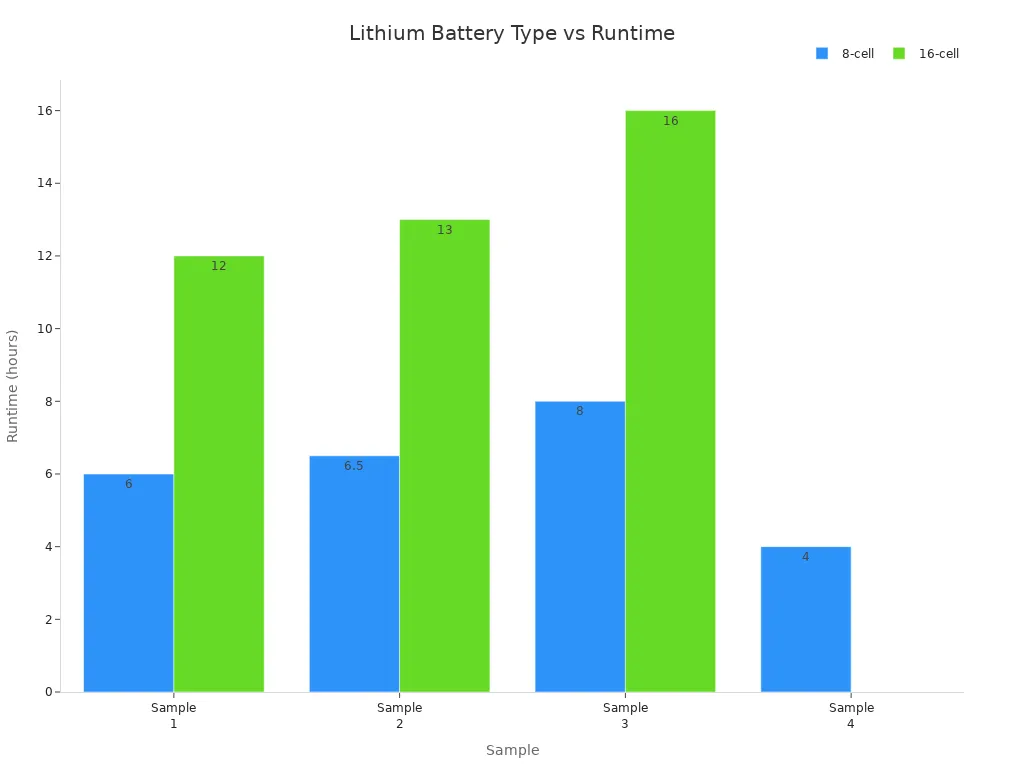

You depend on high-capacity lithium batteries to keep your portable oxygen concentrator running for hours. Battery design plays a critical role in how long you use your portable device without interruption. The table below shows how battery design affects runtime and recharge time.

Battery Type | Runtime (Lowest Setting) | Recharge Time |

|---|---|---|

8-cell | Up to 6 hours | 4 hours max |

16-cell | Up to 12 hours | 8 hours max |

8-cell | Up to 6.5 hours | 3 hours max |

16-cell | Up to 13 hours | 6 hours max |

8-cell | Up to 8 hours | 3.5 hours max |

16-cell | Up to 16 hours | 6 hours max |

8-cell | Up to 4 hours | 2 hours max |

Advanced battery design, such as nano-coating and silicon-composite anodes, increases battery lifespan and reduces costs for your portable devices.

Modern battery design uses:

Improved electrode architecture for longer battery life

Advanced electrolyte formulations for better stability

Battery management systems for extended portable operation

You can optimize battery design and maintenance to maximize runtime and safety for your portable oxygen concentrator.

Key Takeaways

Choose high-capacity lithium batteries with advanced energy density for longer runtimes in portable oxygen concentrators.

Regular maintenance, such as avoiding deep discharges and storing batteries at partial charge, improves battery reliability and lifespan.

Select the right battery chemistry, like LiFePO4 or NMC, to ensure safety and performance in critical medical applications.

