You see rapid trends shaping batteries for robotics as industries demand better performance and safety. Lithium-ion battery technology, including chemistries like LiFePO4, NMC, and LCO, drives growth in robot battery packs. The market expands quickly as you seek longer runtimes and improved energy density. Battery innovation pushes cycle life and fast charging forward. You rely on advanced battery systems to unlock new capabilities and ensure reliability in industrial robotics.

Tip: Monitoring battery health helps you maximize the lifespan and efficiency of your robotic fleet.

Key Takeaways

Lithium-ion batteries dominate the robotics market due to their high energy density and long cycle life, making them ideal for both industrial and consumer applications.

Safety features in battery technology, such as thermal management and battery management systems, are crucial for preventing hazards and ensuring reliable operation in robotics.

Fast charging capabilities are advancing, allowing batteries to reach 80% capacity in under 15 minutes, which significantly reduces downtime and increases productivity.

Modular battery packs enable easy replacement of faulty modules without shutting down systems, enhancing operational efficiency and extending the lifespan of robotic platforms.

The robot battery market is projected to grow rapidly, driven by increased automation and advancements in lithium battery technologies, creating new opportunities for businesses.

Battery Types in Robotics

Lithium-Ion Batteries

You see lithium-ion batteries dominate the robotics market because they deliver high energy density, long cycle life, and reliable performance. In industrial robotics, you often rely on lithium battery packs built with chemistries like LiFePO4, NMC, LCO, and LMO. Each chemistry offers unique benefits:

Chemistry | Platform Voltage | Energy Density (Wh/kg) | Cycle Life (cycles) |

|---|---|---|---|

LiFePO4 | 3.2 V | 90–120 | 2000–5000 |

NMC | 3.7 V | 150–220 | 1000–2000 |

LCO | 3.6 V | 150–200 | 500–1000 |

LMO | 3.7 V | 100–150 | 300–700 |

You choose LiFePO4 for safety and long life in industrial robots. NMC and LCO batteries provide higher energy density, which suits mobile robots and consumer devices. You benefit from lithium-ion battery technology because it supports fast charging and maintains structural integrity, especially in cylindrical or prismatic formats.

Other Chemistries

You may encounter other battery types in robotics, though they hold smaller market shares. These include nickel-metal hydride, lead-acid, and sodium-ion batteries. Nickel-metal hydride batteries offer moderate energy density and good safety, but you find them less common in advanced robotics. Lead-acid batteries remain cost-effective for stationary robots or backup systems, but you sacrifice energy density and cycle life. Sodium-ion batteries emerge as alternatives for specific industrial applications, though you see limited adoption.

Note: Batteries deliver higher specific power than fuel cells or gasoline, making them ideal for untethered robots in both consumer and industrial settings.

Application Scenarios

You apply battery packs across diverse sectors:

Medical robotics: Surgical robots and patient-assist devices require safe, long-lasting batteries.

Security systems: Surveillance robots depend on reliable battery power for continuous operation.

Infrastructure: Transportation robots, such as automated guided vehicles, need robust battery packs for heavy-duty cycles.

Consumer electronics: Home robots and smart devices use compact lithium-ion batteries for portability.

Industrial robotics: Manufacturing robots demand high-capacity battery packs for extended runtimes and frequent charging cycles.

You select battery types based on safety, energy density, and cycle life to match each application’s requirements. You see battery technology as the foundation for innovation in robotics, driving efficiency and reliability in every sector.

Robot Battery Market Growth

Market Size and CAGR

You see the robot battery market expanding rapidly as industries invest in automation and advanced robotics. The global robot battery market shows strong growth, with projections indicating a compound annual growth rate (CAGR) above 15% over the next five years. You notice market dynamics shifting as lithium battery packs become the preferred choice for industrial robotics. Companies in manufacturing, logistics, and healthcare drive demand for high-performance battery solutions. You analyze robot battery market segmentation to identify opportunities in different regions and industries.

