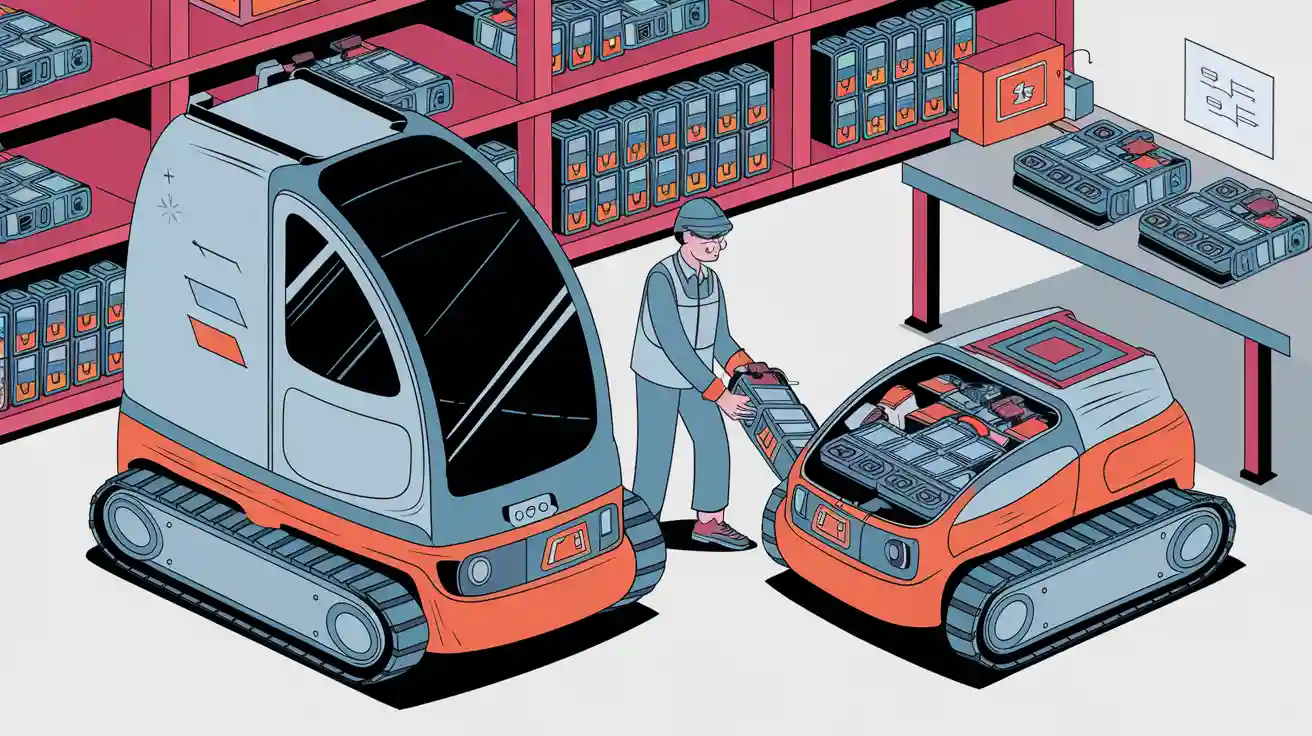

Swappable batteries in AGV & AMR battery systems help you keep your fleet running with minimal downtime.

You can swap a depleted battery for a charged one in about 84 seconds.

Advanced monitoring prevents overheating and overcharging, boosting safety and performance in demanding environments.

Key Takeaways

Swappable batteries allow for quick exchanges, keeping AGVs and AMRs operational with minimal downtime. You can swap a battery in about 84 seconds.

Modular battery systems offer flexibility and scalability, enabling you to customize battery capacity for different applications and improve overall efficiency.

Advanced monitoring features in battery management systems enhance safety by preventing overheating and automating shutdowns during abnormal conditions.

