Maximizing high power output while keeping your battery lightweight challenges even the best engineers. You need advanced materials, smart engineering, and innovative designs to achieve this balance. Many manufacturers now use AF motors, which can lower raw material usage and cut environmental impact by 47% compared to RF motors.

Battery cell balancing stands out as a key technique for electric vehicles and high-density energy storage.

Contribution

Description

Power Delivery Performance

Active balancing delivers strong power by keeping cell charges equal and avoids weak cell limitations.

Usable Capacity

It helps you get the most out of your battery system’s capacity and efficiency.

Lifespan Extension

Balanced cells work safely and last longer, reducing the need for extra capacity and frequent replacements.

Key Takeaways

Battery cell balancing is crucial for maximizing power output and extending battery lifespan. It ensures all cells charge equally, preventing overheating and improving safety.

Choosing lightweight materials like solid-state electrolytes and silicon-based anodes can enhance energy density. This leads to lighter batteries that improve vehicle performance and range.

Effective thermal management is essential for maintaining battery performance. Integrating cooling systems helps prevent overheating and extends battery life.

Innovative packaging techniques, such as nickel strip spot welding and plastic enclosures, can reduce battery weight while maintaining safety and efficiency.

Staying informed about emerging battery technologies, like silicon anode and solid-state batteries, can help you improve energy storage solutions and meet industry demands.

Part 1: The Challenge

1.1 High Power Output vs. Weight

When you design batteries for high power output, you often face a trade-off with weight. To deliver more power, you may need to increase the size or number of cells, which adds weight. This extra weight can limit the efficiency and performance of your system, especially in electric vehicles and portable devices. You want a battery that is both powerful and light, but achieving both at the same time is difficult.

Here is a table that shows the main technical challenges you face when trying to balance high power output with lightweight battery design:

Challenge | Description |

|---|---|

Energy Density | Smaller batteries store less energy, which limits runtime. High discharge rates can cause overheating and voltage drops. |

Structural Integrity | Compact designs may lose mechanical strength, risking damage from vibration or temperature changes. |

Safety | Tight spacing increases safety risks, such as thermal runaway or swelling in lithium batteries. |

You need to consider power density as well. Power density measures how much power a battery can deliver for its size or weight. If you focus only on increasing power, you might end up with a heavier battery that reduces the benefits of your design.

1.2 Impact on Electric Vehicles

In electric vehicles, battery weight plays a major role in performance and range. A heavier vehicle needs more energy to move, which can lower efficiency. Larger batteries can give you longer range, but they also add weight, which may reduce overall efficiency. Managing weight is crucial if you want to optimize performance without sacrificing range.

A heavier battery pack can hurt vehicle efficiency, handling, and overall performance.

Increasing battery weight often leads to diminishing returns in range, especially for vehicles that already have high range.

The relationship between battery weight and range is significant. Heavier batteries are sometimes needed for longer ranges, but this can complicate vehicle performance.

Elon Musk has pointed out that adding battery weight can negatively affect vehicle efficiency and handling. For electric vehicles, you must find the right balance between high power output and weight to achieve the best results.

Battery cell balancing becomes essential here. By keeping all cells at an equal state of charge, you prevent overcharging and over-discharging. This reduces the risk of overheating and thermal runaway, which is critical for safety and long-term performance in high-power applications.

Part 2: Key Factors

2.1 Battery Cell Balancing

You need effective battery cell balancing to achieve high power output and maintain high-density energy storage. Two main methods exist: active and passive balancing. Active balancing uses advanced control systems to redistribute energy between cells, which maximizes energy utilization and achieves faster equalization. Passive balancing relies on simpler circuits that dissipate excess energy as heat, making it less efficient but more affordable.

