Efficient battery design shapes how you approach rehabilitation robot development in the medical industry. You demand high battery performance, safety, and reliability for advanced robotics. Custom lithium battery packs and battery management systems drive operational excellence. You see wearable lower limb rehabilitation robot applications require unique design and safety by design. Intelligent battery management and high-efficiency energy technologies support custom robot design, improve energy use, and extend battery life. These strategies enhance safety, energy efficiency, and training outcomes in human-robot interaction for rehabilitation robots.

Key Takeaways

Choose the right battery chemistry, like lithium-ion or solid-state, to enhance performance and safety in rehabilitation robots.

Implement advanced battery management systems (BMS) to monitor battery health, prevent overheating, and ensure safe operation during training.

Design custom lithium battery packs tailored to the specific needs of wearable lower limb rehabilitation robots for optimal energy efficiency and portability.

Part 1: Battery Design Essentials

1.1 Battery Chemistry

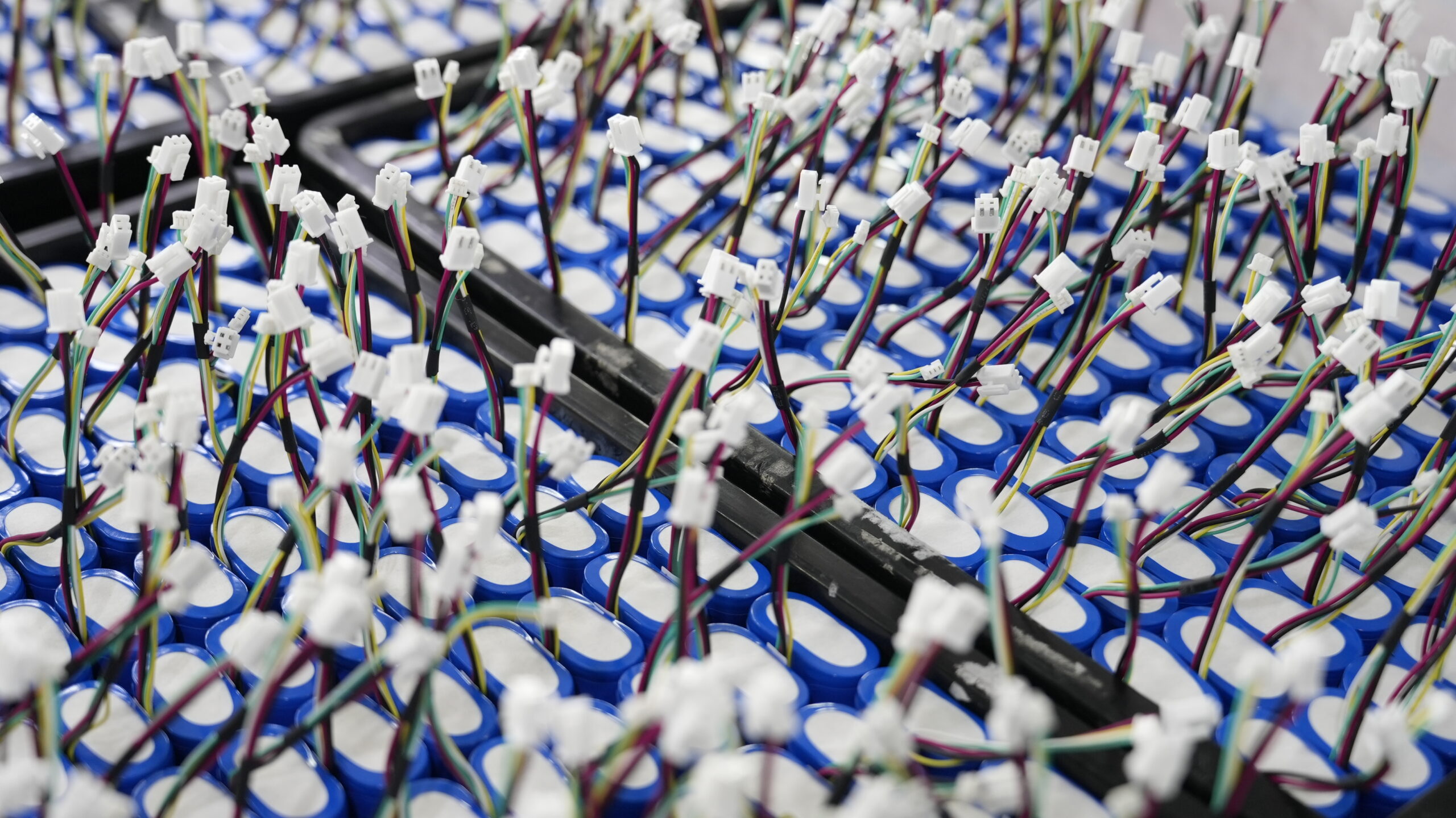

You must select the right battery chemistry to maximize rehabilitation robot performance and safety. The chemistry you choose directly impacts energy density, lifespan, and reliability. In rehabilitation training, lithium-ion batteries (internal link) remain the most common choice for medical and robotics applications due to their high energy density and rechargeability. Solid-State Battery (internal link) technology is emerging, promising even higher energy density and improved safety for future rehabilitation robots.

The following table compares the most widely used lithium battery chemistries in rehabilitation robots and highlights their energy density characteristics:

Battery Chemistry | Energy Density Characteristics |

|---|---|

LiPo (internal link) | Preferred for high current pulses in legged robots |

LFP (internal link) | Suitable for various applications, but less common in legged robots |

LTO (internal link) | Limited commercial availability, similar performance to LFP and LiPo |

NMC (internal link) | Used for longer missions where energy demand is critical |

You must consider trade-offs between energy density and safety. Lithium-ion batteries offer high energy density, but you must manage safety risks. Solid-state batteries may double energy density while enhancing safety, making them ideal for future rehabilitation training robots.

