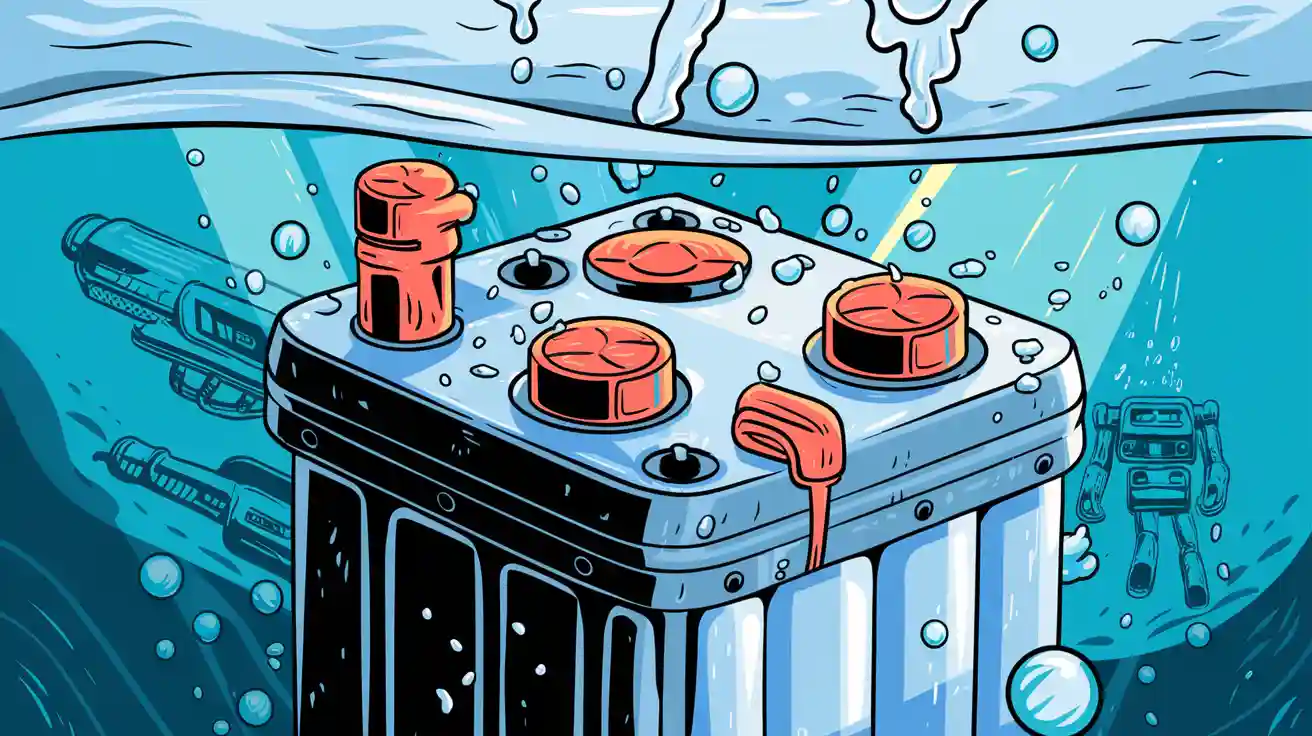

You face unique challenges when you design a waterproof battery pack for subaquatic robots. Lithium battery packs power most underwater robotics. Recent advances in pressure-tolerant lithium-polymer batteries and gel encapsulation offer new battery solutions that withstand harsh underwater conditions. A waterproof battery pack must also include a robust battery management system to ensure reliable and safe operation. You need a waterproof power supply that meets your specific application, so customization is key. Waterproof design and integration remain essential for dependable underwater performance.

Key Takeaways

Choose battery packs that meet IP68 standards for maximum waterproof protection. This ensures reliable performance in harsh underwater environments.

Consider pressure resistance when designing battery packs for deep-sea robots. Use spherical or cylindrical shapes to evenly distribute pressure and prevent implosion.

Select robust enclosures and sealing methods to protect battery packs from water ingress. Use waterproof connectors and conformal coatings for added safety.

Integrate advanced battery management systems to monitor performance and ensure safety. This helps maintain reliable power delivery in underwater applications.

Customize battery solutions to fit the specific needs of your underwater robots. Tailored designs enhance performance in medical, security, and industrial sectors.

