You rely on battery solutions to keep your inspection robot running safely and efficiently in demanding industrial environments. High-performance lithium battery packs play a vital role by integrating smart charging circuits and voltage monitoring systems, which protect your equipment and workers. These batteries also optimize energy management, resulting in more uptime and less operational delay. Custom and drop-in lithium battery options, including those with SMBus communication and varied capacities, let you match power needs to each inspection task. When choosing a battery, consider capacity, safety features, reliability, and how well it integrates with your robot system.

Key Takeaways

Choose lithium battery packs for inspection robots to ensure high energy density, long cycle life, and lightweight design. These features lead to longer runtimes and reduced downtime.

Consider custom battery solutions to meet specific power needs. Custom packs allow you to specify voltage, capacity, and safety features tailored to your robot’s requirements.

Prioritize safety by selecting batteries with advanced features like thermal management and built-in battery management systems. These features protect your equipment and enhance reliability.

Implement smart charging practices to extend battery life. Regularly charge and discharge your batteries, and use manufacturer-approved chargers to maintain optimal performance.

Conduct regular maintenance checks on your battery systems. Monitoring battery health and following preventive maintenance routines can reduce downtime and ensure reliable operation.

Part 1: Best Battery Solutions

1.1 Lithium Battery Packs for Inspection Robots

You need reliable battery solutions to keep your inspection robots working in tough environments. Lithium battery packs have become the industry standard because they offer high energy density, long cycle life, and lightweight design. These features help you achieve longer runtimes and reduce downtime during critical inspections.

You can choose from a range of lithium battery chemistries, such as LiFePO4 (Lithium Iron Phosphate), NMC (Nickel Manganese Cobalt), LCO (Lithium Cobalt Oxide), LMO (Lithium Manganese Oxide), and LTO (Lithium Titanate). Each chemistry offers unique benefits for different inspection tasks. For example, LiFePO4 batteries provide excellent safety and stability, while NMC batteries deliver higher energy density for longer missions.

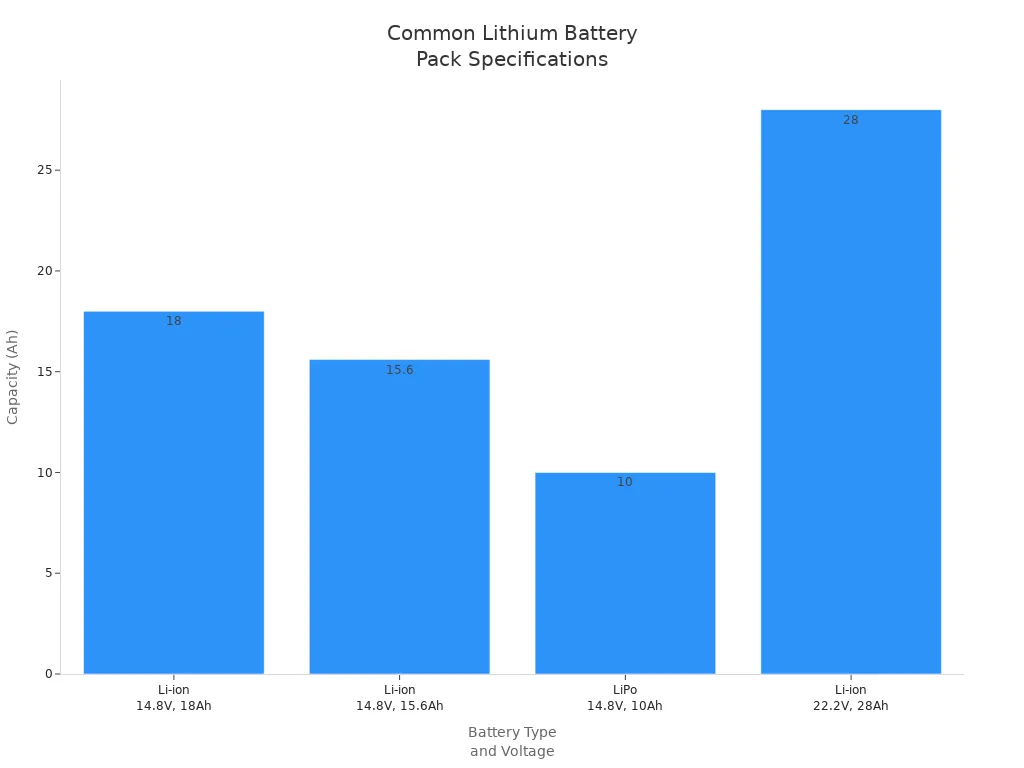

Here is a table showing common lithium battery pack specifications used in inspection robots:

Battery Type | Voltage (Nominal/Max/Min) | Capacity | Cell Count |

|---|---|---|---|

Lithium-ion 14.8V, 18Ah | 14.8 V / 16.8 V / 12.0 V | 18 Ah | 4S |

Lithium-ion 14.8V, 15.6Ah | 14.8 V / 16.8 V / 12.0 V | 15.6 Ah | 4S |

Lithium Polymer 14.8V, 10Ah | 14.8 V / 16.8 V / 12.8 V | 10 Ah | 4S |

Lithium-ion 22.2V, 28Ah | 22.2 V / 25.2 V / 18.0 V | 28 Ah | 6S |

You can see how different voltage and capacity ratings help you match the battery to your robot’s power needs. Many industrial clients prefer custom lithium battery packs, such as 25.2V 60Ah or 51.2V 80Ah, for specialized inspection robots in rail, substation, or infrastructure applications.

Smart features like SMBus communication allow you to monitor battery health, charge status, and temperature in real time. Drop-in lithium iron phosphate batteries (LiFePO4) offer enhanced safety and performance, making them ideal for high-risk environments such as medical, security, and industrial inspection.

Tip: Choose lithium battery packs with built-in battery management systems (BMS) and SMBus communication for maximum safety and reliability.

1.2 Alternative Battery Technologies

You may consider alternative battery technologies for specific inspection tasks. These options include sodium-ion, solid-state, zinc, and aluminum batteries. Each technology has strengths and weaknesses compared to lithium battery packs.

Here is a table comparing lithium batteries to other battery types in terms of energy density and cycle life:

Feature | Lithium Batteries | Other Battery Types |

|---|---|---|

Energy Density | High | Lower |

Cycle Life | Long | Shorter |

Weight | Lightweight | Heavier |

Charging Speed | Fast | Slower |

Smart BMS Features | Yes | Limited |

You can see that lithium batteries outperform most alternatives in energy density, cycle life, and weight. However, sodium-ion batteries are gaining attention for their lower cost and reduced reliance on rare materials. Solid-state batteries promise higher energy density and improved safety, but they are not yet widely available for commercial use. Zinc and aluminum batteries offer rapid rechargeability and structural benefits, but they have limited recharge cycles.

Here is a table summarizing costs and performance metrics for alternative battery technologies:

Battery Type | Energy Density (Wh/kg) | Cost Comparison | Advantages/Disadvantages |

|---|---|---|---|

Lithium-ion | Up to 500 | High due to rare materials | Mature technology, versatile but heavy and costly due to lithium and cobalt extraction. |

Sodium-ion | Lower than lithium | Expected to be significantly cheaper | Reduces reliance on cobalt, gaining traction in development. |

Solid-state | Potentially higher | Not yet commercialized | Safer, higher energy density, and improved stability compared to lithium-ion. |

Zinc | 72 times more energy | Less than one-sixth of lithium | Good for structural applications, but limited rechargeability. |

Aluminium | Rapid rechargeability | Projected to be very low | High performance at elevated temperatures, no dendrite formation. |

You should select battery technology based on your inspection robot’s application, budget, and safety requirements. For most industrial, medical, and security systems, lithium battery packs remain the preferred choice due to their proven reliability and advanced features.

1.3 Custom vs. Standard Battery Solutions

You face a choice between custom and standard battery solutions when designing inspection robots. Standard battery packs offer convenience and quick integration, but they may not meet the unique demands of your application. Custom battery solutions allow you to specify voltage, capacity, form factor, and safety features to match your robot’s requirements.

