In robotics, you demand high-power output and reliable operation from your lithium battery packs. The right battery chemistry matters. For example:

LFP and LTO batteries deliver strong reliability and safety, even under frequent cycles.

NMC and NCA offer higher energy density but less reliability.

Poor heat management threatens both safety and lifespan. Advanced battery management and thermal systems protect your investment.

Key Takeaways

Choose the right battery chemistry for your robotics applications. LiFePO4 batteries offer high safety and long cycle life, making them ideal for industrial use.

Implement advanced battery management systems (BMS) to monitor voltage, current, and temperature. This helps prevent overheating and ensures reliable performance.

Prioritize effective thermal management strategies. Use active cooling systems and phase-change materials to control heat and enhance battery safety.

Part 1: Power & Reliability Challenges

1.1 High-Power Output Demands

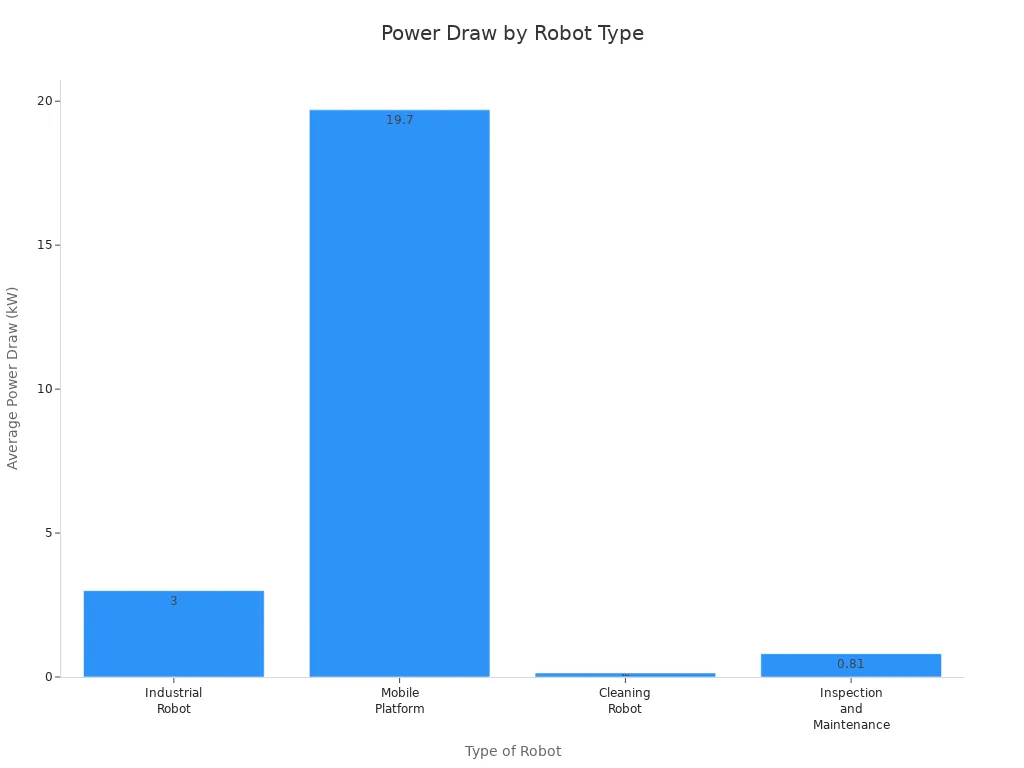

You face significant high-power output requirements in industrial and mobile robotics applications. The average power draw varies by robot type, as shown below:

Type of Robot | Average Power Consumption (kWh/robot) | Operational Time (hours/day) | Average Power Draw (kW) |

|---|---|---|---|

Industrial Robot | 21,915 | 20 | 3 |

Mobile Platform | 21,586 | 3 | 19.7 |

Cleaning Robot | 102 | 2 | 0.14 |

Inspection and Maintenance Robot | 592 | 2 | 0.81 |

Factors such as speed, payload weight, end effector type, and motion complexity all influence power and efficiency. High-power output demands can strain lithium-ion battery packs, making voltage stability and system integration critical for reliable performance.

