Sterile environment compatibility drives your design choices for lithium battery packs in surgical robots. You must prioritize sterile environment compatibility to meet strict hospital protocols. Sterile environment compatibility ensures batteries withstand frequent sterilization cycles. Sterile environment compatibility also supports uninterrupted power during procedures. How do you achieve sterile environment compatibility while maintaining reliable battery performance?

Key Takeaways

Prioritize sterile environment compatibility in battery design to ensure safety and reliability during surgical procedures.

Select materials and enclosures that withstand sterilization processes while maintaining battery performance and biocompatibility.

Utilize custom battery solutions to meet the unique power and size requirements of surgical robots, enhancing their efficiency and safety.

Part 1: Sterile Environment Compatibility in Surgical Robots

1.1 Batteries and Sterility Challenges

You face unique challenges when designing batteries for surgical robots. The operating room demands strict sterile conditions. Every component, including batteries, must withstand repeated cleaning and disinfection. Traditional sterilization methods, such as steam autoclaves, damage sensitive electronics. You cannot use these methods for lithium battery packs. Instead, you must consider alternatives like gamma rays, ethylene oxide gas, or vaporized hydrogen peroxide. Each method brings trade-offs. Gamma rays can degrade rechargeable cells. Ethylene oxide is toxic and poses safety risks. Vaporized hydrogen peroxide offers a safer option, but you must design ruggedized battery packs that survive the process without failing.

You need to select materials and housings that resist harsh chemicals and high temperatures. Custom battery solutions allow you to tailor enclosures and seals for maximum protection. You must ensure that batteries maintain a stable power supply during and after sterilization. If a battery fails, the surgical robot could lose power mid-procedure, risking patient safety. Custom battery solutions help you address these challenges by providing robust designs that meet the demands of the surgical environment.

Tip: Always test your custom battery solutions under real sterilization cycles. This step ensures that batteries deliver reliable performance and safety in every surgical procedure.

1.2 Regulatory and Safety Standards

You must comply with strict safety regulations when designing batteries for surgical robots. International standards set clear requirements for medical devices used in sterile environments. The table below summarizes key safety regulations:

Key Point | Description |

|---|---|

Intrinsically Safe Requirement | Medical devices containing batteries must be ‘Intrinsically Safe’ as per ISO 11135:2007 and NFPA 70 standards to mitigate explosion risks during EtO sterilization. |

Risk of Explosion | Battery-powered devices can be ignition sources in the presence of flammable gases like EtO, necessitating stringent safety measures. |

You must design batteries that meet these standards. Intrinsically safe batteries prevent ignition in the presence of flammable gases. You must also consider the risk of explosion during sterilization. Custom battery solutions help you address these safety concerns. You can select battery chemistries and protective circuits that minimize hazards. You must document every safety feature and test batteries under simulated operating room conditions.

You cannot overlook regulatory compliance. Hospitals and surgical centers require proof that your batteries meet all safety standards. Custom battery solutions give you the flexibility to adapt to changing regulations and new sterilization technologies. You ensure that surgical robots operate safely and reliably in every procedure.

Part 2: Design and Power Solutions for Batteries

2.1 Stable Power Supply Requirements

You must deliver a stable power supply to surgical robots in every procedure. Medical robotics demands continuous, high-wattage power, often ranging from hundreds of watts to several kilowatts. You cannot risk interruptions. Reliable power systems ensure that robots perform complex surgical tasks without delay or error. Certified rack mount UPS units with a 2kVA capacity and 120VAC output meet the minimum requirements for safe operation. These systems provide at least four minutes of runtime, allowing for safe shutdown or transition to backup sources. Compliance with IEC 60601-1 safety standards remains essential for all medical devices in the operating room.

You must also consider the impact of battery failures. If batteries fail, surgical procedures may halt, putting patient safety at risk. Medical professionals face ethical dilemmas when deciding whether to continue or postpone surgeries due to unreliable power. In some cases, surgeries have been aborted to protect patients, highlighting the critical role of reliable batteries in medical robotics.

Note: Reliable power delivery in medical robotics prevents unexpected shutdowns, reduces risk, and supports untethered operations for advanced surgical robots.

You need precise, low-noise power delivery for robotic surgery. Ultra-stable voltage regulation ensures that high-performance components operate without interference. Battery management systems (BMS) provide health monitoring, safety features, and real-time data communication, further enhancing reliability. You can learn more about BMS in our battery management systems guide.

