Lithium-ion batteries deliver high energy density, long lifespan, and extended runtime, making them the leading batteries suitable for robots in today’s market. You need to match battery chemistry with your robot’s size, weight, voltage, and application to achieve high energy efficiency and reliable energy storage.

Lithium-ion and lithium iron phosphate (LiFePO4) have largely replaced older chemistries in mobile robots.

Battery chemistry selection directly affects operational cost and reliability. The right choice ensures optimal performance and reduces downtime.

Key Takeaways

Lithium-ion batteries are the best choice for mobile robots due to their high energy density and long lifespan. They provide longer runtimes and reduce maintenance costs.

Choosing the right battery chemistry impacts your robot’s performance and operational costs. Consider factors like energy density, cycle life, and charging capabilities.

Safety features are crucial when selecting batteries. Implement thermal management systems and protective circuits to prevent overheating and ensure reliable operation.

Evaluate your robot’s specific needs, such as voltage and discharge rate, to select the most suitable battery type. This ensures optimal performance and efficiency.

Always integrate a Battery Management System (BMS) to monitor battery health and safety. A BMS extends battery life and enhances operational reliability.

Part 1: Battery Chemistry Basics

1.1 Types of Battery Chemistry

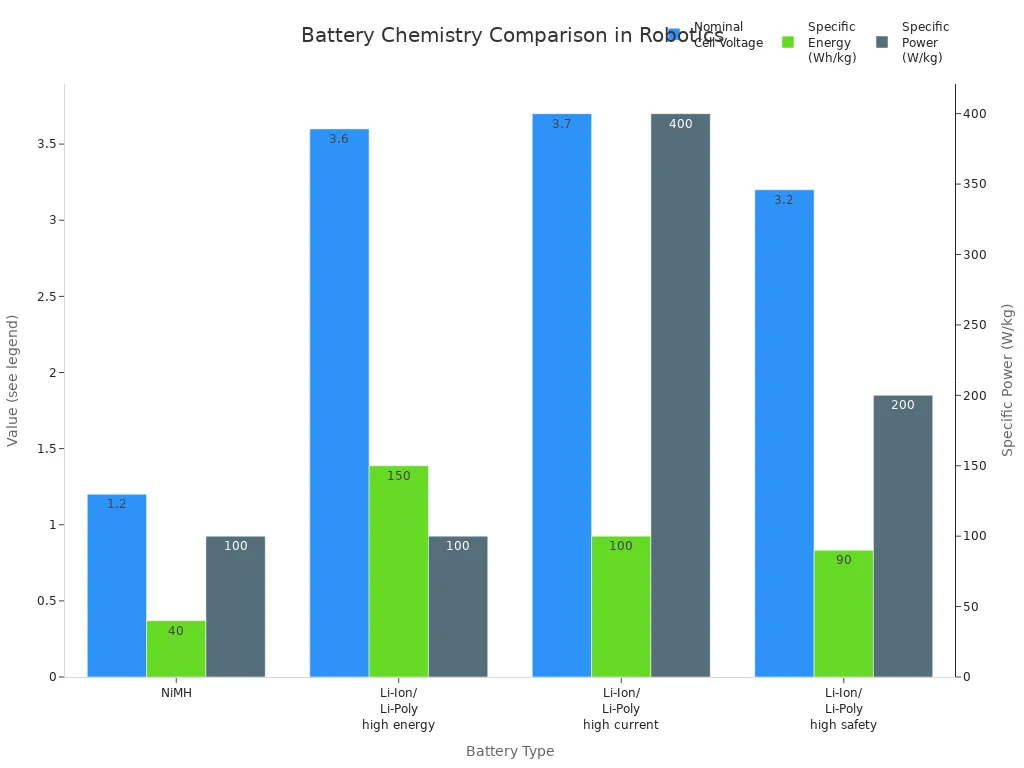

You encounter several battery chemistry options when designing mobile robots. Each chemistry offers unique characteristics that impact your robot’s performance and operational costs. The most common types include NiMH, lithium-ion batteries, and specialized lithium chemistries such as LiFePO4, NMC, LCO, LMO, and LTO. These chemistries differ in voltage, energy density, and power output.