Part 1: High-Capacity Lithium Batteries & Density

1.1 Battery Chemistry Choices

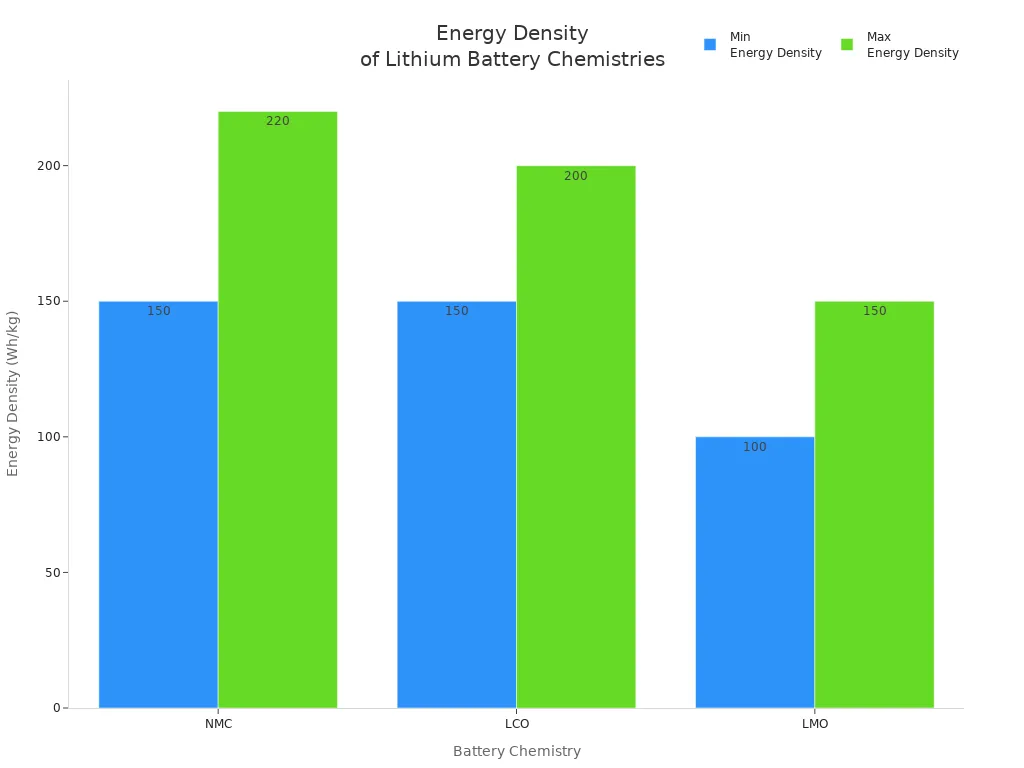

You need to choose the right lithium-ion battery chemistry for your battery pack design to maximize runtime and safety. The most common chemistries for critical medical devices include LiFePO4, lithium-ion (NMC, LCO), and lithium polymer (LiPo). Each chemistry offers different energy density, cycle life, and safety features. The table below compares these options:

Battery Type | Platform Voltage | Energy Density (Wh/kg) | Cycle Life | Safety Features | Ideal Use Case |

|---|---|---|---|---|---|

LiFePO4 | 3.2V | 90–160 | 2,000+ | Very high | Medical, infrastructure |

NMC | 3.7V | 150–220 | 1,000–2,000 | High | Medical, robotics, industrial |

LCO | 3.7V | 150–200 | 500–1,000 | Moderate | Medical, security, consumer electronics |

LiPo | 3.7V | 200–300 | 500–800 | High | Medical, compact devices |

Lithium-ion battery pack design for portable oxygen concentrators often uses NMC or LiPo cells. These chemistries provide high energy density and long cycle life, supporting extended runtime and reliable battery capacity.

1.2 Energy Density Impact

Energy density is the key factor in battery pack design for portable oxygen concentrators. High energy density means you can store more energy in a smaller, lighter battery pack. This directly increases runtime and makes the device easier to carry. For example, lithium-ion battery packs can reach up to 200 Wh/kg, while LiPo packs can go even higher. The chart below shows how different chemistries compare:

A battery pack with high energy density and large battery capacity will deliver longer runtime. This is essential for critical medical devices, where uninterrupted operation is vital.

1.3 Safety and Compliance

Safety is paramount in battery pack design for medical applications. You must select lithium-ion battery packs with advanced safety features, such as battery management systems, thermal protection, and overcharge safeguards. Regular safety checks help prevent risks like thermal runaway or short circuits. Compliance with standards like ANSI/AAMI ES 60601-1, IEC 62133, UL 1642, and UN38.3 ensures your battery pack meets strict safety requirements. These certifications guarantee that your battery capacity and energy density do not compromise patient safety. Always prioritize battery pack design that balances high energy density, battery capacity, and robust safety features for reliable runtime in portable oxygen concentrators.

Part 2: Maximizing Runtime in Portable Oxygen Concentrators

2.1 Runtime Optimization

You want your portable oxygen concentrator to deliver the longest possible runtime for continuous use capacity. Battery capacity, measured in milliamp-hours (mAh), directly affects how long your concentrator operates before you need to recharge. Larger batteries store more energy, which means longer battery life and extended runtime. The table below shows how different factors influence runtime in oxygen concentrators:

Aspect | Description |

|---|---|

Battery Type | Most portable oxygen concentrators use lithium-ion batteries for efficiency. |

Battery Size | Larger batteries provide longer runtime and continuous use capacity. |

Flow Rate Settings | Higher oxygen flow rates consume more power, reducing runtime. |

Pulse Dose vs. Continuous | Pulse dose delivery extends battery life compared to continuous flow. |

You can optimize runtime by adjusting flow rate settings. Lower flow rates use less power, which increases battery life. Pulse dose delivery systems in oxygen concentrators help maximize runtime by delivering oxygen only when you inhale. This method is more efficient than continuous flow and supports longer battery life.

Power management strategies also play a key role in maximizing runtime. You should operate your portable oxygen concentrator in temperate environments and avoid extreme temperatures. Regular cleaning, filter changes, and checking for leaks help maintain efficiency and reliability. Turn off your concentrator when not in use and monitor the runtime display to plan activities around battery capacity. Recharge your battery regularly and avoid full depletion to extend battery life.