1.2 Transient Loads in Robotics

Robotics systems often experience rapid changes in load, known as transient loads. These events challenge battery management and voltage regulation. You must use advanced methods, such as the transition matrix approach and error analysis, to model and predict battery response. Effective integration of these techniques ensures your systems maintain efficiency and reliability during sudden power surges. Selecting batteries with the right current ratings and robust design helps prevent voltage drops and supports consistent performance.

1.3 Heat and Battery Safety

High-power output and transient events generate significant heat within lithium-ion batteries. Poor thermal management can lead to safety incidents, including thermal runaway, gas venting, and even fire. Key triggers include mechanical damage, electrical abuse, and thermal stress. You must prioritize thermal management systems and safety-focused design to protect your robotics investments. Failure to do so can result in costly downtime, structural damage, and reduced reliability across your operations.

Part 2: Solutions for Long-Term Reliability

2.1 Battery Chemistry Selection

Selecting the right battery chemistry forms the foundation of long-term reliability in robotics. Lithium-based batteries dominate industrial robotics due to their high energy density and capacity. These properties deliver longer run-times between charges, which supports efficiency and consistent voltage output in demanding environments.

You should consider lithium iron phosphate (LiFePO4) batteries for your robotics applications. LiFePO4 offers high safety, long cycle life, and robust performance under high-power load conditions. This chemistry provides stable voltage, high discharge current capability, and advanced thermal safety protection. For mobile robotics that require rapid charging and frequent cycling, lithium titanate oxide (LTO) batteries also deliver strong performance and reliability.

The table below compares two leading chemistries for robotics:

Battery Type | Cycle Life (Cycles) | Safety Profile | Thermal Stability |

|---|---|---|---|

LiFePO4 | 2,000–6,000+ | Very High | Non-combustible |

NMC | 1,000–2,000 | Moderate | Prone to thermal runaway |

LiFePO4 batteries excel in safety and thermal stability, making them a preferred choice for industrial robotics where reliability and safety are critical. NMC batteries offer higher energy density but present more challenges in thermal management and voltage stability.

Tip: Prioritize battery chemistries that align with your robotics system’s voltage, safety, and thermal requirements to maximize long-term reliability.

2.2 Battery Management Systems

Advanced battery management systems (BMS) play a central role in maintaining reliability and safety in robotics batteries. A BMS monitors and regulates voltage, current, and temperature, ensuring your battery operates within safe limits. This oversight prevents overheating, cell imbalance, and voltage drops, all of which can threaten long-term reliability.

Key features of modern BMS include:

Feature | Contribution to Reliability |

|---|---|

Real-time Monitoring | Enables predictive maintenance and performance tracking. |

Safety Protections | Ensures voltage, current, and temperature stay within safe bounds. |

Customizability | Allows adaptation for specific applications, enhancing reliability. |

Protection Circuit Module | Provides over/under voltage & temperature protection. |

Battery Monitoring | Offers insights into charge status and battery health. |

Cell Balancing | Prevents capacity limitations and extends battery life. |

Communication Interfaces | Facilitates data transfer and monitoring, crucial for reliability. |

You benefit from BMS features that detect and respond to transient load events. R-C networks simulate battery responses during charging and discharging, while first and second-order models improve dynamic performance. Dynamic Z-Track technology adjusts to changing battery impedance, providing accurate state of charge (SoC) and state of health (SoH) estimates. This integration ensures your robotics systems maintain voltage stability and efficiency during sudden load changes.

A BMS operates as a sensing and control system, balancing power supply and demand. It uses a cascaded control structure with an outer loop for voltage regulation and an inner loop for current regulation. This design maintains system stability and supports long-term reliability, even under fluctuating load conditions.