The choice of battery chemistry affects the lifespan and safety of batteries in medical robotics. Lithium-ion and sodium-ion batteries face challenges with reversibility at the electrode/electrolyte interface, which can lead to unstable solid-electrolyte interphases (SEIs). These SEIs can insulate electron transfer, impacting battery cycling and reliability. Optimizing SEI chemistry and morphology is essential for rehabilitation robots, where reliability and safety are paramount. You must ensure precise state of charge (SOC) and state of health (SOH) calculations to prevent overcharging and over-discharging, which can reduce battery lifespan and pose safety hazards.

Tip: Series elastic actuators (SEAs) provide safe and energy-efficient solutions for rehabilitation robots. SEAs reduce mass and kinetic energy during impacts, improving safety and energy efficiency in bipedal locomotion tasks.

1.2 BMS and Safety

Battery management systems (BMS) play a critical role in rehabilitation robot safety and performance. You rely on BMS to monitor and control battery parameters, ensuring safe operation during rehabilitation training. BMS features include thermal management, electrical safety, mechanical integrity, redundancy, environmental protection, user interfaces, and lifecycle management.

Safety Feature | Description |

|---|---|

Thermal Management | Monitors and controls battery temperature to prevent overheating, using sensors and cooling systems. |

Electrical Safety | Protects against short circuits, overcharging, and over-discharging with fail-safe mechanisms. |

Mechanical Integrity | Designed to withstand physical stresses with ruggedized enclosures and shock-absorbing mounts. |

Redundancy | Includes dual-channel monitoring and redundant safety circuits to prevent single points of failure. |

Environmental Protection | Ensures safe operation in various conditions with specified ingress protection (IP rating). |

User Interfaces | Provides alerts and indicators for battery issues and system malfunctions for user awareness. |

Lifecycle Management | Guidelines for safe charging, storage, transportation, and disposal of batteries. |

You must use BMS to prevent thermal runaway and overcharging in wearable lower limb rehabilitation robot applications. BMS monitor voltage, current, temperature, and SOC to optimize battery performance and prevent electrochemical abuse. Intelligent charging and discharging strategies extend battery life and mitigate risks. Effective battery management reduces the risk of thermal runaway, maintaining battery condition and safety throughout rehabilitation training.