Tip: Use supplemental batteries for longer trips or higher oxygen flow needs. Rotate between multiple batteries to prevent premature aging and maintain reliability.

2.2 Battery Integration

Integrating high-capacity lithium batteries into portable oxygen concentrators impacts device size, weight, and usability. You benefit from longer runtime and continuous use capacity without sacrificing portability. Modern lithium battery packs allow oxygen concentrators to remain compact and lightweight, which improves comfort and mobility for daily use and travel.

However, you must consider technical challenges when integrating larger or more energy-dense batteries. The table below highlights common challenges and solutions in battery integration for oxygen concentrators:

Challenge | Description |

|---|---|

Power-to-Weight Paradox | Maximizing battery life while minimizing weight is crucial for portable oxygen concentrators. |

Battery Chemistry Selection | Choosing the right lithium-ion chemistry ensures safety and performance for medical and industrial applications. |

Thermal Management | High current demands generate heat, which can degrade battery cells and affect reliability. |

The “Dumb” Battery Problem | Simple battery packs may lack communication capabilities, leading to inaccurate runtime estimates and increased anxiety for medical users. |

Inconsistent Quality and Reliability | Variability in battery quality can impact overall reliability and patient trust. |

High Total Cost of Ownership (TCO) | Battery maintenance and replacement costs can be significant for medical and industrial oxygen concentrators. |

Fragmented Supply Chains | Sourcing and integrating battery components can complicate design and manufacturing for oxygen concentrators. |

You should select lithium battery packs with advanced battery management systems (BMS) for improved safety and efficiency. Intelligent control systems, brushless motors, and AI-assisted management enable real-time monitoring and adjustments, ensuring optimal oxygen delivery and runtime. These features enhance reliability and efficiency in portable oxygen concentrators.

2.3 Maintenance for Longevity

Proper battery maintenance is essential for maximizing runtime and reliability in portable oxygen concentrators. You should follow best practices to extend battery life and ensure continuous use capacity. Here are key maintenance tips:

Store spare batteries at a 50% charge if not used for 2-3 months.

Avoid letting the battery drain completely and remain uncharged for long periods.

Rotate between multiple batteries and label them to alternate usage regularly.

Fully drain and recharge the battery at least once every three months.

Store batteries in a cool, dry, dark place with a partial charge of 40-50%.

Avoid using batteries in extreme temperatures (below 41˚F or above 95˚F).

Maintain optimal relative humidity between 35% and 50% for medical oxygen concentrators.

Charging and discharging behavior also affects long-term reliability. Discharging lithium batteries to very low levels can cause significant capacity loss. For example, discharging to 100% can result in a 20%-25% reduction in battery life. You should avoid overcharging and deep discharges to maintain battery health. Monitoring the state of charge (SOC) and state of health (SOH) helps prevent failures and supports reliability.

Note: Fast charging protocols can degrade lithium batteries due to uneven current distribution and increased internal temperatures. Always follow manufacturer guidelines for charging to ensure safety and efficiency.

Higher oxygen flow rates increase power consumption, which reduces runtime. When selecting a battery for your portable oxygen concentrator, consider your prescribed oxygen flow rate in liters per minute (LPM). Higher LPM settings require larger battery capacity to maintain continuous use capacity and reliability. Pulse dose delivery systems and efficient battery management help you achieve longer runtime even at higher flow rates.

Manufacturers validate runtime claims through third-party testing reports for oxygen purity and battery life. You should request sample units for real-world performance testing before bulk orders, especially for medical, industrial, and security applications.

By following these maintenance practices and selecting the right battery integration strategies, you can maximize runtime, efficiency, and reliability for your portable oxygen concentrator.

You can extend runtime in portable oxygen concentrators by selecting high-capacity lithium battery packs with advanced energy density and safety features. Regular battery maintenance and proper disposal at certified recycling centers support long-term reliability and sustainability. For B2B buyers, prioritize medical device battery solutions that offer extended runtime and proven safety.

Key Strategy | Benefit |

|---|---|

High energy density battery | Longer runtime |

Improved reliability | |

Safe recycling | Environmental protection |

FAQ

How do you choose the best lithium battery chemistry for oxygen concentrators?

You should compare LiFePO4, NMC, and LiPo chemistries. Use this table for quick reference:

Chemistry | Energy Density (Wh/kg) | Cycle Life | Safety Level |

|---|---|---|---|

LiFePO4 | 90–160 | 2,000+ | Very High |

NMC | 150–220 | 1,000–2,000 | High |

LiPo | 200–300 | 500–800 | High |

What maintenance steps help extend lithium battery pack life?

You should store batteries at 40–50% charge, avoid deep discharges, rotate usage, and keep them in cool, dry places. Always follow manufacturer guidelines for charging.

How does oxygen flow rate affect battery runtime?

Higher flow rates use more power. You will see shorter runtimes at higher liters per minute (LPM). Pulse dose delivery helps you maximize battery life.