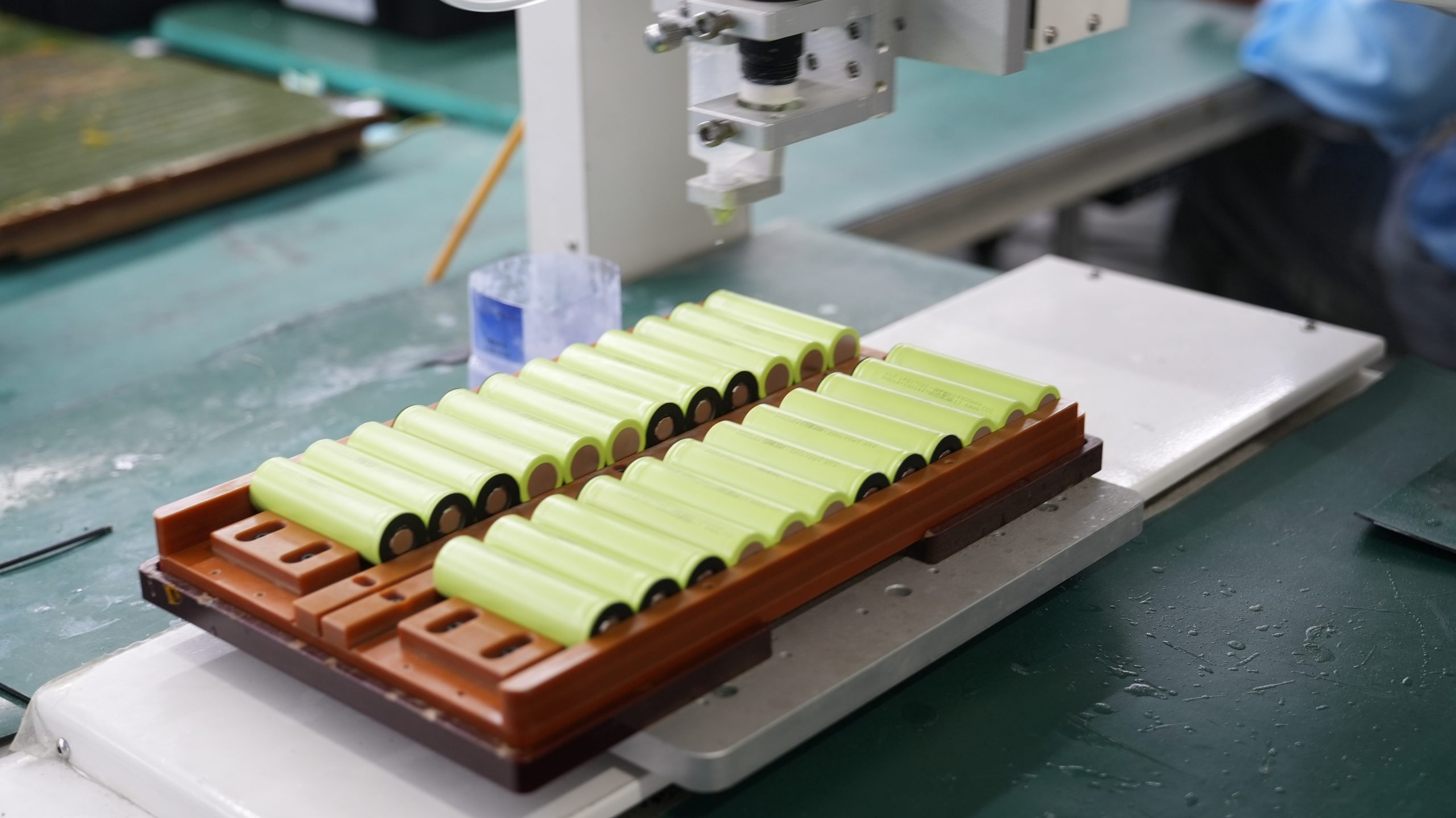

Long-life batteries, especially lithium-ion batteries, help you minimize costs in smart warehouses by supporting continuous operations and reducing labor. You can rely on lithium-ion batteries for AGVs and pallet jack battery packs because they deliver quick charging capabilities and long battery life. Lithium batteries offer lower maintenance, consistent performance, and safer handling. Companies maximize warehouse capabilities with lithium-ion technology, saving on cost and maintenance. You reduce downtime and replacement cycles, keeping batteries running efficiently.

Key Takeaways

Switching to lithium-ion batteries can significantly reduce labor costs by minimizing downtime and eliminating the need for manual battery swaps.

Lithium-ion batteries last longer than lead-acid batteries, reducing replacement frequency and saving money on operational costs.

