Predictive monitoring systems powered by smart BMS transform how you manage inspection robot fleets. Smart BMS uses AI to deliver real-time monitoring, which helps you reduce unexpected failures and keep your robots operating safely. Recent studies show that predictive management can cut unplanned downtime by up to 50% and reduce maintenance costs by 18-25%. The following table highlights key metrics:

Metric | Value |

|---|---|

Reduction in overall maintenance costs | 18-25% compared to traditional approaches |

Reduction in unplanned downtime | 30-50% |

Average loss due to unplanned downtime | $260,000 per hour |

Smart BMS gives you control over robot battery system management, supporting industrial, security, and infrastructure applications.

Key Takeaways

Smart Battery Management Systems (BMS) reduce unexpected failures by providing real-time monitoring, cutting unplanned downtime by up to 50%.

Predictive maintenance helps you save money by lowering maintenance costs by 18-25% and optimizing battery performance.

Remote diagnostics allow you to assess robot health without on-site visits, improving efficiency and reducing human error.

Real-time data collection from smart BMS enables informed decision-making, ensuring your robot fleet operates safely and effectively.

Integrating smart BMS enhances safety and efficiency, protecting equipment and personnel while maximizing uptime.

Part 1: Smart BMS Overview

1.1 Core Functions

You rely on a battery management system to keep your autonomous mobile robot fleet running safely and efficiently. A smart BMS monitors every battery in real time, using sensors and advanced algorithms. This system tracks voltage, current, and temperature, protecting your robot from unsafe operation. You gain insight into the state of charge and health, which helps you plan maintenance and avoid costly downtime. The table below shows the main functions of a battery management system for inspection robots:

Function | Description |

|---|---|

Monitoring | Tracks voltage, current, and temperature to prevent unsafe operation. |

Protection | Acts as a defense against damage or failure by ensuring safe limits are maintained. |

State Estimation | Calculates metrics like state of charge (SoC) and state of health (SoH) for performance insight. |

Cell Balancing | Ensures uniform charging and discharging across battery cells to maintain efficiency. |

Thermal Management | Controls temperature to optimize battery performance and longevity. |

Communication | Shares operational data with other devices for diagnostics and integration. |

You use these functions to support industrial internet of things applications, including medical robots, security systems, and infrastructure inspection.

1.2 Features for Inspection Robots

Smart battery management systems for autonomous mobile robots offer advanced features that standard solutions cannot match. You benefit from robust communication protocols, adaptive charging, and real-time data monitoring. These features allow your robot fleet to operate in harsh environments, such as dusty factories or outdoor infrastructure sites. The table below compares smart BMS for inspection robots with standard BMS solutions:

Feature | Smart BMS for Inspection Robots | Standard BMS Solutions |

|---|---|---|

Communication Protocols | Yes | Limited |

Balancing Techniques | Advanced | Basic |

Protection Plans | Comprehensive | Minimal |

Real-time Data Monitoring | Yes | No |

Adaptive Charging Regulation | Yes | No |

Environmental Resistance | High (dust, shock, moisture) | Low |

You can deploy these systems in industrial internet of things networks, using IoT based system architectures for remote diagnostics and fleet management.

1.3 Lithium Battery Pack Relevance

You need a battery management system that supports the latest lithium battery chemistries for your autonomous mobile robot fleet. Smart BMS platforms work with LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal batteries. You select the chemistry based on your application, whether in medical robots, security systems, or industrial inspection. The table below compares key lithium battery types:

Chemistry | Platform Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO4 | 3.2 | 90-160 | 2000-7000 |

NMC | 3.7 | 150-220 | 1000-2000 |

LCO | 3.7 | 150-200 | 500-1000 |

LMO | 3.7 | 100-150 | 300-700 |

LTO | 2.4 | 70-110 | 7000-20000 |

Solid-state | 3.7 | 250-400 | 1000-5000 |

Lithium Metal | 3.7 | 350-500 | 500-1000 |

Tip: You improve reliability and safety by choosing a battery management system that matches your robot’s battery chemistry and meets industry standards such as ANSI/RIA R15.06, IEC 61508-1, and EN ISO 10218-1. These standards guide you in deploying autonomous mobile robots in industrial internet of things environments.

