A fully charged lithium battery requires 14.6 volts, yet standard charging systems consistently fail to reach this critical threshold. The selection of appropriate lithium battery and charger combinations directly determines system performance, cycle life, and operational safety across power applications.

A fully charged lithium battery requires 14.6 volts, yet standard charging systems consistently fail to reach this critical threshold. The selection of appropriate lithium battery and charger combinations directly determines system performance, cycle life, and operational safety across power applications.

Optimal charging protocols specify 14.4 volts for lithium batteries rather than maximum capacity charging. This approach maintains performance parameters while ensuring adequate protection mechanisms. Standard converters in RV and industrial applications typically output only 13.2 to 13.6 volts, creating a significant performance gap that limits lithium battery utilization. This voltage shortfall necessitates careful evaluation of charging infrastructure compatibility when implementing lithium power systems.

As custom battery pack manufacturers, we have documented these charging limitations across diverse applications. Large Power develops engineered battery and power solutions for complex applications, providing the technical expertise required to address charging compatibility challenges in modern power systems.

This technical guide examines the fundamental differences between lithium and lead-acid charging protocols, methods for identifying compatible charging systems, and specific implementation considerations for various voltage configurations including 36V lithium battery and charger installations. Our integrated design, manufacturing, and testing capabilities ensure power system reliability through proper component matching and performance validation.

Lithium Battery Charging Fundamentals

Image Source: Battle Born Batteries

Image Source: Battle Born Batteries

Lithium battery charging protocols require understanding of fundamental power conversion processes within electrical systems. Proper charging methodology directly influences performance parameters and operational lifespan across lithium power applications.

