Collaborative Robots transform industries such as healthcare and logistics by relying on battery energy density for longer operation and compact design. High energy density and robust safety features matter most in human-centric settings.

Statistic | Value | Year |

|---|---|---|

Projected CAGR | 15.5% | 2023-2028 |

Estimated units sold | 735,000 | 2025 |

The global robot battery market is set for rapid growth, driven by lithium-ion advancements that enhance both safety and performance:

Projected 15% CAGR from 2023 to 2028

Market size expected to reach $12 billion by 2028

Key Takeaways

High energy density in batteries allows collaborative robots to operate longer and fit into compact designs, enhancing efficiency in industries like healthcare and logistics.

Safety features such as thermal management systems and advanced battery management systems are crucial to prevent hazards like thermal runaway and overcharging in lithium-ion batteries.

Investing in solid-state batteries can improve safety and performance, offering higher heat resistance and longer lifespan, making them a valuable choice for demanding robotic applications.

Part 1: High Energy Density in Collaborative Robots

1.1 Battery Energy Density Explained

You need to understand battery energy density to make informed decisions about robot power sources. Battery energy density refers to the amount of energy a battery can store relative to its weight or volume. You will often see two key measurements: specific energy density (Wh/kg), which compares energy to weight, and volumetric energy density (Wh/L), which compares energy to size. In collaborative robots, battery energy density directly impacts efficiency and performance. Higher values mean you can design robots that operate longer and fit more easily into compact spaces, which is essential for industries like Medical and Robotics.

1.2 Benefits for Collaborative Robots

High energy density brings several advantages to collaborative robots:

You achieve longer runtime, which reduces downtime and increases productivity.

You can design robots with smaller, lighter batteries, freeing up space for sensors, actuators, or payloads.

You improve power density, allowing robots to handle demanding tasks in Industrial, Security, and Infrastructure settings.

Modern robotic batteries must deliver high current, support varying loads, and remain stable during high-duty operations. This ensures your collaborative robots can work for extended periods without frequent recharging.

Consider these real-world impacts:

High-energy batteries enable autonomous security robots to patrol longer and monitor continuously.

Advanced humanoid robots gain greater mobility and longer operational time.

Warehouse and healthcare robots benefit from increased power density, supporting efficient workflows and patient care.

In the case of Vbot’s intelligent companion robot, the system architecture increases motor torque density. The robot features a battery compartment with over 600Wh of power—38% above the industry ceiling. With ongoing development, higher-density battery packs are expected to boost capacity by 30%, enabling more than six hours of outdoor operation.

You also see productivity improvements in collaborative robots when you use high energy density batteries. For example, partnerships between Hyundai Motor, Kia, and Samsung SDI focus on developing high-performance batteries tailored for robots. These efforts address the limitations of current battery technology and drive productivity gains across sectors.

High energy density also enables more compact robot designs:

Smaller batteries reduce overall weight and can serve as structural elements, increasing functional space.

Hydraulic humanoid robots integrate hydraulic circuits with mechanical structures, enhancing joint power and heat dissipation.

These design choices make robots more efficient and adaptable for various applications.

Battery energy density requirements differ by application. In healthcare, you need batteries optimized for long operational times to support patient care. In logistics, you may prioritize batteries that handle high-torque movements and quick recharges to keep up with fast-paced environments.

Case Studies

A stretchable battery developed by Kim and co-workers can stretch up to 90% of its length and endure 36,000 deformation cycles, powering soft robots.

Prof. Kotov’s zinc-air battery, with a specific energy of 842 Wh/kg, powers small toy robots and outperforms traditional lithium-ion batteries.

Aubin et al. demonstrated a redox flow battery system that allows a robotic fish to operate for over 36 hours, showcasing the potential for continuous operation.

