Battery pack design shapes how long your underwater cleaning robot performs before needing a recharge. You need a battery pack that delivers consistent power and supports extended runtime. Reliable power ensures your robot pool cleaner keeps working efficiently. Lithium battery technology offers high energy density, making battery pack design more effective for underwater use. Custom battery pack solutions adapt to different power needs, giving you stable output and long-lasting performance. In underwater environments, battery pack durability and robust design protect your investment and keep your operations running smoothly.

Key Takeaways

Choose lithium-ion battery packs for high energy density. This ensures longer runtime and efficient cleaning for underwater robots.

Select 18650 cells for their modular design and reliability. These cells provide high capacity and long cycle life, enhancing performance.

Integrate a battery management system (BMS) for safety and longevity. A BMS monitors critical parameters, preventing overcharging and ensuring safe operation.

Opt for high-capacity battery packs to maximize cleaning coverage. Longer battery life allows robots to clean more efficiently without frequent recharges.

Prioritize durability and waterproofing in battery design. Look for IP67 or IP68 ratings to protect against water exposure and harsh conditions.

Part1: Battery Pack Design Principles

1.1 Lithium Battery Technology

You need a battery pack that delivers reliable power and extended runtime for underwater cleaning robots. Lithium-ion battery technology stands out because it offers high energy density, which means your robot can operate longer between charges. The lightweight nature of lithium batteries improves mobility, allowing robots to clean efficiently in pools, tanks, and industrial water systems. Fast charging times help you minimize downtime, so your cleaning robots spend more time working and less time waiting for a recharge.

Tip: Choosing lithium battery packs with high energy density ensures your robots meet demanding power requirements in underwater environments.

Here’s a comparison of energy density across common battery chemistries used in robotics and industrial applications:

Battery Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LCO | 3.7 | 150-200 | 500-1000 |

NMC | 3.7 | 180-220 | 1000-2000 |

LiFePO₄ | 3.2 | 90-150 | 2000-4000 |

LMO | 3.7 | 100-150 | 300-700 |

LTO | 2.4 | 70-80 | 7000-20000 |

Solid-State | 3.7 | 200-400 | 1000-2000 |

Lithium Metal | 3.7 | 300-500 | 500-1000 |

You see that lithium-ion and solid-state batteries provide the highest energy density, which directly supports longer runtime and better performance and capacity for underwater cleaning robots. These chemistries also serve medical devices, security systems, and industrial robots, where stable output and long cycle life are critical.

1.2 18650 Cell Advantages

When you select a battery pack for underwater cleaning robots, you often choose 18650 cells. These cells offer high capacity, long cycle life, and reliable discharge rates. You benefit from modular design, which lets you tailor the battery pack to meet specific power requirements for different cleaning tasks.

Feature | Description |

|---|---|

Capacity | 18650 cells typically have a capacity ranging from 1200mAh to 3600mAh, allowing for high energy storage. |

Cycle Life | These batteries can achieve a cycle life of over 500 cycles, which is more than double that of standard batteries. |

Discharge Rates | They can be charged and discharged 300-500 times, with optimal performance when partially discharged. |

Feature/Challenge | 18650 Cells Advantages | Unique Challenges for Underwater Systems |

|---|---|---|

Modularity | Flexible configurations for voltage/capacity | Must withstand increasing water pressure |

Energy Density | 200-300 Wh/kg for extended mission times | Complete isolation from conductive saltwater |

Proven Reliability | Hundreds of charge cycles with management | Specialized materials for marine environments |

Temperature Tolerance | Operates in challenging environments | Different cooling challenges than aerial systems |

Immediate shutdown if water intrusion occurs | ||

Marine-grade materials in BMS construction | ||

Critical for inaccessible underwater failures |

You gain flexibility with 18650 cells, which let you build battery packs that match your robot’s performance and capacity needs. These cells also support applications in medical devices, industrial robots, and security systems, where reliability and long runtime matter most.

1.3 Battery Management System

A battery management system (BMS) is essential for maximizing the safety, reliability, and lifespan of your battery pack. The BMS monitors voltage, temperature, and current, helping you prevent overcharging and deep discharge. This protection keeps your battery pack operating safely, even in harsh underwater environments.

