You need medical device battery certification and medical batteries safety certification to protect patients and ensure device reliability. Battery manufacturers must implement quality management systems and Battery Traceability. The table below shows how standards address safety features for use near patients, validation and verification, and serialization and traceability in battery production.

Standard | Requirement |

|---|---|

IEC 62133 | Batteries must meet safety requirements for safe operation. |

UL 2054 | Ensures batteries are designed with safety features for use near patients. |

ISO 13485 | Requires a quality management system to mitigate risks and ensure reliability. |

IEC 60601-1 | Ensures biocompatibility and safety in medical environments. |

FDA | Mandates safety considerations, labeling, and testing for medical device batteries. |

Non-certified battery packs for medical devices can cause thermal runaway, explosions, and fires, especially during charging cycles with alternative chargers.

Key Takeaways

Medical device batteries must meet strict safety standards like ISO 13485 and UL certifications to ensure patient safety and device reliability.

Implementing robust battery traceability systems helps track components from sourcing to end-of-life, enhancing compliance and risk management.

Maintaining comprehensive documentation and supplier audits is essential for regulatory compliance and effective complaint handling in battery production.

Part 1: Medical Batteries Safety Certification

1.1 ISO 13485 Certification

You must meet strict medical device battery requirements to ensure patient safety and device reliability. ISO 13485 certification plays a central role in this process. This standard requires you to implement a robust Quality Management System (QMS) for the design and manufacture of medical device batteries. You need to align your manufacturing processes with ISO 13485 certification to comply with safety regulatory requirements and global regulations.

ISO 13485 certification confirms that your organization can consistently deliver safe and effective batteries for medical applications. You must document every step, from sourcing raw materials to final product testing. The standard emphasizes quality management, safety, reliability, and thorough documentation.

You must establish clear procedures for risk mitigation and product validation.

You need to maintain detailed records for traceability and complaint analysis.

You must ensure that your batteries meet medical device battery requirements for performance and safety.

ISO 13485 certification is not just a regulatory checkbox. It is a foundation for building trust with healthcare providers and device manufacturers.

1.2 FDA and UL Standards

You must navigate both FDA and UL standards to meet medical device battery requirements. The FDA focuses on safety and effectiveness, requiring you to conform to recognized consensus standards. UL standards, such as UL 2054 and UL 1642, emphasize battery safety and performance testing. Certification under these standards streamlines your regulatory process and supports compliance.

Aspect | FDA Approach | UL Approach |

|---|---|---|

Certification Requirement | Conformance with recognized consensus standards supports safety assurance. | Certification is voluntary but recognized standards streamline regulatory processes. |

Focus | Ensures safety and effectiveness of medical devices. | Emphasizes battery safety standards and performance testing. |

Regulatory Impact | Supports premarket review requirements. | Anticipated to drive regulatory compliance among manufacturers. |

You must understand the differences between FDA and UL standards to ensure your batteries meet all medical device battery requirements. FDA regulations require you to address labeling, safety, and testing. UL standards focus on physical construction, electrical performance, and environmental testing.

UL 2054 covers household and commercial batteries.

UL 1642 applies to lithium batteries (cells).

IEC 62133 sets global safety requirements for rechargeable lithium-ion batteries.

You must also consider international standards.

Region | Key Characteristics |

|---|---|

Europe | Stringent regulatory standards, high healthcare expenditure, focus on innovative technologies, compliance with EU directives. |

North America | Dominant market driven by technological innovation, mature infrastructure, emphasis on safety and biocompatibility. |

Asia Pacific | Rapid growth, large patient population, focus on affordable and reliable batteries, local manufacturing strategies. |

1.3 Medical Device Battery Requirements

You must meet several mandatory certifications to comply with medical device battery requirements. These certifications ensure that your batteries are safe, reliable, and suitable for use in handheld medical devices.

