can damage the battery’s internal structure, reducing its ability to store and deliver energy efficiently. For industrial applications, such as robotics and infrastructure, this degradation can compromise operational reliability and increase maintenance costs.

Thermal degradation also affects the cathode and anode materials. For instance, in NMC lithium batteries, high temperatures can cause the cathode to release oxygen, further destabilizing the battery. This chemical instability not only reduces battery performance but also increases safety risks, such as thermal runaway. Implementing advanced cooling systems and monitoring temperature fluctuations can help mitigate these effects.

1.2 Capacity Loss and Reduced Efficiency at High Temperatures

Operating lithium-ion batteries at high temperatures significantly impacts their capacity and efficiency. Studies show that at 30°C (86°F), the cycle life of a battery decreases by 20%. When the temperature rises to 40°C (104°F), the reduction in cycle life doubles to 40%. Charging and discharging at 45°C (113°F) can cut the expected cycle life in half compared to operation at 20°C (68°F). This capacity fade is particularly pronounced at high states of charge (SoCs), where the battery is more susceptible to thermal stress.

In applications like medical devices, where consistent power output is critical, reduced efficiency can lead to operational disruptions. Similarly, in consumer electronics, high temperatures can shorten battery lifespan, resulting in frequent replacements and increased costs. To address these challenges, you should consider integrating smart battery management systems that regulate temperature and optimize charging cycles.

1.3 Safety Risks: Thermal Runaway and Fire Hazards in Lithium Batteries

One of the most critical safety risks associated with high temperatures in lithium-ion batteries is thermal runaway. This phenomenon occurs when excessive heat triggers a self-sustaining reaction within the battery, leading to rapid temperature escalation. Thermal runaway can result in fire or even explosions, posing significant risks in industrial and security system applications.

The risk of thermal runaway increases when batteries are exposed to prolonged high temperatures or physical damage. For example, in transportation infrastructure, where batteries are often subjected to harsh environmental conditions, the likelihood of thermal events can escalate without proper thermal management. To enhance safety, you should implement robust protective measures, such as thermal barriers and advanced cooling technologies, to prevent overheating and ensure operational reliability.

Part 2: Consequences of Prolonged Exposure to High Temperatures

2.1 Accelerated Aging and Shortened Lifespan of Battery Packs

Prolonged exposure to high temperatures accelerates the aging process in lithium-ion batteries. While elevated temperatures may temporarily enhance capacity, they significantly reduce the overall lifespan. For example, research shows that charging a battery at 113°F causes more than double the degradation compared to charging at 77°F. This rapid aging results from increased chemical reactions within the battery, leading to capacity fade and higher impedance.

Every 10°C rise above 25°C doubles the rate of degradation, making thermal management critical for industrial applications like robotics and infrastructure. Controlled cycling tests confirm that high temperatures exacerbate performance decline, particularly in environments requiring consistent power output. To mitigate these effects, you should implement advanced cooling systems and monitor battery storage conditions.

2.2 Increased Risk of Catastrophic Failures in Industrial Applications

High temperatures not only degrade performance but also increase the risk of catastrophic failures. Lithium-ion batteries under thermal stress are more prone to thermal runaway, where excessive heat triggers a chain reaction of failures. This risk is especially concerning in industrial settings, where battery packs power critical systems like transportation and security infrastructure.

Failures often occur when high temperatures combine with full charge states, inducing stress on the battery. During thermal runaway, heat from one failing cell can propagate to adjacent cells, leading to fires or explosions. Historical recalls of lithium-ion batteries highlight how high temperatures exacerbate these risks, even in products that meet safety standards. To enhance safety, you should adopt robust protective measures, such as thermal barriers and temperature-regulating battery management systems.