AC to DC Power Conversion in Mobile and Off-Grid Applications

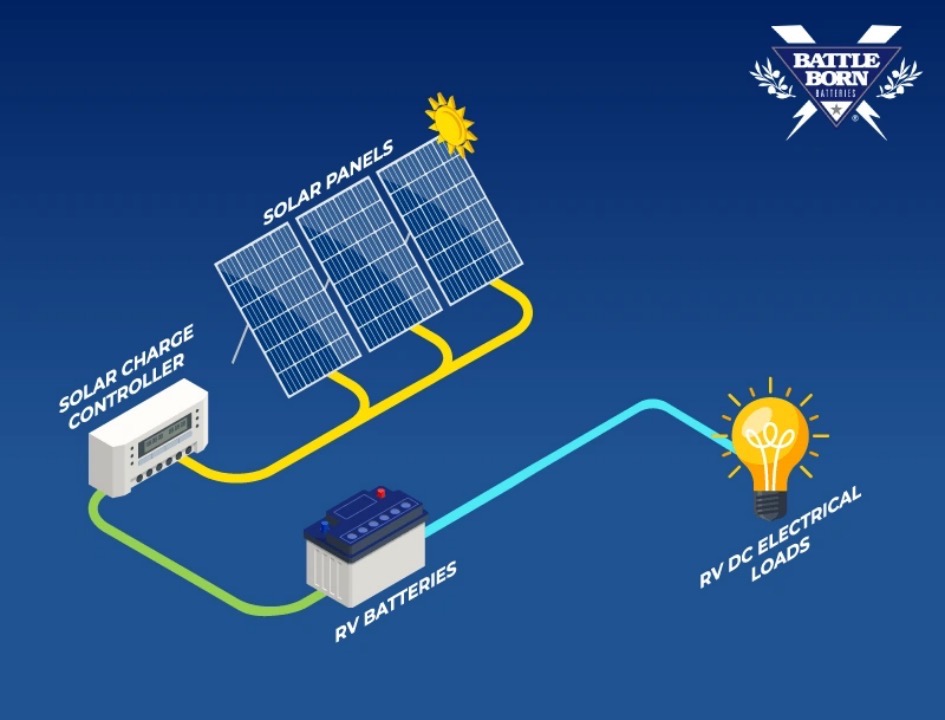

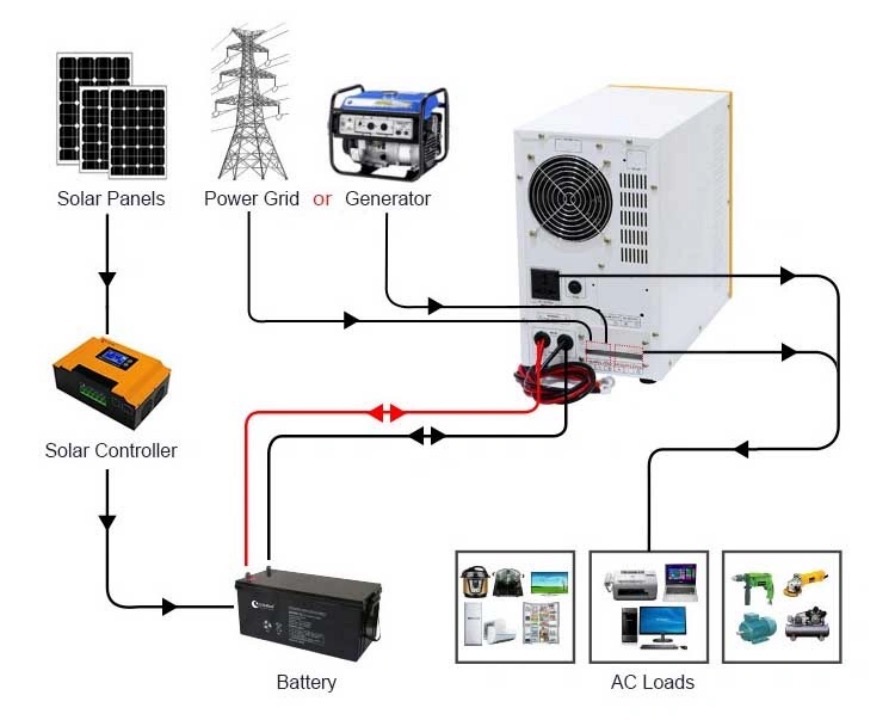

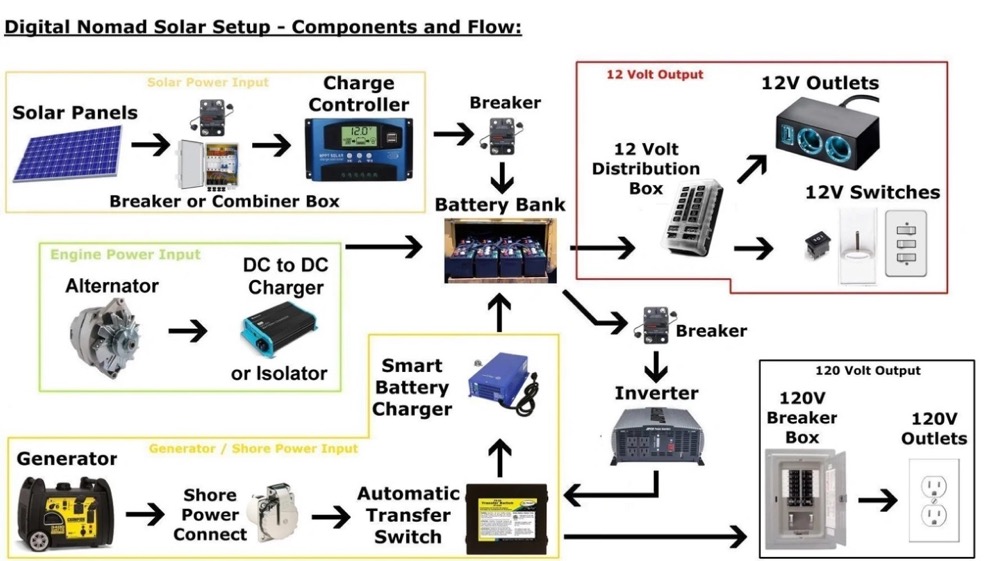

RV and off-grid power systems depend on conversion equipment to transform alternating current (AC) from shore power or generator sources into direct current (DC) for battery storage. These conversion devices, designated as “converters” or “converter-chargers,” perform the essential function of power conditioning.