Part 1: Battery Solutions and Standards

1.1 Waterproof Battery Pack Ratings

You need to understand how waterproof battery pack ratings work when selecting battery solutions for subaquatic robots. The most common system is the IP rating standards, which measure how well a product resists dust and water. IP68 standards set the benchmark for waterproof battery pack performance in harsh underwater environments. You can see the differences in protection levels in the table below:

Rating | Protection Level | Applications |

|---|---|---|

IP68 | Maximum protection for continuous immersion in water under severe conditions | Suitable for extreme environments like agricultural machinery and underwater lighting systems |

IP69K | High-pressure and high-temperature resistance | Ideal for industries with stringent hygiene standards, such as food processing plants exposed to steam cleaning |

You should always look for battery solutions that meet or exceed IP68 standards. This ensures your waterproof battery pack can handle continuous submersion and severe conditions. Ingress protection testing verifies that the battery pack meets these requirements. IP68 standards are especially important for lithium battery packs used in medical, robotics, and industrial sectors.

1.2 Pressure Resistance Criteria

When you deploy a waterproof battery pack in deep-sea robotics, you must consider pressure resistance. Battery solutions for these environments require enclosures that withstand hydrostatic pressure at depths up to 3,800 meters. At this depth, the pressure is 380 times greater than at sea level. You often see engineers use spherical or cylindrical housings for lithium battery packs. These shapes distribute pressure evenly and reduce the risk of implosion. Materials like syntactic foam help keep the waterproof battery pack lightweight and buoyant, which is critical for maneuverability in underwater robots.

1.3 Certification Overview

You should always check for certifications when choosing battery solutions for underwater use. Certifications confirm that a waterproof battery pack meets strict safety and performance standards. Many leading products, such as Bluefin, Kraken, and SWE, have achieved high levels of certification.

Kraken Robotics has achieved military standard certification for their SeaPower Batteries.

Certified battery solutions give you confidence in the reliability and safety of your waterproof battery pack. You can trust these products to perform in demanding environments, from security systems to infrastructure projects. Always verify that your lithium battery packs comply with the latest IP rating standards and industry certifications.

Part 2: Waterproof Design Principles

2.1 Enclosure and Sealing

You need a robust enclosure to protect your lithium battery pack from water and pressure in underwater robots. The right enclosure prevents water ingress and ensures long-term reliability. Many industries, such as robotics, medical, and security systems, rely on advanced battery pack design to meet strict waterproof requirements. You can see the most effective enclosure features in the table below:

Feature | Description |

|---|---|

Waterproof DC output connectors | Equipped with IP67/IP68 caps and latches to prevent water ingress. |

Cable glands | Use compression seals and strain relief to secure connections against water. |

Conformal-coated or potted PCBs | Protect circuit boards from moisture and corrosion. |

IP-rated ventilation membranes | Allow for pressure equalization while preventing water entry. |

Modular design | Facilitates maintenance and access to components. |

High-voltage separation | Enhances sealing safety by grouping paths separately. |

Water intrusion indicators | Provide visual or digital alerts for maintenance needs. |

Chemical resistance materials | Ensure durability against oils and salt. |

You should always select connectors that meet IP68 standards for your battery pack design. Waterproof connectors and cable glands form the first line of defense. You can use conformal coatings or potting on PCBs to add another layer of protection. Modular enclosure design helps you maintain and upgrade your lithium battery packs without compromising waterproof integrity.

Sealing methods play a critical role in battery pack design. You can choose from several options, each with unique benefits:

Sealing Method | Description |

|---|---|

Transparent Epoxies | Used for waterproofing; provides a strong barrier but may allow slow water vapor migration. |

Conformal Coatings | Acts as a second line of defense, protecting against minor condensation and battery leaks. |

Hot-melt Glue | A temporary solution that can be effective for prototypes but may absorb water over time. |

Silicone Sealants | Waterproof but not vapor-proof; can lead to condensation issues if not used with desiccants. |

Liquid Epoxy | Industrial options available; effective for long-term exposure but may yellow over time. |

💡 Always use desiccants with color indicator beads to monitor moisture inside the enclosure. Silica gel beads can reduce humidity, and you can test the right amount with an RH sensor.