Part 2: Remote Monitoring

2.1 Real-Time Data

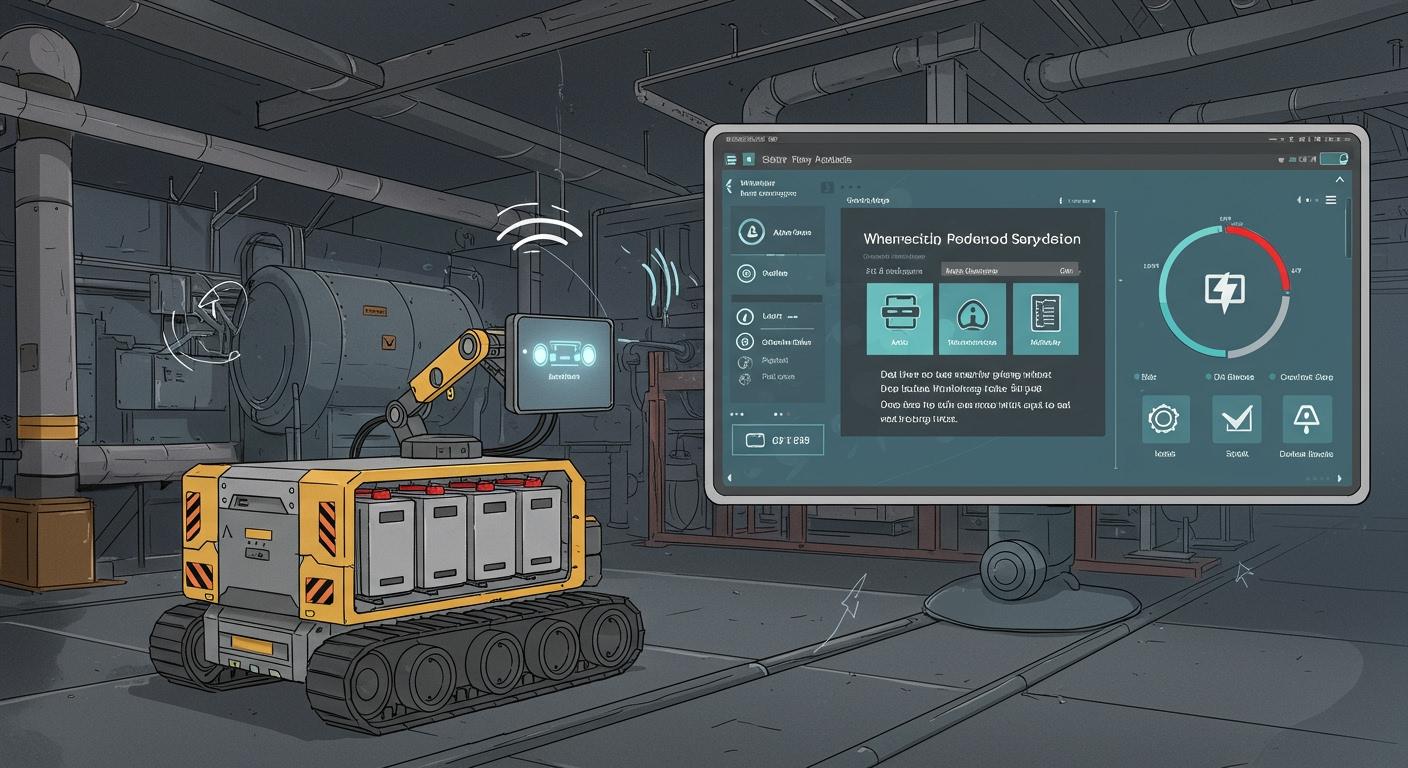

You need real-time monitoring to keep your inspection robot fleet operating at peak performance. Smart BMS platforms use advanced sensors and IoT connectivity, such as LoRa, to collect and transmit critical battery and system data. This approach gives you instant access to the health and status of every robot, no matter where it operates. Real-time monitoring allows you to detect issues early and take action before they disrupt operations.