Modern RV converter-chargers transform 110-volt AC input power into 12-volt DC output suitable for battery charging applications. Installation typically occurs adjacent to the power distribution center to facilitate shore power connections. Output circuits connect directly to the DC load distribution system, supplying power to connected devices while simultaneously charging battery systems.

Standard converter designs present significant limitations for lithium battery applications. Conventional units were engineered for lead-acid battery chemistry and lack the specific charging algorithms required for lithium systems. Field reports indicate that standard converters only charge lithium batteries to approximately 80% capacity due to inadequate voltage output specifications.

Advanced inverter-charger systems provide bidirectional power conversion capabilities. These units convert AC to DC for battery charging operations and subsequently invert battery DC power to usable AC when shore power becomes unavailable. Off-grid solar installations utilize charge controllers, particularly MPPT (Maximum Power Point Tracking) technology, to convert photovoltaic panel voltage into appropriate charging voltage for battery systems.

Lithium Battery Charging Profile Requirements

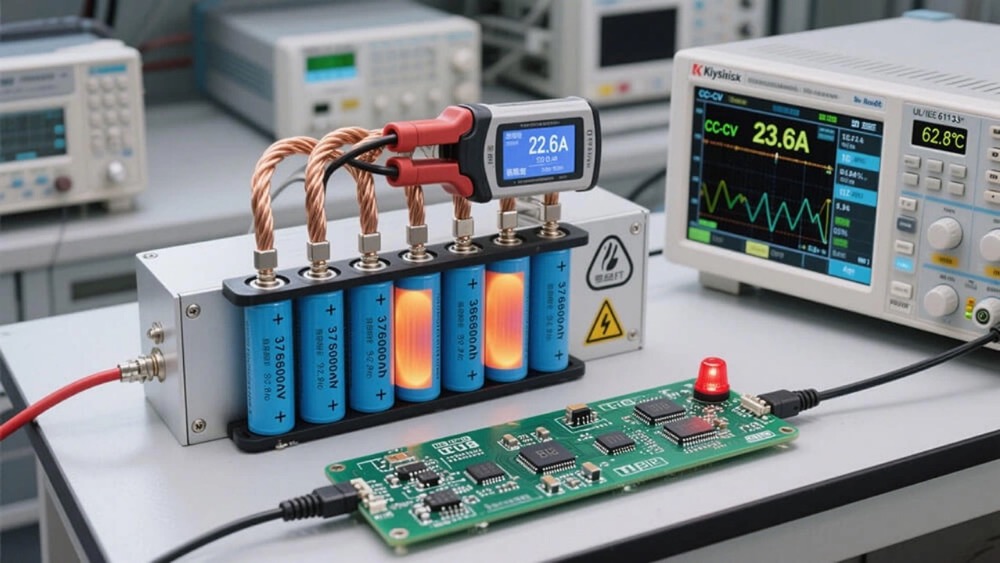

Lithium chemistry demands precise charging control parameters that differ significantly from traditional battery technologies. The charging profile for lithium batteries follows a two-stage process: Constant Current (CC) followed by Constant Voltage (CV). During the CC phase, controlled current flows into the battery until reaching a predetermined voltage threshold. The system then transitions to CV mode, maintaining voltage while current decreases progressively.

This precision requirement stems from lithium ion electrochemical behavior. Within each cell, lithium ions migrate between anode and cathode electrodes through an electrolyte medium. The charging process involves lithium ion release from the cathode and acceptance at the anode—electrochemical reactions requiring exact voltage control for operational safety and efficiency.