Common battery failure modes in rehabilitation robots include internal short circuit, capacity degradation, and electrolyte leakage. You can mitigate these risks by implementing diagnostic techniques and establishing a safety early warning framework.

1.3 Temperature Stability

Temperature stability is vital for battery performance and safety in rehabilitation robots. You must store lithium batteries in a cool, dry environment. The optimal operating temperature range is between 20°C and 25°C (68°F to 77°F). Avoiding extreme temperatures prevents battery degradation and ensures reliable power delivery during rehabilitation training.

Store batteries in recommended temperature range.

Monitor battery temperature during operation.

Use BMS for thermal management and early warning.

Temperature fluctuations can reduce battery efficiency and lifespan. You must design custom lithium battery packs with integrated thermal management to maintain stability and support continuous rehabilitation training.

1.4 Wearable Lower Limb Rehabilitation Robot Needs

Wearable lower limb rehabilitation robot applications present unique energy optimization challenges. These robots use suspension weight reduction technology for gait training, which increases energy demands. You must select lightweight, portable batteries to maximize endurance and power performance. Energy management and optimization are crucial for lower limb devices, focusing on battery management and motion energy consumption.

Lower limb rehabilitation robots require lightweight batteries for portability.

Energy optimization strategies improve endurance and power output.

Battery management systems support safe and efficient operation during rehabilitation training.

Lower extremity rehabilitation robots must balance energy density, safety, and form factor. You must design custom lithium battery packs tailored to the specific needs of wearable lower limb rehabilitation robot applications. This approach ensures reliable power, safety, and efficiency throughout rehabilitation training.

Note: You should consult with battery experts to develop custom solutions for your rehabilitation robot projects. Custom lithium battery packs and advanced BMS technologies deliver optimal energy efficiency, safety, and performance for medical and wearable robotics.

Part 2: Custom Lithium Battery Packs for Rehabilitation

2.1 Energy Optimization

You face unique challenges when designing rehabilitation robots for medical and wearable applications. Custom lithium battery packs offer significant advantages in runtime, energy efficiency, and tailored energy management. You can shape and size custom packs to fit the robot’s internal geometry, which enhances both functionality and portability. This flexibility is essential for wearable lower limb rehabilitation robots, where space and weight constraints directly impact training outcomes.

The following table highlights the main advantages of custom lithium battery packs for rehabilitation robots:

Advantage | Description |

|---|---|

Form Factor Flexibility | You can shape and size custom packs for the robot’s internal geometry, enhancing functionality. |

Power and Voltage Customization | You can deliver precise voltage and current, optimizing runtime and torque for rehabilitation tasks. |

Smart Battery Management Systems | You can integrate BMS to track state of charge and health, boosting uptime and safety through predictive maintenance. |

Modularity | You can build modular units for easy replacement or expansion, ideal for scaling robotic platforms. |

Safety Features | You can include protections like thermal fuses and redundant cutoffs, critical for unpredictable conditions. |

Custom lithium battery packs allow you to optimize energy use for rehabilitation robots during intensive training sessions. You can implement machine learning-based energy management strategies, such as Q-learning and reinforcement learning algorithms, to improve response time and reduce prediction errors. Energy harvesting technologies further enhance battery performance by dynamically managing energy according to actual power demand and supply conditions.

Tip: You should consult with battery experts to develop custom solutions that maximize runtime and energy efficiency for your rehabilitation robot projects.

2.2 Embedded Systems Integration

You must integrate custom lithium battery packs with embedded systems to ensure reliable operation of rehabilitation robots. This integration enables real-time monitoring and control of battery performance, which is critical for medical and wearable robotics. You can provide continuous updates on battery health and charge levels, allowing you to make informed decisions during rehabilitation training.