2.3 Thermal Management Strategies

Effective thermal management is essential for robotics batteries operating under high-power loads. You must address heat generation to protect both safety and long-term reliability. Advanced thermal management systems (BTMS) combine active and passive strategies to control temperature and prevent overheating.

The table below outlines leading thermal management strategies:

Strategy Type | Description |

|---|---|

Liquid Cooling | Provides superior thermal conductivity and heat dissipation, ideal for high-power applications. |

Thermal Sensors | Monitor temperature changes for effective management. |

Advanced BMS | Coordinates thermal and electrical characteristics for optimal performance. |

Many robotics battery designs use phase-change materials (PCMs) alongside active, compressor-based cooling. PCMs absorb transient thermal spikes, reducing the load on compressors and improving energy efficiency. PCMs manage heat by changing phase, absorbing energy during transitions and expelling it as they return to their original state. This passive regulation supports thermal stability without drawing extra power from fans or pumps.

Note: While PCMs offer passive temperature control, their low thermal conductivity and added weight may limit their use in some robotics applications. Active liquid cooling provides precise temperature regulation, making it suitable for high-power, industrial robotics systems.

Integrated battery management and thermal systems enhance long-term reliability by monitoring voltage, current, and temperature in real time. These systems initiate cooling when needed, preventing overheating and cell imbalance. This proactive approach ensures your robotics batteries deliver consistent performance, safety, and efficiency throughout their operational life.

Part 3: Real-World Robotics Applications

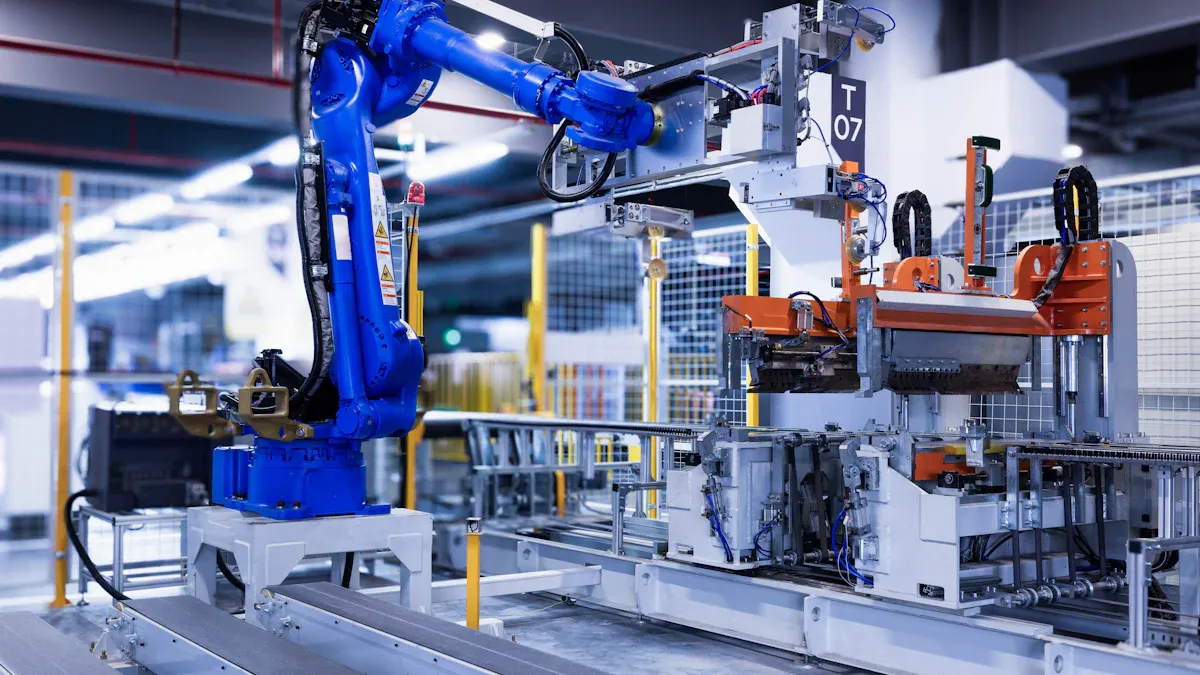

3.1 Industrial Robotics Power Events

In the industrial sector, you often encounter robotics systems that must deliver consistent power during demanding operations. When you manage lithium battery packs in these environments, you must address power events that can disrupt performance. You see that robust battery management systems (BMS) play a critical role in preventing failures.