Region | Growth Factors |

|---|---|

Americas | Strong distribution networks, manufacturing infrastructure, and emphasis on domestic production. |

Europe | Regulatory pressures for sustainability and adoption of cleaner battery technologies. |

Middle East | Infrastructure constraints and capital availability influencing adoption timelines. |

Africa | Modular pack designs and remote diagnostics supporting distributed operations. |

Asia-Pacific | Largest manufacturing base with cost-competitive production and extensive R&D capabilities. |

You observe that Asia-Pacific leads the robot battery market due to its manufacturing base and R&D strength. Europe and the Americas follow, driven by sustainability and infrastructure investments. You track market growth prospects in emerging regions like Africa and the Middle East, where modular lithium battery packs and remote diagnostics create new opportunities.

Drivers of Growth

You recognize several factors fueling robot battery market growth. Industrial robotics adoption increases across manufacturing, automotive, aerospace, and healthcare. You rely on advancements in lithium battery technology, such as LiFePO4, NMC, LCO, and LMO chemistries, which improve energy density and operational time. Government incentives, including tax credits and subsidies, encourage investment in clean energy and battery technologies. You see smart robots requiring advanced battery functionalities, which further expands the market.

Increasing demand for industrial robots in manufacturing, automotive, aerospace, and healthcare.

Advancements in lithium battery technology, boosting energy density and operational time.

Government support for clean energy technologies, including tax credits and subsidies.

Emergence of smart robots needing advanced battery functionalities.

You use robot battery market analysis to evaluate how these drivers impact market segmentation and outlook. You identify opportunities for growth by focusing on lithium battery packs with high cycle life and platform voltage, such as LiFePO4 (3.2 V, 90–120 Wh/kg, 2000–5000 cycles) and NMC (3.7 V, 150–220 Wh/kg, 1000–2000 cycles).

Note: You maximize market opportunities by selecting lithium battery chemistries that match your operational needs and regulatory requirements.

Industrial Adoption

You see industrial adoption of advanced battery technologies accelerating robot battery market growth. Companies demand efficient power sources for robotics in manufacturing and logistics. You benefit from technological advancements in lithium-ion batteries, which improve efficiency and productivity. The increasing use of industrial robots across sectors drives the need for reliable battery solutions. Environmental regulations and sustainability goals push you to adopt cleaner battery technologies.

The rise in demand for efficient power sources leads to significant growth in the industrial robot battery market.

Technological advancements in lithium battery types, especially LiFePO4 and NMC, improve efficiency and productivity.

The increasing use of industrial robots in manufacturing and logistics drives demand for reliable batteries.

Environmental regulations and sustainability accelerate adoption of advanced battery technologies.

You monitor robot battery major market players as they invest in R&D and expand production capacity. You evaluate robot battery market outlook to plan for future investments and partnerships. You focus on lithium battery packs with proven performance and safety features to meet industrial requirements.

Tip: You stay ahead in the robot battery market by adopting modular lithium battery packs and integrating remote diagnostics for predictive maintenance.

Trends in Batteries for Robotics

Energy Density

You see energy density as a top priority in the robot battery market. Higher energy density allows you to design robots that run longer and work harder without increasing weight. Recent advancements in lithium batteries, especially chemistries like NMC (3.7 V, 150–220 Wh/kg, 1000–2000 cycles) and LCO (3.6 V, 150–200 Wh/kg, 500–1000 cycles), have made batteries lighter and more powerful. These improvements let your robots operate for extended periods on a single charge, which increases autonomy and productivity across industrial applications.

You notice that the global robot battery market now demands batteries for robotics that support longer runtimes and higher efficiency. This trend creates new opportunities for growth, especially as you look for ways to reduce downtime and maximize output. As you evaluate battery technology, you focus on energy density to stay competitive in a fast-changing market.

Tip: Higher energy density in lithium battery packs means you can deploy more compact robots or add new features without sacrificing performance.

Safety Features

You recognize that safety remains a critical concern in the robot battery market. Lithium battery packs, while powerful, can present risks such as thermal runaway or fire if not properly managed. You benefit from several new safety features that reduce these risks:

The American Bureau of Shipping developed a simulation model to predict thermal runaway behavior in lithium-ion batteries. This helps you understand and prevent fire hazards before they occur.

A new extinguishing agent targets thermal runaway reactions in lithium-ion batteries, cooling them quickly and stopping fires from spreading.

Comprehensive fire protection standards now guide your battery selection and integration, ensuring you meet the latest safety requirements.