These batteries require almost no maintenance, freeing up your team to focus on core tasks and improving overall safety in the warehouse.

Fast charging capabilities of lithium-ion batteries allow for opportunity charging, keeping equipment operational and reducing interruptions.

Investing in lithium-ion technology supports sustainability goals while enhancing productivity and efficiency in warehouse operations.

Part1: Reduce Labor Costs

1.1 Lithium-Ion for Automation

You can boost warehouse productivity by using lithium-ion batteries in automated guided vehicles (AGVs) and pallet jacks. These lithium batteries deliver longer operating times, which means your equipment runs for more hours without interruption. You do not need to stop operations frequently for charging, so your team spends less time waiting and more time working.

Tip: Lithium-ion batteries allow opportunity charging during short breaks. You can keep your equipment running with minimal downtime.

Here is a comparison of charging times and operational impact:

Charging Type | Charging Time | Downtime Reduction | Operational Impact |

|---|---|---|---|

Lithium-ion | 1-2 hours | Less than 1 hour/week | More hours of forklift usage per day |

Lead-acid | 6-8 hours | Higher downtime | Limited operational hours |

Lithium-ion batteries also have higher energy density. You get longer run times and faster charging, which means your warehouse operations become more efficient. You do not need to assign staff to maintain batteries or handle regular water top-ups. This improvement in productivity lets your team focus on core tasks instead of battery maintenance.

1.2 Minimize Manual Battery Swaps

You can reduce labor costs by switching from lead-acid batteries to lithium-ion batteries. Lithium batteries stay in your equipment during charging, so you do not need special lifting equipment or trained personnel for battery swaps. This change lowers the risk of injury and saves time.

Lithium-ion batteries charge in 1-2 hours, while lead-acid batteries need about 16 hours (8 hours charging plus 8 hours cooling).

You do not need to transport or handle lithium batteries for charging, unlike lead-acid batteries.

Lithium-ion batteries require no maintenance, while lead-acid batteries need regular watering and handling.

A major equipment manufacturer reported saving over $1 million by switching to lithium-ion batteries. You can achieve similar savings by reducing lost productivity from charging and swapping lead-acid batteries. The lightweight design of lithium-ion batteries also makes them easier to maneuver in tight warehouse spaces.

Part2: Minimize Costs with Long-Life Batteries

Long-life batteries play a critical role in helping you minimize costs and stabilize your warehouse budgets. By choosing lithium-ion batteries for your warehouse operations, you can reduce unexpected expenses and achieve a more predictable total cost of ownership. These batteries offer a cost-efficient option for businesses that want to improve productivity and energy efficiency while keeping operational costs under control.

