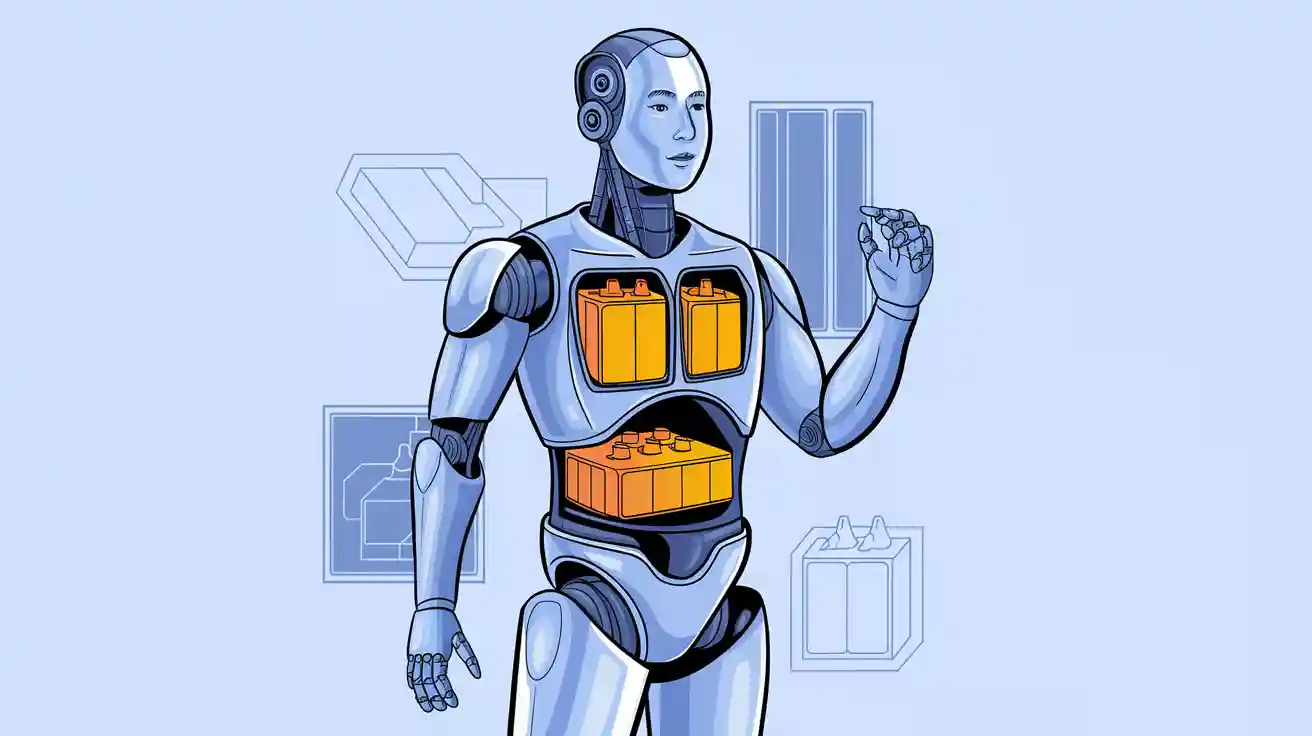

Custom-shaped battery packs let you maximize every millimeter inside humanoid robots, improving both structure and optimized energy storage. Custom lithium battery packs deliver tailored battery performance, advanced safety, and longer runtime. These solutions support robotics in industrial settings, including warehouse robots and autonomous mobile robots, where efficiency and reliability drive operational success.

Benefit | ||

|---|---|---|

Runtime | Longer runtime, fewer charges | Limited runtime |

Efficiency | Reduced downtime | Increased downtime |

Safety | Advanced safety features | Higher risk |

Key Takeaways

Custom-shaped battery packs maximize space in humanoid robots, allowing for better integration of components and increased payload capacity.

These battery packs provide longer runtimes and enhanced safety features, reducing downtime and operational risks in industrial settings.

Advanced battery management systems in custom packs ensure real-time monitoring and protection against overheating, improving reliability and performance.

Part 1: Standard Battery Pack Limits

1.1 Space Wastage in Humanoid Robots

When you use standard battery packs in humanoid robots, you face significant space wastage. These packs come in fixed shapes and sizes, which rarely match the complex internal contours of robots. As a result, you often see empty gaps around the battery, reducing the available space for other critical components. In warehouse robots, this inefficiency means you cannot maximize payload or add advanced sensors. For autonomous mobile robots, every millimeter counts, and wasted space directly impacts operational flexibility.

