If you seek the most suitable Lithium Battery for Industrial-grade mobile lighting lamp in 2025, you should focus on safety, cycle life, and cost.

Industrial buyers value:

Rechargeable battery options for lower lifecycle costs

Sustainability through advanced chemistries that minimize waste

You need reliability and ruggedness for demanding environments.

Key Takeaways

Choose LiFePO4 lithium batteries for industrial mobile lighting in 2025. They offer the best safety, cycle life, and cost-effectiveness.

LiFePO4 batteries provide up to 5000 cycles, reducing maintenance and replacement costs. This makes them ideal for long-term use in demanding environments.

Selecting LiFePO4 supports sustainability goals. These batteries contain fewer hazardous materials and are recognized for their environmental friendliness.

Part 1: Quick Answer

1.1 Best lithium battery for industrial-grade mobile lighting lamp

When you evaluate options for powering industrial mobile lighting, the LiFePO4 Lithium battery stands out as the top choice for 2025. This chemistry delivers the best balance of safety, cycle life, and cost for demanding environments. You can rely on LiFePO4 Lithium battery packs to perform consistently in industrial settings, including infrastructure, security systems, and robotics. Manufacturers select this battery type because it offers robust construction, intrinsic safety, and long-lasting performance.

Tip: LiFePO4 Lithium battery packs can be installed in space-restricted compartments and even on their side, giving you more flexibility in lamp design and deployment.

To help you compare, here is a table summarizing the main lithium battery chemistries relevant to industrial-grade mobile lighting lamp applications:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Safety Level | Typical Use Cases |

|---|---|---|---|---|---|

LiFePO4 Lithium battery | 3.2 | 90-140 | 2000-5000 | Highest | |

NMC Lithium battery | 3.7 | 150-220 | 1000-2000 | Moderate | |

LCO Lithium battery | 3.7 | 150-200 | 500-1000 | Moderate | |

NCA Lithium battery | 3.6 | 180-250 | 500-1000 | Moderate | |

LMO Lithium battery | 3.7 | 100-150 | 300-700 | Moderate | |

LTO Lithium battery | 2.4 | 70-80 | 7000-20000 | Highest |

1.2 Key reasons for selection

You should choose the LiFePO4 Lithium battery for industrial-grade mobile lighting lamp because it meets the most critical benchmarks for safety, cycle life, and cost. Here are the main reasons:

Safety:

LiFePO4 Lithium battery packs have intrinsic safety features.

Overcharge and over-discharge protection reduce the risk of thermal runaway and fire hazards.

Robust construction withstands harsh industrial conditions.

Cycle Life:

LiFePO4 Lithium battery packs deliver up to 5000 cycles, maintaining performance over years of use.

High cycle life means fewer replacements and lower total cost of ownership.

Cost:

While the initial investment may be higher than some alternatives, you benefit from long-term savings due to durability and reliability.

Lower maintenance and replacement costs make LiFePO4 Lithium battery packs ideal for large-scale deployments.

Environmental Impact:

LiFePO4 Lithium battery chemistry is recognized as the most environmentally friendly among lithium-ion batteries.

You support sustainability goals by choosing a battery with minimal hazardous materials.

Reliability:

The failure rate for lithium-ion batteries remains low, but LiFePO4 Lithium battery packs offer enhanced stability and manufacturing quality.

You minimize downtime and safety incidents in critical applications.

“The intrinsic safety of the chemistry and the life cycles of the battery itself are the two fundamental parameters to consider when selecting the chemistry.”

You can trust the LiFePO4 Lithium battery for industrial-grade mobile lighting lamp to deliver reliable power, safety, and value in every industrial application.

Part 2: Battery Types Overview

2.1 LFP (Lithium Iron Phosphate)

You will find LiFePO4 as the most reliable option for industrial mobile lighting. LFP batteries deliver a strong combination of safety, long cycle life, and stable performance. Their thermal and chemical stability reduces the risk of thermal runaway, making them ideal for harsh environments. You can expect over 3,000 cycles, with some packs exceeding 10,000 cycles. LFP batteries also offer a specific energy of 90–160 Wh/kg and an energy density of 325 Wh/L.

LFP batteries provide peace of mind for large-scale energy projects and industrial lighting, thanks to their durability and safety.