2.1 Fewer Replacements

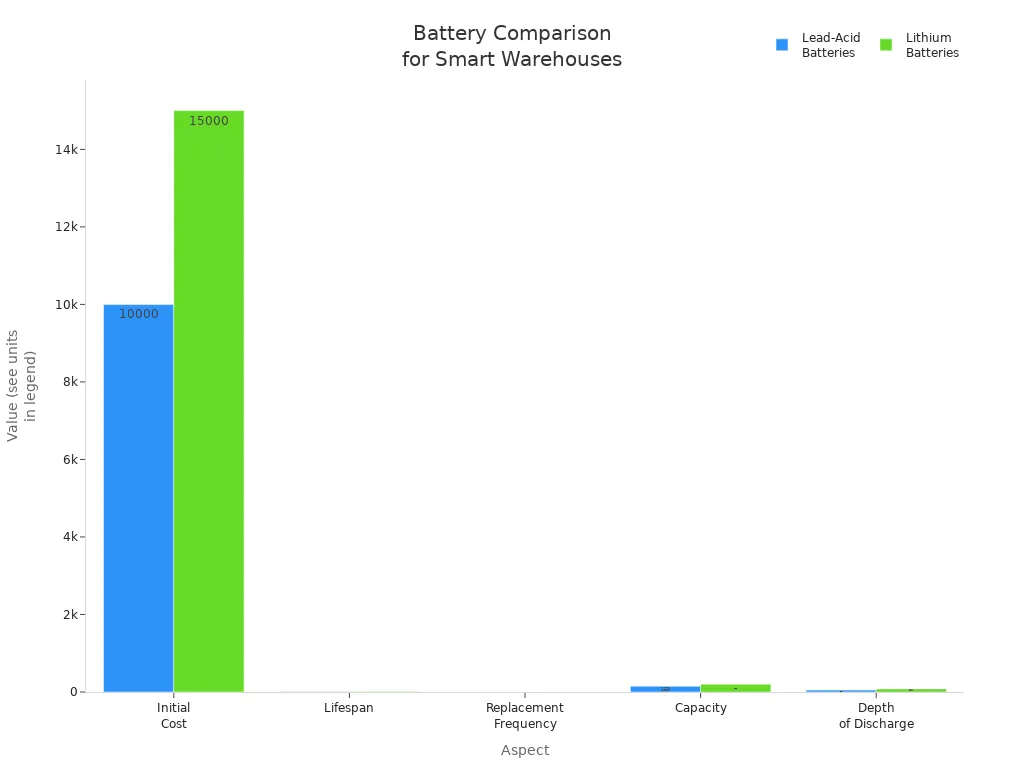

You can significantly lower replacement costs by switching to lithium-ion batteries. These batteries last much longer than traditional lead-acid batteries, which means you do not need to replace them as often. The following table shows the average lifespan of different battery types used in smart warehouses:

Battery Type | Average Lifespan (Cycles) |

|---|---|

2,000 – 10,000 | |

NMC | 1,000 – 2,500 |

Lithium Polymer (LiPo) | 300 – 500 |

Lead-Acid | 3 – 5 years |

Lithium batteries, such as LiFePO4 and NMC, can last between 2,000 and 10,000 cycles. In contrast, lead-acid batteries typically require replacement after only 300-500 full charge-discharge cycles. In high-intensity warehouse operations, this often means replacing lead-acid batteries every 18-24 months. Lithium-ion batteries, on the other hand, can last reliably for 5–8 years, reducing replacement needs by up to 70%. This extended lifespan helps you minimize costs and avoid frequent disruptions to your operations.

Lithium batteries can last up to 3,000 cycles, while lead-acid batteries last about 1,500 cycles.

The total cost of ownership can save you up to $3,000 over the battery’s lifespan due to reduced replacement and maintenance costs.

Lithium-ion batteries extend replacement intervals by years, reducing capital expenditure churn across multiple warehouse sites.

Note: By reducing the frequency of battery replacements, you can reinvest savings into other areas of your business, such as automation, robotics, or infrastructure upgrades.

2.2 Lower Maintenance Needs

Lithium-ion batteries require almost no maintenance compared to lead-acid batteries. You do not need to perform watering, acid checks, or equalizing charges. This zero-maintenance feature eliminates labor strain and lowers the risk of maintenance errors. You also avoid corrosion issues and do not need special ventilation for safe indoor use, making lithium-ion batteries a cost-efficient option for modern warehouses.

No watering required

No acid checks necessary

No equalizing charges needed

No corrosion issues

No ventilation required for indoor safety

By eliminating these maintenance tasks, you reduce labor costs and free up your team to focus on core warehouse operations. This also improves safety and reduces the risk of accidents related to battery handling. The steady voltage and better depth of discharge tolerance of lithium batteries further enhance performance and energy efficiency, supporting continuous productivity in your warehouse.

Tip: Lithium-ion batteries help stabilize your budget and minimize unexpected expenses. Their long cycle life and minimal maintenance needs contribute to lower operational costs. For more on how long-life batteries support sustainability and responsible sourcing, see our approach to sustainability.

Switching to lithium-ion batteries in your pallet jack battery packs and AGVs allows you to minimize costs, improve energy efficiency, and extend the lifespan of your equipment. This approach supports a more sustainable and cost-efficient warehouse environment.

Part3: Energy Efficiency and Downtime

3.1 Lithium-Ion Energy Density

You can improve energy efficiency in warehouses by choosing lithium-ion batteries with high energy density. These batteries store more energy in a smaller space, which means your equipment runs longer between charges. You get consistent power output throughout the battery’s charge cycle, so your pallet jack battery packs and AGVs maintain peak performance. This reliability supports continuous operations in logistics, robotics, and industrial sectors.

Here is a comparison of technical data for different battery chemistries:

Battery Chemistry | Energy Density (Wh/kg) | Cycle Life (cycles) | Application Scenarios |

|---|---|---|---|

Lithium Iron Phosphate | 90-160 | 2,000-10,000 | Industrial, medical, robotics |

Lithium Nickel Manganese Cobalt (NMC) | 150-220 | 1,000-2,500 | Security systems, infrastructure |

Lithium Polymer | 100-200 | 300-500 | Consumer electronics, robotics |

Lead-Acid | 30-50 | 300-500 | Industrial, backup systems |

Lithium-ion batteries outperform lead-acid batteries in both energy density and cycle life. You can use lithium batteries in medical devices, security systems, and industrial automation for longer run times and lower costs. If you want to optimize battery packs, consider integrating a battery management system (BMS) for safety and performance.

Tip: High energy density means fewer battery replacements and less downtime for your warehouse equipment.