Standard | Description |

|---|---|

IEC 62133 | Safety requirements for portable sealed secondary cells containing alkaline or other non-acid electrolytes. |

UL 2054 | Recognized standard in North America for household and commercial batteries. |

DOT UN38.3 | Required for lithium-based products to ensure safe shipping and construction. |

You must certify all electrical and electronic devices, including batteries, under recognized safety standards. Certification does not guarantee continued functionality after abnormal conditions, but it ensures no harm to personnel or property. You may need to follow the certification path of the end product.

Medical device battery requirements include:

Physical construction: You must evaluate the design and materials to prevent hazards.

Electrical performance: You must assess voltage, capacity, and discharge characteristics for safe operation.

Environmental testing: You must ensure performance under various conditions, such as temperature and humidity.

Safety features: You must mandate protection circuits to prevent overcharging and thermal runaway.

IEC 62133 is recognized globally for ensuring the safety of lithium-ion batteries in medical devices. This standard establishes comprehensive testing protocols to mitigate risks and enhance reliability. UL 1642 and UL 2054 further support safety regulatory requirements by addressing risks like overcharging and thermal runaway.

Effective complaint handling processes are essential for risk management. You must comply with ISO 13485:2016 and 21 CFR Part 820 to proactively manage complaints and prevent costly recalls or patient harm.

Certification improves complaint analysis and risk management. You can integrate postmarket surveillance and complaint handling into your risk management framework. This systematic approach helps you collect and analyze postmarket data, improving safety and performance for medical device batteries.

You must stay updated on medical device battery requirements to maintain compliance and protect your reputation in the healthcare sector.