You need a BMS designed to handle extreme conditions, such as overcharging and overheating, to maintain safety and performance.

Rigorous testing under various scenarios helps you identify design flaws before deployment.

Early integration of BMS into your robotics design process ensures effective heat dissipation and physical compatibility.

These strategies help you avoid costly downtime and maintain reliable operation in industrial robotics.

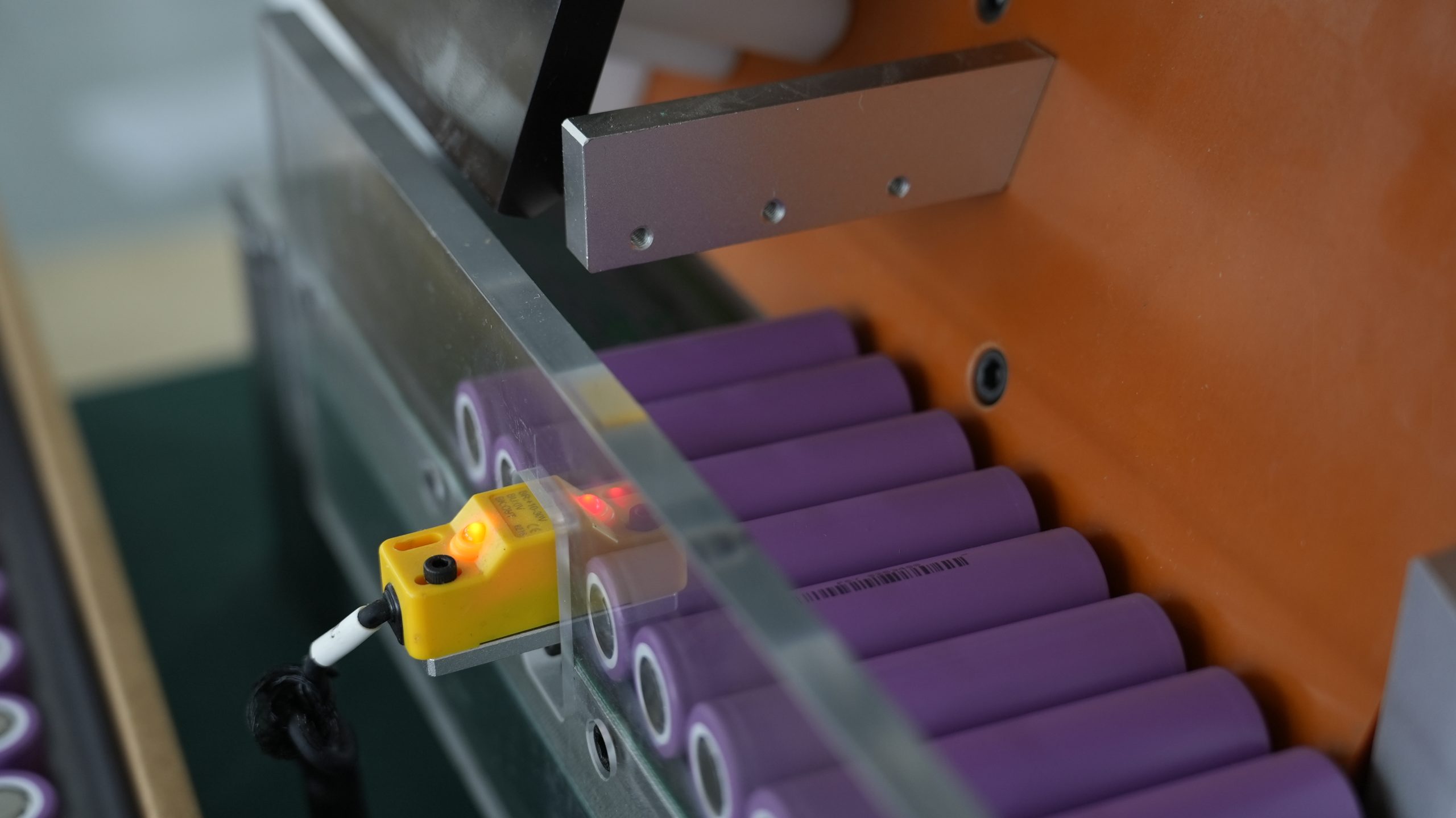

3.2 Mobile Robotics Heat Control

Mobile robotics platforms, used in infrastructure and security applications, face unique thermal challenges. You rely on predictive monitoring systems with temperature sensors to track battery temperature during intensive tasks.

The system issues alerts, such as Yellow or Red, when anomalies or mission-critical issues arise.

An external temperature sensor adds a layer of safety, protecting against overheating and combustion.

You set a temperature threshold, often 50 °C for lithium NMC batteries, to prevent uncontrolled self-ignition.

To address heat-related challenges, you use ceramic coatings, heat-resistant alloys, and predictive maintenance sensors. You also benefit from lithium-ion batteries that automatically shut off and restart, thermally conductive rubber, and advanced cooling systems.

3.3 Reliability Lessons Learned

You gain valuable insights from robotics projects across medical, consumer electronics, and industrial sectors.

Key lessons include the importance of robust battery management and thermal solutions for safety and performance.

Strategy | Description |

|---|---|

Redundant Power Systems | Backup systems ensure continuous operation and reduce failure risks. |

Advanced Thermal Management | Efficient cooling mechanisms prevent overheating and extend component life. |

High-Efficiency Power Supplies | Improved power management reduces energy loss and boosts reliability. |