Note: You can learn more about BMS and protection circuit modules at Large Battery BMS and PCM.

A well-designed BMS offers several benefits:

The BMS continuously monitors voltage and temperature, which is crucial for safe operation in underwater environments.

The BMS allows for a modular design, making it easier to maintain and replace individual components, thus extending the overall lifespan of the battery packs.

Batteries are rated for up to 2000 cycles at full power, maintaining 80% capacity even after extensive use.

You ensure stable output and long-lasting performance by integrating a BMS into your battery pack. This technology supports demanding power requirements and protects your investment, whether you deploy cleaning robots in pools, industrial tanks, or infrastructure systems.

Part2: Key Features of Battery Packs

2.1 Capacity and Runtime

You need a battery pack with high battery capacity to achieve extended battery life and maximize coverage in underwater cleaning robots. Battery capacity determines how long your robot can operate before requiring a recharge. Field data shows a direct link between battery life and cleaning coverage. Robots with less than 3 hours of battery life can only maintain a partially clean pool for 4-5 days. When you use a high-capacity battery pack with 6 hours of battery life, your robot keeps the pool fully clean for up to three days. Robots equipped with battery packs offering 8+ hours of battery life deliver consistently spotless coverage for 2-3 days.

Battery life | Cleaning days | Required pool condition by weekend |

|---|---|---|

Less than 3 hours | 4-5 days | Partially clean |

6 hours | 3 days | Fully clean |

8+ hours | 2-3 days | Consistently spotless |

You see that increased battery capacity leads to longer cleaning cycles and improved coverage. High-capacity battery packs also support demanding cleaning schedules in industrial tanks, medical water systems, and security infrastructure. Custom battery pack solutions allow you to tailor voltage and discharge rates to match specific operational needs, ensuring optimal battery performance and coverage.

Tip: Choose a battery pack with high battery capacity to reduce downtime and increase cleaning coverage for your underwater robots.