You should test your enclosure with fully sealed systems before deployment. This ensures your lithium battery pack will withstand the harshest underwater conditions.

2.2 Material Selection

You must select materials that resist corrosion and pressure for your battery pack design. The right material keeps your enclosure strong and lightweight. Many underwater robots in the industrial and infrastructure sectors use these materials:

Material Type | Properties |

|---|---|

Rigid Polyurethane Composite | Protects equipment in fresh and saltwater environments. |

Stainless Steel Type 316 | Corrosion-resistant hardware for construction. |

Corrosion Resistant Salt Spray Test | Tested according to ASTM B117 standards for corrosion resistance. |

Material choice affects the weight and buoyancy of your battery pack design. Lighter materials increase energy density and improve buoyancy, which is vital for remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs). You can see the impact in the table below:

Evidence Point | Description |

|---|---|

Material Impact | Lighter materials reduce overall weight, enhancing energy density and buoyancy. |

Insulating Oils | Decrease structural weight and improve thermal management. |

Pressure Compensated Structures | Reduce reliance on heavy pressure vessels, increasing buoyancy and reducing weight. |

You should balance strength, corrosion resistance, and weight in your battery pack design. This approach ensures your lithium battery packs perform reliably in medical, robotics, and industrial applications.

2.3 Waterproof Power Supply Integration

You need to integrate your waterproof power supply with care to maintain the integrity of your battery pack design. The process involves several steps to ensure your lithium battery pack remains protected in underwater environments:

Select a suitable battery, such as a 12V 7Ah lithium battery pack, for your ROV or AUV.

Solder wires to the battery terminals for secure connections.

Drill a hole in the enclosure for waterproof connectors.

Connect the battery to the waterproof connectors and insulate all connections.

Seal the hole with epoxy and allow it to cure fully.

Apply a no-leak compound around the enclosure lid and secure it tightly.

Drill holes for wires in electronics boxes, such as relay modules or controllers.

Seal these holes with waterproof epoxy.

Test the enclosure by immersing it in water to verify waterproofing.

🔎 You should always verify the waterproof integrity of your battery pack design before deploying it in the field.

A robust battery management system (BMS) is essential for monitoring and protecting your lithium battery packs in fully sealed systems. Custom battery solutions allow you to tailor your battery pack design for specific ROVs and AUVs. You can achieve reliable performance and safety by focusing on enclosure, connectors, and integration best practices.

Part 3: Technologies for Fully Sealed Systems

3.1 Potting and Encapsulation

You need to protect lithium battery packs in underwater robots from water, pressure, and mechanical stress. Potting and encapsulation techniques create a fully sealed system that shields sensitive electronics from harsh environments. These methods involve surrounding the battery cells and circuitry with a protective compound, forming a barrier against moisture and contaminants.

You can compare the advantages and disadvantages of potting and encapsulation in the table below:

Technique | Advantages | Disadvantages |

|---|---|---|

Potting | Environmental protection from moisture and dust; vibration and shock resistance; helps dissipate heat during operation | Can be difficult to disassemble; may limit heat dissipation in some cases |

Encapsulation | Improved safety by containing hazardous materials; strong barrier against dust and moisture | May add weight to the battery system; potentially higher material cost |

Selecting the right potting compound is crucial for performance and reliability. The table below outlines common compounds used in lithium battery packs for underwater robots:

Potting Compound | Advantages | Disadvantages |

|---|---|---|

Epoxy | High rigidity, excellent moisture resistance, strong electrical insulation | Slow curing time, generates heat during curing |

Polyurethane | Flexible, customizable, protects delicate components | Can absorb moisture over time, limited temperature range |

Silicone | Flexible, good thermal conductivity, environmentally safe | Higher cost, may release gases that affect nearby parts |

You often see potting and encapsulation in robotics and industrial sectors where lithium battery packs must operate reliably under water. These techniques help you achieve a robust, waterproof design that withstands both pressure and vibration.

3.2 Pressure-Tolerant Gel Solutions

Pressure-tolerant gel solutions offer another way to protect lithium battery packs in subaquatic robots. You fill the battery enclosure with a special gel that equalizes external pressure and prevents water ingress. This method allows you to use lighter, non-metallic housings, which improves buoyancy and reduces overall system weight.