Note: Space constraints force you to compromise between battery size and robot functionality. This challenge becomes even more pronounced in robotics applications where compactness and efficiency drive value.

Here’s a quick look at the most common limitations of standard battery packs in robots:

Limitation | Description |

|---|---|

Short Runtime | Most robots operate for no more than 1–3 hours before they need lengthy recharges, limiting their effectiveness. |

Thermal Risks | High-frequency discharging generates heat, leading to potential performance degradation and safety hazards. |

Space Constraints | Compact designs limit battery size, forcing trade-offs between capacity and weight. |

1.2 Design and Performance Constraints

Standard battery pack shapes impose strict design and performance constraints on humanoid robots. You must often redesign the robot’s internal structure to fit the battery, not the other way around. This approach restricts your ability to optimize for weight distribution, balance, and agility—key factors for warehouse robots and autonomous mobile robots.

The following table highlights the main design and performance constraints you encounter:

Constraint Type | Description |

|---|---|

Energy Density | Current battery technologies like LFP and high-nickel ternary batteries (150-300 Wh/L) restrict the capacity available for humanoid robots, which need to balance size and weight with power needs. |

Discharge Rate | Humanoid robots require batteries that can sustain high discharge rates (2-3C) for dynamic tasks, but current lithium solutions face challenges in maintaining performance over time. |

Safety | Ternary lithium batteries pose risks of overheating and combustion, raising safety concerns for indoor use, necessitating safer alternatives like solid-state batteries. |

Endurance | Typical battery life for humanoid robots is only 2-4 hours, which is insufficient for practical applications, highlighting the need for advancements in battery technology to improve runtime. |

You see these constraints most clearly in warehouse robots, where limited runtime and safety risks can disrupt logistics operations. In robotics, these issues slow down innovation and limit the deployment of advanced autonomous mobile robots across industrial environments.

Part 2: Custom-Shaped Battery Packs for Humanoid Robots

2.1 Form Factor Adaptability

Custom-shaped battery packs give you the flexibility to design robots that fit your operational needs, not the other way around. You can mold these packs to match the unique internal contours of humanoid robots, maximizing every available millimeter. This approach eliminates wasted space and allows you to integrate batteries directly into the robot’s torso, limbs, or other structural elements. For warehouse robots, this means you can increase payload capacity or add advanced sensors without sacrificing runtime. In autonomous mobile robots, custom-shaped battery packs support compact designs that enhance agility and maneuverability.

By integrating batteries as structural components, you reduce mass and volume, which is crucial for agile movement and stability in humanoid robots.

A real-world example is the F.03 battery system, which Figure designed specifically for its humanoid robot. This custom-shaped battery pack fits seamlessly into the robot’s torso, resulting in a 94% increase in energy density compared to bulky, rectangular modules. You achieve both structural optimization and improved battery performance, which is essential for demanding industrial environments.

2.2 Enhanced Energy Density

You need high energy density to ensure your robots operate longer between charges. Custom-shaped battery packs use advanced lithium-ion and solid-state chemistries to deliver more energy in less space. This is especially important for warehouse robots and autonomous mobile robots, where every cubic centimeter counts.

Battery Type | Energy Density | Advantages |

|---|---|---|

Lithium-ion | High | Higher energy density than Ni-MH or lead-acid; suitable for miniaturization |

Solid-State Batteries | Potentially Higher | Emerging technology with improved safety and energy density |

To achieve these gains, manufacturers use specialized materials and components:

Component Type | Materials Used |

|---|---|

Current collectors | High-purity copper (anode), aluminium (cathode) |

Electrodes and additives | Graphite, advanced carbons, suitable metal oxides |

Seals and gasketing | PTFE, EPDM for chemical resistance |

Interconnects and insulation | Copper/nickel foils, polyimide films for isolation |

You benefit from tailored voltage, capacity, and discharge characteristics that match your robot’s specific requirements. This ensures optimized energy storage and reliable operation, even in high-demand scenarios.