Part 1: AGV & AMR Battery Systems Benefits

1.1 Swappable Batteries and Uptime

Swappable batteries transform how you manage AGV & AMR battery systems. You can achieve high uptime by swapping depleted batteries for fully charged ones in under two minutes. This process keeps your AGVs and AMRs moving, even during peak hours. Swappable batteries eliminate the need for long charging breaks, so your fleet stays productive.

You can use automatic battery swapping to further reduce manual intervention. This approach ensures that your systems operate with minimal human oversight. Swappable designs also support quick maintenance, allowing you to replace batteries before they cause downtime. As a result, you maintain nearly 100% availability for your AGV & AMR battery systems.

Tip: Swappable batteries help you avoid bottlenecks at charging stations, especially in large facilities with many vehicles.

1.2 Efficiency in High-Demand Environments

Efficiency is the backbone of successful AGV & AMR battery systems. Swappable batteries let you keep your fleet running without waiting for slow charging cycles. You can schedule battery swapping during shift changes or low-traffic periods, which maximizes operational efficiency.

Modular battery systems support flexible deployment and remote monitoring. You can track battery levels and predict maintenance needs using modern MES platforms. This real-time visibility helps you optimize task allocation and charging schedules. The MES logs every movement and action, creating a valuable dataset for predictive maintenance and performance improvement.

You can manage battery levels and predict when to swap or charge batteries.

MES platforms give you real-time updates on each AGV, AMR, and AGF, including battery status and location.

The system logs all fleet actions, helping you plan maintenance and improve efficiency.

Swappable batteries also support partial top-up strategies. You can keep AGVs operational by topping up batteries instead of waiting for a full charge. Modular charging bays reduce congestion and idle time at central charging locations. This approach increases system resilience and prevents single-point failures.

1.3 Modular Design and Flexibility

Modular battery systems give you unmatched flexibility. You can scale your AGV & AMR battery systems as your operations grow. Modular designs allow you to customize battery capacity and configuration for different applications, from small robots to heavy-duty industrial vehicles.

Fast charging is a key advantage of modular systems. High-current connections enable rapid charging, so you spend less time waiting and more time working. The CombiTac connector, for example, offers high-current capabilities and supports both automatic and manual charging. Its safety design and long lifespan make it ideal for continuous operation.

Feature | Benefit |

|---|---|

Fast charging | Enables rapid charging capabilities |

Minimized maintenance | Self-cleaning contacts reduce upkeep needs |

Increased efficiency | Low contact resistance improves signal quality |

Space-saving | High packing density allows compact designs |

Modular solutions | Customizable for various applications |

You can choose from a range of load current options, from 5 to 600 A, and add auxiliary contacts for enhanced functionality. Communication capabilities support bus communication during charging, further improving efficiency.

Note: Modular battery systems combine proven performance and modularity, giving you a cost-effective solution that adapts to your needs.

Swappable and modular battery systems deliver high uptime, efficiency, and performance. You can keep your AGV & AMR battery systems running at peak levels, even in the most demanding environments.

Part 2: Integration and Safety Considerations

2.1 AGV and AMR Fleet Integration

You can integrate modular and swappable battery systems into your automated guided vehicles and autonomous mobile robots with minimal disruption. Start by assessing your current automation infrastructure and identify areas where modular charging stations will improve workflow. Use battery management systems to monitor battery health and automate charging solution scheduling. This approach streamlines battery swaps and charging solution cycles, reducing manual intervention and boosting reliability.

You should select advanced lithium-ion battery solutions that match your fleet’s operational needs. Battery management systems provide real-time monitoring, enabling predictive maintenance and supporting automation. Modular charging stations allow you to scale your charging solution as your fleet grows. Automation platforms can connect with battery management systems for seamless monitoring and control.

Tip: Use automation software to track battery status and automate charging solution assignments for each robot.