Critical factors that differentiate lithium charging specifications include:

- Precise voltage tolerances: Lithium manufacturers specify exact voltage parameters, unlike the voltage flexibility available with lead-acid systems • Elimination of trickle charging: Lithium batteries do not benefit from continuous low-current charging after reaching full capacity • Integrated protection systems: Quality lithium batteries incorporate Battery Management Systems (BMS) that continuously monitor voltage, current, and temperature during charging operations

Standard lead-acid chargers cannot adequately charge lithium iron phosphate (LiFePO4) batteries due to fundamental charging requirement differences. This incompatibility exists because lithium batteries require specific charging algorithms with voltage thresholds that exceed lead-acid system specifications.

Optimal battery performance requires moderate charging rates, typically 0.2C or lower. A 100Ah battery system would charge optimally at 20 amps maximum current. Excessive charging rates can damage electrode structures as lithium ions cannot properly intercalate into graphite electrode materials.

Temperature parameters significantly affect charging processes. Most lithium batteries cannot safely accept charge below 0°C due to electrode thermal contraction and reduced electrolyte conductivity. Operating temperatures exceeding 45°C should be avoided to prevent accelerated capacity degradation.

Our custom lithium battery solutions incorporate integrated BMS technology to maintain proper charging parameters across applications ranging from medical devices to advanced robotics systems.

Fundamental Charging Differences Between Lead-Acid and Lithium Chemistry

Image Source: Battery Power Tips

Image Source: Battery Power Tips

Battery chemistry fundamentally determines charging requirements across power applications. The electrochemical processes within lead-acid versus lithium cells create distinct charging protocols that directly impact system design and operational parameters.

Voltage Requirements: 12.7V vs 14.6V

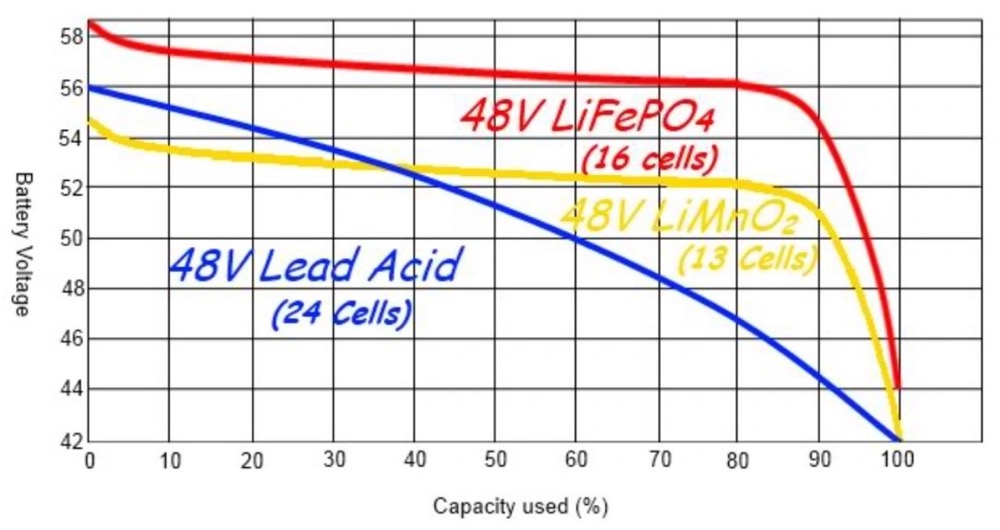

Cell structure defines voltage characteristics between these chemistries. Lead-acid batteries comprise six 2V cells totaling 12V nominal voltage, reaching approximately 12.7V to 12.8V when fully charged. Lithium iron phosphate (LiFePO4) batteries contain four 3.2V cells yielding 12.8V nominal voltage, requiring 14.6V for complete charging. This structural difference creates the 1.9V charging gap that necessitates chemistry-specific charging equipment.