2.2 Material and Enclosure Selection

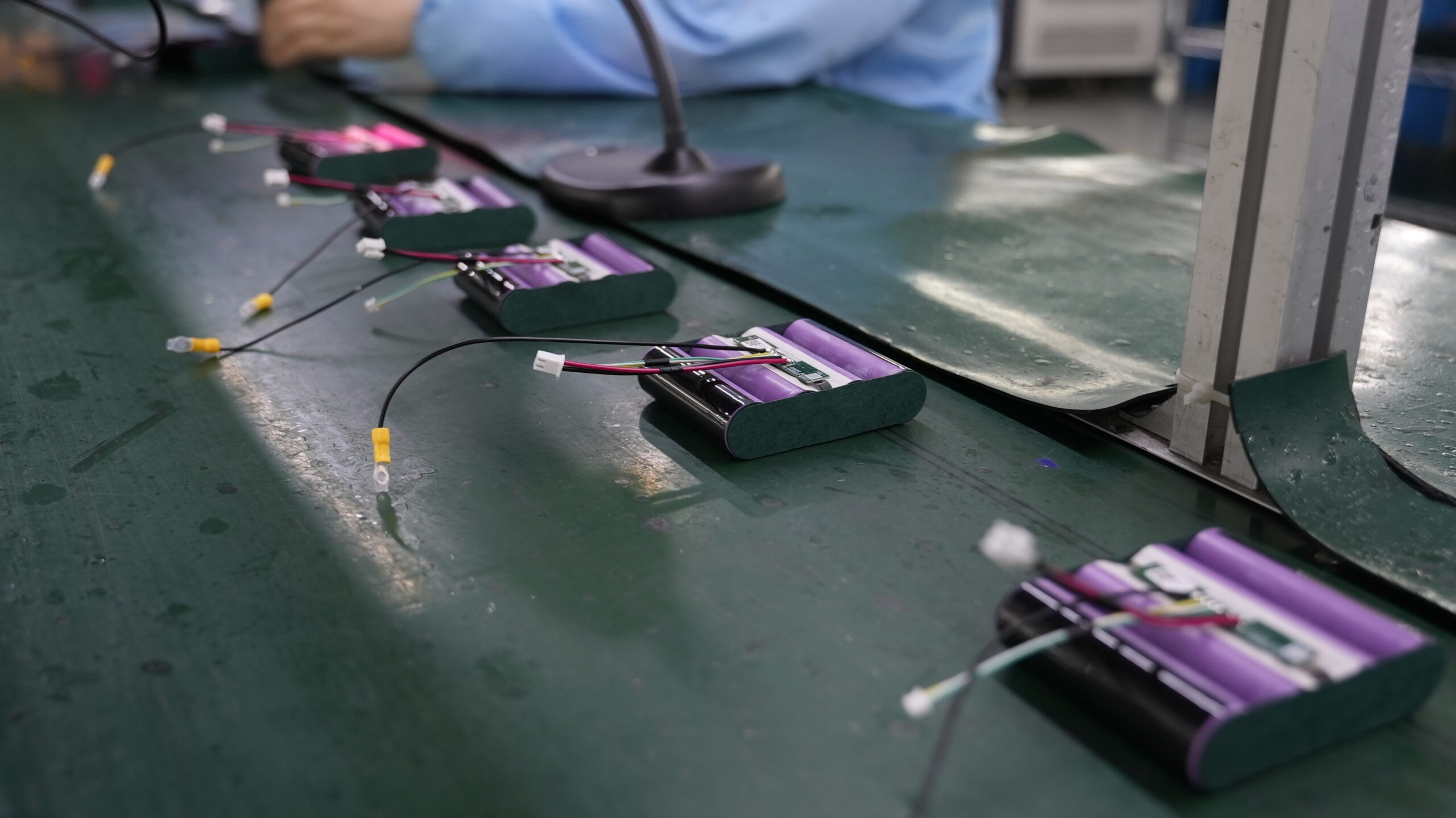

You must select enclosure materials that withstand repeated sterilization cycles. The choice of materials directly affects both the durability and biocompatibility of batteries in surgical robots. Hermetic sealing protects sensitive electronics from harsh chemicals, high temperatures, and pressure during autoclaving. For example, slotted BLDC motors and sterilizable components maintain integrity through over 1,000 sterilization cycles, supporting the demanding needs of medical robotics.