You see these safety innovations as essential for industrial robots, where reliability and compliance drive market growth. You also rely on battery management systems to monitor battery health and prevent failures. As you follow trends in advanced battery technologies, you prioritize safety to protect your assets and workforce.

Fast Charging

You face increasing pressure to keep your robotic fleets running with minimal downtime. Fast charging has become a key trend in the robot battery market. Recent developments in lithium battery technology now allow you to charge batteries to 80% capacity in under 15 minutes, compared to the traditional 2–4 hours. This rapid charging supports opportunity charging, which can boost your fleet utilization by up to 35%.

Nyobolt’s next-generation energy systems deliver ultra-fast charging, reaching 10–80% charge in under 5 minutes. This technology provides high power density and exceptional cycle life, making it ideal for industries that require continuous operation. You can now recharge your robots quickly during short breaks, which increases productivity and reduces operational costs.

Note: Ultra-fast charging not only improves efficiency but also supports your market growth strategy by enabling more flexible deployment of robotic assets.

Lifespan Improvements

You want your investments in robotics to last. Lifespan improvements in lithium battery packs, especially with chemistries like LiFePO4 (3.2 V, 90–120 Wh/kg, 2000–5000 cycles), help you achieve this goal. These batteries offer long cycle life, which means you replace them less often and reduce total cost of ownership.

You see that the robot battery market now values durability as much as performance. Battery management systems play a key role by monitoring usage patterns and optimizing charging cycles. This extends battery life and ensures consistent performance over time. As you analyze market dynamics and conduct robot battery market analysis, you find that longer-lasting batteries create new opportunities for growth and innovation.

Callout: By choosing lithium battery packs with proven lifespan and robust management systems, you position your business for long-term success in the global robot battery market.

Robots Battery Technology Comparison

Lithium-Ion vs. Alternatives

You compare lithium-ion batteries with other chemistries to find the best solution for your robotics applications. Lithium-ion batteries deliver less than 150 mAh/g, which supports reliable performance in most industrial robots. Calcium-ion batteries reach up to 250 Wh/kg and 250 mAh/g, offering longer life and lower costs. Magnesium-ion batteries promise a theoretical capacity of 1000 mAh/g, but their heavier weight can limit use in mobile robots. Sodium-ion batteries have lower energy density and higher costs, but future availability may make them more competitive.

Battery Type | Energy Density (Wh/kg) | Discharge Capacity (mAh/g) | Cycle Life | Cost |

|---|---|---|---|---|

Lithium-ion | <150 | <150 | 500–2000 | Very expensive |

Calcium-ion | Up to 250 | Up to 250 | Long | Lower |

Magnesium-ion | Theoretical 1000 | High | Promising | Medium |

Sodium-ion | Lower | Lower | Emerging | Higher |

Tip: You select lithium-ion batteries for high power consumption robots when performance outweighs cost concerns.