Discharge voltage profiles reveal additional distinctions. Lithium batteries maintain approximately 13V at 20% remaining capacity, whereas lead-acid batteries drop to 11.8V under similar discharge conditions. This voltage retention characteristic provides lithium batteries with superior performance throughout the discharge cycle.

Charging Protocol Variations

Lead-acid charging follows a three-stage process:

- Bulk charge (constant current)

- Absorption charge (constant voltage)

- Float charge (maintenance)

Lithium chemistry employs a simplified two-stage approach:

- Constant Current (CC) phase

- Constant Voltage (CV) phase

This streamlined charging process contributes to lithium’s superior energy efficiency, typically 95-98% compared to lead-acid’s 75-85%. The efficiency improvement translates directly to reduced charging time and lower energy consumption during the charging process.

Charging speed represents another significant advantage. Lithium batteries accept charge approximately four times faster than lead-acid equivalents. Applications requiring rapid recharge cycles benefit substantially from lithium chemistry selection.

Protection Requirements and Battery Management Systems

Overcharging tolerance varies dramatically between these technologies. Lead-acid batteries generally accommodate minor overcharging through float charging protocols. Extended overcharging gradually degrades capacity through electrolyte loss and grid corrosion mechanisms.

Lithium batteries demonstrate heightened sensitivity to overcharging conditions. Excessive charging can trigger thermal runaway, potentially resulting in fire or explosion scenarios. This sensitivity stems from lithium dendrite formation—metallic structures that can puncture cell separators and create short circuits.

Advanced lithium battery solutions incorporate sophisticated Battery Management Systems (BMS) to address these safety requirements. Industry analysis confirms that “Lead acid batteries generally do not have a battery management system”. The BMS continuously monitors cell voltage, current, and temperature parameters, preventing overcharging by calculating safe current limits and communicating with charging equipment.

These fundamental differences require lithium-compatible chargers rather than attempting to adapt lead-acid charging equipment for lithium applications. Proper charger selection ensures optimal safety and performance across demanding applications from medical devices to industrial power systems.

Lithium-Compatible Charger Requirements Assessment

Image Source: Parked In Paradise

Image Source: Parked In Paradise

Charger compatibility assessment represents a critical evaluation process for lithium battery system implementation. Our experience manufacturing custom battery packs has documented numerous compatibility failures that compromise both performance and operational longevity. The following systematic approach determines whether lithium-specific charging equipment is required for your application.

Identifying Incompatible Charging Equipment

Charging system incompatibility typically manifests through documented specifications and operational characteristics. Product documentation frequently contains explicit statements such as “do not support lithium battery”. Standard RV converters, particularly older model designations, lack the necessary charging algorithms to reach the required 14.6V threshold.

Current converter evaluation should identify these incompatibility indicators:

- Exclusive design specifications for lead-acid, AGM, or gel battery chemistries

- Maximum voltage output limitations below 14.6V requirements

- Equalization charging modes that exceed safe lithium voltage parameters

- Absence of lithium-specific charging algorithm programming

- Calcium battery charger configurations with excessive voltage output

Model number verification through manufacturer documentation provides definitive compatibility confirmation. Legacy charging units without programmable voltage control typically cannot accommodate lithium chemistry requirements.

Diagnostic Indicators of Charging Problems

Charging irregularities present through measurable performance characteristics. Undercharging conditions limit batteries to approximately 80% state of charge (SOC) with incompatible charging equipment. This capacity limitation reduces usable energy storage by 5-15% while decreasing operational runtime.

Overcharging conditions produce these observable warning indicators:

- Physical battery case expansion due to electrolyte decomposition

- Elevated temperature generation during charging cycles

- Chemical odor emission from cell venting mechanisms

- Unstable voltage measurements and accelerated self-discharge rates

Battery management system (BMS) protection circuits respond to unsafe parameters by disconnecting charging current. However, dependence on BMS intervention rather than proper charging equipment compromises long-term performance optimization.