Attribute | Active Balancing | Passive Balancing |

|---|---|---|

Equalization Rate | Achieves faster equalization | Slower equalization |

Equalization Efficiency | Maximizes energy utilization | Less efficient, more energy wastage |

Control Complexity | Requires advanced control systems | Simpler control systems |

Cost | Higher initial investment | More affordable |

Application | Suited for high-capacity systems | Ideal for low-power systems |

Circuit Design | Demands sophisticated designs | Relies on basic components |

Active balancing is preferred for lithium battery packs in electric vehicles and high-density energy storage systems. You gain better performance optimization and longer battery lifespan. If you want to learn more about battery management systems (BMS), visit this page.

2.2 Power Density and Energy Density

Power density and energy density shape your custom battery design. High energy density lets you store more energy in a smaller, lighter package, which is crucial for electric vehicles and portable devices. High power output depends on power density, which measures how quickly a battery can deliver energy.

Companies now use silicon-based anodes, lithium metal anodes, and solid-state electrolytes to boost energy density.

Solid-state batteries store more energy in a smaller package, offering higher capacity than traditional lithium-ion batteries.

High energy density allows for more energy storage in a smaller and lighter package, which is crucial for applications like electric vehicles.

A more energy-dense battery requires less material to make, which can lead to reduced weight and size.

High energy density is crucial since it establishes a vehicle’s range, affecting how far it can go on a single charge.

Solid-state batteries can provide two to ten times the capacity of lithium-ion batteries and quicker charging capabilities.

CATL has achieved an energy density of 500 Wh/kg, a 40% improvement over existing lithium-ion batteries.

Samsung is developing solid-state batteries with a 600-mile range and a 9-minute charge time, targeting mass production by 2027.

2.3 Cell Design

Cell architecture and material selection play a major role in balancing high power output and weight. You must optimize electrode composition, current collector thickness, and cell geometry to achieve high energy density and power density. The table below compares key design features for high energy density and high power density:

Component | High Energy Density Features | High Power Density Features |

|---|---|---|

Electrodes | High mass of dried electrode coating, low porosity, medium/large particle sizes, low conductive additive content, minimum binder content | Low mass of dried electrode coating, high porosity, small/medium particle sizes, high conductive additive content |

Current Collectors | Thinner, coated to improve adhesion | Thicker, coated to reduce resistance |

You can further reduce weight by minimizing non-active components, optimizing current collector thickness, and using lightweight casings. Space-efficient cell geometries and bipolar designs help maintain power output while lowering weight. Effective thermal management, such as phase-change materials and microchannel cooling, keeps cells cool during high-discharge operations without adding much mass.

Tip: When selecting lithium battery chemistries for your application, compare platform voltage, energy density, and cycle life. This helps you choose the best option for high-density energy storage and performance optimization.

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO4 | 3.2 | 120-160 | 2000+ |

NMC | 3.7 | 150-220 | 1000-2000 |

LCO | 3.7 | 150-200 | 500-1000 |

LMO | 3.7 | 100-150 | 1000-2000 |

LTO | 2.4 | 70-80 | 7000+ |

Solid-state | 3.7-4.2 | 250-500 | 2000+ |

Lithium metal | 3.7-4.2 | 300-500 | 1000+ |

Part 3: Strategies

3.1 High-Density Energy Storage

You can achieve high-density energy storage by focusing on both material innovation and smart engineering. Recent breakthroughs in zinc-sulfur batteries show that optimizing cathode architecture and adding elements like selenium or tellurium can boost energy density. Electrolyte engineering also plays a key role. By improving reaction kinetics and cycling stability, you address challenges such as low electrical conductivity and the polysulfide shuttle effect. These strategies help you maximize energy density while keeping battery weight low.

When you design lithium-ion batteries for electric vehicles, you need to balance energy density and power output. High energy density allows you to store more energy in a smaller space, which is critical for extending driving range without adding extra weight. You can use advanced cell balancing techniques to ensure each cell operates at peak efficiency, which improves overall battery performance and lifespan.

Tip: Focus on custom battery design that combines high energy density with robust cell balancing. This approach helps you meet the demands of high-density energy storage in electric vehicles and industrial applications.