Custom lithium battery packs can include advanced features such as:

High-capacity cells for extended runtime

Specialized form factors for compact or rugged robots

Enhanced safety systems for hazardous environments

Smart BMS and SMBus communication for real-time monitoring

Standard battery packs work well for consumer electronics and general-purpose robots. Custom solutions are essential for industrial inspection robots, medical devices, and security systems that operate in challenging conditions.

Note: Work with experienced battery suppliers to design custom battery solutions that meet your inspection robot’s power, safety, and integration needs.

Part 2: Battery Impact on Inspection Robots

2.1 Performance and Runtime

You depend on battery solutions to deliver consistent performance for inspection robots across many industries. The right battery chemistry, such as LiFePO4, NMC, or LTO, can make a big difference in how long your robot operates and how well it performs in the field. High energy density in lithium battery packs allows your inspection robot to run longer between charges, which is essential for tasks in industrial, medical, and security environments.

Aspect | Description |

|---|---|

Energy Density | Different battery chemistries provide varying energy densities, crucial for operational tasks. |

Cycle Life | The longevity of batteries affects how often they need replacement, impacting runtime. |

Thermal Management | Effective thermal management is essential for maintaining performance in industrial environments. |

You can see that energy density and cycle life directly affect how much work your inspection robots can complete before needing a recharge or replacement. For example, in infrastructure or rail inspections, you may need your robot to operate for several hours without interruption. Lithium battery packs, especially those with high capacity, help you achieve this goal.

To estimate runtime, follow these steps:

Identify the power draw of your device in watts.

Decide on the desired runtime in hours.

Multiply the power draw by the runtime to calculate the required battery capacity in watt-hours.

For example, if your inspection robot uses 50 watts and you want it to run for 4 hours, you need a 200 watt-hour battery pack. This calculation helps you select the right battery for your application, whether in robotics, medical devices, or security systems.

Tip: Always match your battery capacity to your robot’s power needs to avoid unexpected downtime.

Batteries designed for tough environments must be durable and reliable. Advanced materials and engineering ensure that these batteries withstand harsh conditions, which is vital for maintaining operational performance in industrial and infrastructure settings. You also benefit from fast charging and efficient energy management, which keep your robots ready for the next mission.

2.2 Safety and Reliability

Safety and reliability are top priorities when you deploy inspection robots in high-risk environments, such as high-voltage substations or chemical plants. Specialized battery packs with advanced safety features protect both your equipment and your team.

Safety Feature | Description |

|---|---|

Overcharge Protection | Prevents battery damage by stopping charging when full. |

Over-discharge Protection | Protects against battery depletion that can lead to failure. |

Short-circuit Protection | Stops current flow in case of a short circuit to prevent fires or explosions. |

Thermal Management | Maintains safe operating temperatures to avoid overheating and thermal runaway. |

Real-time Monitoring | Continuously checks battery health and detects early signs of failure. |

Fault Detection | Identifies issues in the battery system to ensure operational safety and reliability. |

You should always choose battery solutions with built-in safety systems. Real-time monitoring and fault detection help you spot problems before they cause downtime or damage. In medical and security applications, these features are critical for protecting sensitive equipment and ensuring continuous operation.

Thermal management also plays a key role. Inspection robots often work in environments with extreme temperatures. Effective thermal management keeps your lithium battery packs operating safely, even in challenging conditions. For more on responsible sourcing and safety, see our conflict minerals statement.

Note: Reliable power solutions with advanced safety features reduce the risk of accidents and extend the life of your inspection robots.

2.3 Maintenance and Cost

You want to keep maintenance simple and costs low. Lithium battery packs require less maintenance than older technologies like lead-acid batteries. This advantage leads to a lower total cost of ownership over the battery’s lifespan.

Lithium battery packs need minimal maintenance.

Reduced maintenance means lower operating costs for your robots.

Fewer components require replacement, which saves you time and money.

You benefit from fewer service interruptions and less technical complexity. This is especially important in industrial, infrastructure, and consumer electronics sectors, where uptime and efficiency drive business success. By choosing high-quality battery solutions, you also support sustainability goals. Learn more about our approach to sustainability.

Tip: Regularly check battery health and follow manufacturer guidelines to maximize lifespan and minimize costs.