Characteristic | Value |

|---|---|

Platform Voltage | 3.2 V |

Energy Density | 90–160 Wh/kg |

Cycle Life | 3,000–10,000+ |

2.2 NMC (Nickel Manganese Cobalt)

Nickel manganese cobalt batteries (NMC) are popular in industrial and medical applications. You benefit from high energy density, ranging from 150 to 220 Wh/kg, which allows for compact and lightweight battery packs. NMC batteries typically last 1,000 to 2,300 cycles. Their balanced performance makes them suitable for robotics and security systems.

NMC batteries offer higher energy density than LFP, but with a shorter cycle life.

2.3 LCO (Lithium Cobalt Oxide)

Lithium cobalt oxide batteries (LCO) deliver high energy density, reaching up to 240 Wh/kg. You often see them in consumer electronics, but their moderate safety profile and shorter lifespan—typically 2-3 years—limit their use in industrial mobile lighting.

LCO batteries provide high energy output but require careful management to ensure safety.

2.4 NCA (Nickel Cobalt Aluminum)

Nickel cobalt aluminum batteries (NCA) bring high specific energy (200–260 Wh/kg) and are used in industrial and medical devices. You can expect a nominal voltage of 3.6 V and a cycle life of around 500 cycles. NCA batteries support fast charging and high discharge rates, but they require strict thermal management.

Characteristic | Details |

|---|---|

Platform Voltage | 3.6 V |

Energy Density | 200–260 Wh/kg |

Cycle Life | ~500 |

2.5 LMO (Lithium Manganese Oxide)

Lithium manganese oxide batteries (LMO) feature a unique spinel structure that improves thermal stability and current handling. You gain fast charge and discharge rates, making LMO suitable for power-intensive industrial lighting. However, LMO batteries have lower energy density and can be sensitive to extreme temperatures.

Benefits | Drawbacks |

|---|---|

High discharge rates | Lower energy density |

Stable over temperature | Cost can be prohibitive |

Lower risk of thermal runaway | Temperature sensitivity |

2.6 LTO (Lithium Titanate)

Lithium titanate batteries (LTO) stand out for their exceptional cycle life, often exceeding 10,000 cycles. You can charge LTO batteries within minutes, making them ideal for robotics and medical devices that require rapid power delivery. While their energy density is lower, their reliability and fast charging set them apart in demanding industrial applications.

Feature | LTO Batteries |

|---|---|

Cycle Life | >10,000 cycles |

Charging Speed | Minutes |

Energy Density | 70–80 Wh/kg |

Part 3: Battery Form Factors

Battery form factors play a critical role in industrial mobile lighting applications. The right form factor ensures your lithium battery packs deliver reliable power, withstand harsh conditions, and maintain high technical performance. You need to consider ruggedness, energy density, and cost efficiency when selecting the best option for your lighting systems.

3.1 Cylindrical (18650, 21700, 26650)

Cylindrical batteries, such as 18650, 21700, and 26650, are widely used in industrial mobile lighting. These batteries offer robust mechanical stability and high energy density, making them ideal for demanding environments. Their rigid structure provides excellent resistance to vibration and impact, which is essential for maintaining safety performance and minimised chances of thermal runaway. Cylindrical batteries also support a high number of cycles, ensuring long lifetimes and consistent efficiency.

Common cylindrical sizes include:

10440

14500

16340

18650

21700

26650

32650

You benefit from the energy density advantage and high peak power output of these batteries. The 18650 size is known for good energy density, while 21700 offers higher capacity and power. The 26650 size suits high-drain applications, providing greater capacity and durability.

Cylindrical batteries excel in industrial settings due to their efficient thermal management and reliable safety profiles.

3.2 Prismatic

Prismatic batteries feature a flat, rectangular shape that maximizes space utilization in your devices. Their modular design allows you to customize the battery pack to fit specific lighting systems. Prismatic batteries deliver high energy density and improved safety performance, thanks to better heat dissipation and robust hard cases. This form factor supports consistent heat distribution, which enhances efficiency and reduces the risk of runaway.

Advantage | Description |

|---|---|

Customizable Design | Modular, fits specific devices |

Increased Energy Density | Stores more energy in less volume |

Enhanced Safety | Better heat dissipation, minimised chances of thermal runaway |

Thin and Light | Ideal for portable, space-limited devices |

Improved Safety Features | Hard cases protect against mechanical stress |

Scalability | Adjustable thickness and size |

Consistent Heat Distribution | Flat surfaces enhance longevity and performance |

Simplified Manufacturing | Easier assembly, potential cost benefits |

Prismatic batteries offer a longer cycle life range and higher durability compared to pouch batteries, making them suitable for industrial mobile lighting where reliability and cost efficiency matter.