Part 2: Battery Traceability Process

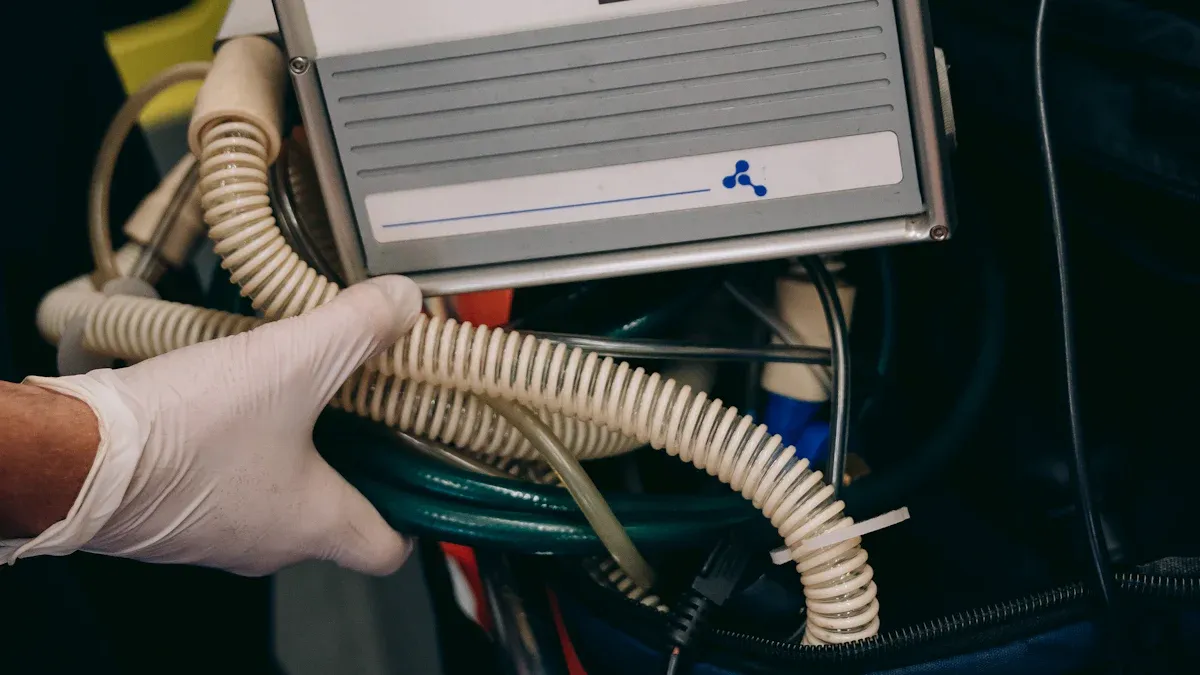

Battery traceability stands at the core of regulatory compliance and risk management for handheld medical devices. You must implement robust systems to track every battery component from raw material sourcing to end-of-life management. This process ensures you can identify and resolve issues quickly, maintain product reliability, and meet global standards such as ISO 13485.

2.1 Supply Chain Tracking

You need to establish a transparent supply chain for lithium battery packs used in medical devices. Supply chain tracking enables you to monitor every step, from sourcing lithium, cobalt, and other critical minerals to final assembly. This approach supports sustainability and conflict minerals statements, which are essential for regulatory audits.

Effective supply chain tracking methods include:

Digital Twins: Use interactive models to visualize and optimize battery production.

AI-Driven Forecasting: Predict demand and align production schedules for lithium-ion, LiFePO4, NMC, LCO, LMO, and LTO chemistries.

Simulation Tools: Test scenarios and optimize performance in real time.

Secure Ledger Systems: Record every transaction from raw materials to delivery, enhancing accountability and preventing fraud.

You should identify vulnerabilities, create contingency plans, and diversify your supplier base to avoid disruptions. Enhanced traceability through product identification data at the packaging line level and digital fingerprinting using barcodes help confirm authenticity and prevent counterfeit batteries. Rigorous supplier evaluation processes ensure safety and compliance, supporting US Unique Device Identification (UDI) and EU Medical Device Regulation (EU MDR) requirements.

Supply Chain Tracking Comparison Table

Method | Benefit | Application Scenario |

|---|---|---|

Digital Twins | Visibility, decision-making | Medical, robotics, industrial |

AI Forecasting | Demand prediction, production alignment | Security, infrastructure |

Simulation Tools | Performance optimization | Consumer electronics, Large Power |

Secure Ledger | Accountability, fraud prevention | Medical, industrial |

Tip: You can use digital fingerprinting and smartphone scans to verify battery authenticity and eliminate counterfeits in medical devices.

2.2 Documentation Practices

You must maintain comprehensive documentation to support battery traceability and regulatory compliance. Proper documentation practices impact supplier selection and quality assurance for lithium battery packs. You should match cells by brand, manufacturing lot, age, and voltage to ensure optimal performance for medical devices.

Best practices for documentation and supplier management:

Implement procedures for verifying battery compliance, including supplier audits and documentation reviews.

Update your Quality Management System to reflect new regulatory requirements.

Communicate with suppliers to ensure they provide the required documentation.

You should conduct in-process inspections to identify issues during assembly, such as poor connections. Effective supplier management involves selection, qualification, development, and ongoing assessment to maintain quality standards. You must record essential information for each battery pack, including serial number, testing date, tester identity, and diagnostic results. Store this data in a cloud-based system and write it back to the device’s chip for easy tracking.

Documentation and Regulatory Compliance Table

Requirement | Description |

|---|---|

Mandatory for battery manufacturers of medical device batteries, ensuring compliance with standards. | |

Traceability | Critical for ensuring safety, reliability, and uniformity in battery production. |

Supply Chain Management | Essential to avoid disruptions in the medical device field, ensuring timely delivery of components. |

Documentation and Record Keeping | Necessary for maintaining ISO 13485 certification and supporting regulatory compliance. |

Note: Effective documentation supports complaint analysis and enables you to trace defects back to their source for swift corrective action.