You benefit from gel encapsulation in several ways:

Maintains electrical insulation even at extreme depths

Reduces the risk of short circuits caused by water intrusion

Allows for flexible enclosure shapes and sizes

Many pressure-tolerant gel solutions have passed tests at depths up to 6,000 meters. This level of performance supports deep-sea exploration, infrastructure inspection, and security systems. You can rely on gel-filled lithium battery packs for long-term missions in harsh underwater environments.

💡 Tip: Pressure-tolerant gel solutions work well with advanced battery management systems (BMS) to monitor cell health and prevent failures during deep dives.

3.3 Waterproof Connectors

You need reliable connectors to maintain the integrity of fully sealed lithium battery packs. Waterproof connectors prevent water and debris from entering the enclosure, ensuring safe and stable power delivery. These connectors play a critical role in medical, robotics, and industrial applications where system failure is not an option.

Common types of waterproof connectors for underwater robots include:

Amphenol LTW Ceres Connectors: Rated IP66 to IP69K, resistant to temperature extremes and UV exposure

LEMO W Series Connectors: Exceed IP68, withstand up to 30 bars of pressure, offer multiple contact options

Smiths Interconnect M23 Series: IP68 rated for depths up to 5 meters, high reliability

Bulgin Buccaneer Connectors: IP68 and IP69K, designed for in-line cable joining, support USB connections

SOURIAU SWIM Connectors: High reliability for shallow water, ideal for ocean drones and small ROVs

Fischer Connectors: IP68/IP69, support high-speed data, extreme sealing for underwater use

SCHURTER Push-Pull Couplers: IP69K, user-friendly with audible engagement

Connector technologies use IP68-rated seals to block moisture and debris. This rating means your connectors can withstand submersion at 1.5 meters for 30 minutes. You protect your lithium battery packs from corrosion and electrical failure by choosing connectors with these features. Reliable connectors ensure your waterproof battery system performs in the most demanding underwater environments.

Part 4: Thermal and Pressure Management

4.1 Heat Dissipation in Sealed Packs

You must address heat dissipation when designing sealed lithium battery packs for underwater robots. Effective cooling strategies help maintain optimal power output and reliability during long-duration missions. The table below shows common cooling methods used in waterproof battery packs for autonomous robots in medical, security systems, and industrial sectors:

Cooling Strategy | Description | Effectiveness |

|---|---|---|

Air cooling integrated liquid spray | Combines air cooling with liquid spray | Effective for high heat generation |

Air cooling integrated PCM cooling | Uses phase change materials with air cooling | Improves temperature management |

Liquid cooling integrated PCM | Integrates liquid cooling and PCMs | Efficient heat dissipation |

Air-liquid-PCM combined cooling | Combines all three methods | Best for high rate discharge conditions |

Metal foam/PCM composites | Metal foam with phase change materials | Reduces battery surface temperature |

Hybrid cooling systems | Active and passive cooling methods | Improves maximum temperature and uniformity |

You improve environmental protection and durability by selecting the right cooling strategy. Proper thermal management extends battery lifespan, prevents thermal runaway, and enhances safety. This is vital for autonomous robots operating in harsh marine environments.

Note: Effective thermal management ensures reliability and environmental protection, especially for lithium battery packs in underwater robots.

4.2 Pressure Equalization

You must ensure pressure equalization in battery packs for deep-sea autonomous robots. Pressure-compensated housings and reinforced casings provide environmental protection and reliability at extreme depths. Common techniques include:

Pressure-compensated battery housings minimize implosion and leakage.

Reinforced casings and potting materials improve durability and insulation.

Pressure-compensated housings maintain stable pressure differentials, preventing deformation and leakage.

Pressure-rated vent membranes and marine-rated materials support water resistance claims and corrosion resistance. These features help your lithium battery packs deliver reliable power in infrastructure and industrial robots during long-duration missions.