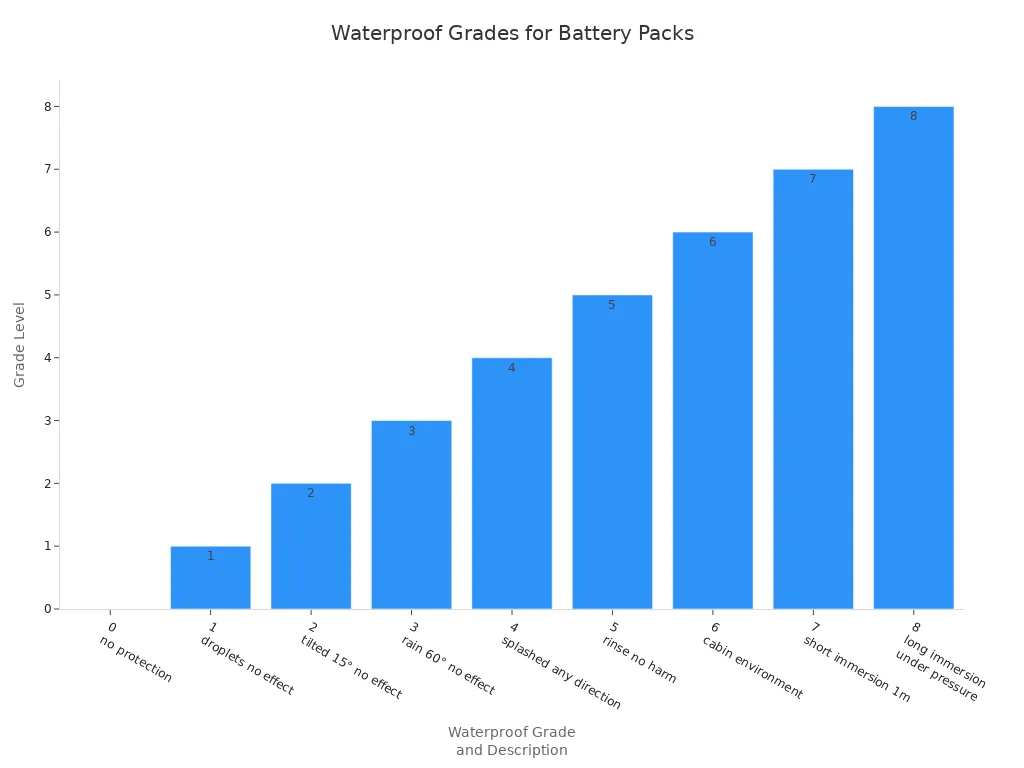

2.2 Durability and Waterproofing

Durability and waterproofing are critical for battery packs in underwater cleaning robots. You need a battery pack that withstands constant exposure to water, pressure, and harsh chemicals. Waterproofing standards such as IP67 and IP68 ensure your battery pack remains protected during submersion and in wet environments. IP67-rated battery packs endure temporary submersion up to 1 meter for 30 minutes, while IP68-rated battery packs provide continuous protection under severe conditions.

Waterproof Grade | Description |

|---|---|

0 | no protection |

1 | Water droplets will not affect the shell |

2 | Water droplets have no effect when tilted to 15 degrees |

3 | Water or rain has no effect from a 60-degree angle |

4 | Liquid splashed from any direction has no harmful effect |

5 | Rinse with water without any harm |

6 | Can be used in the cabin environment |

7 | Resistant to immersion in a short time (1m) |

8 | Long-term immersion in water under certain pressure |

You benefit from battery packs with enhanced sealing and robust construction. These features prevent water ingress and corrosion, increasing durability and extending battery life. Batteries with higher liquid protection ratings are essential for wet or humid environments. Enhanced durability ensures reliable battery performance in industrial, medical, and security system applications.

IP68 for underwater protection

IP66/IP67 for deck protection

IP67 for general outdoor use

IP68 for underwater or flood-prone zones

IP Rating | Description | Application |

|---|---|---|

IP67 | Total dust protection; can endure temporary submersion in water up to 1 meter deep for 30 minutes. | Suitable for docks or industrial wash-down areas. |

IP68 | Highest level of protection for continuous immersion in water under severe conditions. | Ideal for agricultural machinery in muddy fields or underwater lighting systems. |

2.3 Safety and Reliability

Safety mechanisms in battery packs protect your underwater cleaning robots from hazards such as thermal runaway, electrical faults, and water intrusion. You need a battery pack with advanced safety features to ensure reliable operation and minimize risk. Battery management systems (BMS) monitor charging, discharging, and cell balancing. Mechanical design uses robust casings to withstand impacts and punctures. Thermal insulation and sensors limit heat transfer and monitor temperature changes. Gas detection systems identify off-gassing early, while voltage monitoring detects cell degradation.

Mechanism Type | Description |

|---|---|

Battery Management Systems (BMS) | Monitors and controls charging, discharging, and cell balancing. |

Mechanical Design | Protects batteries with robust casings to withstand impacts or punctures. |

Thermal Insulation | Incorporates materials that limit heat transfer between cells. |

Gas Detection Systems | Detects off-gassing during early stages of thermal runaway. |

Thermal Sensors | |

Voltage Monitoring | Identifies irregularities indicating cell degradation or imbalance. |

Acoustic Sensors and AI | Captures ultrasonic signals emitted by stressed batteries, analyzing patterns to detect anomalies. |

Specialized Suppression Agents | Uses agents like Novec 1230 or FM-200 for localized suppression. |

Flooding Systems | Automated systems to manage fires quickly in large robotic facilities. |

Battery Compartments | Isolates batteries in fire-resistant enclosures to limit fire spread. |

Thermal Barriers | Uses non-flammable barriers between cells to prevent thermal propagation. |

Ventilation Systems | Safely vents gases to avoid pressure buildup and potential explosions. |

Feature | Description |

|---|---|

Robust Design | Battery packs are designed to withstand high pressure, corrosive saltwater, and extreme temperatures. |

Advanced Monitoring | Continuous monitoring of voltage, current, temperature, and state of charge to optimize performance. |

Thermal Management | Strategies to maintain optimal operating temperatures, preventing hazards associated with extremes. |

Fault Detection | Systems monitor for abnormalities and can initiate responses to prevent catastrophic failures. |

Safety Features | Includes overcharge protection and mechanisms to isolate faults, enhancing user safety. |

Note: Custom battery pack solutions let you specify voltage, discharge rates, and safety features to meet your operational requirements. You achieve reliable battery performance and maximize coverage in underwater cleaning robots.