3.2 Lightweight Materials

Selecting lightweight materials is essential for balancing power output and reducing battery pack weight. You can use solid-state electrolytes, silicon-based anodes, lithium metal, and high-nickel cathodes to improve both energy density and efficiency. These materials offer several advantages:

Solid-state electrolytes increase safety and energy density, which leads to longer driving ranges and faster charging.

Silicon-based anodes boost battery capacity and efficiency, supporting greater energy storage.

Lithium metal raises energy density, enhancing battery performance.

High-nickel cathodes deliver higher power output and help reduce overall weight.

Lightweight materials also improve structural integrity and crash safety. Engineered polymers and composites provide superior specific strength, meeting mechanical performance requirements. You benefit from extended driving range due to reduced weight, and improved crash safety through materials that absorb energy during impacts. Advanced cooling solutions integrated into lightweight enclosures optimize thermal management, reducing the risk of thermal runaway.

Lightweight enclosures address weight-related issues and enhance vehicle performance.

These enclosures absorb energy during crashes, protecting battery cells.

Integrated cooling solutions ensure effective heat dissipation.

If you want to learn more about sustainable material choices, visit our approach to sustainability.

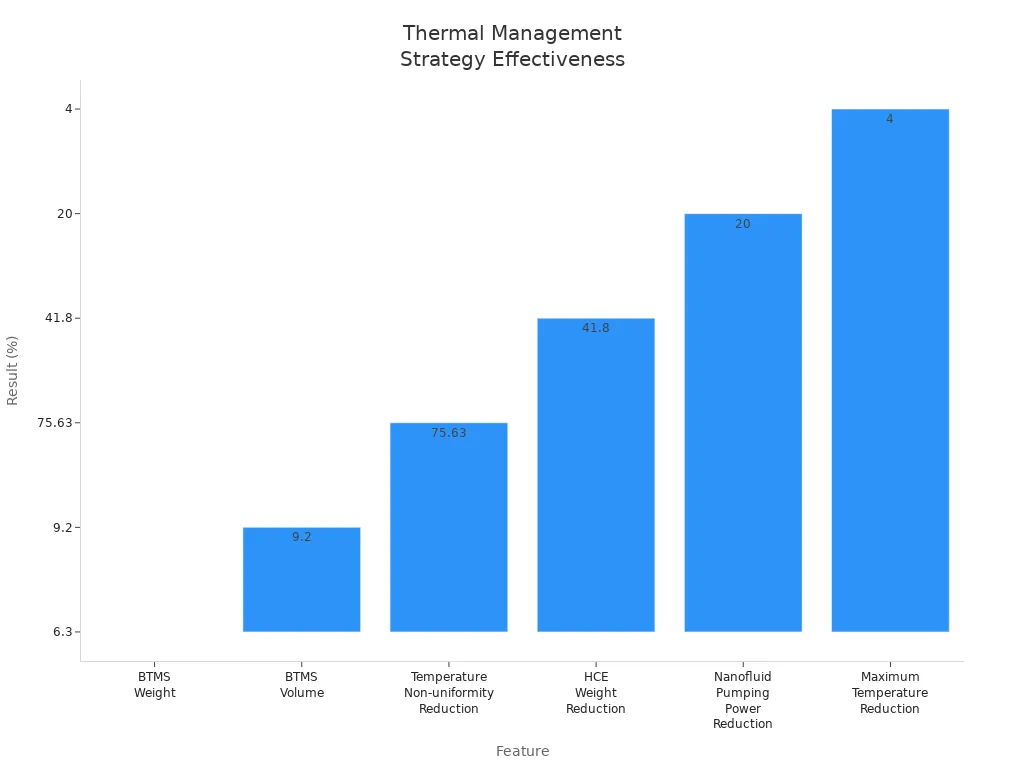

3.3 Thermal Management

Effective thermal management is crucial for maintaining high power output in lightweight battery designs. You can integrate liquid cooling systems with nano-enhanced phase change materials (NEPCMs) to enhance heat dissipation and maintain optimal operating temperatures. This hybrid system reduces internal resistance, improves charge/discharge efficiency, and prolongs battery life. It also mitigates safety risks associated with thermal runaway.