The system collects a wide range of data points that support predictive management and maintenance. You can see the most important types of data in the table below:

Data Type | Description |

|---|---|

State of Charge (SOC) | Shows remaining battery charge as a percentage, helping you predict range and optimize cycles. |

State of Health (SOH) | Measures battery health and capacity loss, supporting predictive maintenance planning. |

Temperature | Monitors battery temperature to prevent overheating and ensure safe operation. |

Voltage | Tracks electrical potential, helping you avoid overcharging or undercharging. |

Charging and Discharging Cycles | Records cycles to estimate battery lifespan and schedule maintenance. |

Energy Efficiency | Calculates how efficiently the battery charges and discharges, supporting system optimization. |

Cell Balancing | Manages individual cell voltages for balanced performance and longer battery life. |

Charging and Discharging Efficiency | Provides insights into energy losses during operation. |

Predictive Maintenance | Analyzes trends to forecast service needs and prevent failures. |

Fault Diagnostics | Captures data for diagnosing problems and planning corrective actions. |

You use this data to make informed decisions about robot deployment, battery management, and predictive maintenance. Real-time monitoring with LoRa and IoT integration ensures you always have up-to-date information, even in remote or hazardous environments.

2.2 Remote Diagnostics

Remote diagnostics give you the power to assess robot and battery health without sending technicians on-site. Smart BMS platforms use sensors, cameras, and software to collect and analyze data from every robot in your fleet. Sensors detect abnormal temperature, voltage, or noise levels in power facilities. Cameras capture high-resolution images from meters and convert them into digital data. Software analyzes this information and transmits it wirelessly, often using LoRa, to your control center for risk assessment and decision-making.

Note: Remote diagnostics reduce the need for manual inspections and lower the risk of human error. You can identify issues early, plan repairs, and avoid costly downtime.

Compared to traditional manual inspection methods, remote monitoring with smart BMS offers several advantages:

You get continuous, real-time monitoring of battery parameters, while manual checks happen only periodically.

The system detects early warning signs and manages battery health proactively.

Safety features operate consistently, reducing risks from human error.

The system prevents overcharging and other harmful conditions, optimizing battery lifespan.

You can manage complex battery systems across large fleets, which manual methods cannot handle efficiently.

With remote diagnostics, you improve operational efficiency and safety in industrial, security, and infrastructure applications.

2.3 Fleet Visibility

Fleet visibility lets you monitor and manage every robot in your network from a central location. Smart BMS platforms with IoT and LoRa connectivity provide a complete view of your fleet’s status, battery health, and operational readiness. You can track each robot’s location, performance, and maintenance needs in real time.

Here are the main benefits of remote fleet visibility:

You collect data and monitor robot conditions remotely, reducing the need for on-site visits.

You make informed decisions based on real-time assessments and predictive insights.

You prioritize repair work and maintenance using predictive analytics, keeping your fleet running smoothly.

Smart BMS platforms use advanced AI technologies to support autonomous inspection robots in hazardous or hard-to-reach environments. Robot-agnostic software enables you to manage diverse fleets, whether you deploy robots for medical, security, or industrial inspection tasks. Semantic scene understanding and data analysis provide reliable information for decision-making, even in unstructured environments.

LoRa-based IoT systems ensure secure, long-range communication between robots and your control center. This approach supports predictive management, reduces operational costs, and improves safety across your entire fleet.

Part 3: Predictive Monitoring System

Smart BMS platforms use predictive monitoring systems to transform how you manage inspection robot fleets. These systems combine AI, analytics, and real-time data to help you prevent failures, optimize maintenance, and extend battery life. You gain a clear view of every robot’s battery health and operational status, which supports better decision-making across industrial, medical, security, and infrastructure applications.

3.1 Predictive Analytics

You rely on predictive analytics to turn raw data into actionable insights. Smart BMS platforms collect data from sensors embedded in each robot. These sensors track voltage, current, temperature, usage patterns, and environmental conditions. The system uses this data to predict battery performance and identify early signs of wear or failure.

You see these predictive analytics techniques at work in every sector. For example, in medical robots, the system predicts when a battery will need replacement, reducing the risk of downtime during critical procedures. In security systems, predictive monitoring ensures robots remain operational during emergencies. In industrial settings, you use these tools to optimize inspection schedules and reduce costs.