Part3: Benefits for Robot Pool Cleaner Operations

3.1 Extended Cleaning Time

You want your robotic pool cleaner to deliver maximum coverage in every cleaning cycle. High-capacity battery packs provide up to 120 minutes of uninterrupted runtime, allowing your robotic pool cleaner to clean the entire pool in one session. This extended runtime means your robotic pool cleaner reaches every corner, removing dirt and debris efficiently. You avoid frequent recharging, which saves time and increases productivity. Advanced lithium battery packs support strong suction and consistent cleaning performance, even in larger pools or industrial tanks. You can rely on your robotic pool cleaner to maintain high standards of cleanliness with fewer interruptions.

Tip: Choose a battery pack with high energy density to maximize runtime and cleaning coverage for your robotic pool cleaner.

Benefit | Description |

|---|---|

Extended Runtime | High-capacity batteries allow for up to two hours of uninterrupted cleaning, enabling full pool coverage in one session. |

Enhanced Cleaning Efficiency | Longer battery life ensures thorough cleaning, reaching every corner without frequent recharges, effectively removing dirt and debris. |

Fewer Interruptions | Continuous operation without the need to recharge mid-task saves time and provides a smoother cleaning experience. |

Improved User Convenience | Users can clean at their own pace without worrying about battery life, reducing hassle with less frequent charging. |

3.2 Maintenance Reduction

You reduce maintenance needs when you use advanced battery packs in your robotic pool cleaner. Extended cleaning times from lithium battery packs help you maintain pool cleanliness more efficiently. Cordless robotic pool cleaners often face battery limitations, especially in larger pools. If the battery depletes before finishing a cleaning cycle, you must recharge and restart the process. This downtime disrupts your maintenance schedule. With high-capacity battery packs, your robotic pool cleaner completes cleaning cycles without interruption. You spend less time on battery management and more time focusing on operational goals. Fewer recharges also mean less wear on the battery, which extends its lifespan and reduces replacement costs.

3.3 Performance Comparison

You can compare the operational benefits of high-capacity battery packs to standard options in real-world cleaning scenarios. The table below highlights key differences in cleaning performance and maintenance efficiency:

Feature | Standard Battery Pack | High-Capacity Battery Pack |

|---|---|---|

Runtime | 60 minutes | 120 minutes |

Cleaning Coverage | Partial pool | Full pool |

Recharge Frequency | 2-3 times per day | 1 time per day |

Cleaning Performance | Moderate | Consistently high |

Maintenance Needs | Frequent | Reduced |

Strong Suction | Limited | Sustained |

You see that high-capacity battery packs deliver longer runtime, better cleaning coverage, and reduced maintenance. Your robotic pool cleaner operates more efficiently, providing reliable cleaning performance in demanding environments.

Part4: Selecting Battery Packs

4.1 Criteria for Selection

When you select a battery pack for underwater cleaning robots, you need to consider several important factors. These criteria help you match the battery pack to your robot’s operational needs and ensure reliable performance in challenging environments.

Cell configuration shapes the arrangement and output of the battery pack.

Capacity determines how long your robot can clean before recharging.

Discharge rates affect how well your robot performs tasks underwater.

Battery management system (BMS) options protect the battery and improve safety.

Certifications like UL, CE, RoHS, and UN38.3 confirm safety and market acceptance.