2.3 Quality Control Measures

You must implement rigorous quality control measures to ensure the reliability of lithium battery packs in medical devices. Electrochemical Impedance Spectroscopy (EIS) helps you estimate battery capacity and detect anomalies without invasive testing. Regular battery diagnostics allow you to monitor battery health and schedule timely replacements.

Key quality control measures:

Perform tests such as open-circuit voltage (OCV), AC internal resistance, and capacity checks.

Shorten test times to maintain production efficiency while ensuring compliance.

Continuously monitor test data to enhance analysis and improve battery performance.

You should serialize each battery pack after testing and record all diagnostic results. This system enables you to troubleshoot individual units and supports complaint analysis. Regulatory agencies evaluate your traceability systems during audits by reviewing raw material sourcing, component manufacturing, assembly, testing, and end-of-life management.

Industry Benchmarks for Battery Reliability

Benchmark | Description | Platform Voltage | Energy Density | Cycle Life |

|---|---|---|---|---|

High Power | Essential for medical and industrial applications | 3.7V-12V | 150-250 Wh/kg | 500-2000 |

Small Size | Supports compact device design | 3.2V-3.7V | 100-200 Wh/kg | 1000+ |

Reliability | Critical during emergencies and procedures | 3.7V-12V | 150-250 Wh/kg | 1000+ |

Safety Features | Includes short-circuit and overcurrent protection | 3.2V-3.7V | 100-200 Wh/kg | 500-2000 |

“Identification and traceability are essential to maintaining medical devices’ safety, quality, and performance. By effectively tracking each device from manufacturing through distribution and use, you can quickly identify and address any issues that may arise. This process ensures that if a defect or non-conformance is detected, it can be traced back to the source, allowing for swift corrective actions.”

You must prioritize battery traceability to enhance device reliability and support complaint analysis. By integrating serialization, cloud-based tracking, and comprehensive documentation, you can meet regulatory requirements and deliver safe, high-quality lithium battery packs for medical devices.

You gain reliability and safety by prioritizing battery traceability and certification for lithium battery packs in medical device applications (custom battery solutions). Ongoing ISO 13485 compliance delivers proactive risk management and preserves product integrity.

Next steps:

Review regulatory standards in the table below.

Strengthen documentation and supplier audits.

Regulatory Standard | Purpose |

|---|---|

UN 38.3 | Battery transport compliance |

IEC 62133 | Consumer and industrial safety |

UL 1642 / UL 2054 | U.S. lithium battery safety |

CE Marking | EU product certification |

Battery ID (2024) | Lifecycle tracking and recycling |

FAQ

What are the main requirements for lithium battery packs in medical devices?

You must meet strict requirements for safety, reliability, and traceability. Requirements include ISO 13485 certification, UL standards, and IEC 62133 compliance for lithium-ion and LiFePO4 chemistries.

How do requirements for lithium battery packs differ across application scenarios?

Requirements vary by sector. Medical, robotics, security, infrastructure, consumer electronics, and industrial platforms require specific requirements for platform voltage, energy density, and cycle life. See the table below.

Sector | Platform Voltage | Energy Density | Cycle Life | Requirements Focus |

|---|---|---|---|---|

3.7V-12V | 150-250 Wh/kg | 500-2000 | Safety, traceability | |

3.2V-3.7V | 100-200 Wh/kg | 1000+ | Reliability, requirements | |

3.7V-12V | 150-250 Wh/kg | 1000+ | Performance, requirements | |

3.2V-3.7V | 100-200 Wh/kg | 500-2000 | Compliance, requirements | |

3.7V-12V | 150-250 Wh/kg | 1000+ | Compactness, requirements | |

3.2V-3.7V | 100-200 Wh/kg | 500-2000 | Durability, requirements |

Where can you find custom battery solutions that meet all requirements?

You can contact Large Power for custom battery solutions that meet all requirements for lithium battery packs in medical, robotics, security, infrastructure, consumer electronics, and industrial sectors. Request a custom battery solution now.