3.2 Less Downtime

You can reduce downtime in your warehouse by using lithium-ion batteries. These batteries charge in just 1-2 hours, while lead-acid batteries need 8 hours to charge and another 8 hours to cool down. You can recharge lithium-ion batteries during operator breaks, so your pallet jack battery packs stay ready for use.

Battery Type | Charging Time | Cooldown Required |

|---|---|---|

Lead-Acid | 8 hours | Yes |

Lithium-Ion | 1-2 hours | No |

Lithium-ion batteries allow opportunity charging during off-peak hours.

Lead-acid batteries require long charging and cooldown periods.

Lithium-ion batteries keep your forklifts and AGVs running longer without battery swaps.

You benefit from fast-charging capabilities and longer operating times. Your warehouse operations continue smoothly, even during demand response events or grid fluctuations. Lithium-ion batteries help you maintain productivity and minimize interruptions. You save on cost by reducing downtime and keeping your equipment available throughout the day.

Part4: Equipment Longevity

4.1 Impact on Warehouse Assets

You can extend the lifespan of your warehouse equipment by choosing lithium-ion batteries over lead-acid batteries. Lithium-ion technology reduces the frequency of battery replacements and keeps your AGVs and pallet jacks running longer. When you use lithium batteries, you lower operational costs and minimize downtime. Rapid charging increases equipment availability, so your operations stay efficient.

Here is a table showing how lithium-ion batteries benefit your warehouse assets:

Feature | Benefit |

|---|---|

Extended Lifespan | Reduces frequency of battery replacements |

Maintenance-Free Operation | Lowers operational costs and downtime |

Rapid Charging | Increases equipment availability |

Advanced Smart Features | Enhances efficiency and productivity |

Many warehouse managers report that lithium batteries last longer between charges than lead-acid batteries. One user shared, “The charge just goes forever and he can finish his shift on just one charge.” Another noted, “It has lasted longer between recharges than the previous battery packs that we’ve used.” These experiences show that lithium-ion batteries help you get more value from your equipment and reduce the need for frequent battery changes.

4.2 Maintenance Best Practices

You can maximize the life of your lithium-ion batteries by following a few simple maintenance strategies. Regular cleaning of battery terminals prevents corrosion and keeps electricity flowing smoothly. Store your batteries in a cool, dry place to avoid damage from extreme temperatures. Timely recharging after each use helps prevent capacity loss, while regular capacity testing lets you monitor battery health.

Clean battery terminals regularly to prevent corrosion.

Store batteries in a cool, dry environment.

Recharge batteries promptly after use.

Test battery capacity to track performance.

Establishing a maintenance routine can extend battery lifespan from a few months to over five years. Since commercial battery systems can cost thousands to replace, these habits save you money and reduce downtime. Small daily actions, like cleaning terminals, have a big impact on battery longevity. For advanced monitoring, consider using a battery management system (BMS) to optimize performance and safety.

You can transform warehouses by investing in lithium-ion battery packs. These batteries deliver longer life, faster charging, and minimal maintenance, which help you reduce labor costs and improve efficiency.

Longer battery life streamlines workflow and minimizes interruptions.

Electric forklifts require less maintenance, leading to fewer breakdowns.

Evaluate your current battery systems for total cost of ownership and operational impact.

Lithium-ion upgrades support sustainability goals and future-ready automation.

Key Performance Indicator | Description |

|---|---|

Charging Time | Faster charging boosts warehouse productivity. |

Depth of Discharge (DoD) | Higher DoD increases reliability and lifespan. |

Maintenance Practices | Simple upkeep extends battery performance. |

FAQ

What are the main benefits of lithium battery packs in smart warehouses?

You gain longer operating times, faster charging, and lower maintenance. Lithium battery packs help you reduce labor costs and minimize downtime. You improve productivity and stabilize your budget across industrial, robotics, and infrastructure applications.

How often do you need to replace lithium battery packs compared to lead-acid batteries?

You replace lithium battery packs every 5–8 years, while lead-acid batteries need replacement every 18–24 months. Lithium chemistries such as LiFePO4 and NMC offer up to 10,000 cycles in industrial and medical sectors.

Can lithium battery packs improve safety in warehouse operations?

You improve safety by using lithium battery packs. These batteries require no watering or acid checks. You avoid risks of spills and corrosion. Lithium packs support secure handling in robotics, security systems, and logistics.

What maintenance do lithium battery packs require?

You perform minimal maintenance. Clean terminals regularly and store batteries in a cool, dry place. Lithium packs do not need watering or equalizing charges. You monitor performance with a battery management system for optimal results.

Which application scenarios benefit most from lithium battery packs?

You see strong results in industrial automation, medical devices, robotics, and security systems. Lithium battery packs deliver high energy density and long cycle life. You support continuous operations and reduce operational costs in these sectors.