Here is a comparison of the main battery types used in robotics:

Battery Type | Chemistry | Nominal Cell Voltage | Specific Energy | Specific Power |

|---|---|---|---|---|

NiMH | NiMH | 1.2V | 40 – 120Wh/kg | 100 – 1000 W/kg |

Li-Ion/Li-Poly high energy type | LiCoO2, LiNiMnCoO2 | 3.6 – 3.7V | 150 – 250Wh/kg | 100 – 400W/kg |

Li-Ion/Li-Poly high current type | LiMn2O4 | 3.7 – 3.8V | 100 – 150Wh/kg | 400 – 5000 W/kg |

Li-Ion/Li-Poly high safety type | LiFePO4 | 3.2 – 3.3V | 90 – 120Wh/kg | 200 – 7000 W/kg |

You see that li-ion batteries deliver higher voltage and specific energy than NiMH. LiFePO4 stands out for safety and cycle life, while NMC and LCO excel in high energy density.

1.2 Why Battery Chemistry Matters

Selecting the right battery chemistry determines how your mobile robot performs in real-world conditions. You must consider how each chemistry affects energy storage, runtime, and reliability. The chemistry you choose influences several critical factors:

Different battery chemistries provide varying energy densities, which directly influence the operational efficiency of mobile robots.

The cycle life of a battery affects how long a mobile robot can operate before needing a replacement, impacting overall lifespan.

Fast-charging capabilities of certain chemistries, like LTO, minimize downtime, allowing robots to recharge quickly and maintain productivity.

Temperature tolerance of battery chemistries ensures reliable performance in diverse environments, which is crucial for mobile robots operating in varying conditions.

You gain longer runtimes and reduced maintenance costs by choosing li-ion batteries with high energy density. LiFePO4 and LTO offer enhanced safety and fast charging, which support demanding industrial applications. Your selection of battery chemistry shapes the productivity and reliability of your robot fleet.

Part 2: Lithium-Ion Batteries in Robotics

2.1 Advantages of Lithium-Ion Batteries

You gain several key benefits when you choose lithium-ion batteries for your mobile robot. These batteries deliver high energy density, which means your robot operates longer between charges. The lightweight design of li-ion cells increases flexibility and efficiency, especially in environments where every gram matters. Fast charging capability allows you to minimize downtime and keep your robot fleet productive.

Here are the main advantages of li-ion batteries in robotics:

High energy density supports sustained power for extended operation.

Lightweight construction improves mobility and efficiency.

Fast charging reduces operational interruptions.

Long cycle life ensures stable performance over many charge cycles.

Integrated safety features protect against overcharge, over-discharge, and overheating.

Reliable performance in extreme temperatures supports use in harsh environments.

Advanced battery management systems (BMS) optimize energy use and extend working time.

Tip: You should always select a battery pack with a BMS to maximize the lifespan and safety of your li-ion batteries.

Li-ion batteries, including LiFePO4, NMC, LCO, LMO, and LTO types, offer stable voltage platforms and high specific energy. These features make them ideal for industrial robots, automated guided vehicles (AGVs), and delivery robots.

2.2 Limitations and Safety

While li-ion batteries provide many advantages, you must address certain limitations and safety concerns. Overheating can occur if you do not manage thermal loads properly. You need to implement active or passive cooling systems and use thermal-resistant materials to prevent heat buildup.

Common safety measures for li-ion batteries include:

Thermal management systems to prevent overheating.

Smart charging circuits and voltage monitoring to avoid overcharging or over-discharging.

Protective circuit modules and fuse systems to prevent short circuits.

Shock-resistant enclosures and vibration-dampening materials for mechanical protection.

Fire-retardant materials and automated suppression systems for fire prevention.

You must design your battery packs with robust safety features. These measures protect your robots from electrical faults and mechanical damage. By prioritizing safety, you reduce the risk of downtime and extend the operational life of your li-ion battery packs.