Charging System Upgrade Decision Criteria

Upgrade requirements depend on specific application parameters and existing equipment capabilities. Initial evaluation should confirm manufacturer charging specifications—certain battery designs accommodate standard chargers while others require lithium-specific equipment.

Replacement becomes necessary under these operational conditions:

- Existing charger lacks lithium chemistry profile programming

- Repeated BMS protection activation during charging cycles

- Application demands for accelerated charging capabilities

- Consistent performance deficiencies despite proper maintenance protocols

- Substantial battery capacity expansion requirements

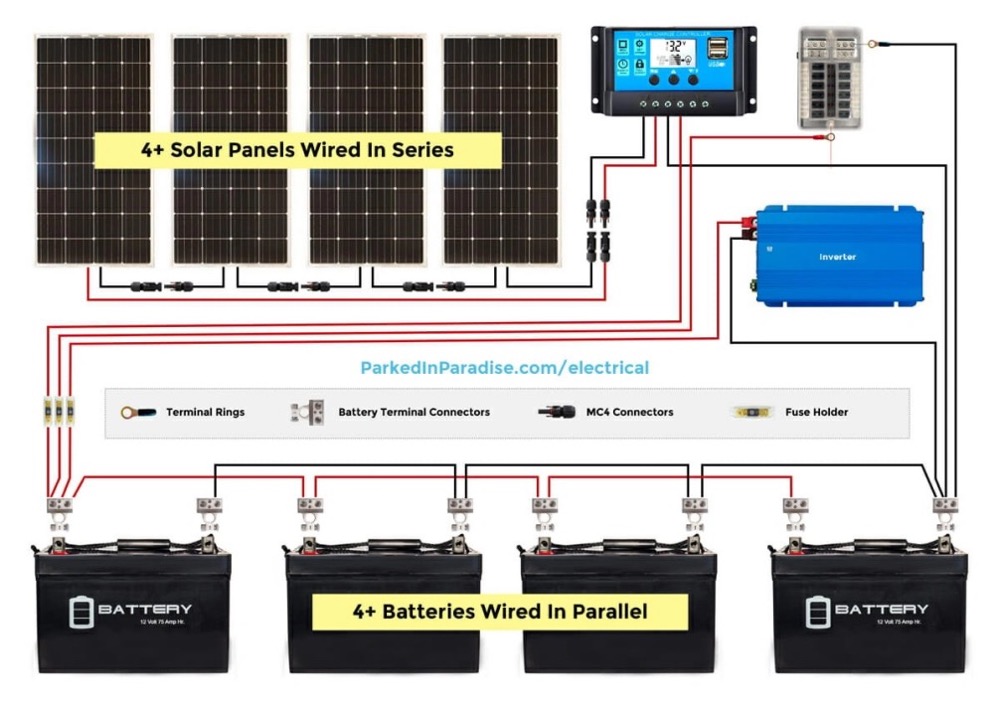

Modern charging equipment offers programmable chemistry profiles supporting lithium applications. Specification requirements include voltage settings between 14-14.6V for bulk/absorption phases and 13.3-13.8V for maintenance charging on 12V configurations. Multi-bank charger systems provide balanced charging across series cell arrangements.

Incompatible charger utilization with lithium batteries represents significant capital waste while introducing performance and safety compromises that undermine system reliability.

Lithium Battery Charger Technologies and Applications

Image Source: Xindun Power

Image Source: Xindun Power

Lithium battery charging equipment encompasses distinct technologies, each optimized for specific operational requirements and system configurations. The selection of appropriate charging technology directly affects system reliability, charging efficiency, and battery cycle life across diverse applications.