3.3 Pouch

Pouch batteries use a flexible, lightweight design that allows for ultra-thin and customizable shapes. You gain high working voltage, large capacity, and good discharge characteristics. Pouch batteries also provide a low self-discharge rate and no memory effect, supporting convenient charging and long lifetimes. However, they have limitations in electrical conductivity and are more sensitive to physical damage and temperature extremes. While pouch batteries show good performance under vibration, high temperatures can accelerate aging and reduce efficiency.

Key benefits of pouch batteries:

High working voltage and large capacity density

Low self-discharge and minimal capacity loss

Long lifespan with over 500 charge cycles

Good safety performance due to soft packaging

Ultra-thin, lightweight, and customizable

Drawbacks include higher cost, poor electrical conductivity, and increased sensitivity to damage. In industrial mobile lighting, pouch batteries provide flexibility and high energy densities, but you must weigh these against durability and cost.

Part 4: Key Comparison Factors

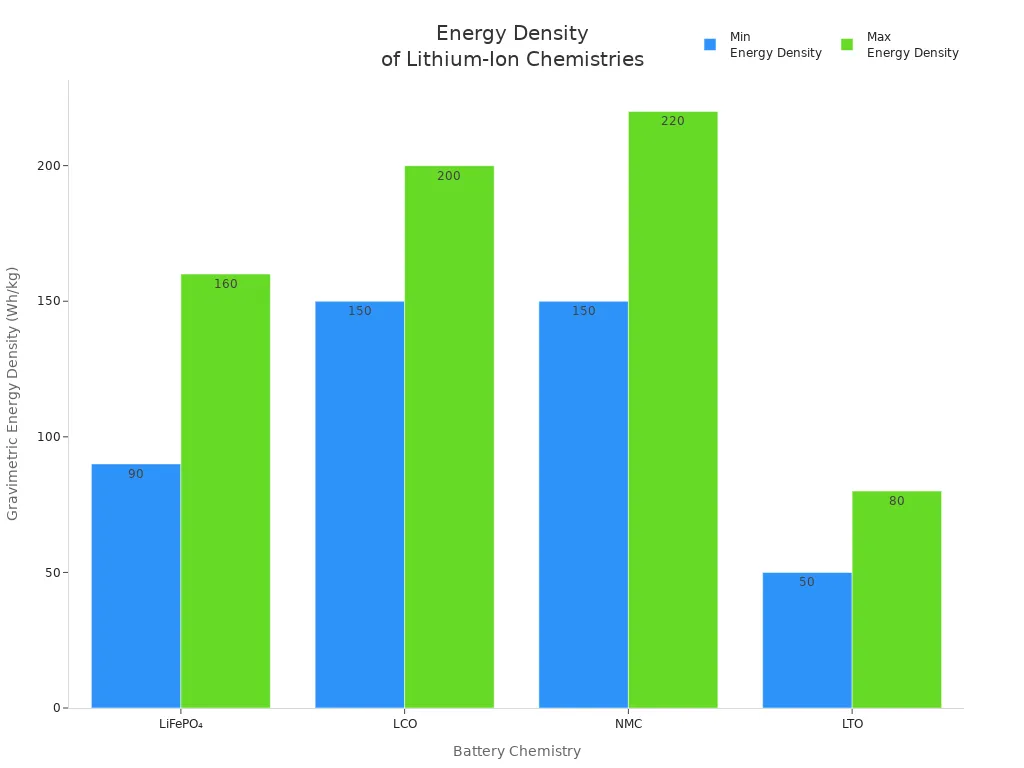

4.1 Energy density in lithium-ion batteries

You need to evaluate energy density when selecting lithium battery packs for industrial mobile lighting. Energy density determines how much energy you can store in a given weight, directly impacting the runtime and portability of your lighting solution. Higher energy density means longer operation times and lighter equipment, which is critical for mobile applications in infrastructure, robotics, and security systems.