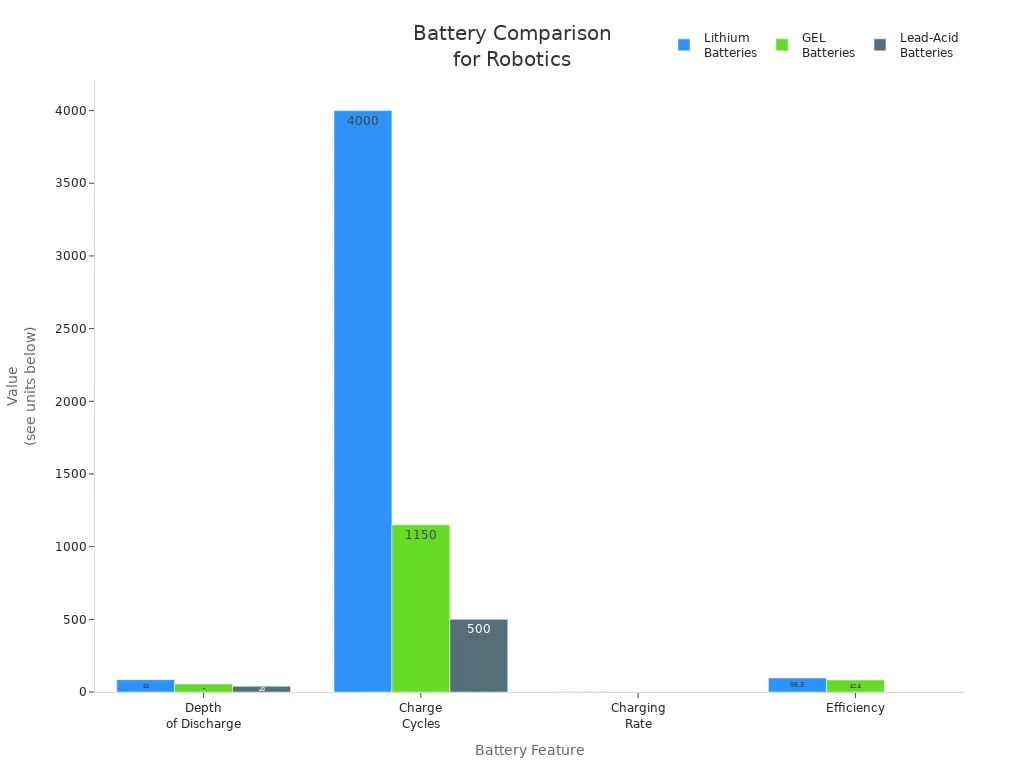

1.3 Lithium Batteries in Robotics

Lithium-ion batteries dominate as the primary power source for collaborative robots. You benefit from their high power density, long cycle life, and fast charging capabilities. Compared to traditional battery types, lithium-ion batteries offer significant advantages in operational efficiency and reliability.

Feature | Lithium-Ion (NMC, LCO, LMO, LTO) | LiFePO4 | GEL Batteries | Lead-Acid Batteries |

|---|---|---|---|---|

Platform Voltage | 3.6-3.7V (NMC, LCO, LMO, LTO) | 3.2V | 2V | 2V |

Energy Density | 150-250 Wh/kg | 90-140 Wh/kg | 30-50 Wh/kg | 30-40 Wh/kg |

Cycle Life | 1000-3000+ | 2000-7000+ | 1000-1300 | 400-600 |

Depth of Discharge | 80-90% | 80-90% | 50-60% | 40% |

Charging Rate | 1C (1 hour) | 1C | 0.3C (3.3 hr) | 0.2C (5 hr) |

Efficiency | 95-98% | 95-98% | 80-85% | N/A |

Memory Effect | None | None | Present | Present |

You gain several key benefits by choosing lithium-ion batteries for collaborative robots:

Longer life: Up to 4500 cycles, far exceeding GEL and lead-acid batteries.

Faster charging: Full charge in about one hour, minimizing downtime.

Higher efficiency: 95-98%, which reduces energy loss and supports demanding applications in Consumer Electronics and Security System.

Lithium-ion batteries, including chemistries like LiFePO4, NMC, LCO, LMO, and LTO, provide the high power density and reliability you need for modern collaborative robots. Their superior depth of discharge and rapid charging rates make them ideal for automated guided vehicles and autonomous mobile robots.

Manufacturers face challenges in increasing battery energy density. You must consider the limitations of current battery technologies, the need for lightweight and efficient power sources, and the complexity of integrating batteries into mobile robot designs. Size and structure constraints, along with the demand for multifunctional batteries that serve as both power and structural elements, drive ongoing innovation in this field.

As you evaluate battery solutions for collaborative robots, prioritize high energy density and power density to maximize operational efficiency and productivity.

Part 2: Safety in Batteries for Collaborative Robots

2.1 Safety Risks and Challenges

When you deploy collaborative robots in environments like Medical, Robotics, or Industrial, you must address the risks of high energy density. Lithium-ion batteries power most collaborative robots, but their chemistry introduces unique hazards. You face several safety risks that can impact both robot performance and workplace safety.

Safety Risk | Description |

|---|---|

Thermal runaway | A condition where a battery overheats and can lead to fires or explosions. |

Overcharging | Charging beyond the required time, causing excess heat and energy. |

Overheating | High temperatures from overuse can accelerate thermal runaway. |

Malfunction | Manufacturing defects or short circuits can generate excess heat. |

Crushing/Penetration | Physical damage to the battery can lead to energy discharge and overheating. |

Moisture | Excess water can cause short circuits and react with battery chemicals, leading to thermal runaway. |

You must consider these risks when integrating lithium-ion batteries into collaborative robots. High energy density increases the potential for thermal events, especially in applications where robots operate near humans. Overcharging, overheating, and physical damage can trigger dangerous reactions. In sectors like Security System and Infrastructure, battery failures can disrupt operations and pose safety threats.

