You see the impact of lightweight battery design in industries demanding ergonomic solutions.

Wearable technology reduces hospital costs by 16% over five years.

63% of Americans use fitness trackers or smartwatches.

Manufacturers rely on lithium-ion and lithium polymer batteries for lightweight devices, longer runtime, and Battery Traceability.

Key Takeaways

Lightweight battery technologies, like thin lithium-ion and lithium polymer batteries, enhance device portability and user comfort.

Choosing the right battery technology improves ergonomics, reduces device weight, and extends runtime, benefiting both medical and industrial applications.

Implementing battery traceability ensures compliance, enhances quality control, and builds trust in supply chains, crucial for B2B clients.

Part 1: Lightweight Battery Technologies

1.1 Thin Lithium Ion Battery

You rely on thin lithium ion battery solutions to achieve optimal battery pack design for portable devices. Thin lithium ion battery advancements drive weight reduction and miniaturization in medical and industrial battery solution applications. Lithium-ion battery innovations include thinner separators (12 to 25.4 micrometers), lightweight polymer separators, and flexible, porous designs. These features improve thermal stability and ion conductivity. Smaller, uniform electrode particles increase surface area, which boosts conductivity and enables faster lithium-ion movement. Thin-film construction techniques, especially with silicon anodes, enhance capacity retention and cycling stability. Flexible lithium ion batteries support ergonomic battery design, making devices lighter and more comfortable for users.

Tip: Advanced lithium battery technology enables you to create smaller, more ergonomic devices without sacrificing power or performance.

1.2 Thin Lithium Polymer Batteries

Thin lithium polymer batteries offer significant advantages for battery pack design. You benefit from their lightweight polymer pouch construction, which reduces device bulk and improves portability. Lithium polymer battery packs deliver high energy density and flexible lithium ion batteries integration. The table below compares thin lithium ion battery and thin lithium polymer batteries:

Feature | Lithium-Ion | Lithium Polymer |

|---|---|---|

Weight | Heavier (metal case) | Lighter (polymer pouch) |

Energy Density | Up to 300 Wh/kg | 250–280 Wh/kg |

Thin lithium polymer batteries support flexible battery design, which is essential for wearables and industrial battery solution devices. You achieve better ergonomics and runtime with flexible lithium ion batteries. Battery technology continues to evolve, with lithium-sulfur and flexible battery technologies offering higher energy density, improved environmental impact, and cost efficiency. The table below highlights these features:

Feature | Description |

|---|---|

Energy Storage Capacity | Can store more than double the energy of conventional lithium-ion batteries. |

Environmental Impact | Uses materials with lower environmental impact and is less reliant on scarce metals. |

Cost Efficiency | Sulfur is inexpensive and widely available compared to cobalt or nickel. |

Flexibility | Design enables ultra-flexible batteries suitable for wearable devices. |

You enhance battery pack design by choosing the right battery technology for your application. Flexible lithium ion batteries and thin lithium polymer batteries improve device comfort and portability, supporting your business goals.

Part 2: Portability and User Comfort

2.1 Device Weight and Ergonomics

You improve device usability and comfort by selecting lightweight lithium battery packs. In medical applications, such as portable ultrasound probes, the choice of battery technology directly affects the energy to weight ratio and overall device weight. The following table compares wired and wireless probe weights and their usability impact:

Device Type | Weight (g) | Usability Impact |

|---|---|---|

Wired Probes | ~100 | Generally lighter, easier to handle for prolonged use. |

Wireless Models | 300-400 | Heavier, can cause discomfort during extended use, affecting imaging quality. |

You see similar trends in industrial devices, where lighter battery packs reduce operator fatigue and improve workflow efficiency. For example, the BioAccess portable small bone drill achieved a 36% weight reduction by switching from alkaline batteries to lithium metal oxide batteries. This change not only lowered the device weight but also increased drilling speed and active drill time. You benefit from a higher energy to weight ratio, which translates to longer runtime and power delivery without sacrificing comfort.

Note: Reducing device bulk with advanced battery technology enhances ergonomics, making devices easier to carry and operate for extended periods.

2.2 Flexible Design Integration

You face technical challenges when integrating flexible battery technology into compact devices. Balancing energy density with power delivery is crucial, as smaller batteries may limit runtime and efficiency. You must also consider structural integrity, since compact designs can compromise mechanical robustness and risk damage under stress. Safety remains a top priority, with increased risks of thermal runaway requiring strict standards and testing.

To overcome these challenges, you can use advanced chemistries like silicon-anode cells, smart battery management systems (BMS), and robust materials. Flexible battery technology often relies on gel polymer or solid-state electrolytes to prevent leakage and maintain flexibility. You may also explore stretchable batteries using materials such as carbon nanotubes (CNTs) and graphene, which enhance both mechanical and electrical properties.