2.2 Safety and Reliability

Safety and reliability remain critical for continuous automation. You must choose battery systems with robust monitoring features, including temperature control and fault detection. Battery management systems help you mitigate risks by providing alerts and automating shutdowns during abnormal conditions. Automation platforms rely on reliable battery systems to maintain uptime and prevent failures.

Regulatory certifications ensure your battery systems meet industry standards. Review the following certifications when selecting battery systems:

Certification | Description |

|---|---|

CE Mark | Compliance with safety, health, and environmental regulations in Europe |

FCC Approval | Required for some U.S. applications |

Other Certifications | Standards for emissions and power levels, varying by region |

You can evaluate the return on investment for modular and swappable battery systems using dedicated calculators. These tools let you input details about your automation operations, compare robot and charging solution requirements, and analyze cost savings. Consider labor cost reductions, safety improvements, less product damage, and increased reliability when calculating ROI.

Input your automation data for personalized ROI analysis.

Compare manual and automated charging solution costs.

Assess labor savings, safety, and reliability improvements.

Continuous monitoring and automation ensure your battery systems deliver maximum reliability and safety for your AGV and AMR fleets.

Part 3: Implementation Strategies

3.1 Deployment Models

You can choose from several deployment models for modular and quick-swap battery systems. Many facilities use centralized energy swap stations, where AGVs and AMRs dock for rapid battery exchange. This model works well in large industrial environments with high vehicle traffic. Some operations prefer distributed charging points, placing energy swap stations near key work zones. This approach reduces travel time and increases system efficiency.

For medical and robotics applications, you may need mobile energy swap units. These units move to the vehicle, minimizing disruption in sensitive areas. In security system and infrastructure scenarios, you can deploy outdoor-rated energy swap stations to support 24/7 uptime. Consumer electronics manufacturers often use compact modular systems to fit tight spaces and support flexible layouts.

Tip: Assess your facility layout and workflow to select the best deployment model for your energy needs.

3.2 Industry Examples

Many industries have adopted modular and quick-swap battery systems to boost uptime and reliability. In a leading industrial warehouse, AGVs use LiFePO4 Lithium battery packs for fast swaps, supporting three-shift operations with minimal downtime. A medical device manufacturer integrated NMC Lithium battery modules into their AMR fleet, enabling safe, sterile, and efficient energy management.

Battery Chemistry | Platform Voltage | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO4 Lithium battery | 3.2V | 90-120 | 2000+ |

NMC Lithium battery | 3.7V | 150-220 | 1000-2000 |

Robotics companies use modular energy systems to support rapid prototyping and deployment. Security system integrators rely on quick-swap batteries for uninterrupted surveillance. Infrastructure projects benefit from scalable energy solutions that adapt to changing site needs. Consumer electronics assembly lines use modular battery systems to keep production moving.

Best Practice: Start with a pilot program. Monitor energy usage and system performance. Scale up once you confirm reliability and efficiency.

You gain higher uptime, better efficiency, and more flexibility with modular and swappable battery systems for AGVs and AMRs. Assess your current battery needs and consult with experts for a custom battery solution. Consider long-term integration for lasting results.

FAQ

What makes modular lithium battery systems ideal for autonomous robots?

You get flexible capacity, fast charging, and easy swaps. Modular lithium battery systems support autonomous robots in industrial, medical, and robotics applications. Large Power offers custom battery solutions.

How do you ensure safety when deploying lithium batteries in autonomous fleets?

You use advanced BMS, temperature sensors, and certified charging infrastructure. Safety features in lithium batteries protect autonomous fleets in medical, security, and industrial environments.

Which lithium battery chemistry suits high-demand autonomous operations best?

You can compare LiFePO4 Lithium battery and NMC Lithium battery chemistries for autonomous fleets using this table:

Chemistry | Platform Voltage | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO4 Lithium battery | 3.2V | 100-180 | 2000+ |

NMC Lithium battery | 3.7V | 160-270 | 1000-2000 |