Part 3: Comparing Battery Chemistries

3.1 Lithium-Ion vs. Lithium-Polymer

You often compare li-ion and li-po batteries when selecting the best battery chemistry for mobile robots. Both chemistries offer high performance, but each has distinct advantages for robotics applications.

Attribute | Lithium Polymer (li-poly) | Lithium Ion (li-ion) |

|---|---|---|

Energy Density | Lower energy density compared to li-ion | Higher energy density (Wh/kg) |

Weight | Generally lighter due to pouch design | Heavier due to cylindrical cells |

Cost | Typically more expensive | Generally less expensive |

Li-poly batteries provide high voltage under load and support high amp draw. You benefit from flexible form factors, which suit custom robot designs. Li-poly cells run cooler during high discharge, but they offer fewer life cycles than li-ion. You must consider that li-poly batteries are more prone to thermal runaway if damaged.

Li-ion batteries deliver higher energy density, which means longer runtimes for your robots. You gain safer operation due to metal enclosures and more discharge options. Li-ion packs usually cost less and last longer. You should always include safety features in your battery packs to protect against overheating and short circuits.

Pros of li-po:

High voltage under load

Flexible shapes for custom designs

Cooler operation at high discharge

Cons of li-po:

Fewer life cycles

Higher risk of thermal runaway

Pros of li-ion:

Longer runtimes

Safer construction

Lower cost

3.2 Lithium-Ion vs. NiMH

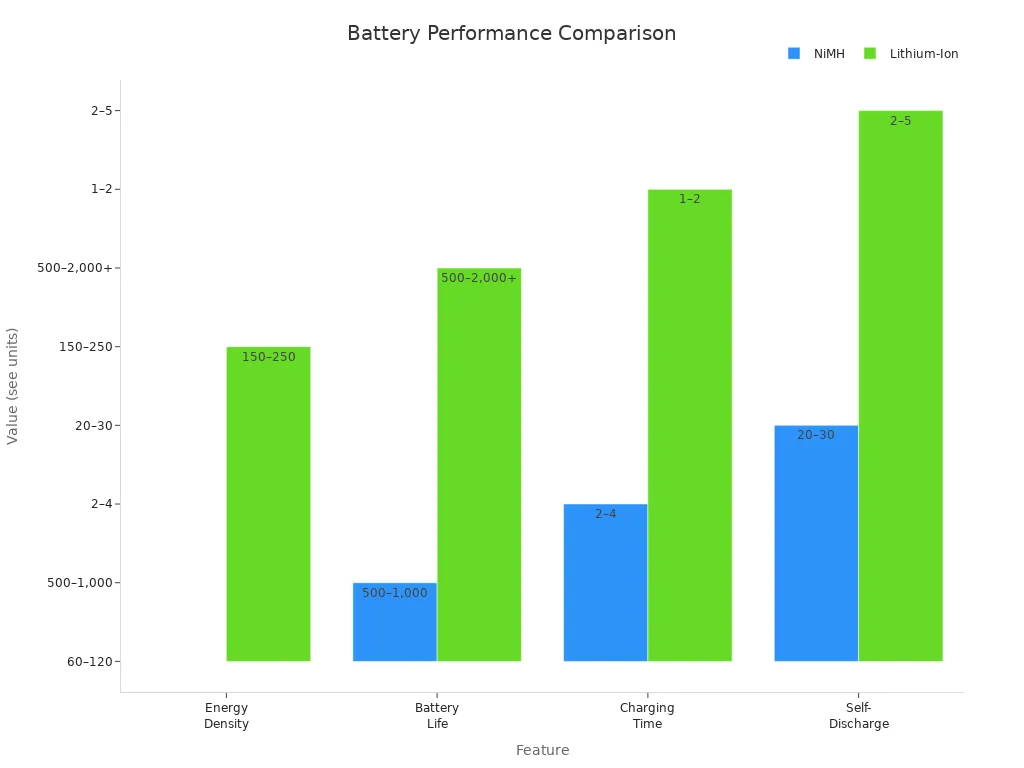

You may also consider NiMH batteries for mobile robots, but li-ion batteries outperform them in most industrial applications. The following table highlights key differences:

Feature | NiMH | Lithium-Ion (li-ion) |

|---|---|---|

Energy Density | 60–120 Wh/kg | 150–250 Wh/kg |

Battery Life | 500–1,000 cycles | 500–2,000+ cycles |

Charging Time | 2–4 hours | 1–2 hours |

Self-Discharge | High (20–30%/month) | Low (2–5%/month) |

Li-ion batteries offer higher energy density and longer battery life. You reduce downtime with faster charging and lower self-discharge rates. NiMH batteries may suit legacy systems, but li-ion packs deliver superior performance and reliability for modern mobile robots.

3.3 Other Chemistries Overview

You encounter several advanced lithium battery chemistries in robotics. Each type offers unique platform voltage, energy density, and cycle life. The table below summarizes the main lithium battery types:

Chemistry | Platform Voltage | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LCO | 3.6–3.7 V | 150–200 | 500–1,000 |

NMC | 3.6–3.7 V | 180–220 | 1,000–2,000 |

LiFePO4 | 3.2–3.3 V | 90–120 | 2,000–7,000 |

LMO | 3.7–3.8 V | 100–150 | 300–700 |

LTO | 2.4 V | 70–80 | 5,000–15,000 |

Solid-State | 3.7 V | 250–350 | 1,000–10,000 |

Lithium Metal | 3.7 V | 400–500 | 500–1,000 |

You should select battery chemistry based on your robot’s operational needs. LiFePO4 and LTO excel in cycle life and safety. NMC and LCO provide high energy density for compact robots. Solid-state and lithium metal chemistries promise future improvements in energy storage and reliability.

Part 4: Key Factors to Choose the Right Battery

Selecting the optimal battery for your mobile robot requires careful evaluation of several technical factors. You must consider voltage, capacity, discharge rate, battery management, and environmental safety. These elements directly impact robot performance, reliability, and operational costs.

4.1 Voltage and Capacity

You need to match the battery voltage to your robot’s motor requirements. If you select a battery with lower voltage than the motor specification, you risk underpowering the motors. This mismatch can cause performance issues or even damage the motors. Proper voltage compatibility allows your robot to operate efficiently and reach peak performance.

Capacity determines how long your robot can run before recharging. You should calculate the total energy demand based on your robot’s workload and select a battery with sufficient amp-hour (Ah) rating. For most mobile robots, li-ion batteries offer high energy density, which means longer runtimes in a compact package. Li-po batteries also provide flexible form factors, making them suitable for custom designs.

Tip: Always use the 20-80% battery rule. Keep your battery charge between 20% and 80% to extend its lifespan and maintain stable performance.

4.2 Discharge Rate and Current

Discharge rate measures how quickly a battery can deliver current to your robot. You must ensure the battery can supply enough current for peak loads, especially during motor startup or heavy-duty tasks. For best results, select a battery with a discharge capacity at least 1.2 times your motor’s stall current.

The table below shows how discharge rate influences battery selection for different robot types:

Discharge Rate | Application Type | Example Battery Specs |

|---|---|---|

≤5C | Constant speed robots (inspection) | 10Ah battery, 5C discharge rate, 50A continuous current |

10C-25C | High-power robots (logistics drones, combat) | 14.8V, 4000mAh, 25C battery, 100A peak current |

Low discharge | High-load scenarios (risk of voltage sag) | Requires real-time monitoring through BMS |

Li-ion batteries excel in high discharge applications, supporting both continuous and peak current demands. Li-poly batteries also perform well in high amp draw scenarios, especially when you need flexible shapes or lighter weight.

4.3 Battery Management System (BMS)

A robust Battery Management System (BMS) is essential for safe and efficient operation of lithium battery packs. You benefit from intelligent battery management, which ensures safe power distribution and economical energy use. The BMS continuously monitors state of charge (SOC) and state of health (SOH), maintaining optimal battery operations. It prevents deep discharges and controls charge cycles, reducing capacity loss over time.