Smart Chargers with Programmable Voltage

Smart charging systems provide the most adaptable lithium battery charging solution for complex applications. These units incorporate adjustable voltage settings spanning 12-84V with programmable charging algorithms designed for multiple battery chemistries. The MEAN WELL HEP-1000 series exemplifies this technology, enabling users to connect with smart charger programmers and configure specific charging parameters for individual lithium battery types. This programmability becomes essential when working with batteries from different manufacturers, as identical chemistry variants frequently require distinct voltage configurations to achieve optimal performance.

Inverter-Charger Combinations for Off-Grid Applications

Inverter-charger units integrate dual functionality essential for off-grid power systems. These systems convert AC to DC for battery charging during power availability, then reverse the process to transform battery DC power into usable AC when grid power fails. High-capacity configurations, including 12000-watt pure sine wave inverter-chargers, incorporate automatic transfer switches enabling seamless transitions between grid and battery power sources. Advanced models include auto-generator start functionality, battery temperature sensors, and configurable AC priority settings for comprehensive power management.

RV-Specific Lithium Charging Solutions

RV lithium chargers provide simplified implementation without complex configuration requirements. Available options include the Powermax PM3 55LK with chemistry selection via switch adjustment, the WFCO WF-9855-LIS featuring jumper terminals for lithium/lead-acid switching, and the Progressive Dynamics PD9160ALV designed exclusively for lithium applications. These purpose-engineered units eliminate compatibility issues when retrofitting lithium batteries into existing RV electrical infrastructures.

36V System Charging Requirements

36V lithium configurations require precise charging parameters for optimal performance. Compatible chargers deliver 42-43V output voltage to achieve complete charging cycles. Current settings typically follow 0.5C to 1C recommendations, where C represents battery capacity in amp-hours, balancing charging speed against thermal stress and cycle life considerations. Rapid charging generates increased heat and mechanical stress, potentially reducing battery lifespan—a critical factor when engineering custom battery solutions for demanding applications.

Charger Selection Methodology for Lithium Battery Systems

Image Source: Skoolie Supply

Image Source: Skoolie Supply

Proper charger selection requires systematic evaluation of technical specifications matched to application requirements. Our experience developing integrated power systems demonstrates that methodical charger-battery matching prevents performance limitations and premature failure modes.

Specification Matching Protocol

Voltage compatibility verification forms the foundation of proper charger selection. The charger output voltage must align precisely with battery nominal voltage requirements. For lithium iron phosphate (LiFePO4) batteries, this specification requires 14.6V for 12V systems. Charging current directly affects both charge time and battery cycle life—optimal performance occurs at 0.5C to 1C rates, where C equals battery capacity in amp-hours.

Application-Specific Charger Requirements

Each application environment imposes distinct charger specifications. RV systems require multi-stage chargers with lithium-specific profiles to accommodate varying power source availability. Solar installations necessitate chargers with MPPT controller integration for maximum energy harvest efficiency. Marine environments demand waterproof enclosures with IP67 ratings to withstand saltwater exposure. Industrial applications require robust construction with high reliability ratings and network communication capabilities for remote system monitoring.

Manufacturing Partnership Considerations

Collaboration with experienced battery pack suppliers ensures optimal component compatibility across the entire power system. Qualified manufacturers provide technical guidance on charger selection based on specific application parameters. This partnership approach helps identify chargers with appropriate charging algorithms for the selected battery chemistry, preventing common implementation errors that compromise battery performance.

Required Safety Certifications and Standards

Safety certification verification provides assurance of proper engineering design and testing protocols. Essential certifications include UL listings (ANSI/UL1564 for industrial chargers), CSA certification (CAN/CSA-C22.2 NO. 107.2), and CE marking for European market compliance. FCC certification prevents electromagnetic interference with sensitive electronic equipment. International applications may require additional country-specific certifications—Japan mandates PSE certification, while South Korea and Australia maintain distinct certification standards.