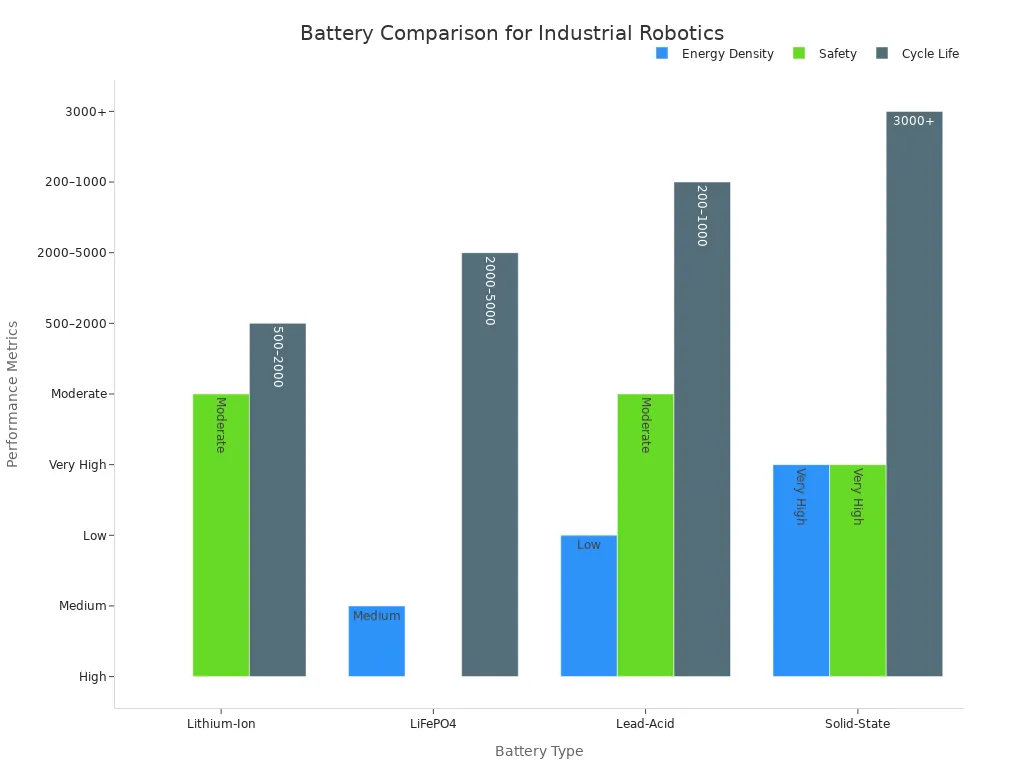

Suitability for Industrial Use

You need batteries that meet strict safety, performance, and cycle life requirements in industrial robotics. Lithium-ion and LiFePO4 batteries provide high energy density and long cycle life. Solid-state batteries offer very high energy density and safety, but their cost remains a challenge. Lead-acid batteries are heavy and have low energy density, making them less suitable for mobile robots.

Battery Type | Energy Density | Safety | Cycle Life | Weight | Cost | BMS Requirement |

|---|---|---|---|---|---|---|

Lithium-Ion | High | Moderate | 500–2000 cycles | Light | Medium | Cell balancing, thermal management |

LiFePO4 | Medium | High | 2000–5000 cycles | Medium | Medium | Cell balancing, overcharge protection |

Lead-Acid | Low | Moderate | 200–1000 cycles | Heavy | Low | Overcharge/discharge, temp monitoring |

Solid-State | Very High | Very High | 3000+ cycles | Light | High | Advanced BMS for voltage, thermal, safety |

You rely on robots battery technology that balances safety and performance. Lithium battery packs, especially LiFePO4 and NMC, meet most industrial needs for cycle life and platform voltage.

Suitability for Consumer Use

You consider several factors when choosing battery technology for consumer robots. Performance, safety, and compliance shape your decision. Lithium-ion batteries offer high energy output and long lifespan, which supports frequent use. Safety features prevent overheating and power surges. Compliance with shipping and certification standards ensures smooth market entry.

Factor | Description |

|---|---|

Performance | Maximizing energy output, lifespan, and charge cycles. |

Safety | Preventing thermal runaway, overheating, and power surges. |

Compliance | Meeting international shipping and certification standards to avoid disruptions. |

Note: You choose lithium battery packs for consumer robots to achieve reliable performance and meet global market standards.

Battery Management Systems

BMS Functions

You rely on battery management systems to keep your lithium battery packs safe and efficient in robotics. These systems perform several key functions:

Monitor voltage, current, temperature, and State of Charge (SOC) in real time. This helps you forecast battery performance and avoid unexpected downtime.

Safeguard against overcharging, deep discharging, overcurrent, short-circuits, and overheating. You protect your robots and your investment by preventing damage to the battery and system.

Equalize the SOC among all cells in a battery pack. This prevents imbalances that can arise from differences in cell capacities, especially in packs built with LiFePO4 (3.2 V, 90–120 Wh/kg, 2000–5000 cycles), NMC (3.7 V, 150–220 Wh/kg, 1000–2000 cycles), LCO (3.6 V, 150–200 Wh/kg, 500–1000 cycles), or LMO (3.7 V, 100–150 Wh/kg, 300–700 cycles).

Report crucial data such as SOC, State of Health (SOH), and fault conditions to your control systems or operators.

Monitoring and Diagnostics

You use advanced battery technologies to extend the lifespan of your robots battery technology. Real-time monitoring and diagnostics play a vital role:

Voltage and current monitoring for each cell ensures optimal performance.