Key BMS features for mobile robot battery packs include:

Feature | Description |

|---|---|

Cell Balancing | Ensures all cells in the battery pack are charged equally to enhance battery life and performance. |

State of Charge (SoC) | Provides real-time information on the battery’s charge level, crucial for operational efficiency. |

State of Health (SoH) | Monitors the overall health of the battery, predicting its lifespan and performance capabilities. |

Thermal Management | Regulates temperature to prevent overheating and ensure safe operation of the battery. |

Safety Protections | Implements various safety measures to prevent overcharging, short circuits, and other hazards. |

Data Communication | Facilitates communication with other systems via protocols like CAN or Bluetooth for monitoring. |

You should look for advanced BMS functions such as small total measurement error, simultaneous cell voltage measurement, passive cell balancing, and low power cell monitoring. These features help you maintain battery safety and maximize operational uptime. For more details, visit BMS and PCM solutions.

The BMS monitors and protects the battery, ensuring it operates within safe limits.

It balances the battery cells to enhance performance and longevity.

The system manages thermal conditions to prevent overheating, which is crucial for safety.

4.4 Safety and Temperature

You must prioritize safety features when designing your robot’s battery system. Extreme temperatures can degrade battery performance and lifespan. Low temperatures reduce battery capacity by up to 23% due to increased internal resistance. High temperatures can cause thermal runaway, which poses risks of fire and explosion. Performance may drop by as much as 40% in harsh environments.

To ensure safe operation, select batteries with built-in protections against short-circuit, over-temperature, and explosion. You should also verify that your battery packs meet industry standards such as UN38.3, CE, RoHS, and MSDS. These certifications confirm that your battery system complies with transport safety and environmental regulations.

Note: Always integrate thermal management systems and monitor battery temperature in real time. This practice helps you avoid unexpected shutdowns and extends battery life.

Li-ion batteries offer reliable performance across a wide temperature range, making them suitable for industrial robots and AGVs. Li-poly batteries require careful handling and monitoring, especially in high-power or custom applications.

Part 5: Battery Pack Formats and Design

When you select a battery pack for your mobile robot, you must consider the cell format. The choice between cylindrical, prismatic, and pouch cells affects not only the energy density and mechanical strength but also the weight distribution and stability of your robot. Each format offers unique advantages for different industrial applications, including robotics, medical devices, security systems, infrastructure, and industrial automation.

5.1 Cylindrical Cells

Cylindrical cells remain a popular choice for li-ion battery packs in robotics and industrial sectors. You benefit from their robust construction and consistent performance. These cells provide high energy density and withstand mechanical stress, making them ideal for demanding environments such as automated guided vehicles (AGVs) and security robots.

Cell Type | Energy Density | Mechanical Robustness | Applications |

|---|---|---|---|

Cylindrical | High | Very robust | Robotics, EVs, Industry |

Tip: Cylindrical cells help you maintain a low center of gravity, which improves stability and maneuverability in mobile robots.

5.2 Prismatic Cells

Prismatic cells feature a flat, rectangular design with a rigid casing. You gain high energy density and efficient use of space, which suits applications where you need compact battery packs. Prismatic cells offer excellent durability and thermal management, making them suitable for infrastructure projects, medical robots, and industrial automation.

Prismatic cells provide a scalable design for large battery packs.

The rigid casing protects against vibration and impact, which is essential for mobile robots operating in harsh environments.

5.3 Pouch Cells

Pouch cells, often used in li-poly battery packs, deliver high energy density in a lightweight and flexible format. You can shape these cells to fit custom enclosures, which is valuable for advanced robotics, medical devices, and compact security systems. However, pouch cells require careful thermal management due to the risk of swelling.

li-poly pouch cells allow you to optimize weight distribution and maintain a low center of gravity.

Flexible design supports innovative robot architectures and space-saving solutions.

You must monitor pouch cells closely to prevent overheating and ensure long-term reliability.

Cell Type | Energy Density | Mechanical Robustness | Applications |

|---|---|---|---|

Pouch | High | Flexible, risk of swelling | Robotics, Medical, Security, Consumer |

Note: li-poly pouch cells excel in applications where you need lightweight, custom-shaped battery packs, but always implement robust safety and monitoring systems.