You can use the following strategies to optimize thermal management:

Liquid cooling systems provide high heat transfer coefficients for efficient heat removal.

NEPCMs absorb excess heat, preventing temperature spikes.

The combination ensures uniform temperature distribution, enhancing battery performance and longevity.

The system reduces thermal degradation and the risk of thermal runaway.

Thermal management directly influences safety and lifespan. Fast response time to thermal changes is crucial for safety. You need a wide operational temperature range, from -40°C to +85°C, to maintain performance. Integrated heating for sub-zero environments helps prevent battery failure in cold conditions. Aging can lead to thickening of the interfacial film and generation of reductive gas, which increases cell impedance and decreases thermal stability. Proper thermal management addresses these issues and enhances battery safety.

Feature | Result |

|---|---|

BTMS Weight | 6.3% of battery module |

BTMS Volume | 9.2% of battery module |

Temperature Non-uniformity Reduction | 75.63% |

HCE Weight Reduction | 41.8% |

Nanofluid Pumping Power Reduction | 20% |

Maximum Temperature Reduction | 4% |

Packaging Techniques for Balancing Power and Weight

You can use advanced packaging techniques to balance high power output with minimal battery weight in commercial battery packs. The table below summarizes key methods:

Technique | Description | Benefits |

|---|---|---|

Nickel Strip Spot Welding | Provides conductive pathways between cells, affecting efficiency and safety. | Balances cost, precision, and production volume; critical for maintaining pack integrity. |

Busbar Design | Rigid conductors for high-power applications, balancing current and thermal management. | Excellent conductivity and thermal stability; allows for weight optimization with material choice. |

Plastic Enclosures | Lightweight and provide electrical isolation, reducing overall system weight. | 40-60% weight reduction compared to metal; excellent chemical resistance and manufacturing efficiency. |

Metal Enclosures | Offer structural integrity and thermal conductivity, essential for durability. | 30-50% weight reduction compared to steel; maintain performance in extreme temperatures. |

By combining these strategies—high-density energy storage, lightweight materials, effective thermal management, and advanced packaging—you can achieve optimal balancing of power output and battery weight. These approaches are especially important for lithium-ion batteries in electric vehicles, where every gram counts for performance and safety.

Part 4: Technologies and Applications

4.1 Emerging Battery Technologies

You see rapid progress in battery technology as manufacturers push for high energy density and lightweight design. Silicon anode batteries now lead the way. These batteries store more energy than traditional graphite anode types, making them ideal for electric vehicles and portable devices. You benefit from longer driving ranges and lighter products. Solid-state batteries and nanomaterials also play a key role in high-density energy storage. They enable thinner, more efficient batteries with improved safety and faster ion transport.

Benefit | Description |

|---|---|

Higher Energy Density | Enables lithium-metal anodes, boosting capacity. |

Compact and Lightweight | Allows for thinner and more efficient battery designs. |

Improved Electronic Conductivity | Creates a conductive network within the cathode and anode for faster electron transfer. |

Enhanced Interface Contact | Acts as a buffer layer, reducing interfacial resistance and improving ion transport. |

Mechanical Reinforcement | Provides structural stability, preventing cracks during charging/discharging. |

Faster Ion Transport | Improves ionic conductivity in composite electrolytes due to large surface area and porous structure. |

Recent advancements include the use of higher nickel cathode materials and the addition of silicon to anode materials. These trends increase energy storage capacity and extend runtime, which is essential for high-density energy storage in demanding applications.

4.2 Electric Vehicles Case Studies

You can see how real-world companies address the challenge of balancing power and weight in battery design. Svolt Energy uses novel stacking technology to achieve higher energy density and better thermal management. Their cobalt-free cathode material supports sustainability goals. GM’s Ultium battery platform features a unique pouch cell design, a wireless battery management system, and silicon-rich anodes. These features help reduce weight and improve efficiency in electric vehicles.