Technical Summary

Lithium battery charger selection represents a critical engineering decision affecting system performance, operational safety, and service life. The charging profile for lithium chemistry requires 14.6V for 12V systems compared to 12.7V for lead-acid batteries. Standard chargers designed for conventional batteries consistently fail to deliver proper charging parameters, limiting capacity utilization and reducing cycle life.

Lithium batteries utilize a two-stage charging process rather than the three-stage approach required for lead-acid systems. This fundamental difference necessitates lithium-specific charging equipment for optimal performance. Proper charging protocols prevent both undercharging and overcharging conditions that permanently damage cell electrodes.

Smart chargers with programmable voltage settings provide the most effective solution across diverse applications. RV installations, solar systems, marine applications, and industrial environments each require careful specification matching between charger output parameters and lithium battery requirements. Optimal charging current ranges between 0.5C to 1C, balancing charge rate against thermal stress on cell components.

Safety certifications remain mandatory for reliable operation. UL, CSA, and CE certifications ensure charging equipment meets established testing standards for electromagnetic compatibility and operational safety. These certifications provide verification of proper design and manufacturing quality control processes.

Custom battery manufacturers with integrated engineering capabilities understand the technical complexities involved in power system design. Experienced battery pack suppliers provide essential guidance during charger selection, ensuring compatibility between charging systems and battery specifications. This collaboration produces optimized performance and extended operational life for custom lithium battery applications.

Battery technology continues advancing through improvements in cell chemistry and charging methodologies. The fundamental principles remain constant: voltage parameter matching, current limitation compliance, and appropriate safety standard implementation. Proper charger selection ensures maximum return on lithium battery system investments across lithium battery systems.

Key Takeaways

Choosing the right lithium battery charger is crucial for maximizing performance, safety, and battery lifespan in your power system.

- Voltage matters critically: Lithium batteries require 14.6V for full charging versus 12.7V for lead-acid batteries—standard chargers often fall short at 13.2-13.6V.

- Smart chargers offer best versatility: Programmable voltage settings (12-84V) and lithium-specific algorithms ensure optimal charging across different battery chemistries and applications.

- Match charger current to battery specs: Charge at 0.5C to 1C rate (where C equals battery capacity) to balance charging speed with battery longevity.

- Application-specific features are essential: RV systems need multi-stage profiles, marine environments require IP67 waterproofing, and industrial uses demand network monitoring capabilities.

- Safety certifications prevent costly failures: Look for UL, CSA, and CE certifications to ensure your charger meets rigorous testing standards for reliable operation.

Proper charger selection directly impacts your lithium battery investment—incompatible chargers can reduce usable capacity by 15-20% and trigger protective shutdowns. Working with experienced battery manufacturers ensures optimal compatibility and system performance across diverse applications from RVs to industrial power systems.

FAQs

Q1. What voltage is required to fully charge a lithium battery? A lithium battery typically requires 14.6V for full charging, compared to 12.7V for lead-acid batteries. Standard chargers often only reach 13.2-13.6V, which is insufficient for lithium batteries.

Q2. Are special chargers needed for lithium batteries? Yes, lithium batteries require specific chargers designed for their chemistry. Standard lead-acid chargers lack the appropriate charging profiles and voltage levels needed to properly charge and maintain lithium batteries.

Q3. What features should I look for in a lithium battery charger? Look for smart chargers with programmable voltage settings (12-84V), lithium-specific charging algorithms, and the ability to match your battery’s specs. Also consider application-specific features like multi-stage profiles for RVs or waterproofing for marine use.

Q4. How do I determine the right charging current for my lithium battery? The optimal charging current is typically between 0.5C to 1C, where C equals the battery capacity in amp-hours. For example, a 100Ah battery would charge best at 50-100A. This range balances charging speed with battery longevity.

Q5. What safety certifications should a lithium battery charger have? Look for chargers with UL, CSA, and CE certifications, which ensure the equipment meets rigorous testing standards for safe and reliable operation. FCC certification is also important to prevent electromagnetic interference with other devices.