Voltage and current data: You monitor these during charging and discharging cycles to detect abnormal patterns.

Temperature data: You track cell temperatures to prevent overheating and extend battery life.

Usage patterns: You analyze discharge rates, idle times, and load conditions to forecast maintenance needs.

Environmental conditions: You monitor ambient temperature and humidity to adjust maintenance schedules.

AI algorithms now automate data collection and analysis. You receive real-time insights that help you act before problems escalate. The shift from manual inspections to AI-powered monitoring improves both efficiency and accuracy.

3.2 Failure Prediction

Predictive monitoring systems give you the power to forecast failures before they disrupt operations. The system uses deep learning and advanced analytics to detect subtle changes in battery behavior. You benefit from early warnings that allow you to schedule maintenance and avoid costly downtime.

Current predictive analytics models, especially those using deep learning, show strong potential for forecasting battery failures in inspection robots.

These models achieve significant detection power, but complex fault mechanisms can limit accuracy.

New predictive algorithms improve detection performance and reduce fault and inspection costs by 33–50%.

You see the impact of predictive monitoring in real-world results:

AI predictive maintenance can reduce unplanned downtime by up to 50%.

A Fortune 500 manufacturer achieved a 45% reduction in unplanned downtime, saving $2.8 million annually.

McKinsey reports that organizations using AI maintenance strategies see 15-25% gains in equipment effectiveness.

Frito-Lay reduced unplanned disruptions to just 2.88% with predictive systems.

General Motors reported a 15% reduction in unexpected downtime, saving $20 million annually.

Deloitte noted a 5%-20% boost in productivity due to predictive maintenance.

Technique | Description |

|---|---|

Condition-Based Monitoring | Uses sensors to track real-time equipment conditions, triggering maintenance when parameters deviate from normal. |

Data-Driven Maintenance | Employs analytics and machine learning to forecast potential failures based on historical and real-time data. |

Prognostic Maintenance | Estimates the remaining useful life of machinery, aiding in accurate maintenance scheduling and avoiding unnecessary work. |

Real-Time Insights | Provides immediate information about equipment conditions for timely interventions. |

Actionable Alerts | Generates alerts for maintenance teams about potential issues, enabling proactive corrective actions. |

You use these predictive monitoring system techniques to reduce both the frequency and severity of unexpected failures. In robotics and infrastructure, this means fewer emergency repairs and more reliable operations. In consumer electronics, predictive monitoring helps you deliver longer-lasting products.

3.3 Maintenance Scheduling

You optimize maintenance scheduling by using predictive monitoring systems that analyze real-time and historical data. The system adapts to varying usage patterns and environmental conditions, ensuring each robot receives maintenance at the right time.

Method | Purpose |

|---|---|

Data Analytics | Use statistical models and machine learning for insights on scheduling. |

Condition Monitoring | Set up condition triggers for maintenance needs based on equipment status. |

Real-time Data Collection | Collect data to forecast maintenance needs and improve scheduling efficiency. |

Real-time data analysis helps you forecast faults and optimize maintenance schedules. You avoid unnecessary work and reduce costs by focusing on actual needs rather than fixed intervals. Continuous monitoring of equipment health enables proactive scheduling, which is crucial for adapting to different usage patterns in medical, security, and industrial robots.

Tip: Predictive monitoring systems help you balance maintenance workloads, extend battery life, and maximize uptime across your entire fleet.

AI-driven predictive maintenance systems automate the scheduling process. The system sends actionable alerts when it detects anomalies or predicts a failure. You can then prioritize repairs and allocate resources efficiently. This approach supports better battery management and reduces the risk of unexpected downtime.

You see these benefits in every sector. In medical robots, predictive scheduling ensures devices are always ready for patient care. In infrastructure inspection, you minimize disruptions by planning maintenance during low-usage periods. In security systems, you keep robots operational during critical events.

Predictive monitoring systems give you the tools to manage complex fleets with confidence. You improve reliability, reduce costs, and deliver better service to your clients.