2.2 Safety Features in Battery Design

You need robust safety features to protect both your robots and the people working alongside them. Battery packs for collaborative robots now include multiple layers of protection. These features help prevent common hazards and ensure compliance with international safety standards.

Key safety features include:

Thermal management systems: These systems monitor and regulate battery temperature, reducing the risk of overheating.

Overcharge and over-discharge protection: Integrated circuits prevent batteries from charging or discharging beyond safe limits.

Physical barriers and enclosures: Reinforced casings protect batteries from crushing or penetration.

Advanced Battery Management Systems (BMS): These systems provide real-time monitoring, fault detection, and automatic shutdown in case of anomalies.

You must also comply with global safety standards to ensure safe operation. The following table summarizes the most relevant standards for collaborative robot batteries:

Safety Standard | Description |

|---|---|

ISO/TS 15066 | Guides design and operation of collaborative robots, defining safety requirements for human-robot interaction. |

IEC 62133 | Provides guidelines for the safety of lithium-ion batteries, focusing on thermal management and overcharge protection. |

IEC 61508 | Addresses functional safety for electronic systems, ensuring safe operation of battery management systems. |

You should always verify that your lithium-ion batteries and battery packs meet these standards before deployment. In Medical and Consumer Electronics applications, adherence to these guidelines is critical for both regulatory compliance and user safety.

2.3 Innovations in Battery Safety

Recent innovations have transformed battery safety for collaborative robots. Solid-state batteries now offer a safer alternative to traditional lithium-ion batteries. You gain several advantages by choosing solid-state batteries for your robots:

Feature | Solid-State Batteries | Traditional Lithium-Ion Batteries |

|---|---|---|

Heat Resistance | Operate at up to 125°C | Lower heat tolerance |

Flammability | Non-flammable due to absence of liquid | Flammable due to liquid electrolytes |

Lifespan | 90% capacity for 100 days at 60°C | 90% capacity for 10 days at 60°C |

Maintenance Needs | Maintenance-free environment | Frequent replacements needed |

Solid-state batteries use solid electrolytes, which eliminate the risk of leakage and reduce flammability. You benefit from higher heat resistance and longer operational life, especially in demanding Industrial and Robotics environments. These batteries also require less maintenance, lowering the risk of unexpected downtime.

Advanced battery management systems (BMS) further enhance safety. Modern BMS solutions provide real-time monitoring, predictive analytics, and automated fault response. You can detect issues before they escalate, ensuring continuous and safe operation. These systems align with standards like IEC 61508, which focus on functional safety for electronic systems.

However, you must consider the cost implications of implementing advanced safety features. The following table outlines the main cost factors:

Cost Factor | Description |

|---|---|

Initial Investment | Advanced safety features contribute to a higher initial investment for collaborative robots. |

Ongoing Operational Costs | These features lead to increased ongoing operational costs, including maintenance and power. |

The TCO includes all costs associated with the robot, emphasizing the importance of considering these factors before purchase. |

You may face higher upfront costs when adopting solid-state batteries or advanced BMS, but these investments reduce long-term risks and improve reliability. For custom consultation on battery safety solutions, click here.

You should always balance the need for high energy density with robust safety features. By investing in the latest battery technologies and management systems, you protect your workforce, ensure compliance, and maximize the value of your collaborative robots.

You must balance high energy density and safety to achieve optimal performance in collaborative robots. Consider battery chemistry, thermal management, and intelligent monitoring for efficiency and lifespan. Choose battery options that meet your application’s needs. The future of batteries will drive greater efficiency, longer lifespan, and enhanced performance.

Factor | Description |

|---|---|

Battery Chemistry | Impacts efficiency, lifespan, and safety. |

Thermal Management | Maintains performance and prevents overheating. |

Intelligent Battery Management | Extends lifespan and ensures optimal performance. |

Application Requirements | Dictate the best battery options for efficiency and safety. |

FAQ

What makes Large Power’s lithium battery packs suitable for collaborative robots?

You gain reliable performance and advanced safety features. Large Power customizes battery packs for Robotics, Medical, and Industrial applications. Explore custom battery solutions.

How do you compare lithium-ion, LiFePO4, and solid-state batteries for collaborative robots?

Chemistry | Energy Density | Cycle Life | Safety Level |

|---|---|---|---|

lithium-ion | 150-250 Wh/kg | 1000-3000+ | Moderate |

LiFePO4 | 2000-7000+ | High | |

Solid-State Battery | 250-350 Wh/kg | 3000-8000+ | Very High |

For detailed guidance, request a custom consultation.

Why should you choose a custom battery solution for your collaborative robot project?

You address unique power, safety, and space requirements. Custom battery packs from Large Power ensure optimal fit and compliance for your Robotics or Industrial deployment.