Battery Chemistry | Gravimetric Energy Density (Wh/kg) | Weight per 1kWh (kg) | Common Use Cases |

|---|---|---|---|

Lithium Iron Phosphate (LiFePO₄) | 90–160 | 6.5–11 | Solar, RVs, off-grid backup |

Lithium Cobalt Oxide (LCO) | 150–200 | 5–6.6 | Smartphones, laptops |

Lithium Nickel Manganese Cobalt (NMC) | 150–220 | 4.5–6.6 | EVs, power banks |

Lithium Titanate (LTO) | 50–80 | 12.5–20 | Industrial, grid storage |

You benefit from higher energy density in lithium-ion batteries, which allows for longer operation times on a single charge.

Lithium-ion batteries outperform lead-acid and nickel-cadmium batteries in energy density.

The battery chemistry you choose will significantly affect the operational duration of your mobile lighting solution.

You should consider energy density as a key factor when designing energy storage systems for industrial mobile lighting. NMC and LCO chemistries offer the highest energy density, but LiFePO₄ provides a balance between energy density and safety, making it suitable for rugged environments.

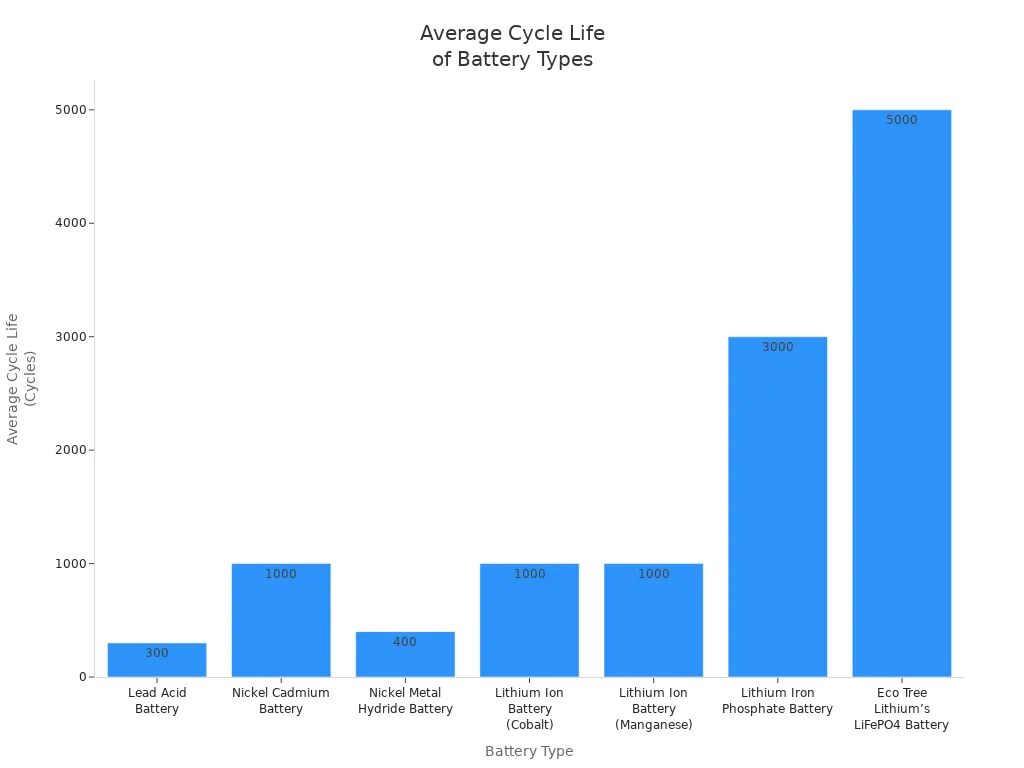

4.2 Cycle life and reliability

Cycle life measures how many charge and discharge cycles a battery can complete before its capacity drops below a usable level. Reliability ensures your energy storage systems perform consistently in demanding industrial settings. You must prioritize both factors to minimize downtime and replacement costs.

Battery Type | Average Cycle Life |

|---|---|

Lead Acid Battery | 300 Cycles |

Nickel Cadmium Battery | 1000 Cycles |

Nickel Metal Hydride Battery | 400 Cycles |

Lithium Ion Battery (Cobalt) | 1000 Cycles |

Lithium Ion Battery (Manganese) | 1000 Cycles |

Lithium Iron Phosphate Battery | 3000 Cycles |

Eco Tree Lithium’s LiFePO4 Battery | 5000 Cycles |

Lithium Iron Phosphate (LiFePO₄) batteries excel in reliability and cycle life. You can expect up to 5000 cycles with advanced LiFePO₄ packs, which reduces maintenance and replacement frequency in your energy storage systems. These batteries endure harsh conditions and maintain performance over time, making them ideal for industrial mobile lighting.