Part 4: Benefits and Implementation

4.1 Uptime and Cost Savings

You maximize uptime and reduce costs by deploying a smart battery management system in your robot fleet. Predictive monitoring helps you schedule maintenance before failures occur. This approach keeps your robots operating in medical, security, and industrial environments. Smart management improves battery performance, lowering the total cost of ownership. Lithium-ion batteries deliver up to 98% energy efficiency, cutting utility costs by about 20% compared to older chemistries. You benefit from continuous opportunity charging, which allows 100% asset utilization and minimizes maintenance needs. Predictive analytics optimize battery cycles, reducing downtime and space requirements. For more on sustainable practices, see our approach to sustainability.

Enhanced battery management lowers operational costs.

Predictive monitoring reduces unplanned downtime.

Smart system design increases productivity across all sectors.

4.2 Safety and Efficiency

You improve safety and operational efficiency with advanced battery management strategies. Smart BMS regulates battery performance, preventing overheating and protecting equipment. Real-time monitoring directs energy where needed, minimizing losses. Predictive analytics optimize utilization during peak demand, reducing wastage. Digitalization enables remote management, which enhances safety for operators in hazardous environments like infrastructure inspection or medical robotics.

Real-time monitoring supports predictive maintenance.

Remote management increases operational efficiency.

Integration with smart energy infrastructure optimizes battery use.

BMS protects personnel by ensuring secure working conditions.

You can read our conflict minerals statement for more on responsible sourcing.

4.3 Integration and Security

You face challenges when integrating smart battery management systems into your robot fleet. Best practices help you overcome these obstacles. Use end-to-end encryption to secure communications and prevent data interception. Keep software up to date to protect against vulnerabilities. Isolate robots on secure networks and verify user identities to block unauthorized access. Segment sensitive data for layered protection. Conduct regular security assessments to identify and fix weaknesses.

Security Threats | Mitigation Strategies |

|---|---|

Wireless jamming | Strong authentication processes |

Reconnaissance and scanning | Continuous monitoring |

Information disclosure | AI-based and cryptographic solutions |

Abuse of privilege | Access control policies |

Information interception | Encryption of communication channels |

Physical damage | Tamper-resistant equipment |

Service disruption | Data integrity checks and redundancy |

You ensure robust integration by following these steps. For more on BMS integration, visit BMS and PCM.

Smart battery management systems and predictive monitoring transform how you maintain inspection robots. You use real-time data and advanced analytics to improve reliability, safety, and cost savings. The system automates battery management, delegates missions, and estimates battery consumption for each robot. You benefit from continuous data tracking, temperature monitoring, and anomaly detection. The system alerts you to issues and helps you optimize robot deployment in medical, security, infrastructure, and industrial sectors. You should evaluate your current management system and consult with solution providers to maximize fleet performance.

Mission delegation based on battery status increases robot efficiency.

Real-time data monitoring and diagnostics support predictive maintenance.

Battery consumption estimation and anomaly detection improve operational reliability.

Automating battery management reduces human error and enhances safety with AI-driven object detection models.

FAQ

What makes a smart battery management system essential for inspection robots?

You need a smart battery management system to monitor and protect each battery in your robot. This system helps you avoid failures, extend battery life, and ensure safe operation in industrial, medical, and security environments.

How does predictive maintenance improve battery performance?

Predictive maintenance uses real-time battery data to forecast issues before they happen. You can schedule service only when needed. This approach reduces downtime, lowers costs, and keeps your battery running efficiently in robots across infrastructure and industrial sectors.

Can a smart battery management system support different lithium battery chemistries?

Yes. You can use a smart battery management system with LiFePO4, NMC, LCO, LMO, LTO, solid-state, and lithium metal batteries. This flexibility lets you choose the best battery for your robotic applications.

How does remote monitoring help manage large robot fleets?

Remote monitoring gives you instant access to battery status and health for every robot in your fleet. You can track performance, detect problems early, and plan maintenance. This system supports efficient operations in security, infrastructure, and industrial settings.

What security measures protect battery data in smart systems?

You protect battery data by using encryption, secure networks, and regular software updates. These measures keep your system safe from threats and ensure reliable operation for robots in critical applications.