SOC estimation predicts remaining runtime, helping you manage energy efficiently.

SOH analysis evaluates battery aging, allowing you to schedule maintenance before failures occur.

The development of the PINN surrogate model enables rapid SOH predictions. You benefit from quicker decision-making about battery usage and maintenance. This approach helps you identify degradation signals early and adapt charging techniques, which extends battery life and supports your market strategy.

Feature | Contribution to Safety and Performance |

|---|---|

State of Charge (SOC) | Ensures optimal battery usage and prevents overcharging |

State of Health (SOH) | Monitors battery condition to prevent failures |

Thermal Management | Prevents overheating, enhancing safety |

Cell Balancing | Ensures uniform charging and discharging for efficiency |

Real-time Diagnostics | Provides immediate feedback on battery status |

Fault Detection | Identifies potential problems before they escalate |

Integration with Robotics

You integrate battery management systems directly with robotics control systems to maximize efficiency and safety. In autonomous mobile robots, you monitor key battery parameters such as SOC, depth of discharge (DoD), and SOH. This integration allows you to measure battery capacity accurately and optimize robot performance in demanding environments. You rely on features like overcharge protection and overcurrent detection to ensure reliable operation. These capabilities help you meet market demands for productivity and safety in industrial robotics.

Tip: Integrating battery management systems with your robotics fleet supports predictive maintenance and reduces operational costs.

Design and Integration

Modular Packs

You improve your robotics operations by using modular battery packs. This design allows you to replace individual faulty modules without shutting down your system. You keep your robots running during maintenance, which dramatically boosts operational efficiency in your market. Modular systems let you hot-swap batteries, so you minimize downtime and extend the operational life of your robotic platforms. You upgrade batteries without taking the entire robot offline, which supports continuous improvement. Modular designs also improve thermal dissipation, addressing critical challenges in large battery systems. Integrated thermal management keeps your devices safe during operation. Selective module replacement enhances the total system lifespan, often prolonging it to 10–15 years. You reduce the need for frequent updates, which saves resources and supports your market growth.

Replace faulty modules without system shutdown

Enable hot-swapping for minimal downtime

Upgrade batteries while robots remain online

Improve thermal dissipation and safety

Extend system lifespan to 10–15 years

Tip: Modular lithium battery packs help you adapt quickly to changing market demands and operational requirements.

Safety Protocols

You protect your robotics investments by following strict safety protocols in battery design. You use Battery Management Systems (BMS) for real-time monitoring and control. Robust mechanical designs shield batteries from impacts. Thermal insulation limits heat transfer, which reduces risk in your market. Early detection methods include gas detection systems, thermal sensors, voltage monitoring, and advanced acoustic sensors paired with AI. These tools help you spot anomalies before they become problems. Suppression techniques use agents like Novec 1230 and FM-200, along with automated flooding systems in larger facilities. You contain risks by isolating batteries in fire-resistant enclosures, using thermal barriers, and installing ventilation systems to safely vent gases.

Monitor and control with BMS

Use mechanical protection and thermal insulation

Detect anomalies early with sensors and AI

Suppress fires with specialized agents

Contain risks with fire-resistant enclosures and ventilation

Note: Safety protocols in lithium battery packs are essential for maintaining reliability and compliance in your market.

Compliance

You meet global market requirements by adhering to strict compliance standards for robotics batteries. You ensure safe transport and handling by following UN 38.3. You validate product safety and performance with UL certification. You meet electrical safety and performance standards set by IEC. You promote environmental safety by complying with RoHS regulations. These standards help you access new markets and build consumer confidence.

Compliance Standard | Description | Importance |

|---|---|---|

UN 38.3 | Safety standard for the transport of lithium batteries | Ensures safe transport and handling |

UL | Underwriters Laboratories safety certification | Validates product safety and performance |

IEC | International Electrotechnical Commission standards | Ensures electrical safety and performance |

RoHS | Restriction of Hazardous Substances | Promotes environmental safety and compliance |

Comply with UN 38.3, UL, IEC, and RoHS for market access

Enhance consumer safety and confidence

Support environmental responsibility

Callout: Compliance with international standards for lithium battery packs positions you for success in every major market.