Manufacturer | Strategy | Key Features |

|---|---|---|

Svolt Energy | Novel stacking technology | Higher energy density, improved thermal management, cobalt-free cathode material |

GM | Ultium battery platform | Unique pouch cell design, wireless battery management system, silicon-rich anodes, lightweight materials |

You also find these technologies in medical devices, robotics, and security systems. For example, brushless DC motors and closed loop servo systems deliver high power output with minimal weight, supporting advanced robotics and portable medical equipment. In infrastructure and industrial sectors, lithium-ion batteries provide reliable backup power and efficient energy storage.

4.3 Design Trade-Offs

When you design high-power, lightweight battery systems, you must weigh safety, cost, and performance. Cylindrical cells offer strong mechanical protection and lower risk of thermal runaway. Prismatic cells save space but may swell under stress. Pouch cells are light and flexible but can suffer from physical damage.

Battery Type | Power Output | Weight | Safety Features |

|---|---|---|---|

Lithium-ion (Li-ion) | High energy density | Lightweight | Good safety, but risks of overheating and fires if mishandled. |

Lithium Iron Phosphate (LFP) | Lower energy density | Heavier than Li-ion | Excellent thermal stability, incombustible, safer under high temperatures. |

Solid-state batteries | Potentially higher | Lighter and more compact | Highly resistant to fire and explosion, safer than liquid electrolyte batteries. |

Silicon anode batteries | Higher energy density | Lighter | Improved safety features, but still under development for mass production. |

You should also consider the lifecycle of your battery. Lightweight materials like composites and advanced plastics reduce weight and improve fuel efficiency. Smart packaging with sensors and microcontrollers lets you monitor battery performance in real time, which helps extend battery life. Life-cycle assessment ensures you select materials and processes that minimize environmental impact from production to recycling. If you want to learn more about sustainability and conflict minerals, visit our sustainability approach.

Note: Balancing these factors is key to delivering safe, cost-effective, and high-performance lithium-ion batteries for electric vehicles and industrial applications.

You can achieve a balance between high power output and lightweight battery design by using advanced materials, optimizing cell architecture, and applying smart engineering.

High power lithium-ion cells use smaller active material particles and higher porosity cathodes. You minimize resistance and shorten lithium ion diffusion paths to boost performance.

Description | Impact on Performance and Safety |

|---|---|

Active balancing reduces cell aging and prevents overcharging. | You extend battery lifespan and improve safety in electric vehicles and energy storage systems. |

Charge transfer between cells ensures uniform energy distribution. | You increase efficiency and capacity utilization. |

High-density energy storage supports compact, lightweight battery packs.

Custom designs and material selection improve energy density and safety.

Innovative structures optimize power, cycle life, and reliability.

Stay updated on new battery technologies. This knowledge helps you improve vehicle range, safety, and cost-effectiveness in the electric vehicle industry.

FAQ

What is battery cell balancing, and why does it matter for lithium battery packs?

Battery cell balancing keeps each cell at the same charge level. You prevent weak cells from limiting performance. This process extends battery life and improves safety. For more details, see our BMS and PCM guide.

How do lightweight materials impact battery pack performance?

Lightweight materials reduce total battery weight. You gain higher energy density and better efficiency. These materials also improve crash safety and make installation easier. You can learn more about our approach to sustainability.

Which lithium battery chemistry should you choose for high power and low weight?

You should compare chemistries like LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal. Each offers different platform voltage, energy density, and cycle life. Use the data in our tables to select the best fit for your application.

How does thermal management affect lithium battery pack safety?

Thermal management keeps battery temperature stable. You avoid overheating and reduce the risk of thermal runaway. Good systems use liquid cooling or phase change materials. This helps you maintain performance and extend battery lifespan.