Different enclosure materials, such as medical-grade stainless steel, PEEK, and advanced polymers, offer varying levels of resistance to sterilization processes. These materials ensure that batteries remain safe, functional, and biocompatible after exposure to steam, gamma rays, or vaporized hydrogen peroxide. You must also consider the impact of enclosure design on heat dissipation and mechanical protection. Custom battery solutions allow you to tailor enclosures for optimal performance and sterility.

Tip: Always verify that your enclosure materials meet both biocompatibility and sterilization standards for medical devices.

Lithium Battery Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) | Application Scenarios |

|---|---|---|---|---|

LCO | 3.7 | 150-200 | 500-1,000 | Consumer electronics, medical, robotics |

NMC | 3.7 | 150-220 | 1,000-2,000 | Medical, robotics, security, infrastructure, industrial |

LiFePO4 | 3.2 | 90-160 | 2,000-5,000 | Medical, robotics, security, infrastructure, industrial |

LMO | 3.7 | 100-150 | 300-700 | Medical, robotics, consumer electronics |

LTO | 2.4 | 70-80 | 5,000-10,000 | Medical, robotics, infrastructure, industrial |

solid-state | 3.7-4.2 | 250-400 | 2,000-10,000 | Medical, robotics, security, infrastructure, industrial, consumer electronics |

lithium metal | 3.7-4.2 | 350-500 | 500-1,000 | Medical, robotics, high-performance components, surgical technology |

2.3 Custom Battery Solutions and Innovations

You need custom battery solutions to address the unique requirements of surgical robots. Off-the-shelf batteries rarely meet the specific power, size, and biocompatibility needs of medical robotics. Custom lithium battery packs enhance performance, safety, and efficiency. These solutions enable you to optimize robotic surgery by supporting untethered operations and integrating advanced battery technologies.

Custom batteries allow you to meet demanding speed and torque requirements while keeping robots cool during operation. Fully sterilizable drive systems now withstand over 1,000 sterilization cycles, ensuring that robots remain reliable in the harshest environments. Advanced lithium battery packs contribute to the miniaturization of medical devices, making robots more ergonomic and easier to handle. This design reduces operator fatigue and improves overall performance.

You can now sterilize surgical robots without removing the battery, streamlining workflow and maintaining sterility. Fast-charging custom batteries allow robots to return to service quickly, supporting efficient operating room workflows. For example, a full battery can provide one hour of driving, two hours of manipulating, or four hours of waiting, with charging completed in just 30 minutes.

Battery management systems play a vital role in custom solutions. They monitor battery health, balance cells, and provide real-time data to the robot’s control system. These systems detect faults and alert maintenance teams before failures occur, ensuring reliable power delivery. Custom battery designs also integrate with overall safety systems, offering redundant safety, updateable firmware, and compliance with IEC 60601-1 standards.

Callout: Custom battery solutions drive innovation in medical robotics, enabling you to deliver reliable, high-performance robots for every surgical application.

For more information on custom battery solutions, visit our custom battery solutions page. Explore the latest in lithium-ion, LiFePO4, lithium-polymer, and solid-state battery technologies for medical, robotics, security, infrastructure, consumer electronics, and industrial applications.

You achieve sterile environment compatibility by following best practices:

Use proper loading techniques for sterilization cycles.

Space batteries and instruments evenly to allow sterilizing agents to flow.

Conduct biological monitoring for every load to maintain process integrity.

Stable power, regulatory compliance, and custom lithium battery solutions remain essential. Watch for new sterilization-resistant materials and smart battery monitoring in future designs.

FAQ

What makes Large Power’s custom lithium battery packs suitable for operating room robots?

You get battery packs designed for sterilization, stable power, and compliance. Large Power customizes solutions for medical, robotics, and industrial sectors.

How do you select the right lithium battery chemistry for your medical robotics application?

You compare platform voltage, energy density, and cycle life. For example, LiFePO4 offers 3.2V, 90-160 Wh/kg, and 2,000-5,000 cycles. Application scenarios include medical, robotics, and infrastructure.

Tip: Consult Large Power for tailored battery solutions based on your sterilization process and runtime needs.

Can you request a custom consultation for your lithium battery project?

You can contact Large Power for a custom consultation. Their engineers assess your requirements and propose solutions for medical, robotics, security, and industrial applications.