You should also review the voltage and discharge requirements for your specific robot model. The table below shows how these characteristics influence battery pack selection:

Characteristic | Impact on Battery Selection |

|---|---|

Specific Energy (Wh/kg) | Higher specific energy allows for longer mission durations or smaller battery packs. |

Specific Power (W/kg) | Higher specific power enables faster response times and higher peak power demands. |

Voltage Profile | Determines the operating voltage range of the robot’s electrical system. |

Capacity | Determines the total energy storage of the battery pack. |

Rate Capability | Determines the maximum discharge current and power output of the battery. |

Cell Configuration | Affects voltage and current output; series increases voltage, parallel increases current and capacity. |

Power Requirements | Peak power demand and average power consumption dictate required power density and discharge rate. |

Mission Duration | Longer missions require higher energy density or larger battery packs; shorter missions may prioritize power density. |

Tip: Always verify that your battery pack meets the voltage and discharge needs of your underwater cleaning robot.

4.2 Customization Options

You can customize your battery pack to fit the exact requirements of your underwater cleaning robot. Customization improves compatibility and boosts performance. You may select voltage, capacity, current, size, and appearance to match your robot’s needs.

Customization Aspect | Options Available |

|---|---|

Voltage | 7.4V, 24V, 48V |

Battery Chemistry | 18650, 21700, LiFePO₄, LiPo |

BMS Integration | Communication (CAN, RS485) |

Connector Types | XT60, Anderson, or custom |

You can request tailor-made battery packs with specific voltage and discharge rates. These packs include safety features such as thermal cutoffs and overcharge protection. Battery pack enclosures protect the battery from physical damage and environmental hazards, which is essential for underwater cleaning robots.

Note: Custom battery packs help you achieve optimal performance and safety in harsh underwater environments.

4.3 Future Trends

You will see new trends shaping battery pack design for underwater robotics. Modular packs make it easier to swap or scale capacity. AI-enabled battery management systems use predictive analytics to extend battery lifespan and adapt to mission changes. Manufacturers are exploring new chemistries for safer, more energy-dense batteries. Wireless charging stations inside hulls allow robots to recharge without surfacing.

Trend | Description |

|---|---|

Modular Packs | Easier to swap or scale capacity. |

AI-Enabled BMS | Predictive analytics to extend lifespan and adapt to mission changes. |

New Chemistries | Exploring safer, more energy-dense materials. |

Wireless Charging | In-hull charging stations to extend missions. |

If you want to learn more about sustainability or conflict minerals in battery pack design, you can read our approach to sustainability and our conflict minerals statement.

Advanced battery pack design increases the efficiency and reliability of underwater cleaning robots. You see improved runtime and stable output when you use lithium battery packs with high energy density. For best results, consider these tips:

Choose lithium-ion battery packs for greater energy density and efficiency.

Select lightweight battery options to improve mobility and cleaning effectiveness.

Work with manufacturers who have a proven record of quality and reliability.

Look for customization in voltage and capacity to match your operational needs.

Ensure your battery includes safety features such as short circuit protection.

You can expect future battery innovations to deliver longer runtimes and smarter management systems. These advances will support industrial, medical, and security applications, making underwater cleaning robots more dependable.

FAQ

What lithium battery chemistries work best for underwater cleaning robots?

You should consider NMC, LiFePO4, and solid-state chemistries. NMC offers high energy density and long cycle life. LiFePO4 provides stability and safety. Solid-state batteries deliver advanced performance for industrial and robotics applications.

How do you ensure battery safety in underwater environments?

You need a robust battery management system. This system monitors temperature, voltage, and current. It prevents overcharging and deep discharge. Waterproof casings and thermal sensors add extra protection for medical, security, and industrial robots.

Can you customize battery packs for specific cleaning robots?

You can request custom battery packs with tailored voltage, capacity, and discharge rates. Manufacturers design packs for robotics, infrastructure, and security systems. Customization improves compatibility and performance in demanding underwater scenarios.

What is the expected lifespan of a lithium battery pack in industrial robots?

You can expect lithium battery packs to last between 1000 and 4000 cycles, depending on the chemistry. NMC and LiFePO4 batteries offer long cycle life. Proper management and maintenance extend battery lifespan in industrial and medical sectors.

How does battery capacity affect cleaning coverage?

You achieve longer cleaning cycles with higher battery capacity. Robots with large battery packs clean more area before recharging. This improves efficiency in industrial tanks, medical water systems, and security infrastructure.