You should match the cell format to your robot’s operational needs. For example, li-ion cylindrical cells suit high-performance industrial robots, while li-poly pouch cells fit compact, lightweight designs in medical and security fields. Prismatic cells bridge the gap, offering durability and efficient space usage for infrastructure and large-scale robotics.

Part 6: Application Examples

6.1 Small Robots

You often design small robots for indoor inspection, educational tasks, or light-duty automation. These robots require compact, lightweight battery packs. You benefit from li-poly batteries in these cases. Their flexible pouch cells fit tight spaces and reduce overall weight. You can shape li-poly packs to match custom enclosures, which is ideal for small robots with unique designs. The high discharge rate of li-poly batteries supports quick bursts of power, which is useful for agile movement. However, you must monitor temperature and swelling closely to ensure safety.

Tip: For small robots, choose li-poly batteries with integrated protection circuits. This approach helps you maintain safety without adding extra bulk.

6.2 Medium Robots

Medium-sized robots, such as delivery robots or warehouse assistants, need more energy and longer runtimes. You often select li-ion battery packs for these robots because they offer higher energy density and longer cycle life. A single 12V li-ion pack can power a medium robot efficiently. If weight is a concern, you may use an 11.1V li-poly battery. This option provides a balance between performance and portability. You should always consider the robot’s voltage and current requirements before finalizing your battery choice.

Robot Size | Voltage Options | |

|---|---|---|

Medium-sized | 12V | Typically uses one 12V battery; lead acid or single NiMh battery pack (or an 11.1V li-poly battery if weight is an issue). |

Large | Uses one or more lead acid battery packs. |

6.3 Large Robots

Large robots, such as industrial AGVs or heavy-duty service robots, demand robust battery solutions. You usually require higher voltage, such as 24V, and greater capacity to support long shifts and heavy loads. In these cases, you often deploy multiple li-ion packs in series or parallel. This setup delivers both the voltage and runtime needed for continuous operation. You must also integrate advanced battery management systems to monitor cell health and ensure safety. For large robots, li-poly batteries are less common due to their lower mechanical robustness, but you may still use them in custom applications where weight reduction is critical.

Note: Always match your battery system to the robot’s operational profile. Consider energy needs, safety, and maintenance requirements for optimal performance.

Part 7: How to Choose the Right Battery for Your Robot

7.1 Assessment Steps

Selecting the optimal battery for your mobile robot requires a systematic approach. You must analyze your robot’s technical requirements and operational environment before you choose the right battery. Follow these steps to ensure your battery selection supports performance, safety, and cost-effectiveness:

Evaluate Battery Size and Weight

Check the available space inside your robot. Select a battery that fits the enclosure and keeps the robot lightweight for better mobility. Li-poly batteries offer flexible pouch formats, which help you optimize weight and shape for compact designs.Verify Discharge Current

Assess your robot’s peak current demands, especially during motor startup or heavy-duty tasks. Choose a battery with a maximum discharge current that exceeds your robot’s requirements. Li-poly batteries excel in high-discharge scenarios, supporting rapid bursts of power.Review Battery Lifespan

Prioritize chemistries with long cycle life to reduce maintenance costs. LiFePO4 batteries deliver thousands of cycles, making them ideal for robots with frequent charge-discharge cycles.Check Environmental Compatibility

Ensure your battery operates reliably within your robot’s temperature range. For outdoor or industrial robots, select IP-rated battery packs that resist humidity, dust, and extreme temperatures. Use PCBs rated for -40 °C to +85 °C and polycarbonate enclosures for UV and heat resistance.Assess Communication Protocols

Verify that your battery pack supports your robot’s communication needs, such as CAN, RS485, UART, or TCP/IP. This compatibility ensures seamless integration with your robot’s control system.

Tip: Use tools like the Amp-Hour Calculator by Steve Judd or the Torque and Amp-Hour Calculator from Team Run Amok to estimate battery capacity and chemistry for your robot’s drive system.