2.3 Reduced Power Output and Performance in High Temperature Environments

Operating lithium-ion batteries in high-temperature environments reduces their power output and efficiency. Prolonged exposure increases internal resistance, which lowers energy efficiency and shortens run times. For instance, LiFePO4 batteries experience decreased charge acceptance and energy output under thermal stress. Devices relying on these batteries, such as consumer electronics, may exhibit inconsistent performance and shorter operational lifespans.

High temperatures also accelerate chemical reactions, further degrading battery performance. Increased internal resistance leads to energy loss, making it essential to optimize battery storage and operating conditions. By integrating smart battery management systems, you can regulate temperature and maintain consistent performance, even in challenging environments.

Part 3: Strategies to Mitigate Heat-Related Issues in Lithium Battery Packs

3.1 Advanced Cooling Systems for Industrial Battery Packs

Effective cooling systems are essential for managing heat in lithium-ion batteries, especially in industrial applications like robotics and infrastructure. High temperatures can lead to thermal runaway, reduced efficiency, and shortened lifespan. Advanced cooling technologies, such as liquid cooling and phase-change materials, help dissipate heat efficiently. Liquid cooling systems circulate a coolant through the battery pack, absorbing excess heat and maintaining optimal operating temperatures. Phase-change materials, on the other hand, absorb heat during phase transitions, providing passive thermal management.

Research highlights the importance of designing battery packs with integrated cooling systems to prevent thermal runaway. Experimental and simulation studies have shown that optimized cooling designs not only enhance safety but also improve performance and cost efficiency in mass-produced electric vehicle battery packs. For industrial applications, adopting these advanced cooling solutions ensures operational reliability and minimizes the risk of catastrophic failures.

Tip: Regular maintenance of cooling systems is crucial to ensure their effectiveness over time. Neglecting this can lead to overheating and reduced battery performance.