LFP batteries handle wide temperature ranges and high discharge currents. You gain durability and thermal stability, which are critical for reliability in industrial environments. While LFP batteries have lower energy density, their longevity and safety offset this limitation.

4.3 Safety and minimised chances of thermal runaway

Safety is a top priority for industrial mobile lighting. You must select battery chemistries that minimize the risk of thermal runaway, fire, and hazardous failures. LiFePO₄ batteries offer intrinsic safety features, including stable chemical structure and robust construction. You benefit from overcharge and over-discharge protection, which reduces the risk of accidents in your energy storage systems.

LFP batteries do not contain cobalt, which improves safety and reduces environmental concerns. Their thermal and chemical stability makes them suitable for demanding applications in infrastructure, robotics, and security systems. You should also consider battery management systems (BMS) to further enhance safety and monitor battery health. Learn more about BMS.

NMC and LCO batteries provide higher energy density but require strict thermal management. You must implement advanced safety protocols when using these chemistries in industrial settings.

Tip: Always integrate a reliable BMS to monitor temperature, voltage, and current in your energy storage systems.

4.4 Cost and availability

Cost and availability influence the total cost of ownership for industrial mobile lighting. Lithium battery prices have dropped significantly over the past decade, making advanced energy storage systems more accessible.

Year | Price (USD/kWh) |

|---|---|

2010 | 1400 |

2023 | <150 |

You can now deploy lithium battery packs at scale without prohibitive upfront costs. LiFePO₄ batteries offer a favorable balance between initial investment and long-term savings. Their extended cycle life and low maintenance requirements reduce overall expenses in your energy storage systems.

NMC and LCO batteries may cost more due to higher energy density, but you must weigh this against shorter cycle life and increased safety management costs. LTO batteries provide exceptional longevity but come with higher initial costs and lower energy density.

4.5 Suitability for industrial-grade mobile lighting lamp

You must match battery chemistry to your application requirements. For industrial mobile lighting, you need energy storage systems that deliver:

Long operational runtime

High reliability in harsh conditions

Intrinsic safety and minimized risk of thermal runaway

Cost-effective lifecycle performance

LiFePO₄ batteries meet these criteria. You gain robust performance, extended cycle life, and superior safety. NMC batteries suit applications where compact size and high energy density are critical, but you must manage safety risks. LTO batteries excel in rapid charging and extreme cycle life, making them suitable for specialized energy storage systems in robotics and medical devices.

Environmental impact and sustainability play an increasing role in battery selection for 2025. LiFePO₄ batteries contain fewer hazardous materials and support recycling initiatives. You contribute to sustainability goals by choosing chemistries with lower environmental footprints. Learn more about sustainability.

If your supply chain involves cobalt or other conflict minerals, you should review sourcing practices to ensure ethical compliance. Learn more about conflict minerals.

Note: Always assess your specific operational needs and consult with battery pack suppliers to optimize your energy storage systems for industrial mobile lighting.

You gain the most value by choosing LiFePO₄ lithium battery packs for industrial mobile lighting in 2025. These batteries deliver:

Superior safety and reliability

Long cycle life and rugged construction

Cost-effective performance for demanding environments

Assess your operational needs and consult with trusted battery pack suppliers to optimize your lighting systems.

FAQ

1. What makes LiFePO₄ batteries the best choice for industrial mobile lighting?

You gain superior safety, long cycle life (up to 5,000 cycles), and reliable performance. LiFePO₄ batteries from Large Power meet strict industrial standards for ruggedness and cost efficiency.

2. How do LiFePO₄ and NMC batteries compare for robotics and security systems?

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO₄ | 3.2 | 90–140 | 2,000–5,000 |

NMC | 3.7 | 150–220 | 1,000–2,000 |

LiFePO₄ offers longer life and safety. NMC provides higher energy density.

3. Can you request custom lithium battery packs for industrial applications?

Yes. You can request custom lithium battery solutions from Large Power for medical, robotics, security system, infrastructure, and industrial needs. Learn more about custom battery solutions.