7.2 Common Mistakes to Avoid

You must avoid several pitfalls when selecting batteries for mobile robots. These mistakes can lead to poor performance, increased costs, and operational downtime.

Poor Project Design

Failing to gather accurate data or plan your robot’s layout and environment can result in mismatched battery specifications. Always define your processes and calculate the required number of robots before you choose the right battery.Using Immature Technology

Not all suppliers have experience with your specific application. Request references and visit operational installations to verify technology maturity before purchasing.Overlooking After-Sales Support

Ensure your supplier offers local maintenance and includes preventive and corrective services in your contract. Reliable support reduces downtime and extends battery life.Ignoring Power Consumption Details

You must understand the current drawn by each robot component and their operational duration. Calculate total power consumption to select a battery that meets your robot’s hardware and task requirements.Neglecting Environmental Factors

Avoid using ABS or basic PVC housings for outdoor robots. Opt for industrial polymers and perform salt spray and UV testing to verify long-term resistance. Design mechanical structures to allow for thermal expansion without cracking.Skipping Safety and Compliance Checks

Always verify that your battery packs meet industry standards such as UN38.3, CE, RoHS, and MSDS. These certifications confirm compliance with transport safety and environmental regulations.

Note: When you select li-poly batteries, monitor temperature and swelling closely. Integrate thermal paste or insulating pads around key PCB components to prevent overheating.

B2B Battery Selection Checklist

Use this checklist to streamline your battery selection process for mobile robots:

Match battery voltage and capacity to robot specifications

Confirm battery size and weight fit your design

Verify discharge current meets peak load requirements

Prioritize long cycle life chemistries (LiFePO4, NMC, LCO, LMO, LTO)

Ensure environmental compatibility and IP rating

Integrate safety features and real-time monitoring

Check communication protocol compatibility

Use industrial-grade enclosures and PCBs

Plan for after-sales support and maintenance

Test for thermal expansion and UV resistance

Monitor li-poly batteries for swelling and overheating

Callout: You improve reliability and reduce operational costs when you follow a structured assessment and avoid common mistakes. Li-poly batteries offer flexibility and high discharge rates, but require careful monitoring and robust safety systems.

You gain the most value from lithium-ion batteries, but the best battery chemistry depends on your robot’s size, workload, and safety needs. Always assess key factors like chemistry, voltage, capacity, safety, and BMS before making a decision.

Factor | Impact on Total Cost of Ownership |

|---|---|

Price per kilowatt-hour | $151 per kWh, lower than previous years |

Expected Battery Lifespan | 1,000–3,000 cycles, reduces replacement costs |

Maintenance and Warranty | 5–10 years, lowers ongoing expenses |

For tailored solutions, consult with leading suppliers such as Panasonic, BYD, Samsung SDI, Tesla, or MANLY Battery. Their expertise ensures your mobile robots achieve optimal performance and reliability.

FAQ

What is the best lithium battery chemistry for industrial mobile robots?

You often choose LiFePO4 or NMC for industrial robots. LiFePO4 offers long cycle life and high safety. NMC provides higher energy density. Both chemistries deliver stable platform voltage and reliable performance in demanding environments.

How do you calculate the required battery capacity for your robot?

First, determine your robot’s average current draw and desired runtime. Multiply these values to get amp-hours (Ah). Add a safety margin of 20–30%. For example:

Required Capacity (Ah) = Average Current (A) × Runtime (hours) × 1.2

Why does your robot need a Battery Management System (BMS)?

A BMS protects your lithium battery pack from overcharge, over-discharge, and overheating. You gain real-time monitoring, cell balancing, and improved safety. This system extends battery lifespan and reduces maintenance costs.

Can lithium battery packs operate in extreme temperatures?

You can use lithium battery packs in a wide temperature range. LiFePO4 and LTO chemistries perform well from -20°C to 60°C. Always verify your battery’s specifications and integrate thermal management for best results.

What certifications should your lithium battery pack have?

You should look for certifications such as UN38.3, CE, RoHS, and MSDS. These standards confirm safety, environmental compliance, and transport readiness for your lithium battery packs.