3.2 Proper Storage Practices to Minimize Heat Exposure

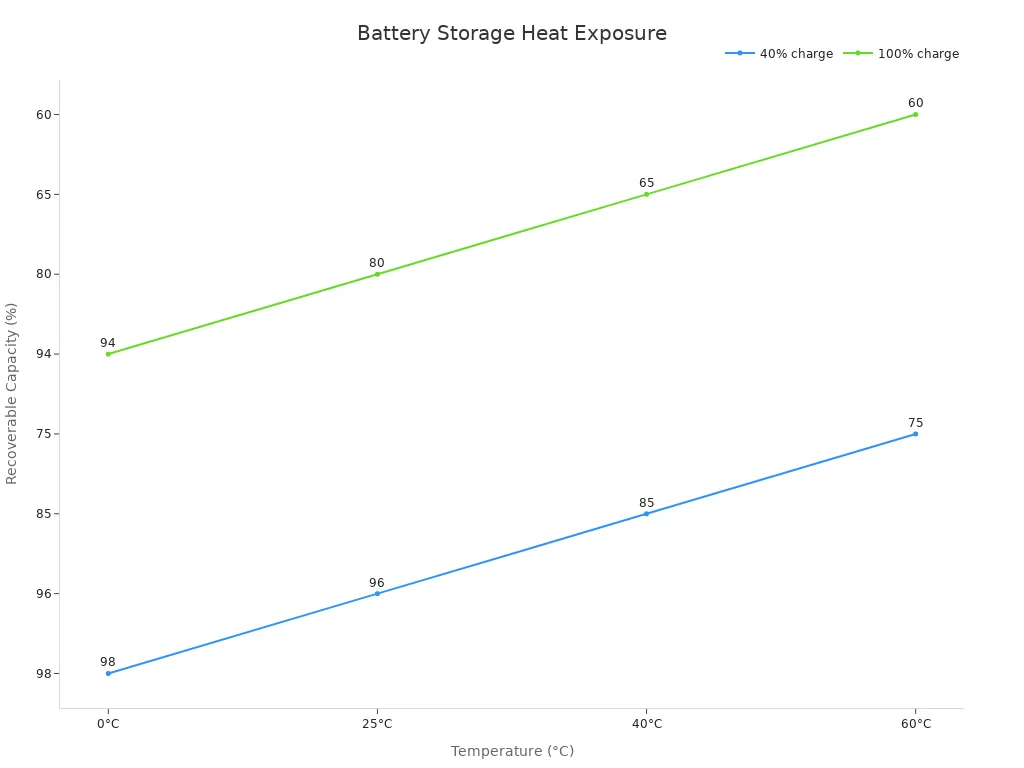

Proper storage practices play a critical role in reducing heat exposure and preserving the lifespan of lithium-ion batteries. Storing batteries in environments with controlled temperatures prevents thermal stress and capacity loss. For instance, keeping batteries at 25°C instead of 40°C can significantly improve recoverable capacity, as shown in the table below:

Temperature | Recoverable Capacity at 40% Charge | Recoverable Capacity at 100% Charge |

|---|---|---|

0°C | 98% | 94% |

25°C | 96% | 80% |

40°C | 85% | 65% |

60°C | 75% | 60% (after 3 months) |

To minimize heat exposure, you should store batteries in well-ventilated areas away from direct sunlight or heat sources. For industrial battery packs, consider using temperature-controlled storage units. These units maintain a stable environment, reducing the risk of thermal degradation and ensuring consistent performance.

Note: Avoid storing batteries at full charge for extended periods, as this increases thermal stress and accelerates aging.

3.3 Smart Battery Management Systems for Temperature Regulation

Smart battery management systems (BMS) are indispensable for effective temperature regulation in lithium-ion batteries. These systems monitor and control battery temperature, ensuring it remains within the optimal range of 20°C to 45°C. By integrating advanced sensors and algorithms, a BMS can detect temperature fluctuations and activate cooling or heating mechanisms as needed.

A well-designed BMS employs both passive and active cooling strategies. Passive cooling utilizes the surrounding environment to dissipate heat, while active cooling involves refrigeration systems for more precise temperature control. Additionally, some systems use PTC heaters to warm batteries in cold conditions, facilitating charging and preconditioning. The table below outlines key mechanisms of a smart BMS:

Mechanism | Description |

|---|---|

Heating | Utilizes PTC heaters to warm batteries in cold conditions, facilitating charging and preconditioning. |

Cooling | Employs passive cooling when the environment is cooler and active cooling with refrigeration when it’s hotter. |

Temperature Range | Maintains battery temperature between 20°C to 45°C, crucial for health and efficiency. |

System Operation | The BTMS master controller communicates with the VCU to optimize battery operation based on temperature data. |

Smart BMS technology is particularly beneficial for applications like medical devices, robotics, and security systems, where consistent performance is critical. By regulating temperature effectively, these systems enhance battery safety, extend lifespan, and reduce the risk of thermal runaway.

Tip: When selecting a BMS, prioritize systems with real-time monitoring and predictive analytics to ensure optimal performance under temperature extremes.

High temperatures can severely compromise lithium-ion battery performance, lifespan, and safety. Elevated temperatures increase the risk of thermal runaway, which can lead to fires or explosions in industrial settings. You must adopt robust thermal management strategies to prevent cascading failures and ensure operational safety. Proper cooling systems and smart storage practices are essential for maintaining reliability.

Tip: Consult Large Power for customized solutions to enhance battery safety and performance.

FAQ

1. How does heat affect lithium battery safety?

High temperatures increase the risk of thermal runaway, which can cause fires or explosions. Proper cooling systems and monitoring reduce these risks effectively.

2. Can storing batteries at high temperatures damage them?

Yes, storing batteries in hot environments accelerates chemical reactions, leading to capacity loss and reduced lifespan. Always store batteries in cool, well-ventilated areas.

3. What is the ideal operating temperature for lithium batteries?

Lithium batteries perform best between 20°C and 45°C. Operating outside this range can reduce efficiency and increase the risk of thermal degradation.

Tip: For professional guidance on operating temperature for lithium batteries, visit Large Power.