Real-World Applications

Industrial Robots

You see industrial robots leading the way in the robot battery market. These robots rely on advanced batteries for robotics to handle demanding tasks in manufacturing, logistics, and healthcare. Lithium-ion batteries provide high energy density, quick charging, and longer operation between charges. LiFePO4 batteries offer safety, stability, and extended lifespan, making them ideal for harsh environments. You benefit from these technologies because they support continuous operation and reduce downtime.

Lithium-ion batteries: High energy density, fast charging, long runtime

LiFePO4 batteries: Safety, stability, long lifespan

You use these battery solutions to improve productivity and meet strict safety standards. The robot battery market continues to grow as more industries adopt automation and seek reliable power sources.

Consumer Robots

You notice that batteries for robotics have transformed consumer robots. Lithium-ion batteries allow home and retail robots to operate longer without frequent recharging. You gain efficient and long-lasting power, which supports applications like cleaning, delivery, and security. The robot battery market responds to your need for compact, lightweight designs that maximize runtime. You select lithium battery packs with chemistries such as NMC and LCO for their energy density and cycle life. These choices help you deliver consistent performance and meet market expectations for safety and reliability.

Future Outlook

You see new trends shaping the future of the robot battery market. Innovations in battery recycling, hydrogen storage, and advanced materials create fresh opportunities for your business. You track developments in nanotechnology and renewable energy storage, which promise higher energy density and faster charging.

Trend | Description |

|---|---|

Battery Recycling | Reusing materials to reduce waste and environmental impact. |

Hydrogen Storage | Clean energy carrier for future systems. |

Advanced Battery Materials | Enhancing performance and sustainability. |

Nanotechnology | Improving energy density and charging speeds. |

Renewable Energy Storage | Storing energy from renewable sources for reliability. |

Grid Energy Storage | Stabilizing and improving energy grids. |

Solid-state Batteries | Higher energy densities and safety. |

Flow Batteries | Scalable energy storage solutions. |

Electric Vehicle Batteries | Promoting sustainable transportation. |

Battery Analytics | Monitoring and optimizing battery performance. |

You explore solid-state batteries, which could double the driving range for electric vehicles and boost adoption in robotics. Aluminum-ion batteries offer faster charging and longer lifecycles, helping you reduce electronic waste. Sodium-ion batteries provide cost-effective and scalable solutions for renewable energy storage. You stay alert to these trends to find new opportunities in the robot battery market and strengthen your position as technology evolves.

You see rapid growth in the robotics battery market as lithium battery packs with advanced chemistries like LiFePO4, NMC, and LCO drive new possibilities. Innovations such as silicon anodes and sand batteries promise higher energy density and longer cycle life, making robotics more efficient. Battery management systems now optimize performance and safety, supporting predictive maintenance and reducing downtime.

Lithium-ion batteries remain dominant, but you notice alternatives and eco-friendly solutions gaining traction.

Fast-charging and recycling systems support sustainable market growth.

You can expect continued innovation to shape the future, helping your business lead in automation and robotics.

FAQ

What lithium battery chemistry suits industrial robotics best?

You benefit most from LiFePO4 lithium battery packs in industrial robotics. These packs offer 3.2 V platform voltage, 90–120 Wh/kg energy density, and 2000–5000 cycle life. You gain safety, long lifespan, and stable performance for demanding environments.

How do battery management systems improve safety?

You rely on battery management systems to monitor voltage, temperature, and State of Charge. These systems prevent overcharging, overheating, and short-circuits. You protect your robots and extend battery life by using real-time diagnostics and cell balancing.

What is the typical cycle life for lithium battery packs in robotics?

You see cycle life vary by chemistry. LiFePO4 packs last 2000–5000 cycles. NMC packs offer 1000–2000 cycles. LCO packs provide 500–1000 cycles. You choose based on your operational needs and expected robot usage.

Can you hot-swap modular lithium battery packs during operation?

You can hot-swap modular lithium battery packs in many robotic systems. This design lets you replace faulty modules without shutting down your robots. You minimize downtime and keep your operations running efficiently.

What compliance standards must lithium battery packs meet?

You ensure lithium battery packs comply with UN 38.3 for transport, UL for safety, IEC for electrical standards, and RoHS for environmental safety. You meet these standards to access global markets and build trust with business clients.