You should consider environmental factors like temperature, humidity, and vibration during design and integration. Modular battery systems allow you to scale power resources in real time, improving efficiency. Staying updated on innovations, such as solid-state batteries, helps you maintain a competitive edge in robotics.

You achieve reliable high-power output in robotics batteries by focusing on proven strategies.

Strategy | Description |

|---|---|

Power Supply Selection | Evaluate voltage and current regulation for stable performance and energy efficiency. |

Energy Efficiency | High-efficiency power supplies reduce wasted energy, extending operational runtime. |

Thermal Management | Advanced cooling mechanisms prevent component degradation due to excessive heat. |

Scalability | Modular designs allow easy adaptation to future energy demands. |

Compliance | Meet industry standards for safety and reliability. |

You should prioritize battery chemistry, advanced management systems, and robust thermal solutions. Industry standards guide safe design. The market continues to grow, with solid-state batteries and fast-charging technologies driving innovation. Stay engaged and collaborate to shape the future of robotics battery technology.

FAQ

What makes Large Power lithium battery packs suitable for industrial robotics?

Large Power designs lithium battery packs for high-power output, robust safety, and long cycle life.

Request a custom consultation for tailored solutions.

How do LiFePO4 and NMC chemistries compare for transient load management?

Chemistry | Cycle Life | Safety | Thermal Stability |

|---|---|---|---|

LiFePO4 | 2,000–6,000+ | Very High | Non-combustible |

NMC | 1,000–2,000 | Moderate | Prone to runaway |

LiFePO4 offers superior safety and stability for transient loads.

Can you integrate advanced thermal management in battery packs for mobile platforms?

You can integrate liquid cooling, phase-change materials, and predictive sensors in battery packs. These solutions enhance heat control for mobile robotics in industrial environments.