Characteristic | Description |

|---|---|

Voltage | Tailored to provide the necessary power while ensuring safe operation for the robot. |

Capacity | Indicates how long the robot can operate before needing a recharge, measured in ampere hours. |

Discharge Rate | The speed at which the battery depletes its charge, crucial for matching the robot’s consumption patterns. |

2.3 Battery Management and Safety

You cannot compromise on safety when deploying robots in industrial or public environments. Custom-shaped battery packs integrate advanced battery management systems (BMS) that monitor and control every aspect of battery performance. These systems provide real-time monitoring, fault detection, and preventative measures to mitigate risks such as overcharging, overheating, and short circuits. The BMS manages charge and discharge processes, monitors temperature and voltage, and implements overcharge protection and thermal cutoffs.

Advanced BMS features ensure the safety of both robots and humans by preventing hazardous events and maintaining optimal battery health.

Learn more about BMS in robotics.

Key safety improvements include:

Overcharge protection, which stops charging once the battery is full to prevent overheating.

Thermal cutoffs, which disconnect power if temperatures exceed safe limits.

Short circuit protection, which breaks the circuit to reduce fire hazards.

These features are essential for warehouse robots and autonomous mobile robots, which often operate near people and sensitive equipment.

2.4 Thermal Management Features

Robots generate significant heat during operation, especially in high-performance environments like warehouses. Custom-shaped battery packs incorporate advanced thermal management features to maintain optimal battery temperature and prevent overheating.

Feature | Description |

|---|---|

Fast Charge | 2 kW fast charge with active cooling. |

Active Cooling System | Integrated cooling components minimize thermal resistances and local heat generation, enabling fast charging through forced convection cooling. |

Anti-Propagation & Flame Containment | Safety measures prevent thermal runaway from spreading to adjacent cells and contain flames, using a thermally insulative potting compound and a flame arrestor pack vent. |

Integrated thermal management systems are essential for humanoid robots. They manage the heat generated by advanced processors and other components, ensuring efficient heat transfer and dissipation. Without these systems, overheating can lead to reduced performance or even system failure. By maintaining safe operating temperatures, you extend the lifespan of both the battery and the robot.

2.5 Custom Lithium Battery Packs: Performance Benefits

Custom lithium battery packs deliver measurable performance improvements for robots in real-world applications. You see these benefits most clearly in warehouse robots and autonomous mobile robots, where operational uptime and efficiency are critical.

Custom battery packs match specific voltage, capacity, and discharge requirements, enhancing robot performance.

Optimized energy storage leads to longer operational uptime and reduced downtime due to charging.

Features like thermal cutoffs and overcharge protection ensure safety and efficiency.

Custom lithium solutions drive peak performance in high-demand environments, supporting extended runtime and high-torque movements.

Battery performance directly affects runtime, payload, mobility, and processing power in robotics.

The F.03 battery system for the Figure 01 humanoid robot demonstrates these advantages. It provides a capacity of 2.3 kWh, enabling five hours of peak performance runtime. The battery supports 2 kW fast charging with an integrated active cooling system, enhancing operational efficiency. Structural integration saves mass and volume, which is crucial for agile robot design. Multiple layers of safety architecture prevent thermal runaway and ensure reliable operation.

Custom-shaped battery packs are designed to ensure optimal performance tailored to the specific needs of humanoid robots, enhancing their reliability in various environments. Features such as thermal management help dissipate waste heat, maintaining safe operating temperatures and preventing overheating. Real-time monitoring capabilities allow for immediate detection of issues, further contributing to the reliability of the robots.

If you want to explore custom-shaped battery packs for your robotics projects, click here for a custom consultation.

Custom-shaped lithium battery packs let you optimize every inch of your humanoid robot’s structure. You gain longer runtime, improved safety, and higher efficiency. Recent research shows robots need batteries with high energy density and fast charging. The robotics industry expects a 6.2% CAGR for custom battery solutions through 2032, driven by rapid innovation.

FAQ

What advantages do custom-shaped battery packs offer for humanoid robots in industrial environments?

You achieve optimized energy storage and improved battery performance. Custom lithium battery packs maximize space, boost runtime, and enhance safety for warehouse robots and autonomous mobile robots.

How does Large Power ensure battery safety and reliability for robotics applications?

Large Power integrates advanced BMS, thermal management, and anti-propagation features. You receive reliable custom lithium battery packs for medical, security, and industrial robots.

Can you request a custom consultation for custom-shaped battery packs?

You can request a consultation for custom-shaped battery packs by clicking here. Large Power tailors solutions for robotics, infrastructure, and security systems.