Part 3: Selecting Battery Solutions

3.1 Power and Capacity Needs

You need to match your inspection robot’s power and capacity requirements to the demands of each application. Rail and substation inspections often require 24/7 operation, automatic battery management, and coverage of hundreds of inspection points. You should consider technological advancements, market dynamics, regulatory compliance, and customer-centric models when selecting battery solutions.

Factor | Description |

|---|---|

Technological Advancements | Latest innovations in battery technology enhance performance and efficiency. |

Market Dynamics | Demand patterns and pricing pressures influence battery solutions. |

Regulatory Compliance | Regulations impact battery usage and safety standards. |

Customer-Centric Models | Personalization and engagement strategies improve satisfaction and retention. |

Feature | Description |

|---|---|

Operation Time | 24/7 operation |

Battery Management | Automatically recharges batteries |

Coverage | Hundreds of inspection points |

3.2 Safety Features

You must prioritize safety certifications and advanced protection systems. Inspection robots in industrial and medical sectors require batteries with certifications such as IEC 62133, IEC 61960, CE Marking, RoHS, and IEEE 1725. These standards ensure safe operation and compliance with global regulations.

Certification | Description |

|---|---|

IEC 62133 | Safety for portable sealed secondary cells and batteries. |

IEC 61960 | Safety for secondary lithium cells and batteries. |

CE Marking | EU product safety compliance. |

RoHS | Limits hazardous materials. |

IEEE 1725 | Design criteria for rechargeable lithium-ion batteries. |

Advanced safety features include thermal management systems that dissipate heat efficiently, battery management systems (BMS) that monitor temperature, and protective circuit modules (PCM) that prevent short circuits. These features help you avoid overheating and electrical hazards.

Tip: Always select batteries with robust safety certifications and integrated protection systems.

3.3 Reliability and Lifecycle

You depend on reliable energy storage solutions for continuous operation. Lithium battery packs experience chemical and mechanical degradation, but predictive modeling helps estimate lifespan. Performance optimization and smart controls enhance reliability and minimize degradation.

Aspect | Description |

|---|---|

Battery Degradation Mechanisms | Chemical and mechanical degradation from environment and cycling. |

Predictive Modeling | Machine learning predicts battery lifespan. |

Performance Optimization | Optimizes controls and designs for reliability. |

Hot-swappable batteries, multi-battery parallel capability, and IP67 ratings increase durability and minimize downtime. Wireless charging systems also reduce maintenance needs and ensure consistent power delivery, which is vital for mission-critical operations.

Wireless charging minimizes maintenance.

Hot-swappable batteries reduce downtime.

IP67 rating protects against dust and water.

3.4 Integration and Form Factor

You face integration challenges when fitting battery packs into inspection robot designs. Switching to 48V battery packs enables cable-free movement and improves operational efficiency. Swappable and fixed battery packs minimize downtime and save operators time.

Custom battery packs solve cable management issues.

Swappable packs enable quick changes.

Fixed packs provide stability for rugged robots.

You should select battery solutions that fit seamlessly into your robot’s form factor and operational workflow.

3.5 Smart Battery Management

You benefit from smart battery management systems (BMS) and SMBus communication. These features provide cell balancing, state of charge (SoC) and state of health (SoH) estimation, thermal management, and safety protections. Data communication protocols like CAN, RS485, and Bluetooth integrate with robot controllers for real-time diagnostics.

Feature | Description |

|---|---|

Cell Balancing | Uniform voltage across cells maximizes capacity. |

SoC/SoH Estimation | Predicts remaining charge and battery health. |

Thermal Management | Regulates temperature to prevent overheating. |

Safety Protections | Guards against overcharge, over-discharge, and short circuits. |

Data Communication | Integrates with controllers via CAN, RS485, or Bluetooth. |

Smart battery management reduces unexpected failures, increases lifespan, and enables predictive maintenance. You can learn more about BMS and PCM features.

Note: Smart battery management systems help you schedule service, avoid costly downtime, and optimize your energy storage solution.