Key integration challenges and solutions:

Performance: Balancing energy density and power delivery.

Structural Integrity: Ensuring mechanical robustness.

Safety: Meeting strict safety standards.

Electrolyte Challenges: Using gel polymer or solid-state electrolytes.

Stretchability: Developing materials that bend and stretch.

Material Innovations: Utilizing CNTs and graphene.

Flexible battery packs allow you to design devices that conform to the user’s body or workspace, improving comfort and reducing bulk. In wearable medical devices, flexible batteries bend and stretch to fit the body’s contours, enhancing comfort and minimizing bulkiness. You also benefit from improved airflow, which reduces heat and moisture buildup during prolonged use.

2.3 Application Examples

You see the impact of lightweight battery technology across multiple sectors. In medical devices, implantable medical devices (IMDs) such as pacemakers and deep brain stimulators rely on advanced lithium battery packs for critical treatments. These devices report improved patient outcomes and reduced need for battery replacement or recharging. Energy harvesting techniques, including electromagnetic, ultrasound, and thermoelectric generators (TEGs), provide sustainable power sources and enhance device functionality.

Application Type | Example Devices | Reported Outcomes |

|---|---|---|

Implantable Medical Devices (IMDs) | Pacemakers, Deep Brain Stimulators | Improved patient outcomes, critical treatments, reduced need for battery replacement or recharging. |

Energy Harvesting Techniques | Electromagnetic, Ultrasound, TEGs | Sustainable power sources, enhanced device functionality, access to inexhaustible energy from the body. |

In industrial settings, thin lithium-ion and lithium polymer battery packs deliver operational efficiency and safety. You benefit from enhanced safety, lighter weight, higher energy density, better thermal stability, and faster charging times. The following table summarizes these advantages:

Advantage | Description |

|---|---|

Enhanced Safety | Polymer batteries use solid or gel-like electrolytes, reducing the risk of leaks and fires. |

Lighter Weight | They are generally lighter, which is crucial for devices needing to minimize weight. |

Higher Energy Density | Polymer batteries can store more energy in a smaller space, leading to longer battery life. |

Better Thermal Stability | They handle heat better, reducing the risk of overheating during use. |

Enhanced Durability | Longer lifespan due to stable electrolytes, resulting in fewer replacements needed. |

Faster Charging Times | Superior conductivity allows for quicker charging, improving productivity and reducing downtime. |

You also find applications in robotics, security systems, infrastructure, and consumer electronics. Lightweight battery technology improves the energy to weight ratio, enabling longer runtime and power delivery in compact devices. You achieve greater portability, enhanced user comfort, and improved operational efficiency across these sectors.