4.3 Monitoring and Safety

You need advanced monitoring and safety features in your battery management system (BMS) to ensure reliability and environmental protection. The table below highlights key BMS features for autonomous underwater robots:

Feature Description | Details |

|---|---|

State of Charge (SoC) Accuracy | 2% or better |

Under Voltage Protection | Prevents over discharge |

Over Voltage Protection | Prevents dangerous charge levels |

Short Circuit Protection | Ensures safety during faults |

Over/Under Temperature Protection | Maintains safe operating conditions |

Charging Method | Standard USB C laptop power delivery charger |

Rugged Charging Cable | Attached/detached without tools |

Auto Cell Balancing | Balances cells internally |

Status Reporting | Sends status values to BlueROV navigator computer |

Internal Heating System | Optimizes performance in cold water |

Depth Rating | Deep rated (600m+) |

Safety protocols differ between shallow-water and deep-sea robots. Deep-sea applications require enhanced packaging, advanced shock-absorbing materials, and specific protocols for extreme conditions. You must use marine-grade cabling and waterproof connectors to support water resistance claims and reliability.

Tip: Integrate a robust BMS for real-time monitoring and safety. This ensures power delivery and environmental protection for autonomous robots in medical, security, and industrial sectors.

Part 5: Testing and Application Best Practices

5.1 Validation Protocols

You need to validate every lithium battery pack before deploying it in marine robotics. Start with pressure and waterproof testing to confirm the enclosure and connectors can withstand the intended depth. Use electrical safety checks to verify that all components operate correctly under load. Functional testing ensures the battery delivers stable power to all critical components, including sensors and propulsion systems. You should also perform cycle life tests to measure how the battery performs over repeated charge and discharge cycles. These steps help you avoid unexpected failures in autonomous marine robots and reduce downtime in industrial or security system applications.

Tip: Always document your validation protocols. This practice helps you track performance trends and supports compliance with industry standards.

5.2 Customization for ROVs and AUVs

You can tailor lithium battery packs for different types of marine robotics. Customization lets you match voltage, capacity, and mechanical design to the needs of your ROVs or AUVs. Companies like Large Power offer a range of options: custom battery systems for subsea operations, technical consultation, engineered for extreme conditions, advanced battery management systems, safety compliance.

You can request advanced battery management systems, unique connectors, or specialized components to fit your project. Customization also helps you scale solutions for both small and large autonomous marine robots.

5.3 Maintenance and Reliability

You improve long-term reliability and reduce operational costs by choosing battery packs with low maintenance requirements. Seawater batteries, for example, use an open cathode structure that enhances heat dissipation and safety. This design extends service life and lowers maintenance expenses. Using seawater as a sodium source also reduces raw material costs and simplifies operations. When you select lithium battery packs with robust components and reliable connectors, you ensure consistent performance in marine robotics. Regular inspection and timely replacement of worn connectors and components keep your autonomous marine robots running smoothly in demanding environments.

Note: Reliable maintenance protocols protect your investment and support continuous operation in medical, security, and industrial marine robotics.

You can achieve reliable subaquatic robots by following these steps:

Choose lithium battery packs with proven waterproof and pressure-resistant designs.

Verify compliance with IP68 and industry certifications.

Integrate advanced technologies like pressure-tolerant gel encapsulation.

Customize solutions for your application in medical, robotics, security systems, or infrastructure.

Prioritize safety and reliability. Invest in robust lithium battery packs to power your underwater innovations with confidence.

FAQ

What makes a lithium battery pack suitable for underwater robots?

You need a lithium battery pack with waterproof and pressure-resistant features. Look for IP68-rated enclosures, robust sealing, and advanced battery management systems. These features ensure reliable power for robotics and industrial underwater applications.

How do you test the waterproof integrity of a battery pack?

You should immerse the battery pack in water and monitor for leaks. Use pressure chambers to simulate deep-sea conditions. Always check connectors and seals before deployment in security systems or infrastructure robots.

Why is pressure-tolerant gel important in lithium battery packs?

Pressure-tolerant gel protects lithium battery packs from water intrusion and equalizes pressure. This technology supports deep-sea robots in industrial and medical sectors. You gain improved reliability and longer mission durations.

Can you customize lithium battery packs for different underwater robots?

Yes. You can request custom voltage, capacity, and enclosure designs. Large Power offer tailored battery solutions for ROVs, AUVs, and other robotics.

What maintenance steps help extend the life of lithium battery packs in marine robots?

You should inspect connectors, seals, and enclosures regularly. Replace worn parts and monitor battery health with a battery management system. Routine checks ensure safe operation in industrial, medical, and security applications.