Chemistry | Energy Density (Wh/kg) | Cycle Life | Safety | Typical Application |

|---|---|---|---|---|

LiFePO4 | 90-160 | 2000+ | High | Industrial, medical |

NMC | 150-220 | 1000-2000 | Medium | Robotics, security |

LCO | 150-200 | Low | Consumer electronics | |

LMO | 100-150 | 300-700 | Medium | Infrastructure |

LTO | 70-80 | 7000+ | Industrial | |

Solid-state | 250+ | 2000+ | High | Emerging sectors |

Lithium metal | 400+ | 1000+ | Medium | Advanced robotics |

Part 4: Optimizing Battery Performance

4.1 Charging Best Practices

You can extend the life and performance of your inspection robot’s lithium battery pack by following smart charging habits.

Allow the battery to fully charge and discharge from time to time. This helps maintain its health and capacity.

Recharge before the battery drops below 20% to prevent irreversible damage.

Use only manufacturer-approved chargers and accessories.

Make sure your robot aligns properly with its charging station. Poor contact can reduce charging efficiency.

Avoid pushing the robot manually onto the dock, as this can cause poor connections.

Store batteries at 40%-60% charge in a cool, dry place (around 23°C and 60% humidity).

Charge at least once every six months if the robot is not in use.

Use chargers with built-in overcharge protection to avoid exceeding safe charge levels.

Tip: Complete charge and discharge cycles help preserve battery condition, especially for lithium chemistries like LiFePO4 and NMC.

4.2 Preventive Maintenance

Regular maintenance routines reduce downtime and keep your inspection robots ready for action in industrial, medical, and security environments.

Here is a table of recommended preventive maintenance tasks:

Maintenance Routine | Description |

|---|---|

Check the batteries | Ensure batteries are properly charged and functioning correctly. |

Replace batteries | Replace batteries annually to prevent functionality issues. |

Check battery level | Regularly check the battery level and charge as needed, ensuring proper installation and connection. |

Test and replace RAM and APC batteries | Test and replace RAM and APC batteries as required to maintain functionality. |

Note: Consistent preventive maintenance supports reliable operation in robotics, infrastructure, and consumer electronics.

4.3 Monitoring and Diagnostics

You can use advanced monitoring and diagnostics to optimize battery health and performance. Smart Battery Management Systems (BMS) with SMBus communication enable real-time monitoring of battery health and performance.

The BMS continuously communicates battery status and operating conditions.

It provides recommendations for optimal charging and discharging cycles based on the battery’s state of health.

The BMS indicates when to maintain the battery within specific temperature ranges to prevent wear and tear.

Proactive management through BMS extends battery life and reduces unexpected failures.

For more details on BMS and its benefits, visit BMS and PCM.

Tip: Real-time diagnostics help you schedule maintenance, avoid costly downtime, and ensure safe operation in all sectors.

You improve inspection robot performance when you select the right battery for your application. Lithium battery packs, including custom options, support safety, reliability, and seamless integration in industrial, medical, and security systems. Review your power needs, safety certifications, and smart management features before making a decision. Consult battery experts for tailored solutions and ongoing support. Reach out today to discuss your inspection robot requirements.

FAQ

What battery chemistry works best for industrial inspection robots?

You often choose LiFePO4 or NMC lithium battery packs for industrial inspection robots. These chemistries offer high energy density, long cycle life, and strong safety features. They support long runtimes and reliable operation in harsh environments.

How do you ensure battery safety in medical and security robots?

You select lithium battery packs with advanced BMS, thermal management, and certifications like IEC 62133 or CE Marking. These features protect your equipment and staff in medical and security systems.

Can you customize lithium battery packs for unique robot designs?

Yes, you can work with suppliers to design custom lithium battery packs. You specify voltage, capacity, form factor, and safety features. Customization supports robotics, infrastructure, and consumer electronics applications.

What maintenance do lithium battery packs require in industrial settings?

You perform regular health checks, monitor charge cycles, and follow manufacturer guidelines. Preventive maintenance reduces downtime and extends battery life for industrial robots and infrastructure systems.

How does smart battery management improve robot performance?

Smart BMS and SMBus communication let you monitor battery health, balance cells, and predict maintenance needs. These features help you avoid unexpected failures and optimize performance in robotics and security sectors.