Part 3: Trade-Offs and Battery Traceability

3.1 Performance vs. Weight

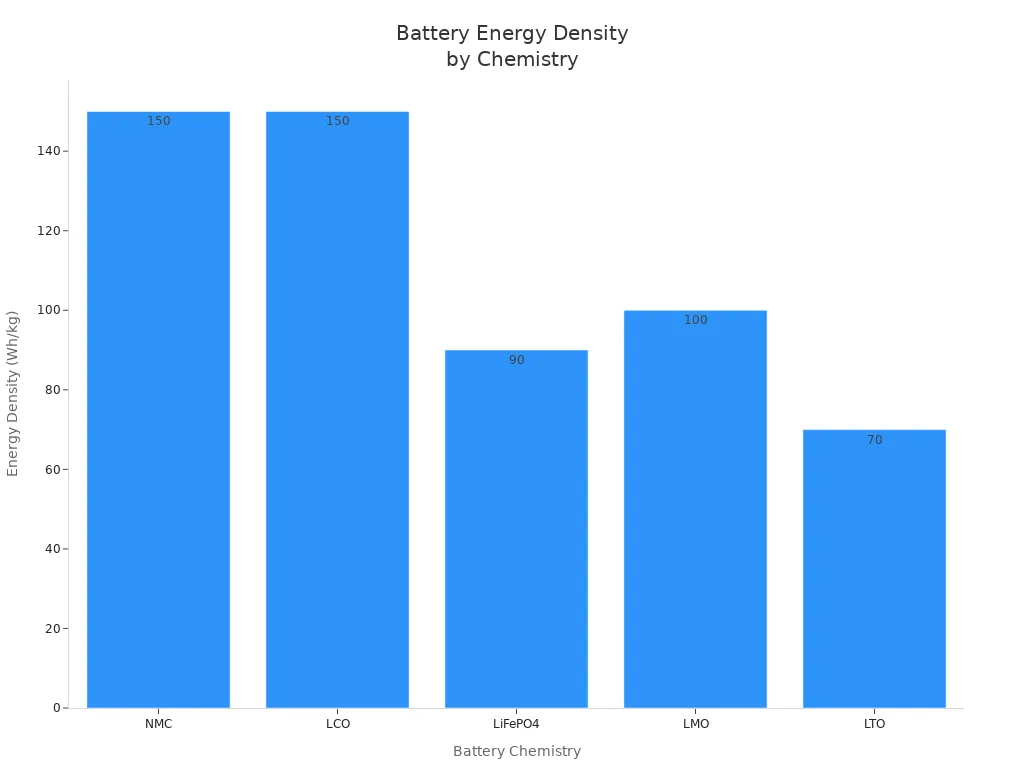

You face critical decisions when selecting a thin lithium ion battery for portable devices. Balancing energy density, cycle life, and weight determines your device’s runtime and user experience. The table below compares key lithium battery chemistries:

Chemistry | Energy Density (Wh/kg) | Cycle Life (cycles) | Use Cases |

|---|---|---|---|

NMC | 160–270 | 1,000–2,000 | Electric vehicles, portable power |

LCO | 180–230 | 500–1,000 | Laptops, medical devices |

LiFePO4 | 100–180 | 2,000–5,000 | Infrastructure, stationary storage |

LMO | 120–170 | 300–700 | Power tools, medical equipment |

LTO | 60–90 | 10,000–20,000 | Grid storage, rapid-charge vehicles |

Reducing battery weight with a thin lithium ion battery increases portability and extends device runtime. You achieve longer operational times, which is essential for medical and industrial applications. Devices with higher energy density and specific energy deliver better performance and user satisfaction.

3.2 Durability and Safety

You must prioritize durability and safety when integrating thin lithium ion battery packs into high-use environments. Industrial applications demand batteries that withstand frequent cycles and short current peaks. The 18650 lithium-ion cell, rated at 2Ah and 3.60 volts, demonstrates reliability in demanding conditions. Safety certifications such as UL 1642, UL 2054, IEC 62133, and CE Marking ensure compliance and protect users. The table below summarizes key safety standards:

Certification | Description |

|---|---|

UL 1642 | Tests lithium cells for safety |

UL 2054 | Covers battery packs for portable applications |

IEC 62133 | Safety for portable sealed secondary cells |

CE Marking | Health, safety, and environmental protection |

Tip: Always verify that your thin lithium ion battery meets international safety standards and environmental requirements. For sustainability practices, see sustainability. For conflict minerals compliance, refer to the conflict minerals statement.

3.3 Battery Traceability

Battery traceability plays a vital role in compliance and quality assurance for B2B clients. You need digital records to track each thin lithium ion battery from production to end-of-life. This process increases supply chain visibility, improves quality control, and reduces risk. The table below highlights battery traceability benefits:

Aspect | Description |

|---|---|

Regulatory Landscape | Evolving regulations require traceability in supply chains |

Digital Records | Track lifecycle of each battery |

Stakeholder Trust | Ensures adherence to safety and environmental standards |

Visibility in Supply Chain | Improves compliance and quality assurance |

To implement battery traceability, you should assess compliance readiness, establish continuous data collection, audit lifecycle data, and invest in secure data sharing systems. These steps help you meet regulatory requirements and maintain high standards in medical and industrial device manufacturing.

You gain compact design, lightweight nature, high energy density, long lifespan, and versatility with thin lithium polymer batteries.

Benefit | Description |

|---|---|

Compact Design | Occupies up to 80% less space |

Lightweight Nature | Weighs 60-80% less than alternatives |

High Energy Density | Up to 95% charge/discharge efficiency |

Long Lifespan | Up to 10 years, 2,000-5,000 cycles |

Versatility | Suitable for diverse industries |

Tips for selection:

Choose thin lithium polymer batteries for portability and long battery life.

Prioritize traceability for compliance.

Assess cost factors and integration needs.

Request a custom battery solution for tailored support.

Emerging trends in miniaturization and flexible batteries will further enhance device comfort and portability.

FAQ

What lithium battery chemistries does Large Power recommend for lightweight B2B devices?

Chemistry | Voltage (V) | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

3.6 | 150–300 | 500–2,000 | |

3.7 | 250–280 | 1,000–2,000 |

How does battery traceability benefit your business?

You improve compliance, quality assurance, and supply chain transparency. Traceability helps you meet regulatory standards and reduces risk in medical and industrial device manufacturing.

Can Large Power provide custom lithium battery solutions for unique B2B applications?

You can request a custom battery solution from Large Power. The team tailors lithium battery packs to your device specifications and industry requirements.