The table below outlines the key aspects of embedded systems integration for rehabilitation robots:

Aspect | Description |

|---|---|

Real-time Data | You receive continuous updates on battery health and charge levels, essential for effective monitoring. |

Battery Management System | You ensure safe operation, optimize battery life, and prevent failures, which is crucial for medical reliability. |

Safety Mechanisms | You implement protective measures to avoid risks such as overcharging and overheating of batteries. |

You must address design limitations when integrating custom lithium battery packs with embedded systems. Standard batteries may not fit unique form factors required by rehabilitation robots. High peak current demands during training can lead to failures if you use generic batteries. Custom solutions allow you to balance energy density, weight, and form factor, ensuring stability and safety in wearable lower limb rehabilitation robots.

Challenge | Description |

|---|---|

Design Limitations | You must fit custom battery packs to unique form factors, which standard batteries may not accommodate. |

Inadequate Power Delivery | You must meet high peak current demands from robotic systems, which can lead to failures with standard batteries. |

Safety and Reliability Risks | You must include necessary safety features, as generic batteries may increase risks in sensitive environments. |

You can leverage advancements in exoskeleton technology for rehabilitation, but you must address the scarcity of specialized algorithms for standing balance control. Ensuring stability and safety in standing balance remains a key issue in exoskeleton research. You can use custom lithium battery packs to support these advanced control strategies and improve training outcomes.

2.3 Regulatory Considerations

You must comply with strict regulatory standards when designing custom lithium battery packs for rehabilitation robots. Companies must adhere to quality assurance practices to ensure safety and environmental friendliness of lithium-ion battery packs. You must comply with regulations like the Dodd-Frank Act (internal link) if you are involved in the production of these battery packs. Batteries that meet stringent quality requirements are suitable for integration into medical devices, including rehabilitation robots.

You must follow quality assurance practices for safety and environmental friendliness.

You must comply with the Dodd-Frank Act and other relevant regulations.

You must ensure batteries meet stringent quality requirements for medical device integration.

You should prioritize sustainability (internal link) and responsible sourcing of materials when developing custom lithium battery packs for rehabilitation robots. You must select battery chemistries and components that meet regulatory and certification requirements for medical and wearable robotics. You can consult with experts to ensure your custom solutions align with industry standards and support safe, reliable rehabilitation training.

Note: You should work with experienced battery manufacturers to develop custom lithium battery packs that meet regulatory standards and application-specific requirements for rehabilitation robots.

You improve rehabilitation robot performance by focusing on custom lithium battery packs, advanced BMS, and temperature stability.

Custom packs support efficient, long-term rehabilitation therapy and seamless mobility.

Advanced BMS increases safety and durability for every robot in rehabilitation training.

Future battery technology will drive better rehabilitation therapy and mobility.

Feature | Benefit |

|---|---|

Enhanced safety | Reduces risks for rehabilitation robots |

Superior longevity | Extends robot lifespan in training |

Increased capacity | Supports longer rehabilitation sessions |

Tailored solutions | Meets unique rehabilitation requirements |

You should consult battery experts to ensure your robot achieves optimal performance.

FAQ

What makes lithium battery packs ideal for rehabilitation robots?

Lithium battery packs deliver high energy density and reliability. You achieve longer runtime and safer operation for rehabilitation robots. Large Power offers custom solutions for your rehabilitation needs.

How do you ensure safety in rehabilitation robot battery design?

You use advanced BMS, thermal management, and mechanical protection. Large Power integrates these features into lithium battery packs for rehabilitation robots. Request a custom consultation for tailored safety solutions.

Can you compare lithium battery chemistries for rehabilitation applications?

Chemistry | Energy Density | Safety | Application Scenario |

|---|---|---|---|

LiPo | High | Moderate | Legged rehabilitation robots |

LFP | Moderate | High | General rehabilitation robots |

NMC | Very High | Moderate | Long-duration rehabilitation |

You select chemistry based on rehabilitation robot requirements.